Ready-made Color Solutions OMNICOLOR® Multipurpose ... - Clariant

Ready-made Color Solutions OMNICOLOR® Multipurpose ... - Clariant

Ready-made Color Solutions OMNICOLOR® Multipurpose ... - Clariant

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

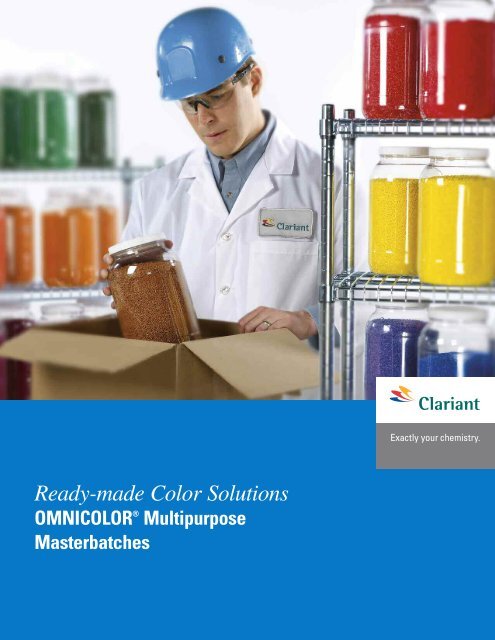

<strong>Ready</strong>-<strong>made</strong> <strong>Color</strong> <strong>Solutions</strong>OMNICOLOR ® <strong>Multipurpose</strong>Masterbatches

OMNICOLOR ® <strong>Multipurpose</strong><strong>Color</strong> ConcentratesThe industry’s first effective line ofmultipurpose color concentrates,OMNICOLOR offers excellent colorperformance across the broadestrange of polymers, while also helpingto minimize costs.OMNICOLOR delivers consistentlybrilliant batch-to-batch color withexceptional reliability and quality. Itslow usage ratio (100:1), low minimumorder (25 lbs., 5 kg), and pelletizedform for easy handling and storagemake it a versatile and cost-effectivechoice for injection molders.Available in a wide range of colors,OMNICOLOR concentrates are suitablefor use with over 25 different polymersincluding PVC, nylon and ABS. Theyare compatible with most commonadditives, including UV stabilizers, antistatsand slip agents. All OMNICOLORconcentrates are heavy-metal- andcadmium-free.OMNICOLOR color concentrates arebased on a multipurpose compatiblecarrier system. These concentratesare suitable for usewith a wide range ofpolymers at theaddition ratesrecommended inthe table below:Recommended Addition RatesPolyethylene 1%Polypropylene 1%GP Polystyrene 1%HI Polystyrene 1-2%Acrylics (Opaque) 1%PBT Polyester 1%PET Polyester 1%Polyurethane 1-2%Polyamide (Nylon) 1%Acetal 1%SAN 1%ABS 1-3%PVC 1-3%Polycarbonate 1%Thermoplastic 1-3%RubberAlloys & Blends 1-3%EVA 1%Filled Polymers 1-3%Concentrate SelectionOMNICOLOR concentrates are generallyselected because of their versatilitywhere a wide range of polymers areprocessed and their availability forsale in small quantities.Utilization of OMNICOLOR BlendingThorough premixing of OMNICOLORand polymer is required to obtainconsistency of color throughout theproduction run. This can be achievedby tumble mixing or by the use ofconcentrate metering devices.ProcessingIt is very important that the processingmachine has good plasticizingcapability. Improvements can oftenbe achieved by making the followingadjustments:1. Increasing the back pressure2. Reducing the screw speed3. Raising the temperature in themiddle zone of the barrel4. Cooling the feed zone of the barrelto prevent premature melting of thethe concentrateThermal StabilityOMNICOLOR processing temperaturespertain to the colorant system only.The carrier system also has a thermalceiling and is dependent on both timeand temperature. Care should be usedwhen processing OMNICOLOR wheremelt temperatures may exceed 600°F.General Information onOMNICOLOR CarrierThe term multipurpose concentrateimplies that the concentrate carrier iscompatible with most polymers. Thecarrier resin could cause performanceproblems in a few polymers. Therefore,OMNICOLOR should not be used in:1. Cellulosic polymers2. Transparent acrylic colors

Pigment CompatibilityThe OMNICOLOR range has beenformulated with high quality heavymetal-freepigments that will performwell in a wide range of polymers undermost processing conditions.Food, Toy and Critical ApplicationRegulationsOMNICOLOR masterbatches arenot suitable for food, primary pharmaceutical,cosmetic, toy, or medicalapplications or other applications thatrequire a US FDA letter of compliance.Detailed statements relating tocompliance with EU and US legislationand standards are available uponrequest:Denise M. RichardsonProduct Stewardship/EnvironmentalManager<strong>Clariant</strong> CorporationBusiness Unit Masterbatches926 Elliot Road, Albion, MI 49224, USATel: +1 517 629 7703Email: denise.richardson@clariant.comProcess CompatibilityOMNICOLOR masterbatches canbe used for injection molding, blowmolding, profile and sheet extrusionand will withstand the dryingtemperatures of most polymers thatrequire drying before processing,such as ABS and nylons. For polymerdrying in excess of 225˚F (100˚C),add the masterbatch after the dryingprocess or alternatively contact ourtechnical staff for availability ofhigh-temperature grades.LightfastnessThis is measured on the Blue WoolScale (BWS) from a minimumof 1 to a maximum of 8.OMNICOLOR offersa broad spectrum ofcolors with lightfastnessratings to suitmost applications.OMNICOLORconcentrates do notcontain UV stabilizers; outdoorapplications must be reviewed on acase-by-case basis. Please checkwith our technical department whencolorant is required for a light-specificor critical application.WeatherabilityThis refers to loss of color and outdoorexposure due to elemental action.Good lightfastness does not alwaysindicate good weatherability. Ifweatherability is of prime importance,this should be specified.<strong>Color</strong> Shade and OpacityAll pigments vary in color strengthand opacity. The formulations used tocreate OMNICOLOR combine the hightinting strength of organic pigmentswith the opacity of inorganics. Thehiding power of the formulations doesdiffer and should be tested for in allopaque and filled polymers beforestarting production.Flame Retardant PolymersOMNICOLOR masterbatches arenot suitable for flame retardantapplications.

OMNICOLOR ® – Ordering Information,Troubleshooting and Cost CalculationTroubleshooting OMNICOLORSYMPTOM CAUSE REMEDY1. <strong>Color</strong> variation shot to shot. Poor OMNICOLOR preblending. More thorough blending.Pigment has insufficient Ensure correct machine temperaturethermal stability.control.2. Screw slip. Premature melting of Reduce heat in feed zone.OMNICOLOR.Excessive addition rate. Check addition rate and reduce if necessary.3. Overall good distributive Poor pigment dispersion in Return concentrate for replacement.mixing with streaks or dots concentrate.of another color.4. Black streaks or splotches. Degraded polymer in barrel. Clean screw and barrel.5. Poor distributive mixing Insufficient plastification. See processing instructions.(streaking).6. Loss of color. Pigment has insufficient Change to more heat stable concentrate.thermal stability.Ensure correct machine temperature control.* OMNICOLOR does not contain UV stabilizers or fluorocarbons. Effects of gamma ray sterilization on OMNICOLOR have not been tested.How to Calculate Your <strong>Color</strong>ing CostsCost/lb. of Concentrate – Cost/lb. of Resin = <strong>Color</strong>ing CostLet-Down Ratio + 1In the US, OMNICOLOR stock colorsare available for next-day delivery.The remaining standardcolors are available fordelivery within 5 to 7working days. Smallerquantities may beavailable: call+1 888 621 1282.FREE3.5 oz. (100 gm)sampleson request.NOTICE:The term multipurpose color concentrate signifiesthat the concentrate is based on a carrier materialthat is compatible with a wide range of thermoplastics.Product is supplied on the understanding that it willbe assessed for suitability of application under localconditions in the intended use. The information givenherein and otherwise supplied to users is based onour current knowledge and experience. However, dueto many factors beyond our knowledge and controlthat may affect processing and application, we givethis information without obligation or liability of anykind whatsoever. <strong>Color</strong>s shown are simulations only.Actual color may vary depending on specific resin andprocessing conditions.

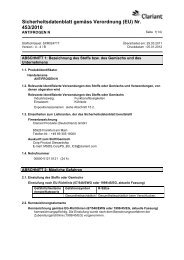

OMNICOLOR Processing TemperaturesRECOMMENDED MAXIMUM PROCESSING TEMPERATURES FOR OMNICOLORIN SELECTED POLYMERS IN °CCOLOR NO. COLOR PVC PE/PP/PURPS ABS ACETAL PBT NYLON PC/PESUN0001 White 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN0005 Bright White 200+ 260 260+ 260 200+ 300+ NS 300+UN0330 Polar White 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN0332 Coconut 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN1275 Magnolia **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN1293 Vanilla **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN1625 Sunflower Yellow 200+ 280 260 260 200+ 280 NS 280UN1637 Daffodil Yellow 200 240 220 NS NS NS NS NSUN1690 Citrus # *200+ NS 260 250 NS 280+ NS 280+UN1693 Banana *200+ NS 280+ 280+ NS 280+ NS 280+UN1696 Jasmine 200+ 280 260 260 200+ 280+ NS 280+UN1700 Canary Yellow 200+ 280 260 260 200+ 280 NS 280UN1702 Marigold # *200+ NS 260+ 260+ NS 300 NS 300UN1704 Ivory **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN1707 Cream 200+ 280+ 260+ 260+ 200+ 300+ 280+ 300+UN2239 Seville Orange 200+ 280 260 260 200+ NS NS NSUN2243 Mandarin Orange 200 240 220 NS NS NS NS NSUN2250 Pumpkin 200+ 280 260 240 200+ NS NS NSUN2252 Nectarine # *200+ NS 280+ 280+ NS 300 NS 300UN3223 Strawberry Red 200+ 280 260 260 200+ NS NS NSUN3364 Rose Pink 200+ 280 260 260 200+ NS NS NSUN3513 Flesh Pink **200+ 280 260 260 200+ NS NS NSUN3788 Cherry Red 200+ 280 260 260 200+ NS NS NSUN3801 Pastel Pink 200+ 280 260 260 200+ NS NS NSUN3820 Flame Red *200 NS 280+ 280+ NS 280+ 280+ 280+UN3849 Lobster Red 200 260 220 NS NS NS NS NSUN3850 Tomato Red 200+ 280 260 260 200+ 280 NS 280UN3853 Fuchsia 200 260 220 NS NS NS NS NSUN3856 Admiral Red # *200+ NS 260+ 260+ NS 300 NS 300UN3861 Cardinal Red 200+ 280 260 260 200+ 280 NS 280UN3864 Fire Engine Red # *200+ NS 260+ 260 NS 300 NS 300UN3872 Rocket Red *200 NS 280+ 280+ 280+ 280+ NS 280+UN3879 Raspberry 200 260 220 NS NS NS NS NSUN4043 Burgundy 200 230 200 NS 200 NS NS NSUN4204 Mulberry 200+ 280 260 260 200 280 NS 280UN4211 Aubergine # *200+ NS 260 260 NS 280 NS 280UN5001 Sky Blue 200+ 260 260+ 280 200+ 280 280 280UN5009 Powder Blue 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN5011 Mid Blue 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN5027 Royal Blue 200+ 240 220 NS 200 NS NS NSUN5034 Pale Blue 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN5065 Navy Blue 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN5179 Ultra Blue 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN5485 Pacific Blue 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN5982 Baby Blue 200+ 260+ 260+ 280+ 200+ 300 280+ 300UN55094 Purple 200+ 260 240 240 200+ NS NS NSUN55157 Ice Blue 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN55160 Midnight Blue # *200+ NS 260 260 NS 300 NS 300UN55162 Cornflower Blue 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN55171 Baltic Blue 200+ 260+ 240+ 240+ 200+ 280+ NS 280+TEMPERATURE CONVERSION TABLE°C 200 220 240 260 280 300°F 392 428 464 500 536 572RECOMMENDED MAXIMUM PROCESSING TEMPERATURES FOR OMNICOLORIN SELECTED POLYMERS IN °CCOLOR NO. COLOR PVC PE/PP/PURPS ABS ACETAL PBT NYLON PC/PESUN6969 Alpine Green 200+ 280 260 260 200+ 280 NS 280UN6985 Spearmint Green 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN6994 Leaf Green 200 240 220 NS NS NS NS NSUN66070 Fern Green 200+ 280 260 260 200+ 280 NS 280UN66072 Springtime 200+ 280 260 260 200+ 280 NS 280UN66075 Racing Green 200+ 280 260 260 200+ 280+ NS 280+UN66083 Fresh Green 200+ 280 260 260 200+ 280 NS 280UN66087 Sage Green 200+ 280 260 260 200+ 280 NS 280UN66088 Marine Blue 200+ 280 260 260 200 280 NS 280UN66099 Lime Green *200+ NS 260 250 NS 280+ NS 280+UN66100 Olive Green 200+ 280+ 260+ 260+ 200+ 300+ 280+ 300+UN7002 Light Grey 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN7020 Dark Grey 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN7021 Ash Grey 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN7053 Mid Grey 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN7378 Dove Grey 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN7759 Soft Grey 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN7994 Graphite 200+ 280+ 260+ 280+ 200+ 300 280 300UN7996 Moonstone 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN7999 Pebble **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN77000 Cloud Grey 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN77007 Mink **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN77013 Dusk 200+ 280+ 260+ 280+ 200+ 300 280+ 300UN8004 Chocolate Brown **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN8005 Terracotta **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN8018 Light Brown **200+ 280+ 260+ 280+ 200+ 300+ 280 300+UN8021 Mushroom **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN8029 Mid Brown **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN8142 Dark Brown **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN8332 Mahogany **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN8399 Rosewood **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN88721 Toffee **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN88723 Honey Beige **200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN88726 Chestnut Brown **200+ 280 260 260 200+ 280+ 280+ 280+UN88729 Beige **200+ 280+ 260+ 260+ 200+ 300+ 280+ 300+UN0055 Deep Black 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN0086 Ebony # *200+ NS 260 260 NS 300 NS 300UN0541 Gold NS 240 240 240 200+ NS NS NSUN0548 Aztec Gold # *200+ NS 260 260 NS 300 NS 300UN0567 Copper NS 240 240 240 200+ NS NS NSUN0701 Silver 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN0739 Pewter 200+ 280+ 260+ 280+ 200+ 300+ 280+ 300+UN1268 FL Yellow *200+ NS 260+ 260+ NS 300 NS 300UN3752 FL Pink # *200+ NS 260+ 260+ NS 300 NS 300UN6941 FL Green # *200+ NS 260+ 260+ NS 300 NS 300UN2034TR TR Amber # *200+ NS 260 280 NS 300 NS 300UN3012TR TR Red # *200+ NS 260+ 260 NS 300 NS 300UN5016TR TR Blue # *200+ NS 260+ 260 NS 280 NS 280UN6881TR TR Green # *200+ NS 260+ 260 NS 300 NS 300UN7903TR TR Grey *200+ 280+ 260+ 280+ 200+ 300 280+ 300* Suitable for use in all PVC except plasticized PVC.** Suitable for use in all PVC except tin stabilized PVC.+ Potential use at temperatures above those indicated.NS Not suitable for use in polymer indicated.# Contains dyestuff which will migrate from PE/PP and all other polyolefins.

OMNICOLOR ®<strong>Color</strong> ChartWhiteUN0001MarigoldUN1702Flame RedUN3820Sky BlueUN5001Bright WhiteUN0005IvoryUN1704Lobster RedUN3849Powder BlueUN5009Polar WhiteUN0330CreamUN1707Tomato RedUN3850Mid BlueUN5011CoconutUN0332Seville OrangeUN2239FuchsiaUN3853Royal BlueUN5027MagnoliaUN1275Mandarin OrangeUN2243Admiral RedUN3856Pale BlueUN5034VanillaUN1293PumpkinUN2250Cardinal RedUN3861Navy BlueUN5065Sunflower YellowUN1625NectarineUN2252Fire Engine RedUN3864Ultra BlueUN5179Daffodil YellowUN1637Strawberry RedUN3223Rocket RedUN3872Pacific BlueUN5485CitrusUN1690Rose PinkUN3364RaspberryUN3879Baby BlueUN5982BananaUN1693Flesh PinkUN3513BurgundyUN4043PurpleUN55094JasmineUN1696Cherry RedUN3788MulberryUN4204Ice BlueUN55157Canary YellowUN1700Pastel PinkUN3801AubergineUN4211Midnight BlueUN55160

Cornflower BlueUN55162Olive GreenUN66100DuskUN77013BeigeUN88729Baltic BlueUN55171Light GreyUN7002Chocolate BrownUN8004Deep BlackUN0055Alpine GreenUN6969Dark GreyUN7020TerracottaUN8005EbonyUN0086Spearmint GreenUN6985Ash GreyUN7021Light BrownUN8018GoldUN0541Leaf GreenUN6994Mid GreyUN7053MushroomUN8021Aztec GoldUN0548Fern GreenUN66070SpringtimeUN66072Racing GreenUN66075Fresh GreenUN66083Sage GreenUN66087Dove GreyUN7378Soft GreyUN7759GraphiteUN7994MoonstoneUN7996PebbleUN7999Mid BrownUN8029Dark BrownUN8142MahoganyUN8332RosewoodUN8399ToffeeUN88721CopperUN0567SilverUN0701PewterUN0739Fluorescent YellowUN1268Fluorescent PinkUN3752METALLICS FLUORESCENTSMarine BlueUN66088Cloud GreyUN77000Honey BeigeUN88723Fluorescent GreenUN6941Lime GreenUN66099MinkUN77007Chestnut BrownUN88726<strong>Clariant</strong> also offers five transparent colors. See the processing chart in this publication for a complete listing of these colors andrecommended polymers/maximum processing temperatures. For free color chip samples, please contact your <strong>Clariant</strong> representative.

A Partner in InnovationA global color technologyleader, <strong>Clariant</strong> offers theindustry’s broadest range ofhigh-performance masterbatchesfor plastics, includingOMNICOLOR ® universalcolor masterbatches;REMAFIN ® masterbatchesfor polyolefins; RENOL ®masterbatches for engineeringresins, styrenics and PVC;MEVOPUR ® masterbatchesfor medical and pharma;CESA ® additive masterbatches;HYDROCEROL ®chemical foaming andnucleating agents; andENIGMA ® special effects.<strong>Clariant</strong>’s in-depth marketknowledge, formulationexpertise and customercommitment are recognizedworldwide. A global networkof ISO 9000 facilitiesincorporates the mostdemanding manufacturingstandards to ensure thequality and consistencyof <strong>Clariant</strong> masterbatcheswherever they are used.<strong>Clariant</strong> also continues todrive new dimensions incolor creativity. Through itsglobal <strong>Color</strong>Works designservices network, inspirationand technology meldtogether, helping customersstrengthen brand recognition,enhance new productdevelopment and acceleratespeed to market.Additional information about<strong>Clariant</strong> products and technicalsupport is availablefrom all our global facilities.Start a dialog with theexperts at the <strong>Clariant</strong>location nearest you.www.clariant.masterbatches.com<strong>Clariant</strong> Masterbatches85 Industrial DriveHolden, MA 01520Tel: +1 888 621 1282 (in US)Tel: +1 508 829 6321Fax: +1 508 829 7887The information in this publication corresponds to the present state of our knowledge and is intended to describe our products and theirgeneral possible applications. Because conditions of use are outside our control, <strong>Clariant</strong> makes no warranties, express or implied, andassumes no liability in connection with any use of this information. Any existing intellectual/industrial property rights must be observed. Qualityis guaranteed in accordance with our general conditions of sale. For additional information, please contact your <strong>Clariant</strong> representative.® OMNICOLOR, REMAFIN, RENOL, MEVOPUR, CESA, HYDROCEROL and ENIGMA are registered trademarks of <strong>Clariant</strong>. <strong>Color</strong>Works is a trademark of <strong>Clariant</strong>.© 2011 <strong>Clariant</strong> Corporation. Printed in USA.MB1191 10.11