Modern Materials Handling - April 2010

Modern Materials Handling - April 2010

Modern Materials Handling - April 2010

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

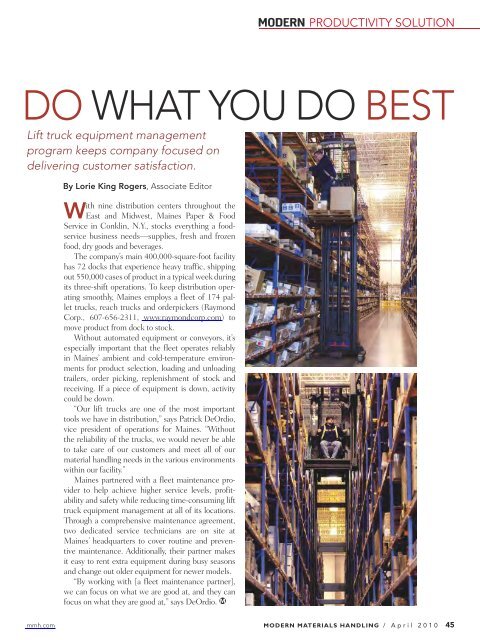

PRODUCTIVITY SOLUTIONDO WHAT YOU DO BESTLift truck equipment managementprogram keeps company focused ondelivering customer satisfaction.By Lorie King Rogers, Associate EditorWith nine distribution centers throughout theEast and Midwest, Maines Paper & FoodService in Conklin, N.Y., stocks everything a foodservicebusiness needs—supplies, fresh and frozenfood, dry goods and beverages.The company’s main 400,000-square-foot facilityhas 72 docks that experience heavy traffic, shippingout 550,000 cases of product in a typical week duringits three-shift operations. To keep distribution operatingsmoothly, Maines employs a fleet of 174 pallettrucks, reach trucks and orderpickers (RaymondCorp., 607-656-2311, www.raymondcorp.com) tomove product from dock to stock.Without automated equipment or conveyors, it’sespecially important that the fleet operates reliablyin Maines’ ambient and cold-temperature environmentsfor product selection, loading and unloadingtrailers, order picking, replenishment of stock andreceiving. If a piece of equipment is down, activitycould be down.“Our lift trucks are one of the most importanttools we have in distribution,” says Patrick DeOrdio,vice president of operations for Maines. “Withoutthe reliability of the trucks, we would never be ableto take care of our customers and meet all of ourmaterial handling needs in the various environmentswithin our facility.”Maines partnered with a fleet maintenance providerto help achieve higher service levels, profitabilityand safety while reducing time-consuming lifttruck equipment management at all of its locations.Through a comprehensive maintenance agreement,two dedicated service technicians are on site atMaines’ headquarters to cover routine and preventivemaintenance. Additionally, their partner makesit easy to rent extra equipment during busy seasonsand change out older equipment for newer models.“By working with [a fleet maintenance partner],we can focus on what we are good at, and they canfocus on what they are good at,” says DeOrdio.mmh.com MODERN MATERIALS HANDLING / A p r i l 2 0 1 0 45