Megger DLRO200 Low Resistance Testing - Actoolsupply.com

Megger DLRO200 Low Resistance Testing - Actoolsupply.com

Megger DLRO200 Low Resistance Testing - Actoolsupply.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

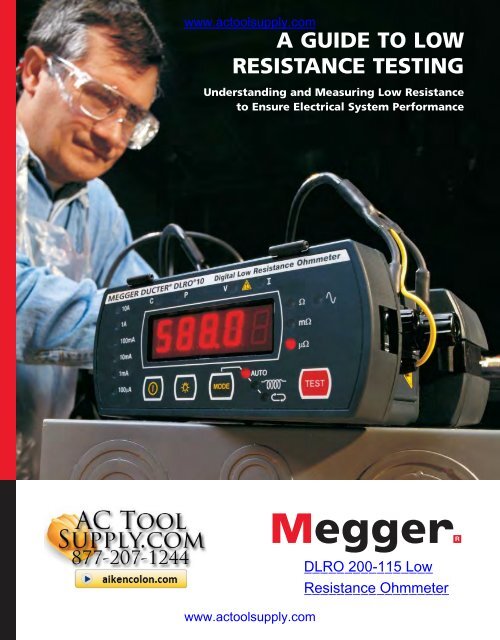

www.actoolsupply.<strong>com</strong>A GUIDE TO LOWRESISTANCE TESTINGUnderstanding and Measuring <strong>Low</strong> <strong>Resistance</strong>to Ensure Electrical System Performancewww.actoolsupply.<strong>com</strong>

www.actoolsupply.<strong>com</strong>TABLE OF CONTENTSIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . .2Why Measure <strong>Low</strong> <strong>Resistance</strong>? . . . . . . . . . . . . .3What is a <strong>Low</strong> <strong>Resistance</strong> Measurement? . . . . . . . .3What Does the <strong>Low</strong> <strong>Resistance</strong> MeasurementTell the Operator? . . . . . . . . . . . . . . . . . . . . . . . . . . .3What Problems Create the Need toPerform the Test? . . . . . . . . . . . . . . . . . . . . . . . . . . .4Industries with Significant <strong>Resistance</strong> Problems . . . .4Specific Examples of Apparatus in Need of <strong>Low</strong><strong>Resistance</strong> <strong>Testing</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . .4Motor Armature . . . . . . . . . . . . . . . . . . . . . . . . . . .5Automotive Assembly . . . . . . . . . . . . . . . . . . . . . .5Power Generation and Distribution(high current joints, connections and bus bars) . . .5Transformer <strong>Testing</strong> . . . . . . . . . . . . . . . . . . . . . . . .5Uninterruptible Power Supply - Battery Straps . . .5Cement Plants and other Raw MaterialProcessing Applications . . . . . . . . . . . . . . . . . . . . .6Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . .6Aircraft Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .7Strap and Wire Bonds between Rail Segments(Railroad Industry) . . . . . . . . . . . . . . . . . . . . . . . . .7Graphite Electrodes . . . . . . . . . . . . . . . . . . . . . . . .7Welding Spot or Seam . . . . . . . . . . . . . . . . . . . . . .7Cable Reels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7How do You Measure <strong>Low</strong> <strong>Resistance</strong> . . . . . . .82-Wire, 3-Wire and 4-Wire DC Measurements . . . . .8Two-Wire Measurements . . . . . . . . . . . . . . . . . . . .8Three-Wire Measurements . . . . . . . . . . . . . . . . . . .9Four-Wire Measurements . . . . . . . . . . . . . . . . . . . .9DC vs. AC <strong>Testing</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . .9How Does a <strong>Low</strong> <strong>Resistance</strong> Ohmmeter Operate? .10Current Selection . . . . . . . . . . . . . . . . . . . . . . . . . . .10Probe and Lead Selection . . . . . . . . . . . . . . . . . . . .11<strong>Low</strong> Range <strong>Testing</strong> . . . . . . . . . . . . . . . . . . . . . . . . .11Test on “Dead” Test Samples . . . . . . . . . . . . . . . . . .12Types of Testers/How to Choose . . . . . . . . . . .12Evaluation/Interpretation of Results . . . . . . .14Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14Spot Readings/Base Expectations for Readings . . . .14Trending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . .15Stand-by Battery Back-up Systems . . . . . . . . . . . .15Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . .16Potential Sources of Error/EnsuringQuality Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Test Leads/Probes . . . . . . . . . . . . . . . . . . . . . . . . .16Accuracy Statements . . . . . . . . . . . . . . . . . . . . . .17Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17Delivery of Stated Test Current Under Load . . . .17Taking the Measurement at a Stable Plateau . . .17Material Resistivity . . . . . . . . . . . . . . . . . . . . . . . . .17Effects of Temperature on Measured <strong>Resistance</strong>Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18Effects of Humidity . . . . . . . . . . . . . . . . . . . . . . . . .19Background Noise Conditions,Current and Voltage . . . . . . . . . . . . . . . . . . . . . . . .19Use and Misuse of <strong>Low</strong> <strong>Resistance</strong> Ohmmeters . . .19Brief History of <strong>Low</strong> <strong>Resistance</strong> Ohmmeters . . . . . .20Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20Ingress Protection . . . . . . . . . . . . . . . . . . . . . . . . . .20Various Test Modes . . . . . . . . . . . . . . . . . . . . . . . . .22Models Designed in the 1970s and 1980s . . . . . .22Recently Designed 10 Amp Models . . . . . . . . . . .22Nominal versus Absolute Test Current Levels . . . . .22Autoranging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23Transformer <strong>Testing</strong> . . . . . . . . . . . . . . . . . . . . . . . . .23Bar to Bar <strong>Testing</strong> . . . . . . . . . . . . . . . . . . . . . . . . . .24Battery Strap <strong>Testing</strong> . . . . . . . . . . . . . . . . . . . . . . . .26Wheatstone and Kelvin Bridges . . . . . . . . . . . . . . .27Wheatstone Bridge . . . . . . . . . . . . . . . . . . . . . . .27Kelvin Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . .27Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28<strong>Megger</strong> Products Overview . . . . . . . . . . . . . . .29Front Cover<strong>Low</strong> <strong>Resistance</strong> Ohmmeter shown being usedto measure contact resistance of a low voltagemolded case breaker.Milli-Ohmmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . .1210-A Micro-Ohmmeter . . . . . . . . . . . . . . . . . . . . . .12100+ A Micro-Ohmmeter . . . . . . . . . . . . . . . . . . . . .12Transformer Ohmmeter . . . . . . . . . . . . . . . . . . . . . .13Lab Micro-Ohmmeter . . . . . . . . . . . . . . . . . . . . . . .13www.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 1

www.actoolsupply.<strong>com</strong>INTRODUCTIONThe quantitative study of electrical circuits originated in 1827,when Georg Simon Ohm published his famous book “Diegalvanische Kette, mathematisch bearbeitet” in which hegave his <strong>com</strong>plete theory of electricity. In this seminal work,he introduced the relationship or “Law” that carries hisname:Resistivity ii Temperature Thermal emfComposition Micro-ohms Ohms for Cir. Coefficient Against CopperPercent for cm Cube mil Foot per ºC µv/ ºCCu 84%Mn 12% 44 µΩ 264 Ω *±0.00001º 1.7Ni 4%<strong>Resistance</strong> (R) = Voltage (E) / Current (I)At that time, the standards for Voltage, Current and<strong>Resistance</strong> had not been developed. Ohm’s Law expressed thefact that the magnitude of the current flowing in a circuitdepended directly on the electrical forces or pressure andinversely on a property of the circuit known as the resistance.Obviously, however, he did not have units of the size of ourpresent volt, ampere, and ohm to measure these quantities.At this time, laboratories developed resistance elements,constructed of iron, copper or other available alloy materials.The laboratories needed stable alloys that could be movedfrom place to place to certify the measurements underreview. The standard for the ohm had to be temperaturestable and with minimum effects due to the materialconnected to the ohm standard.In 1861, a <strong>com</strong>mittee was established to develop a resistancestandard. This <strong>com</strong>mittee included a number of famous menwith whom we are now familiar, including James ClerkMaxwell, James Prescott Joule, Lord William Thomson Kelvinand Sir Charles Wheatstone i . In 1864, a coil of platinum-silveralloy wire sealed in a container filled with paraffin was usedas a standard. This was used for 20 years while studies weremade for a more reliable standard. These studies continued asthe old National Bureau of Standards (NBS), now known asthe National Institute of Standards and Technology (NIST),controlled the standard for the “OHM.” Today the industryuses Manganin alloy because it has a low temperaturecoefficient so that its resistance changes very little with*Manganin shows zero effect from 20º to 30º C.temperature (see figure 1). The table below from Melvin B.Stout’s “Basic Electrical Measurements” highlights the keyproperties of Manganin.The thermal emf against copper indicates the thermocoupleactivity of the material whereby a voltage is generated simplyby connecting two different metals together. The goal is tominimize thermocouple activity as it introduces error into themeasurement.With the metric system, the measurements are in meters andthe resistivity is determined for a one-meter cube of thematerial. However, more practical units are based on acentimeter cube. With the USA system, the resistivity isdefined in ohms per mil foot. The wire diameter is measuredin circular mils (0.001) 2 and the length in feet.Figure 1 shows the temperature-resistance curve forManganin wire at 20º C. For Manganin shunts, the 20° Ccurve shifts to 50º C, as this material will be operating at ahigher temperature due to the The Manganin alloy wasdesigned for use in coils used to perform stable measuringconditions at 20º C ambient room conditions. The alloy ismodified for strips of material used in measuring shunts,which operate at a higher ambient, up to 50º C.The purpose of this booklet is to help the engineer, technicianor operator:■ Understand the rationale behind low resistancetesting.■ Understand how to make a low resistancemeasurement.■ Understand how to select the proper instrument for thetesting application.■ Understand how to interpret and use the results.<strong>Resistance</strong>1.000.99Wire Coil20 ° C350° C50°CTemperatureStrip - ShuntFigure 1: Qualitative <strong>Resistance</strong>-Temperature Curve for Manganin iiiWHY MEASURE LOW RESISTANCE?Measuring low resistance helps identify resistance elementsthat have increased above acceptable values. The operation ofelectrical equipment depends on the controlled flow ofcurrent within the design parameters of the given piece ofequipment. Ohm’s Law dictates that for a specified energysource, operating on V ac or V dc, the amount of currentdrawn will be dependent upon the resistance of the circuit or<strong>com</strong>ponent.In the modern age of electronics, increased demands areplaced on all aspects of electrical circuitry. Years ago theability to measure 10 milli-ohms was acceptable, but, in thepresent industrial electronic environments, the field testengineer is now required to make measurements which showrepeatability within a few micro-ohms or less. These types ofmeasurements require the unique characteristics of a lowresistance ohmmeter’s four-wire test method, which iscovered on page 9 in this booklet.<strong>Low</strong> resistance measurements are required to prevent longterm damage to existing equipment and to minimize energywasted as heat. They indicate any restrictions in current flowthat might prevent a machine from generating its full poweror allow insufficient current to flow to activate protectivedevices in the case of a fault.Periodic tests are made to evaluate an initial condition or toidentify unexpected changes in the measured values, and thetrending of this data helps indicate and may forecast possiblefailure conditions. Excessive changes in measured values pointto the need for corrective action to prevent a major failure.When making field measurements, the operator ought tohave reference values that apply to the device being tested(the manufacturer should include this information in theliterature or name-plate supplied with the device). If the testsare a repeat of prior tests, then these records may also beused to observe the range of the anticipated measurements.If, when conducting tests, the operator records the resultsand the conditions under which the tests were performed,the information be<strong>com</strong>es the beginning of a database thatcan be used to identify any changes from fatigue, corrosion,vibration, temperature or other condition that may occur atthe test site.What is a <strong>Low</strong> <strong>Resistance</strong> Measurement?A low resistance measurement is typically a measurementbelow 1.000 ohm. At this level it is important to use testequipment that will minimize errors introduced by the testlead resistance and/or contact resistance between the probeand the material being tested. Also, at this level, standingvoltages across the item being measured (e.g. thermal emfsat junctions between different metals) may cause errors,which need to be identified.To allow a measurement to <strong>com</strong>pensate the errors, a fourterminalmeasurement method is employed with a reversibletest current and a suitable Kelvin Bridge meter. <strong>Low</strong>resistance ohmmeters are designed specifically for theseapplications. In addition the upper span on a number ofthese meters will range into kilohms, which covers the lowerranges of a Wheatstone Bridge (please see the appendix for adiscussion of the Wheatstone and Kelvin Bridge methods).The lower range on many low resistance ohmmeters willresolve 0.1 micro-ohms. This level of measurement is requiredto perform a number of low range resistance tests.What Does the <strong>Low</strong> <strong>Resistance</strong> Measurement Tellthe Operator?<strong>Resistance</strong> (R) is the property of a circuit or element thatdetermines, for a given current, the rate at which electricalenergy is converted to heat in accordance with the formulaW=I 2 R. The practical unit is the ohm. The low resistancemeasurement will indicate to the observant operator whendegradation has or is taking place within an electrical device.Changes in the value of a low resistance element are one ofthe best and quickest indications of degradation taking placebetween two contact points. Alternatively, readings can be<strong>com</strong>pared to “like” test specimens. These elements includei Swoope’s Lessons in Practical Electricity; Eighteenth Edition; Erich Hausmann, E.E., ScD.; page 111ii Swoope’s Lessons in Practical Electricity; Eighteenth Edition; Erich Hausmann, E.E., ScD.; page 118iii Basic Electrical Measurements; Melvin B. Stout; 1950; page 612 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 3

www.actoolsupply.<strong>com</strong>rail bonds, ground bonds, circuit breaker contacts, switches,transformer windings, battery strap connections, motorwindings, squirrel cage bars, bus bar with cable joints andbond connections to ground beds.The measurement will alert the operator to changes havingtaken place from the initial and/or subsequentmeasurements. These changes can occur from a number ofinfluences including temperature, chemical corrosion,vibration, loss of torque between mating surfaces, fatigueand improper handling.These measurements are required on a regular timed cycle inorder to chart any changes taking place. Seasonal changesmay be evident when summer and winter data are reviewed.What Problems Create the Need to Perform the Test?Assuming a device has been correctly installed in the firstplace, temperature, cycling, fatigue, vibration and corrosionall work to cause the gradual degradation of the resistancevalue of an electrical device. These influences build up over aperiod of time until a level is reached at which the device nolonger operates correctly. The critical degrading factor will bedetermined by the application.Environmental and chemical attacks are relentless. Even airwill oxidize organic materials while the ingress of moisture,oil and salt will degrade connections even more rapidly.Chemical corrosion can attack the cross sectional area of anelement, reducing the area while increasing the resistance ofthe <strong>com</strong>ponent. Electrical stresses, particularly sustainedovervoltages or impulses, can cause welds to loosen.Mechanical stress from vibration during operation can alsodegrade connections, causing resistance to rise. Theseconditions result in excessive heating at the location whenthe <strong>com</strong>ponent is carrying the rated current, based on theformula W=I 2 R. For example:6000 A across a 100 µΩ bus = 3600 Watts.6000 A across a 1 µΩ bus = 36,000 Watts, which will resultin excessive heating.If left unattended, these types of problems can lead to failurein the electrical system containing the affected <strong>com</strong>ponents.Excessive heating will ultimately result in failure due toburnout, which may open an energized circuit.Backup battery power supplies provide a good practicalexample of how degradation can occur under normaloperating conditions. Changes in current flow causeexpansion and contraction of the terminal connections,causing them to loosen or corrode. Additionally, connectionsare exposed to acid vapors, causing further degradation.These conditions result in a decrease in the surface-to-surfacecontact area with an associated increase in surface-to-surfacecontact resistance, ultimately causing excessive heating at thejunction.Industries with Significant <strong>Resistance</strong> ProblemsIndustries that consume vast amounts of electrical powermust include low resistance ohmmeter measurements in theirmaintenance operations. Not only does abnormally highresistance cause unwanted heating, possibly leading todanger, but it also causes energy losses which increaseoperating costs; in effect you are paying for energy whichyou can’t use.In addition, there are industries that have criticalspecifications on bond connections to ensure solidconnections to “ground beds.” Poor connections reduce theeffectiveness of the ground bed and can cause significantpower quality-related problems and/or catastrophic failure inthe event of major electrical surge. A number of subassemblyoperations supply <strong>com</strong>ponents to aircraftmanufacturers that specify low resistance connections to theairframe. Strap connections between cells on a power backupbattery system also require very low resistance. A generallist of industries include:■ Power generation and distribution <strong>com</strong>panies■ Chemical plants■ Refineries■ Mines■ Railroads■ Tele<strong>com</strong>munications <strong>com</strong>panies■ Automotive manufacturers■ Aircraft manufacturers■ Anyone with UPS battery back-up systemsSpecific Examples of Apparatus in Needof <strong>Low</strong> <strong>Resistance</strong> <strong>Testing</strong>As we have shown, low resistance ohmmeters haveapplication in a wide range of industries and can help identifya number of problems that could lead to apparatus failure. Ingeneral manufacturing industries, motor windings, circuitbreakers, bus bar connections, coils, ground bonds, switches,weld joints, lightning conductors, small transformers andresistive <strong>com</strong>ponents all require low resistance testing.C2P2C1P1Figure 2: Bar to Bar <strong>Testing</strong> on DC Motor RotorC1P1 AP2 AFigure 3: Bus Bar ConnectionsP1 BP1 CP1 DP2 BP2 CP2 DFollowing are some of the more typical applications.Motor ArmatureArmature windings can be tested to identify shortingbetween adjacent coils or conductors. Squirrel cage bars inthe rotor can separate from the end plates, resulting in lossof performance. If a motor appears to be losing power, a lowresistance test should be performed. Alternatively, tests canbe made when bearings are being replaced at a periodic orannual shutdown.Bar to bar testing on dc motor rotors is performed to identifyopen or shorted coils (see Figure 2). These tests areperformed with spring loaded hand probes. This is a dynamicmethod to determine the conditions of the windings and thesoldered connections to the riser on the <strong>com</strong>mutatorsegments. When test data is reviewed periodically, the effectsof overheating due to excessive temperature rise can beidentified.Automotive AssemblyCable leads in a “robot” spot welder can work-hardenthrough continual flexing. Eventually fatigue can occurcausing strands to break. This condition results in a high leadresistance with loss of power to the weld, producing a poorspot-weld (nugget) or even <strong>com</strong>plete failure of the machine.P1 NP2 NC2Power Generation and Distribution (high current joints,connections and bus bars)Bus bars in a power system consisting of lap joints and otherconnections, are used to deliver current to the elements inthe system. These bolted connections can be degraded byvibration and corrosion. (See Figure 3.) The bolts are stressedto a specific tightness (torque), and the quickest and mosteconomical way to determine the quality of the connection isto measure the resistance across the joint. The operatorshould have historical data to make the determination on thesuitability of the connection. If left uncorrected, loss of powerand/or excessive heating could lead to a meltdown at theconnection.Transformer <strong>Testing</strong>Transformer winding tests are performed in the factory andthen periodically in the field. The factory test is performed atambient temperature. A second factory test is a heat run toverify that, at rated power, the resistance of the windingsremains within its designed temperature rise characteristics.Large transformers have “taps” on both the primary andsecondary windings. The condition of the taps requiresverification, since the secondary taps are operated daily andare exposed to excessive wear and vibration as the powerdistribution system balances the load carried on the variouscircuits. The taps on the primary side are critical to majoradjustments in the power distribution and should be testedto ensure that a low resistance connection is available for thenew power condition. Tap connections can corrode when notin use and may overheat due to the high current (which canresult in a fire).Uninterruptible Power Supply - Battery StrapsOn series connected industrial batteries, straps (lead coatedcopper bars) are secured to the posts on adjacent batteries,(+) to (-), with stainless steel bolts. These surfaces arecleaned, greased and tightened to a preset torque value. Asnoted previously, they are subject to vibration, chemicalcorrosion and heat due to the charging and high currentdischarges associated with the application. The quickest andbest way to determine the quality of the connections is tomeasure the resistance between the two adjacent batteryterminals (see Figures 4 and 5). This is the only fieldapplication in which the operator makes measurements on anenergized system. Please see the appendix for more detail onbattery strap testing.4 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 5

www.actoolsupply.<strong>com</strong>Please note that there are various levels of “float current” ina battery system and the test procedure must account for thiscurrent flow. A test is performed with the test current addedto the float current and a second test is made with the testcurrent opposed to the float current. These twomeasurements are averaged to determine the “ohmic”value of the connection.Standard procedures require measurements on a regularschedule, as past experience has determined that batterystraps are one of the weakest elements in the operation of abattery system. When not attended to on a regular testprogram, high resistance connections can develop. Thissituation can result in the battery being unable to deliversufficient current when called for, or when <strong>com</strong>bined withcurrent surge and hydrogen gas evolved from the batterycells, can cause a fire in the battery system, destroyingthe UPS.Carrier strips “carry” the plates in a cell. The plates aresuspended from the carrier strips into the liquid in the cell. Ifthe resistance of the terminal to carrier strip welds is toohigh, the battery’s ability to carry current is limited. Inaddition to measuring strap resistance, a low resistanceohmmeter can also be used to measure the quality of thesewelds (see Figure 6).Cement Plants and other Raw Material Processing ApplicationsThe electrical system at a cement plant or other raw materialsprocessing facility includes motors, relays, disconnectswitches, etc. The testing of these power-carrying elementsas part of a regular program or when major retrofits takeplace is critical to the ongoing operation of the plant.The quality of the current connections can identify weakelements or connections in the system. Note that cementdust is chemically active (corrosive) and will attack metallicconnection.Circuit BreakersDue to arcing at the circuit breaker pads, carbonized layerswill build up and the live contact area will reduce or be<strong>com</strong>epitted, leading to increased resistance and heating. Thissituation reduces the efficiency of the breaker and can leadto failure on an active transmission system resulting in theloss of a substation. When planning a test, the operator mustbe aware of IEC62271-100 and ANSI C37.09 for test currentrequirements. When testing large oil circuit breakers, the bestinstrument is one that ramps up current, holds it for a periodof time and then ramps down. This test method reduces theC1 P1 P2 C2Figure 4: Single Strap with Two Contact SurfacesC1P1C1P1++C2 C1P2 P1C2 C1P2 P1++Figure 5: Parallel Straps on a Large Battery ComplexPlatesABCCell #1 Cell #2A to B – Intercell strap resistanceA to C – Carrier strip resistanceFigure 6: Measuring Carrier Strip <strong>Resistance</strong>C2P2C2P2CarrierStripmagnetizing, which would otherwise be created by thesudden switching on and off of the test current. This canresult in inaccurate “CT” measurements when the system isreturned to normal ac operation.Care should be taken when making a measurement across aCT as high dc currents may saturate the CT, desensitizing it topotential faults. Also, ripple on the test current may causecircuit breakers to trip. Careful positioning of the currentprobes should prevent this happening, and the ripple presenton the current waveform may be minimized by separating thetest leads.Aircraft AssemblyBond testing of all the main frame electrical and mechanicalconnections is required to ensure a stable “ground plane”within an aircraft. These physical “bond” connections providea uniform path for static electricity to be discharged to thewicks on the trailing edge of the wings and tail assembly. Thispath reduces the chance of lightning damaging the avionicsin the event of a lightning strike situation. Over time, thebonding of static wicks, antenna, control linkage and batteryterminals should be inspected. The integrity of a weldedexhaust system should also be verified and documented. Innormal operations, excessive static electricity will not effectthe operation of most navigation and <strong>com</strong>municationssystems. The best (lowest) resistance connections will improvethe performance of such systems.Strap and Wire Bonds between Rail Segments(Railroad Industry)In the railroad environment, bonds are exposed to vibration asthe wheels pass over the rails (each click-clack causesvibration across the interface bonding the strap to the rail).These bonds are part of the control system which tells theoperator the location of different trains. Within the railsystem, a telephone system uses the rail conductors to<strong>com</strong>municate. The resistance of these bonds is critical to theperformance of the control system. In systems that use threerails, the third rail is the active source of power for theengine, and power lost across a high resistance bond (such asa poor Cadweld joint) reduces the efficiency of the transitsystem. The operator can select a five-foot section of trackwithout a bond, make a measurement and then measure afive-foot section with a bond to determine the quality of theconnection. As a rule of thumb, these measurements shouldbe within a few micro-ohms (or ±5%).Graphite ElectrodesGraphite electrodes have a negative temperaturecharacteristic. (As the temperature of the element increasesthe resistance measurement will decrease.) Graphite slugs areextruded as large diameter cylinders and may be up to sixfeet in length. One of the applications for these large slugs isin aluminum refineries where high currents (150,000 A) areused to reduce bauxite ore to high-grade aluminum.<strong>Low</strong> resistance testing is done as a quality control step toverify the density of the graphite extrusion. Due to the size ofthe electrodes, this test requires a special test fixture tointroduce the test current across the surface of the ends,ensuring a uniform current density through the volume of thesample. The potential probes are then connected across aknown length of the sample to determine the “ohms per unitlength” (see Figure 7 on the following page).Welding Spot or SeamThe quality of a spot weld can be determined by measuringthe resistance across the joined materials. The quality of aseam weld can be determined by a series of tests along theweld seam. Readings should remain within a narrow band ofvalues. An increase and then drop in readings is an indicationthat the uniformity of the weld is out of specification. Tomake the measurement properly, the operator shouldfabricate a fixture to keep the probes in a fixed relationship.Readings are then taken at a number of points across theweld seam and plotted (see Figure 8). These measurementsare normally in the micro-ohm region and special care isrequired in the design of the test fixture.Cable ReelsA reel of insulated copper wire may have a tag indicating thewire gauge along with the ohms per unit length. When wireremains on the reel after partial utilization, the remaininglength can be calculated by measuring the resistance of thewire and making a calculation using the ohms per lengthspecification (see Figure 9).Alternatively, if the tag has been destroyed, the operator cancut off a known length of wire, measure that sample anddetermine the ohms per length. This value can then be usedwith the reading taken when measuring the balance of wireon the reel to calculate the remaining length. Thetemperature of the reel of cable will be approximately thesame as the temperature of the sample. Though the internaltemperature of the reel may be slightly different, a reasonableestimate of the remaining length of cable can be calculated.6 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 7

www.actoolsupply.<strong>com</strong>If the operator reviews the temperature charts on pages 18and 19 in this book, an estimate of the inaccuracy can bedetermined. This method also applies to aluminum and steelwires as long as the wire has an insulating coating to preventshorting between adjacent loops of wire.HOW DO YOU MEASURE LOW RESISTANCE2-Wire, 3-Wire and 4-Wire DC MeasurementsWhy do we have resistance measuring instruments, somewith only two test leads, some with three and even somewith four test leads? The answer depends on the degree ofinformation required from the measurement, and themagnitude of the resistance being measured. <strong>Resistance</strong>readings cover a wide range of values from micro-ohms intothe thousands of meg-ohms region. Figure 10 showsthe measurement range in which each type ofinstrument performs best.Two-Wire MeasurementsTwo–wire testing is the simplest method and it is usedto make a general assessment of a circuit element,conductor or the routing of a conductor in a circuit.The two-wire lead configuration is most familiar tomany operators as it is the configuration used on mostmultimeters. It is generally used when the probe’scontact resistance, series lead resistance or parallelleakage resistances do not degrade the quality of themeasurement beyond a point acceptable to theoperator.The measured value will include the test lead wire resistanceand contact probe resistance values, which will affect themeasurement by adding some tens of milli-ohms to theactual resistance. In most instances this will make littlepractical difference to the measured value, but when themeasurement is below 1.000 ohm the two-wire method caneasily introduce an error, which could be several percent, intothe measured resistance value.The specifications on some hand-held meters indicate a 200milli-ohm range with one milli-ohm sensitivity. The leadresistance may be zeroed out, but that leaves the uncertaintyof the contact resistances, which can change with eachmeasurement. Contact resistance values may be in the 35milli-ohm range at each probe and can vary with thetemperature of the material under investigation.The two-wire test method is best used for readings above10.00 ohms up to 1.0 to 10.0 megohms.C1 P1P2C2Test 1Figure 7: <strong>Testing</strong> Graphite Slugs for Uniform Density (ohms/inch)<strong>Testing</strong> PathC1 P1P2C2Test NWeld SeamFigure 8: Series of Measurements Across a Weld Seam<strong>Low</strong> <strong>Resistance</strong>OhmmeterC2P2Zone with PoorWeld Penetration1 NTest PositionFigure 9: Determining the Remaining Length of Cable on a ReelC1P1Three-Wire MeasurementsThree-wire dc testing is reserved for very high resistanceand is typically used for measurements above 10.0 megohms.We normally associate this type of testing with diagnosticinsulation resistance. The test method uses a third test leadas a guard, and allows for resistances in parallel with the testcircuit to be eliminated from the measurement. This parallelresistance is usually considerably lower than the insulationresistance being measured. In fact it may, in severe cases,effectively short out the insulation resistance such that ameaningful measurement cannot be carried out without theuse of a guarding circuit.DC vs. AC <strong>Testing</strong>The issue here is the selection ofthe correct type of test current. Adc instrument should be usedwhen trying to measure the pureresistance of a circuit or device.An ac instrument is used forapplications such as ground bedtesting or impedance testing.A special impedance meter isused to perform tests onindustrial batteries. The wordimpedance is used to indicate ameasurement <strong>com</strong>prised of aresistance and reactance, whichcan be either an inductive orcapacitive <strong>com</strong>ponent. Thesemeasurements are conducted aspart of a battery maintenance program; typically a lowresistance ohmmeter is used to perform strap connectionverification tests.Three or four-wire ac measuring systems are used to performtests on “ground beds” with special frequencies that excludemeasurement errors from 50/60 Hz ground currents. The useof ac prevents the test current polarizing ions in the soil,thereby changing the conditions and thus the measuredvalues. This is an area of interest to the electrical powerdistribution and tele<strong>com</strong>munication fields. The low groundresistance path is required for maintaining the potential ofthe ground wire to the “earth” potential. ElectricalThis test method is described and illustrated in the <strong>Megger</strong> performance of the power system minimizes shock hazardsbooklets “A Stitch in Time…” and “A Guide To Diagnostic as a path to ground is made available for the energy fromInsulation <strong>Testing</strong> Above 1 kV.”lightning and other static voltages that may affect the powercontrol system. The same conditions pertain to the telephoneFour-Wire Measurementssystems, as high resistance grounds can cause excessive noiseFour-wire testing is the most accurate method whenon the voice and data links. Please see the <strong>Megger</strong> bookletmeasuring circuits below 10.00 ohms as this method“Getting Down to Earth” for more information on groundeliminates errors due to lead and contact resistances. This isresistance testing. Both of these industries require not onlythe test method associated with low resistance ohmmeters.low ground bed resistance but also low resistance “ac/dcFour-wire dc measurements uses two current and twobonds” between the ground bed and the active circuits.potential leads (see Figure 11). The four-wire dcmeasurement negates the errors due to the probe lead wireand any contact resistance valuesin the final reading, ensuring4-wire 2-wire 3-wiremore accurate measurements.Exponential of Ten151050-5-10100 mΩ1 µΩ10 µΩ100 µΩ1 mΩ10 mΩ100 mΩ1 Ω10 Ω100 Ω1 kΩ10 kΩMeasurement Range (Ohms)Figure 10: Selection of Optimum Measuring Technique100 kΩ1 MΩ10 MΩ100 MΩ1 GΩ10 GΩ100 GΩ1 TΩ8 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 9

www.actoolsupply.<strong>com</strong>How Does a <strong>Low</strong> <strong>Resistance</strong> Ohmmeter Operate?A low resistance ohmmeter uses two internal measuringcircuits. The supply injects a current into the test samplethrough two leads, usually identified as C1 and C2, and themagnitude of the current is measured. Concurrently, twoprobes (normally referred to as P1 and P2) measure thepotential across the sample. The instrument then performsan internal calculation to determine the resistance of thetest sample.Why does this approach result in a measurement that isindependent of lead resistance and contact resistance?We have represented the <strong>com</strong>plete measurement circuit inFigure 12. Current is injected into the item under test vialeads C1 and C2. The current that flows will be dependentupon the total resistance of this loop and the poweravailable to push the current through that resistance. Sincethis current is measured, and the measured value is used insubsequent calculations, the loop resistance, including thecontact resistance of the C1 and C2 contacts and the leadresistance of C1 and C2, does not have an effect on thefinal result.From Ohm’s Law, if we pass a current through a resistancewe will generate a voltage across the resistance. This voltageis detected by the P1 and P2 probes. The voltmeter to whichthese probes are connected internally has a high impedance,which prevents current flowing in this potential loop. Sinceno current flows, the contact resistance of the P1 and P2contacts produces no voltage and thus has no effect on thepotential difference (voltage) detected by the probes.Furthermore, since no current flows through the P leads theirresistance has no effect.A high current output is one of the qualifying characteristicsof a true low resistance ohmmeter. Generic multimeters donot supply enough current to give a reliable indication of thecurrent-carrying capabilities of joints, welds, bonds and thelike under real operating conditions. At the same time, littlevoltage is required, as measurements are typically being madeat the extreme low end of the resistance spectrum. Only thevoltage drop across the measured resistance is critical, and itis measured at the millivolt level.Good instruments alert the operator of open circuitconditions on the test leads while a few models haveautomatic range selection.Current SelectionDepending on the instrument chosen, the current selectioncan be either manual or automatic. The operator shouldselect the highest current suitable for the test to provide thebest signal to noise ratio for the measurement. Oninstruments that offer current levels in excess of 10 amps,care is required to minimize any heating of the sample thatwould itself cause the resistance of the sample to change.CurrentProbe 1(C1)PotentialProbe 1(P1)Measured <strong>Resistance</strong>Length<strong>Low</strong> <strong>Resistance</strong> OhmmeterConstant CurrentDC SourceMeasuring Circuit(with digital display; R=E/I)DC VoltmeterC1 P1 P2 C2<strong>Resistance</strong>MeasuredPotentialProbe 2(P2)Figure 11: Simplified Example of a 4-Wire MeasurementCurrentProbe 2(C2)Instruments designed for circuit breaker testing have muchhigher current characteristics and the operator must becareful when setting the test current level. Instrumentsdesigned specifically for transformer testing have a specialhigh-voltage power level at the beginning of the test tosaturate the winding. These units then switch to a lowerconstant current mode to measure the winding on thetransformer.Probe and Lead SelectionThe potential and current leads are either connectedseparately or to a probe. When probes are used the potentialconnection is identified with a “P.” The connections areplaced in contact with the sample so that the P-identifiedcontacts or leads are positioned towards each other. Thecurrent contacts are then positioned outside or away fromthe potential connections. This causes the current to flowwith a more uniform current density across the sample beingmeasured.For the more rigorous tests, separate test leads are used andthe current connections are positioned away from thepotential connections by a distance that is 1 1 ⁄2 times thecircumference of the sample being measured. ASTM StandardB193-65 provides guidelines for making a measurement thatwill establish uniform current density. This standard suggestsseparating the current probes from the potential probes by1 1 ⁄2 times the cross sectional perimeter of the test specimen.Figure 13 shows a test being made to the standard on acylindrical test item.The use of probes, Kelvin Clips, or C-clamps will meet mostfield requirements as the operator should be makingrepetitive measurements under the same conditions. Thesharp points on the probes should leave a mark on thespecimen for future testing. In some situations a marker pencan indicate the test area and the probe positions will beidentified by the probe indents.Leads are available in a number of lengths to meet differentfield application requirements. The probe selection is madefrom separate current and potential leads with clips toconnect to the test sample. Helical spring point probes haveboth potential and current probes in the same handle. The“P” identification on the probe identifies the position on thesample at which the measurement is taken. This probearrangement provides a practical method when makingrepetitive measurements (ideal when testing strapconnections in UPS battery supply systems).Kelvin Clips and C-clamps have the current and potentialconnections 180º from each other, providing separate currentand potential connections. The size of the terminalconnection determines which one to select. See Figure 14 forthe different probe/lead configurations.Note: The order of connection of potential and current clips isnot important. However, never connect the potential clip tothe current clip as this will cause an error in the measurementdue to the voltage drop at the current connection interface atthe sample.<strong>Low</strong> Range <strong>Testing</strong>When measuring on the extreme edge of precision andsensitivity, factors be<strong>com</strong>e significant that would be too smallto be of consequence in conventional testing. In lowresistance testing, thermal emfs (electromotive forces) canproduce voltage gradients across the test sample. Althoughonly on the milli-volt level, and of little or no influence on<strong>com</strong>mon multimeter tests, these can cause fluctuations ofseveral digits. Such instability defeats the purpose of a highprecisionmeasurement. In addition, alternating currentinterference can be induced by nearby electric or magneticfields, or may be present from the float charge on standbybattery systems, or through leaky switches, electricalimbalance and so on.C11.5(Cir)P1Circumference (Cir) = 2 Π rZone with UniformCurrent DensityFigure 13: ASTM Standard B193-65P21.5(Cir)C2Figure 12: Basic Operation Diagram10 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 11

www.actoolsupply.<strong>com</strong>EVALUATION/INTERPRETATION OF RESULTSRepeatabilityA good quality low resistance ohmmeter will providerepeatable readings within the accuracy specifications forthe instrument. A typical accuracy specification is ±0.2%of reading, ±2 lsd (least significant digit). For a reading of1500.0, this accuracy specification allows a variance of±3.2 (0.2% x 1500 = 3; 2 lsd = 0.2).Additionally, the temperature coefficient must be factoredinto the reading if the ambient temperature deviates from thestandard calibration temperature.Spot Readings/Base Expectations for ReadingsSpot readings can be very important in understanding thecondition of an electrical system. The operator should havesome idea of the level of the expected measurement basedon the system’s data sheet or the supplier’s nameplate. Usingthis information as a baseline, variances can be identified andanalyzed. A <strong>com</strong>parison can also be made with data collectedon similar equipment.As noted, the data sheet or nameplate on a device shouldinclude electrical data relevant to its operation. The voltage,current and power requirements can be used to estimate theresistance of a circuit, and the operating specification can beused to determine the allowed change in a device (forexample, with battery straps, connection resistances willchange with time). Various national standards provideguidance for periodic test cycles.The temperature of the device will have a strong influence onthe expected reading. As an example, the data collected on ahot motor will be different from a cold reading at the time ofthe installation. As the motor warms up, the resistancereadings will go up. The resistance of copper windingsresponds to changes in temperature based on the basicnature of copper as a material. A more detailed review oftemperature effects is covered in the appendix. Using thenameplate data for a motor, the expected percentage changein resistance due to temperature can be estimated using thetable shown to the right for copper windings or the equationon which it is based.Different materials will have different temperaturecoefficients. As a result, the temperature correction equationwill vary depending on the material being tested.Copper – Temperature/<strong>Resistance</strong> RelationshipTemp. Temp. <strong>Resistance</strong> PercentºF ºC µΩ ChangeTrending-40º -40º 764.2 µΩ -23.6%32º 0º 921.5 µΩ -7.8%68º 20º 1000.0 µΩ 0.0%104º 40º 1078.6 µΩ +7.9%140º 60º 1157.2 µΩ +15.7%176º 80º 1235.8 µΩ +23.6%212º 100º 1314.3 µΩ +31.4%221º 105º 1334.0 µΩ +33.4%R (end of test) /R (beginning of test)= (234.5 + T (end of test) )/(234.5 + T (beginning of test)In addition to <strong>com</strong>paring measurements made with a lowresistance ohmmeter against some preset standard (spot test),the results should be saved and tracked against past andfuture measurements. Logging of measurements on standardforms with the data registered in a central database willimprove the efficiency of the testing operation. Prior test datacan be reviewed by the operator, and then on-site conditionscan be determined.Developing a trend of readings helps the operator betterpredict when a joint, weld, connection, or other <strong>com</strong>ponentwill be<strong>com</strong>e unsafe, and make the necessary fix(es).Remember that degradation can be a slow process. Electricalequipment faces mechanical operations or thermal cycles thatcan fatigue the leads, contacts and bond connections.Additionally, these <strong>com</strong>ponents may also be exposed tochemical attack from either the atmosphere or man-madesituations. Periodic testing and recording of the resultsprovides a database of values that can be used to developresistance trends.Note: When taking periodic measurements, theoperator should always connect the probes in the sameplace on the test sample to ensure similar testconditions.Following are several examples of where trending can helpthe operator make better-informed maintenance decisions:Circuit BreakersAs noted previously, mechanical wear and tear on circuitbreaker contacts that reduces the area of the contact surfaces<strong>com</strong>bined with sparking and/or arcing will increase theresistance across the working connections. This condition willproduce heat that can reduce the effectiveness of the circuitbreaker. Periodic measurements will show the rate of increaseof the contact resistance value. When these values are<strong>com</strong>pared to the original manufacturer’s specification, adecision can be made to continue or repair. By tracking thetrend of the readings, the operator will get an idea of whenthe circuit breaker should be pulled for service before damageis done.Stand-by Battery Back-up SystemsThe interface between the terminals and the straps on batteryback-up systems is subject to chemical attack from the acidatmosphere, thermal changes due to the charging anddischarge currents and mechanical stress from vibration. Eachof these factors can cause the resistance bond to degrade,resulting in the potential for a fire at a critical powerdischarge (due to the hydrogen gas atmosphere). Batterysystems require diligent attention, as replacement batteriesare both expensive and not off-the-shelf items. A failuresituation can result in a battery system being out of servicefor a number of weeks. Periodic measurements of the strapresistance will identify those bondconnections that have degraded since thelast test and corrective action can beplanned.Note: When connections have higherthan normal resistance measurements,the operator should not retighten thebolts, as this will over stress the soft leadconnection. Over tightening does notcure the problem. The proper procedureis to disassemble the straps, clean,grease and then reconnect with thebolts tightened to the supplier’s torquelevel. All the connections should bebalanced within a narrow tolerance of±10 to 20%.<strong>Resistance</strong> - Micro-Ohms140.0135.0130.0125.0120.0115.0123.00In these and many other systems, time lost to repair defectiveequipment may be small <strong>com</strong>pared to the cost of havingequipment out of service for weeks. Periodic testing can avertmany problems. Analyzing data against past results andreasonable standards allows the operator to select the timewhen corrective work should be done.The value of a system is in its ability to perform on demand.Operations are predicated on many systems being available atan instant’s notice. When elements break, production is lostand time is wasted making emergency repairs. Taking andanalyzing periodic low resistance measurements saves<strong>com</strong>panies money by helping identify problems before theyresult in catastrophic failure.The practical example shown in Figure 15 shows howtrending low resistance measurements made on a periodicbasis provides critical information to the operator. When lowresistance measurements are made on stranded cables onspot welding robot #23, the operator is gathering data toestimate when fatigue to the current conductor will degradethe quality of the weld nugget. The test data begins with thewire manufacturer’s specifications. It has been determinedthat a resistance increase of up to 10% is acceptable. In thiscase, measurements are made after a specific number ofweld operations. When charting this data, observe the rate ofchange as the readings approach the end of life for thestranded cable (see Figure 15). The critical factor could havebeen long-term exposure to a chemical solvent. In otheroperations the critical factor is time, with testing performedseasonal or on specified number of days.Allow for a 10% increase;5,000123.0 x 1.1 = 135.3;Scheduled <strong>Resistance</strong> Readings - Robot #23100-105K operations10,00015,00020,00025,00030,00035,00040,00045,00050,00055,00060,000Number of Operations65,00070,00075,00080,000Area of Concern85,00090,000132.995,000134.1100,000136.0105,000Figure 15: Trending Analysis of <strong>Low</strong> <strong>Resistance</strong> Readings14 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 15

www.actoolsupply.<strong>com</strong>APPENDICESPotential Sources of Error/Ensuring Quality ResultsThe operator can <strong>com</strong>promise low resistance measurements ifthe wrong test equipment is selected or the temperature atthe test site is not determined and noted on the test datasheet. Prior to testing, surface preparation may be critical.Heavy scale or oxide coatings should be removed to expose aclean surface and ensure good current connections.Test Leads/ProbesAn instrument’s specification should have a re<strong>com</strong>mendedlisting of suitable test leads. The operator should alwaysverify that the correct leads are being used as leads may lookalike but have different resistances, which may limit themaximum current that the instrument can produce.Do not use thermocouple extension wire in place of copperleads as the material mismatch will produce erratic data thatwill change as the site temperature varies with the seasons.The probe selection is also critical. High current tests requiresecure connections to the work surface because highresistance at the contacting point can limit the expected levelof test current, causing a poor signal-to-noise ratio, witherratic results. Use of unsuitable probes for the particularapplication can lead to unreliable results.In all cases tests are performed with current injection andpotential measurements made at separate locations on the<strong>com</strong>ponent. Potential test clips must never be connected tothe current connection as the voltage drop at the currentinterface will be added to the potential measurement andproduce an error in the reading. The ideal current connectioninjects current above the potential measurement position.When these points are close to each other the Kelvin Clip orC-clamp connectors are used, injecting current 180º from thepotential connection (see Figure 16).CPCCorrect Correct WrongPPCProbes are available in five basic styles; each is designed toaddress specific field and/or application situations. Figure 17shows some of the different styles.Fixed Point: Most economical and lightweight probes.Kelvin Clips: Feature spade lugs on the outboard end andalligator clips with insulated silver or gold plated jaws.Linear Spring Points: These probes are designed with springpoints, which recess into the handle to allow for unevennessof the surface. They are designed for clean surfaces as theyhave no “cutting” action to allow them to bite throughsurface contamination.Helical Spring Points: Tips rotate and <strong>com</strong>press into the bodyof the probe, allowing the probes to break through anygrease or surface film, ensuring an accurate measurement.Additionally, these probes will leave a mark on the testsurface to identify the points where the test was performed.Care should be taken when using these probes if the surfacebeing contacted is sensitive to pressure points.C-Clamps: Current passes through the C-clamp and screwthread while the potential passes through a four-point anvilinsulated from the clamp metal.The test leads are matched to battery-operated meters toensure that the nominal level of test current will be deliveredto the test specimen.Finally, probes are designed to make electrical connectionwith the test sample. They are not intended to be used toclean surfaces, open tins, etc.Figure 17: Basic Styles of ProbesAccuracy StatementsQuality low resistance ohmmeters will show their accuracystatement as “±X.X% of reading, ±X lsd.” Beware ofinstrument accuracies stated as a percent of range ratherthan a percent of reading. While these accuracy statementsmay look alike, the measurements made on an instrumentwith (% of range) accuracy would provide readings that areless accurate.The resolution of an instrument reading is typically one-halfthe least significant digit (lsd) noted in the accuracystatement. The magnitude of the lsd influences therepeatability of the measurement. A large lsd number is dueto the low sensitivity of the instrument, adding an additionalerror to the measurement.Check the temperature coefficient of the selected instrument.The temperature coefficient (% of reading per degree) ismultiplied by the site temperature difference from theinstrument’s calibrated temperature and will influence theaccuracy of the field measurements. An instrument thatincludes an accuracy notation of +0.2%/ ºC should not beused in the field, as its best utilization would be in alaboratory with a constant ambient environment.The operator must be aware of all these characteristics whenselecting the test instrument.InterferenceA strong electrical field, flux linkage from a high currentcircuit or voltage induced from a high voltage conductor cancause interference at the test site. In addition ground currentscan induce noise on a conductor. Interference can reducesensitivity and produce unstable readings. An instrument withlow noise rejection, or hum attenuation may be stable whentested on the bench but be erratic in selective fieldconditions. Modern electronics can detect the level of noiseand some instruments use this to indicate when excessivenoise is present to make a valid measurement.Delivery of Stated Test Current Under LoadBattery operated, digital low resistance ohmmeters havedifferent test currents dependent on the selected range. Thelowest resistance range has the highest current level and asthe range increases the current will decrease. (As the rangeincreases by a factor of ten the test current will decrease by afactor of ten.) This feature allows for an effective balancebetween weight and functionality.The output current delivered by the instrument is not critical,as the instrument will be measuring the actual test current atthe time of the test. However, the instrument must be able todeliver sufficient current to produce a clear signal in thepresence of typical noise. A typical instrument can have a10% to 20% tolerance on the maximum current rating. But,to make a good potential measurement, the current must bestable. The critical factor for the measurement is the voltagemeasurement via the potential leads (Ohms Law; R = V/I).The one testing area where the test current is critical is on atransformer due to the magnetic characteristics of thewinding. Sufficient current is needed to saturate the winding,and then a lower constant current is used to perform themeasurement.Taking the Measurement at a Stable PlateauA de-energized test specimen provides a stable platform onwhich to make the measurement. Live circuits can produce anunstable test platform. An example of the latter is the testingof battery straps on a UPS system. The charging and/ordischarging currents may induce noise across the batterystraps being measured, and at the same time cause theresistance values to increase (due to heating of the strap andits connections). When collecting data, the operator mustdefine the test conditions. As noted previously, temperaturecan have a significant influence on any measurements made.The operator should note the temperature and document anyelectrical equipment that is in operation in the test area.Material ResistivityConductors of the same dimensions have different resistancesif they are made of different materials due to varying numberof free electrons in varying substances. We account for thesedifferences with the term resistivity, which is the resistance ofa sample of the material having dimensions with specifiedunit values. While scientists tend to look at cubes of materialas the measurement standard (one centimeter cube or oneinch cube), conductors tend to be circular, making a circularstandard important for practical use. The resistivity of amaterial is defined in ohm-circular mils per foot; that is, theresistance (in ohms) of a piece of material one foot long andone circular mil cross section. It is defined at a temperature of20º C/68º F.Figure 16: Correct and Incorrect Probe Placements16 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 17

www.actoolsupply.<strong>com</strong>The following table shows the resistivities for a number ofconducting materials iv :Resistivities of ConductorsMicro-Ohms Ohm-CMSubstance CM Cube In. Cube per FootAluminum 2.83 1.11 17.0Carbon (Graphite) 700 275 4210Constantan 49 19.3 295(Cu 60%, Ni 40%)Copper (annealed) 1.72 0.68 10.4Iron (99.98% pure) 10 3.94 60.2Lead 22 8.66 132Manganin 44 17.3 264(Cu 84%, Ni 4%, Mn 12%)Mercury 95.78 37.7 576Platinum 9.9 3.9 59.5Silver 1.65 0.65 9.9Tungsten 5.5 2.17 33.1Zinc 6.1 2.4 36.7In most field applications the operator will determine thesuitability of a field measurement against a pre-selectedspecification. In most cases, these specifications have beengenerated from the following formula (at 20º C/68º F):R = ρL/AWhere:ρ = resistivity of the material in ohm-CM per foot.L = distance between two points on thematerial, in feet.A = cross section area measured in circular mils.Effects of Temperature on Measured <strong>Resistance</strong> Values<strong>Resistance</strong> measurements are dependent on temperature. Ifthe original data was read at one temperature but later testsare conducted at other temperatures, this temperature data isrequired to determine the suitability of the measurements. Allmaterials do not react to temperature to the same degree.Aluminum, steel, copper and graphite have specifictemperature coefficients that will affect the degree ofchanges that may take place with temperature at the site ofthe measurement.<strong>Low</strong> resistance measurements rely on the operatorconducting the tests within the operating temperature rangeof the instrument (the operator must be aware of fieldconditions). When the operator sees out-of-tolerancemeasurements, one of the first steps is to verify theinstrument’s reading with a suitable calibration shunt.As mentioned previously, resistance measurements aredependent on temperature. The resistance of all pure metalsincreases with rising temperature. The proportional change inresistance for a specific material with a unit change intemperature is called the temperature coefficient of resistancefor that material. Temperature coefficients are expressed asthe relative increase in resistance for a one-degree increase intemperature. While most materials have positive temperaturecoefficients (resistance increases as temperature rises), carbongraphite materials have negative temperature coefficients(resistance decreases as temperature rises).The following table shows the temperature coefficients ofresistance for selected materials v .Temperature Coefficients of <strong>Resistance</strong>Material Per ºC Per ºFAluminum 0.0038 0.0021Carbon (0-1850 ºC) -0.00025 -0.00014Constantan (0-100 ºC) negligible negligibleCopper (@ 20 ºC) 0.00393 0.00218Iron 0.0050 0.0028Lead 0.0043 0.0024Manganin (0-100 ºC) negligible negligibleMercury 0.00090 0.00050Platinum 0.0038 0.0021Silver 0.0040 0.0021Tungsten 0.0045 0.0025Zinc 0.0037 0.0021Figure 18 shows the temperature-resistancecurves for some of these materials (basedon a baseline reading of 1000 micro-ohmsat 20º C).When making a measurement on a specificmaterial, the operator can calculate thechange in resistance due to a change intemperature by multiplying the resistance atthe reference temperature by thetemperature coefficient of resistance and bythe change in temperature.R 2 -R 1 = (R 1 )(a)(T 2 – T 1 )Where:R 1 = resistance of the conductor at thereference temperatureR 2 = resistance of the conductor whenthe measurement is madeT 1 = reference temperatureT 2 = temperature at which the measurement is madea = temperature coefficient of resistance for the materialbeing testedThe operator should also be aware of operating and storagetemperature specifications of the instrument he/she is usingto ensure that it is suitable for the environment in which itwill be used.Effects of HumidityThe relative humidity of the test specimen should not affectthe resistance reading unless the material is hygroscopic, inwhich case more moisture will be absorbed into the sampleat higher humidities. This will change the measurementconditions and will affect the achieved result. However, mostconductors are non-hygroscopic. Therefore, since instrumentsare typically designed with an operating range of from 0 to95% RH, providing that moisture is not actually condensingon the instrument then a correct reading will be obtained.Background Noise Conditions, Current and Voltage<strong>Resistance</strong> measurements can be degraded by static voltagesand ripple currents (electrical noise) impressed on the testspecimen. The operator should be aware of the level of noiserejection in the instrument being used. Changing to adifferent model may help the operator make a measurementat a difficult test site.<strong>Resistance</strong> - Micro-ohms1600.01500.01400.01300.01200.01100.01000.0900.0800.0-40 -20 0 20 40 60 80 100Temperature - Degrees CFigure 18: Temperature-<strong>Resistance</strong> Curves for Iron, Copper and CarbonCarbonCopperThe magnitude of the test current used by the instrumentwill affect the noise rejection capability of that instrument.A 10 Amp test current will provide much better noiserejection than a 0.1 Amp test current. Beware of excessivetest currents which can change or damage the test sampledue to heating (W = I 2 R). If 100 Amp is used in place of 10Amp, the sample will experience 100 times the heat of thelower test current.The open circuit voltage on most low resistance ohmmeters islow. When making measurements on transformer windings,additional power is required to saturate the winding andallow the meter to stabilize more rapidly. Instrumentsdesigned for this type of application have a higher opencircuit voltage (in the 30 Vdc range) to deliver the energyneeded to saturate the windings. Then a constant currentmode of operation is used to perform the resistancemeasurement.Use and Misuse of <strong>Low</strong> <strong>Resistance</strong> OhmmetersThe effective operation of a low resistance ohmmeter relieson the operator using the correct test leads. Battery operatedinstruments are designed for a specific lead resistance, basedon the operational life of the test sequence. The specifiedleads allow for a reasonable current drain from the powersupply for the testing cycle. If leads with a higher resistanceare used, the current used for the testing may be lower thanthe meter requires, potentially causing a signal-to-noiseproblem that may reduce the accuracy and/or repeatabilityof the measurement.Ironiv Electrical Metermen’s Handbook; Third Edition; 1965; page 479v Electrical Metermen’s Handbook; Third Edition; 1965; page 48018 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 19

www.actoolsupply.<strong>com</strong>If leads with lower than the specified resistance values areused, the test cycle for the instrument will be shorter thananticipated. This situation may be suitable if the meter is tobe used in a test program with high background electricalnoise. The use of special leads with shielding may also be asolution for these high noise situations.A <strong>com</strong>mon error in the field is to use a low resistanceohmmeter to sample the resistance of a ground bed. Thisapplication is incorrect, as the ground bed test methodrequires an instrument that toggles the test signal at a knownfrequency and current level. A low resistance ohmmeter usedin this application will provide an erroneous reading as theground current will have an undue influence on themeasurement. A proper ground tester performs in essentiallythe same way as a low resistance ohmmeter, that is, byinjecting a current into the test sample and measuring thevoltage drop across it. However, the earth typically carriesnumerous currents originating from other sources, such asthe utility. These will interfere with the dc measurementbeing performed by a low resistance ohmmeter. The genuineground tester, however, operates with a definitive alternatingsquare wave of a frequency distinct from utility harmonics. Inthis manner, it is able to perform a discrete measurement,free of noise influence.Brief History of <strong>Low</strong> <strong>Resistance</strong> OhmmetersThe original DUCTER low resistance ohmmeter vi wasdeveloped by Evershed & Vignoles (one of the <strong>com</strong>paniesthat evolved into <strong>Megger</strong> and the developer of the firstinsulation resistance tester) in 1908 and employed the crosscoilsmeter movement that was already used in the insulationresistance tester. This initial design evolved into field units inthe 1920s that required a leveling procedure at the time ofthe test due to the sensitivity of the coil (to being level).These early models did not travel well and were sensitive toshock and vibration.For fifty years, field portable low resistance ohmmeters wereanalog units. In 1976, in response to numerous customerrequests, the James G. Biddle Company (another one of the<strong>com</strong>panies that ultimately became <strong>Megger</strong>) developed andintroduced a digital low resistance ohmmeter. This unit wasknown by its trade name, the DLRO ® (a registered trademarkof <strong>Megger</strong>). Ultimately, the James G. Biddle Companyreleased 10 amp and 100 amp versions of the DLRO,including a single box design for some versions that simplifiedthe testing process, and an extended range model.This style of instrument served the industry well for a numberof years, and the various versions continue to help end userssolve problems. However, electronics and battery technologyadvanced to the point where a considerable number ofimprovements could be made to the 1970s designs. Newlydesigned low resistance ohmmeters by <strong>Megger</strong> include datastorage and downloading capability, additional test modes,reduced weight, extended battery life, etc.CalibrationCalibration of low resistance ohmmeters can be checked inthe field by the use of a shunt. Calibration is performed withindividual current and potential 12-gauge copper leads toensure correct current distribution through the shunt and anaccurate potential measurement. Be aware that “test probes”do not provide accurate positioning of the leads to verify theinstrument calibration. They can, however, be used todetermine the relative calibration of the instrument.The following table shows <strong>com</strong>mercially available shunts:<strong>Resistance</strong> ±0.25% ValueCurrent Rating10.000 ohm 1.0 mA1.0000 ohm 10 mA0.1000 ohm 100 mA0.0100 ohm 1 A0.0010 ohm 10 A0.0001 ohm 100 AThese calibration shunts when used with a Certificate ofCalibration, traceable to National Standards, help the fieldservice engineer demonstrate to a customer the accuracy ofthe tests being conducted.Ingress ProtectionSomewhere in the fine print (specifications) of most testinstrument product bulletins is an IP rating, a number thatgives the operator vital information. In fact, the IP rating letsthe operator know whether a piece of test equipment issuitable for his/her application and test environment.“IP” stands for “ingress protection.” That is the degree towhich the instrument can withstand invasion by foreignmatter. The IP rating system has been established by the IEC(International Electrotechnical Commission), in theirStandard 529, and is used as a guide to help the operatorprotect the life of the instrument. It also can help theoperator make a more informed purchase decision byensuring that the piece of test equipment is designed towork in the environment(s) that the user faces.The IP rating is <strong>com</strong>prised of two digits, each signifying aseparate characteristic. The designation indicates how wellthe item is sealed against invasion by foreign matter, bothmoisture and dust (the higher the number(s), the better thedegree of protection). What would a typical rating of IP54 tella buyer about the application capabilities of a model? If youwant to sound thoroughly knowledgeable, that’s IP five-four,not fifty-four. Each digit relates to a separate rating, not toeach other.The first digit refers to particulate ingress, reflecting thedegree to which solid objects can penetrate the enclosure. Alevel of “5” indicates “dust protected” as well as protectedfrom invasion with a wire down to 1.0 mm. There is only onehigher category: “dust tight.”The second digit refers to moisture. A rating of “4” meansresistance to “splashing water, any direction.” The higherratings of 5 through 8 indicate “jetting water” and“temporary” or “continuous” immersion.As an example, suppose an instrument under considerationwas rated only to IP43. What would that tell the operatorabout its usability? Could it be thoroughly utilized in aquarry or cement plant? Hardly! The particulate rating 4indicates “objects equal or greater than 1 mm.” That’s aboulder in <strong>com</strong>parison to particles typically produced byindustrial processes. Flying dust could put the instrument outof <strong>com</strong>mission.Suppose the instrument is rated at IP42. A moisture rating of2 indicates dripping water. Therefore, it would not beresistant to flying spray. Acquiring an instrument for anenvironment that exceeds its IP capabilities likely means thatthe operator will need another very soon. What about arating of IP40? A moisture rating of 0 means that theinstrument is not protected against any liquid ingress.The following charts provide a guide to various IP ratings andwhat they mean to the operator.Protection against Access to Hazardous Parts(First Digit)NumberProtection against Ingress of Solid Foreign Objects(First Digit)NumberDescription0 Non-protected1 Objects equal or greater than 50 mm2 Objects equal or greater than 12.5 mm3 Objects equal or greater than 2.5 mm4 Objects equal or greater than 1 mm5 Dust protected6 Dust tightProtection against Ingress of Liquids (Second Digit)NumberDescription0 Non-protected1 Protected against access with back ofhand (50 mm)2 Protected against access with jointedfinger (12 x 80 mm)3 Protected against access with a tool(2.5 mm)4,5,6 Protected against access with a wire(1.0 mm)Description0 Non-protected1 Water dripping vertically2 Water dripping, enclosure tiltedup to 15°3 Spraying water, up to 60° anglefrom vertical4 Splashing water, any direction5 Jetting water, any direction6 Powerful jetting water, any direction7 Temporary immersion in water8 Continuous immersion in watervi Basic Electrical Measurements; Melvin B. Stout; 1950; page 6120 A GUIDE TO LOW RESISTANCE TESTINGwww.actoolsupply.<strong>com</strong>A GUIDE TO LOW RESISTANCE TESTING 21