Worm Gear Pair

Worm Gear Pair

Worm Gear Pair

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

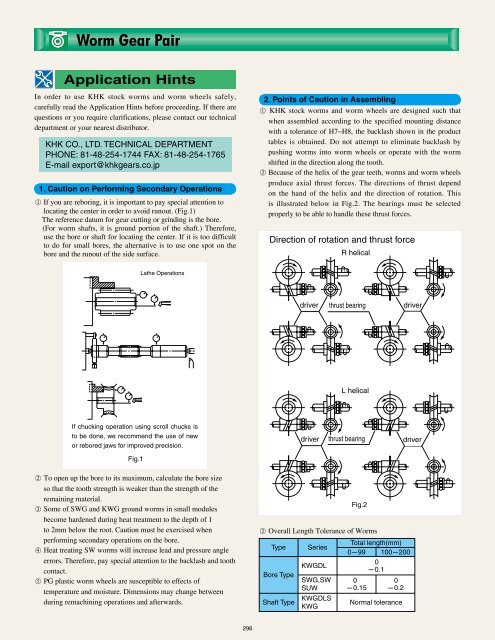

<strong>Worm</strong> <strong>Gear</strong> <strong>Pair</strong>Application HintsIn order to use KHK stock worms and worm wheels safely,carefully read the Application Hints before proceeding. If there arequestions or you require clarifications, please contact our technicaldepartment or your nearest distributor.KHK CO., LTD. TECHNICAL DEPARTMENTPHONE: 81-48-254-1744 FAX: 81-48-254-1765E-mail export@khkgears.co.jp1. Caution on Performing Secondary Operations1 If you are reboring, it is important to pay special attention tolocating the center in order to avoid runout. (Fig.1)The reference datum for gear cutting or grinding is the bore.(For worm shafts, it is ground portion of the shaft.) Therefore,use the bore or shaft for locating the center. If it is too difficultto do for small bores, the alternative is to use one spot on thebore and the runout of the side surface.2. Points of Caution in Assembling1 KHK stock worms and worm wheels are designed such thatwhen assembled according to the specified mounting distancewith a tolerance of H7~H8, the backlash shown in the producttables is obtained. Do not attempt to eliminate backlash bypushing worms into worm wheels or operate with the wormshifted in the direction along the tooth.2 Because of the helix of the gear teeth, worms and worm wheelsproduce axial thrust forces. The directions of thrust dependon the hand of the helix and the direction of rotation. Thisis illustrated below in Fig.2. The bearings must be selectedproperly to be able to handle these thrust forces.Direction of rotation and thrust forceR helicalLathe Operationsdriverthrust bearingdriverL helicalIf chucking operation using scroll chucks isto be done, we recommend the use of newor rebored jaws for improved precision.driverthrust bearingdriverFig.12 To open up the bore to its maximum, calculate the bore sizeso that the tooth strength is weaker than the strength of theremaining material.3 Some of SWG and KWG ground worms in small modulesbecome hardened during heat treatment to the depth of 1to 2mm below the root. Caution must be exercised whenperforming secondary operations on the bore.4 Heat treating SW worms will increase lead and pressure angleerrors. Therefore, pay special attention to the backlash and toothcontact.5 PG plastic worm wheels are susceptible to effects oftemperature and moisture. Dimensions may change betweenduring remachining operations and afterwards.Bore TypeFig.23 Overall Length Tolerance of <strong>Worm</strong>sTypeShaft TypeSeriesKWGDLSWG,SWSUWKWGDLSKWGTotal length(mm)0~99 100~2000.1-0.1- 0.15-0.150.1-0.2Normal tolerance296