Saw Bands

Saw Bands

Saw Bands

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

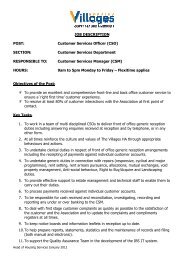

BAND SELECTION TABLERolled steelproductsProfile steelBundledsmallMaterialsNormal steel,Non-ferrous metals *1Cold working steel,case-hardened steelHot forming tool steel,stainless steelHigh heat-resistantspecial alloysSt-37, St-52,StE 3801.2510, 1.0301, 1.7012,1.7218, 1.69551.2341, 1.2735,1.2303, 1.23791.2344, 1.4301,1.4564Inconel, titanium,aluminum, Hastelloy<strong>Saw</strong> band typeAXCELA G Series(patent applied for) *2BIMETAL CARBIDEAXCELA H Series(patent applied for) *2CTBAURORA(patented) *3MAGNUM HL M71(patented) *3MAGNUM HLG M71(patented) *4SIGMASUPER HL(patented) *3SUPER HLGCHIPBREAKERHI-LORATIO HI-LOSGLBPROTECTOR M42(patented) *5PROTEC(patented) *5DUOS M42(patented) *42*1 Non-ferrous metals are mainly aluminum, aluminum alloys, copper and copper alloys.In some cases, these materials can be just as hard as difficult to machine steels or even harder.In such cases, it is recommended to contact AMADA in advance.*2 JP. PAT. P.*3 US. PAT.*4 JP. PAT.*5 JP. PAT. (2/3P, 3/4P, 4/6P)

Select the band according to the material form and quality to be sawn taking account ofthe task.When sawing wide, rolled H profiles, the saw band can jam in thematerial to be sawn. In order to prevent this effect, a WS (wide offset)is available for „PROTECTOR“ *5 .For solid material with larger diameters, we provide an Anti-Pinchingvariant (AP) of the „SUPER HL“ *3 for prevention of the jammingeffect.<strong>Saw</strong> band typeTooth tip materialTooth tiphardness *6PropertiesAXCELA G Series(patent applied for) *2Carbide + variouscoatingsup to 2500 HVdepending on typeCarbide saw bands for maximum performance with outstanding tool life.The types AXCELA G: BN-3, BS-3, BN-4, BN-2 and CS-2 are suitable for various materials.AXCELA H Series(patent applied for) *2CTBAURORA(patented) *3MAGNUM HL M71(patented) *3MAGNUM HLG M71(patented) *4SIGMASUPER HL(patented) *3SUPER HLGCHIPBREAKERCarbide1600 HV1600 HVCarbide saw bands for challenging materials.For optimum results, the AXCELA H Series has many application-specific types; AXCELA H: BN-1, CS-1,SS-1, SR-1, CY-1 and CG-1.Due to its carbide teeth tips, this offset band is intended for extra hard materials which can no longerbe sawn with HSS bimetal saw bands. Also very well suited for conventional sawing without carbidefinishing.M42 + TiN 950 + 2300 HV TiN coated high-performance saw band for difficult to machine materials with extremely long tool life.AMADA M71 HSSM42 HSS1000 HV1000 HV950 HV950 HV950 HV950 HVHILO tooth geometry and precision offsetting result in friction reduction.High-performance tooth tip material and sectional cutting channel using patented tooth geometry.Can be used for difficult to machine materials including high heat-resistant special alloys.HILO tooth geometry and precision offsetting result in friction reduction.Outstanding cutting performance for tool steel.Sectional cutting channel using patented tooth geometry for the reduction of cutting resistance.Can be used for difficult to machine materials. Particularly recommended for stainless steels.HILO tooth geometry and precision offsetting result in friction reduction.The sectional cutting channel reduces the cutting resistance. For materials in the medium and largediameter range. An Anti-Pinching variant is available for materials with internal clamping.HILO tooth geometry and precision offsetting result in friction reduction.Wide application area from normal steel to difficult to machine materials.Special tooth profile in combination with HILO tooth geometry reduces the heat development at thetooth tip and promotes the formation of smaller chips. As a result, particularly suitable for materials withunfavorable chip for.BIMETAL CARBIDEHI-LO> 950 HVSpecial tooth profile in combination with HILO tooth geometry and a particular production methodenables the economic cutting of tubes made of high strength materials such as duplex steel.RATIO HI-LOMatrix HSSM42 Basis900 HVProven, patented AMADA HILO tooth shape reduces the friction and enables high cutting performancefor materials with a strength up to 950 N/mm 2 .SGLBPROTECTOR M42(patented) *5M42 HSS950 HV Universal band with wide range of applications.950 HV <strong>Saw</strong> band specially for profile steel and tubes with reinforced tooth back for reduction of tooth breakouts.PROTEC(patented) *5Matrix HSSM42 Basis900 HV<strong>Saw</strong> band specially for profile steel and tubes with reinforced tooth back for reduction of tooth breakouts.Particularly suitable for steels with a strength up to 950 N/mm 2 .DUOS M42(patented) *4M42 HSS950 HVDue to the special offsetting and the different tooth heights, the sawing of a wide range of dimensionswithout band replacement is possible. Particularly suitable for light weight workshop machines.*2 JP. PAT. P.*3 US. PAT.*4 JP. PAT.*5 JP. PAT. (2/3P, 3/4P, 4/6P)*6 The hardness of the tooth tips refers to the average values published by AMADA. These can be different depending on typeand dimensions of the product.The basic requirement for sawing is that the tooth tip must be harder than the material to be sawn. As a general rule of thumb,the tooth tips should be at least twice as hard as the material to be sawn.3

SELECTION OF THE TOOTH PITCH PER MATERIALMaximum cutting widthMaterialRolled profilesProfile steel, bundled tubes[mm]50 100 150 200 250 300 400 500 700 1000[inch] 2" 4" 6" 8" 10" 12" 16" 20" 28" 40"6/10 Z &5/7 Z4/6 ZBundled small diameters, normal steelSolidmaterialCold working steel, case-hardened steelHot forming tool steel, stainless steel3/4 Z 2/3 Z 1,5/2 Z 1,1/1,5 Z0,7/1 ZExtreme heat-resistant special alloysComments1. For optimum sawing, we recommend selecting a toothing whichalways has 10 to 20 teeth in the material.2. For sawing deformed workpieces or workpieces with varyingcutting width, it is recommended during the sawing that at leasttwo teeth penetrate the material simultaneously.3. The above table is based on a quality „SGLB“ as guideline.Specific applications of other bands vary occasionally due to theircharacteristic properties. For example, a 3/4 teeth PROTECTORcan also saw material from the above 4/6 teeth/inch range.BASICS OF THE CUTTING PARAMETERS SELECTION1. Select a suitable saw band according to the saw band quality table.2. Select a suitable tooth pitch according to the tooth pitch selectiontable.3. Set the band speed according to the table below.4. In relation to the cutting performance specified in the table, setthe feed rate so that the cutting time calculated according to thetable below is achieved.Note: If a new band is used, carry out the running-in process(see „General Instructions“)DETERMINATION OF THE CUTTING PERFORMANCECutting performance means the machined area per minute andis expressed using the unit cm 2 /min. To achieve the target cuttingperformance, calculate the cutting time according to the followingequation and set the feed rate.Cutting time (minutes) =Material surface area (cm 2 )Cutting performance (cm 2 /min)For simplified calculation of the surface area, use the followingformula*:■■Surface area of square material = width (cm) x height (cm)■■Surface area of round material = Ø (cm) x Ø (cm) x 0.785* For bundle cutting, multiply the number of the bundled materials by the value of theindividual surface areas.Normal steelCold working steelCase-hardened steelHot forming tool steelStainless steelHigh heat-resistantspecial alloysMaterial dimensions [mm]Area [cm 2 ]10079200314Band speed [m/min] 48 – 75 48 – 75 48 – 75 43 – 65 39 – 58 34 – 51 30 – 44Cutting performance [cm 2 /min] 36 – 54 72 – 108 72 – 108 60 – 91 49 – 73 37 – 56 26 – 38Band speed [m/min] 28 – 42 28 – 42 28 – 42 25 – 38 23 – 34 20 – 30 18 – 26Cutting performance [cm 2 /min] 11 – 23 23 – 46 23 – 46 20 – 40 17 – 35 15 – 25 12 – 20Band speed [m/min] 44 – 66 44 – 66 44 – 66 39 – 59 35 – 52 30 – 45 26 – 38Cutting performance [cm 2 /min] 28 – 42 56 – 84 56 – 84 47 – 71 39 – 58 30 – 45 22 – 32Band speed [m/min] 24 – 36 24 – 36 22 – 32 19 – 29 17 – 26 17 – 26 17 – 26Cutting performance [cm 2 /min] 8 – 15 16 – 30 14 – 27 14 – 27 13 – 24 13 – 24 13 – 24Band speed [m/min] 40 – 60 40 – 60 40 – 60 35 – 53 31 – 46 26 – 39 22 – 32Cutting performance [cm 2 /min] 20 – 30 40 – 60 40 – 60 34 – 52 29 – 43 23 – 35 18 – 26Band speed [m/min] 10 – 20 10 – 25 10 – 25 10 – 25 10 – 25 10 – 20 10 – 15Cutting performance [cm 2 /min] 2 – 10 3 – 15 3 – 15 3 – 15 3 – 15 3 – 15 3 – 15Orientation values – real performance is strongly dependent on the machine used. These performance figures are significantly exceeded with AMADA band saws of the PCSAW series.30070740012565001963700384710007850GENERAL INFORMATION■■In order to achieve optimal tool lives, saw bands should always berun in. We recommend running in each saw band using a cuttingarea of approx. 3000 cm 2 . Reduce the band speed here by approx.30% and the cutting performance by approx. 50%.■■Ensure that the chip brush(es) of your machine is (are) alwaysengaged. Replace worn brushes in good time, otherwise the qualityof the cut face and the tool life reduce.■■Ensure sufficient concentration of the cooling lubricant; this shouldusually be approx. 10%. For stainless steels, a slightly increasedconcentration of approx. 12% has proven itself. Only cast iron andplastic should be sawn dry.

AMADA MACHINE TOOLS CO., LTDwww.amada.com200, Ishida, Isehara-shi, Kanagawa, 259-1196, JapanTelefon: +81-463-96-3353■■AMADA MACHINE TOOLS AMERICA INC.2324 Palmer Dr. Schaumburg, IL, 60173, USA Telephone: +1-847-285-4800■■AMADA MACHINE TOOLS EUROPE GmbHAMADA Allee 3, 42781 Haan, Germany Telephone: +49-2104-1777-0France subsidiaryZone industrielle PARIS Nord II, 96 Avenue de la Pyramide, 93290 Tremblay, France Telephone: +33-0149-903-094Italy subsidiaryVia Amada I, 1/3 29010 Pontenure, Piacenza, Italy Telephone: +39-0523-872-311Russia subsidiaryOOO Amada, ul. Dokukina, 16/3, Moscow 129226, Russia Telephone: +7 495 518-99-03■■AMADA CO., LTD.200, Ishida, Isehara-shi, Kanagawa, 259-1196, Japan Telephone: +81-463-96-1111■■The information in this catalogue is as of October 2011 and can change without notification.■■Some machines in this catalogue require safety accessories for legal reasons which are not illustrated here for reasons of clarity.■■Read the manuals for the machines for safe operation.■■The stated performance data are based on a special example. We are happy to determine exact values for your application together with youin our Haan Technical Centre.© AMADA MACHINE TOOLS CO., LTD. All rights reserved. – 1BL-10911-A001 – October 2011CA-B-LINEUP-SAWBLADE-G-09.2011