Literature PDF

Literature PDF

Literature PDF

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

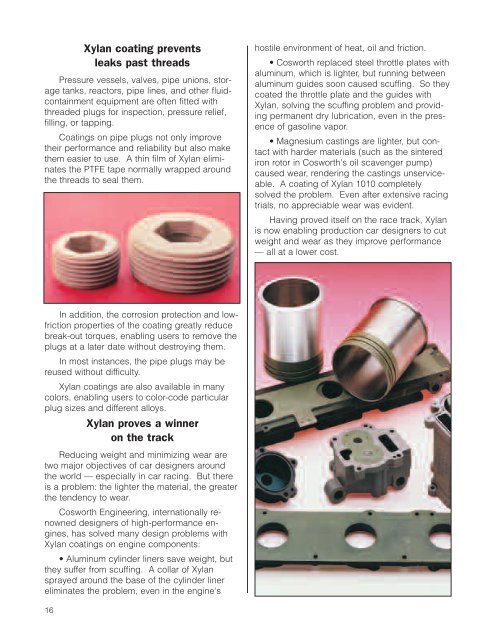

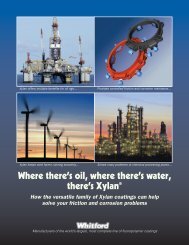

Xylan coating preventsleaks past threadsPressure vessels, valves, pipe unions, storagetanks, reactors, pipe lines, and other fluidcontainmentequipment are often fitted withthreaded plugs for inspection, pressure relief,filling, or tapping.Coatings on pipe plugs not only improvetheir performance and reliability but also makethem easier to use. A thin film of Xylan eliminatesthe PTFE tape normally wrapped aroundthe threads to seal them.hostile environment of heat, oil and friction.• Cosworth replaced steel throttle plates withaluminum, which is lighter, but running betweenaluminum guides soon caused scuffing. So theycoated the throttle plate and the guides withXylan, solving the scuffing problem and providingpermanent dry lubrication, even in the presenceof gasoline vapor.• Magnesium castings are lighter, but contactwith harder materials (such as the sinterediron rotor in Cosworth's oil scavenger pump)caused wear, rendering the castings unserviceable.A coating of Xylan 1010 completelysolved the problem. Even after extensive racingtrials, no appreciable wear was evident.Having proved itself on the race track, Xylanis now enabling production car designers to cutweight and wear as they improve performance— all at a lower cost.In addition, the corrosion protection and lowfrictionproperties of the coating greatly reducebreak-out torques, enabling users to remove theplugs at a later date without destroying them.In most instances, the pipe plugs may bereused without difficulty.Xylan coatings are also available in manycolors, enabling users to color-code particularplug sizes and different alloys.Xylan proves a winneron the trackReducing weight and minimizing wear aretwo major objectives of car designers aroundthe world — especially in car racing. But thereis a problem: the lighter the material, the greaterthe tendency to wear.Cosworth Engineering, internationally renowneddesigners of high-performance engines,has solved many design problems withXylan coatings on engine components:• Aluminum cylinder liners save weight, butthey suffer from scuffing. A collar of Xylansprayed around the base of the cylinder linereliminates the problem, even in the engine's16