DISPERBYK-2010 DISPERBYK-2015 - Farbeundlack.de

DISPERBYK-2010 DISPERBYK-2015 - Farbeundlack.de

DISPERBYK-2010 DISPERBYK-2015 - Farbeundlack.de

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

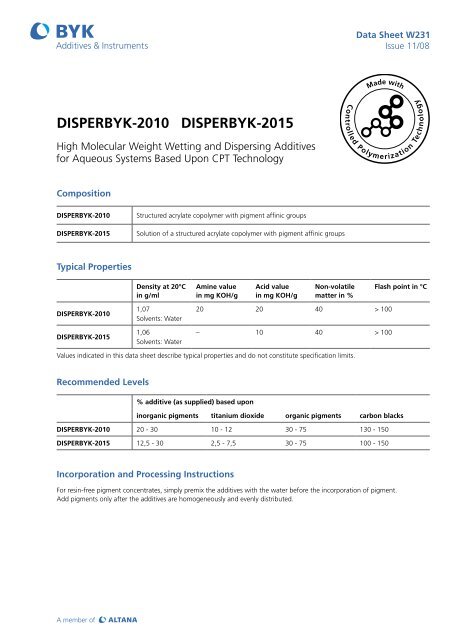

cControlled Polymerization TeData Sheet W231Issue 11/08Ma<strong>de</strong> withhnology<strong>DISPERBYK</strong>-<strong>2010</strong><strong>DISPERBYK</strong>-<strong>2015</strong>High Molecular Weight Wetting and Dispersing Additivesfor Aqueous Systems Based Upon CPT TechnologyComposition<strong>DISPERBYK</strong>-<strong>2010</strong><strong>DISPERBYK</strong>-<strong>2015</strong>Structured acrylate copolymer with pigment affinic groupsSolution of a structured acrylate copolymer with pigment affinic groupsTypical PropertiesDensity at 20°Cin g/mlAmine valuein mg KOH/gAcid valuein mg KOH/gNon-volatilematter in %Flash point in °C<strong>DISPERBYK</strong>-<strong>2010</strong><strong>DISPERBYK</strong>-<strong>2015</strong>1,07 20 20 40 > 100Solvents: Water1,06 – 10 40 > 100Solvents: WaterValues indicated in this data sheet <strong>de</strong>scribe typical properties and do not constitute specification limits.Recommen<strong>de</strong>d Levels% additive (as supplied) based uponinorganic pigments titanium dioxi<strong>de</strong> organic pigments carbon blacks<strong>DISPERBYK</strong>-<strong>2010</strong> 20 - 30 10 - 12 30 - 75 130 - 150<strong>DISPERBYK</strong>-<strong>2015</strong> 12,5 - 30 2,5 - 7,5 30 - 75 100 - 150Incorporation and Processing InstructionsFor resin-free pigment concentrates, simply premix the additives with the water before the incorporation of pigment.Add pigments only after the additives are homogeneously and evenly distributed.

Data Sheet W231Issue 11/08ApplicationsIndustrialcoatingsAutomotivecoatingsWoodcoatingsArchitecturalcoatingsProtectivecoatingsPrinting inks<strong>DISPERBYK</strong>-<strong>2010</strong> –<strong>DISPERBYK</strong>-<strong>2015</strong> –recommen<strong>de</strong>dsuitableFunction<strong>DISPERBYK</strong>-<strong>2010</strong> causes a strong viscosity reduction in the millbase. It <strong>de</strong>flocculates and stabilizes pigments through sterichindrance and electrostatic repulsion. Color strength <strong>de</strong>velopment, transparency as well as hiding power and gloss are improveddue to the small particle sizes of the <strong>de</strong>flocculated pigments. Additionally, <strong>DISPERBYK</strong>-<strong>2010</strong> has a positive effect on flowproperties.<strong>DISPERBYK</strong>-<strong>2015</strong> <strong>de</strong>flocculates pigments through steric hindrance. Due to the small particle sizes of the <strong>de</strong>flocculated pigments,high gloss is achieved and color strength is improved. Additionally, transparency and hiding power are increased.<strong>DISPERBYK</strong>-<strong>2015</strong> reduces viscosity. Subsequently, leveling is improved and higher pigment loading is possible.Special Features and Benefits<strong>DISPERBYK</strong>-<strong>2010</strong><strong>DISPERBYK</strong>-<strong>2015</strong><strong>DISPERBYK</strong>-<strong>2010</strong> has a relatively hydrophobic backbone to minimize the impact on water resistanceof the dried coating film.<strong>DISPERBYK</strong>-<strong>2010</strong> is especially <strong>de</strong>signed for the production of resin-free, stable pigment concentratesfor aqueous coating systems. For optimum performance, the grind should only consist of water,<strong>DISPERBYK</strong>-<strong>2010</strong> and pigments; the grind should not be comprised of resin, amine, or co-solvents.<strong>DISPERBYK</strong>-<strong>2010</strong> does not contain organic solvents and is only suitable for aqueous systems.<strong>DISPERBYK</strong>-<strong>2015</strong> is especially <strong>de</strong>signed for the production of resin- and VOC-free pigment concentratesfor aqueous coating systems. For optimum performance, we recommend using only pigments,<strong>DISPERBYK</strong>-<strong>2015</strong> and water for pigment grindings (resin-, amine, and co-solvent-free).<strong>DISPERBYK</strong>-<strong>2015</strong> is only suitable for aqueous systems.Special Note<strong>DISPERBYK</strong>-<strong>2010</strong><strong>DISPERBYK</strong>-<strong>2015</strong>This product is an emulsion.This product is a solution.Storage and Transportation<strong>DISPERBYK</strong>-<strong>2010</strong><strong>DISPERBYK</strong>-<strong>2015</strong>Temperature sensitive.Temperature for transport and storage must be between 5 °C and 40 °C.Separation or turbidity may occur during storage and transportation. Mix well before use.Separation or turbidity may occur at temperatures below 0°C. Warm up to 20°C and mix well.BYK-Chemie GmbHP.O. Box 10 024546462 WeselGermanyTel +49 281 670-0Fax +49 281 65735info@byk.comwww.byk.com/additivesANTI-TERRA ® , BYK ® , BYK ® -DYNWET ® , BYK ® -SILCLEAN ® , BYKANOL ® , BYKETOL ® , BYKOPLAST ® , BYKUMEN ® , <strong>DISPERBYK</strong> ® , DISPERPLAST ® , LACTIMON ® ,NANOBYK ® , SILBYK ® and VISCOBYK ® are registered tra<strong>de</strong>marks of BYK-Chemie.AQUACER ® , AQUAFLOUR ® , AQUAMAT ® , CERACOL ® , CERAFAK ® , CERAFLOUR ® , CERAMAT ® , CERATIX ® and MINERPOL ® are registered tra<strong>de</strong>marks ofBYK-Cera.This information is given to the best of our knowledge. Because of the multitu<strong>de</strong> of formulations, production and application conditions, all theabove‐mentioned statements have to be adjusted to the circumstances of the processor. No liabilities, including those for patent rights, can be <strong>de</strong>rivedfrom this fact for individual cases.This data sheet replaces all previous issues - Printed in Germany