Literature PDF

Literature PDF

Literature PDF

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

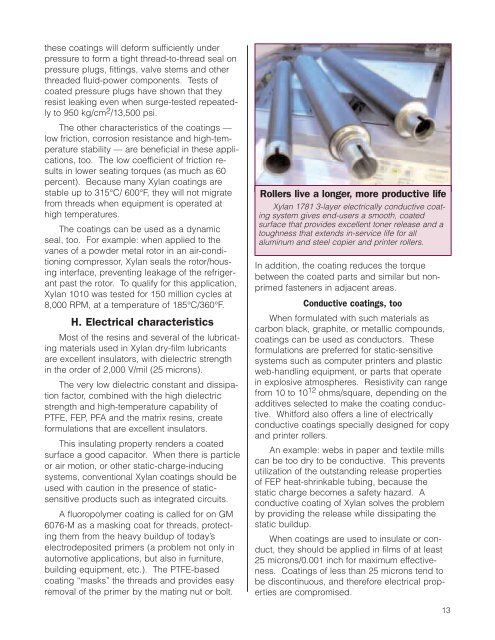

these coatings will deform sufficiently underpressure to form a tight thread-to-thread seal onpressure plugs, fittings, valve stems and otherthreaded fluid-power components. Tests ofcoated pressure plugs have shown that theyresist leaking even when surge-tested repeatedlyto 950 kg/cm 2 /13,500 psi.The other characteristics of the coatings —low friction, corrosion resistance and high-temperaturestability — are beneficial in these applications,too. The low coefficient of friction resultsin lower seating torques (as much as 60percent). Because many Xylan coatings arestable up to 315°C/ 600°F, they will not migratefrom threads when equipment is operated athigh temperatures.The coatings can be used as a dynamicseal, too. For example: when applied to thevanes of a powder metal rotor in an air-conditioningcompressor, Xylan seals the rotor/housinginterface, preventing leakage of the refrigerantpast the rotor. To qualify for this application,Xylan 1010 was tested for 150 million cycles at8,000 RPM, at a temperature of 185°C/360°F.H. Electrical characteristicsMost of the resins and several of the lubricatingmaterials used in Xylan dry-film lubricantsare excellent insulators, with dielectric strengthin the order of 2,000 V/mil (25 microns).The very low dielectric constant and dissipationfactor, combined with the high dielectricstrength and high-temperature capability ofPTFE, FEP, PFA and the matrix resins, createformulations that are excellent insulators.This insulating property renders a coatedsurface a good capacitor. When there is particleor air motion, or other static-charge-inducingsystems, conventional Xylan coatings should beused with caution in the presence of staticsensitiveproducts such as integrated circuits.A fluoropolymer coating is called for on GM6076-M as a masking coat for threads, protectingthem from the heavy buildup of today’selectrodeposited primers (a problem not only inautomotive applications, but also in furniture,building equipment, etc.). The PTFE-basedcoating “masks” the threads and provides easyremoval of the primer by the mating nut or bolt.Rollers live a longer, more productive lifeXylan 1781 3-layer electrically conductive coatingsystem gives end-users a smooth, coatedsurface that provides excellent toner release and atoughness that extends in-service life for allaluminum and steel copier and printer rollers.In addition, the coating reduces the torquebetween the coated parts and similar but nonprimedfasteners in adjacent areas.Conductive coatings, tooWhen formulated with such materials ascarbon black, graphite, or metallic compounds,coatings can be used as conductors. Theseformulations are preferred for static-sensitivesystems such as computer printers and plasticweb-handling equipment, or parts that operatein explosive atmospheres. Resistivity can rangefrom 10 to 10 12 ohms/square, depending on theadditives selected to make the coating conductive.Whitford also offers a line of electricallyconductive coatings specially designed for copyand printer rollers.An example: webs in paper and textile millscan be too dry to be conductive. This preventsutilization of the outstanding release propertiesof FEP heat-shrinkable tubing, because thestatic charge becomes a safety hazard. Aconductive coating of Xylan solves the problemby providing the release while dissipating thestatic buildup.When coatings are used to insulate or conduct,they should be applied in films of at least25 microns/0.001 inch for maximum effectiveness.Coatings of less than 25 microns tend tobe discontinuous, and therefore electrical propertiesare compromised.13