MAJOR 3-DAY AUCTION JUNE 14-16, 2011 SHIPYARD

MAJOR 3-DAY AUCTION JUNE 14-16, 2011 SHIPYARD

MAJOR 3-DAY AUCTION JUNE 14-16, 2011 SHIPYARD

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

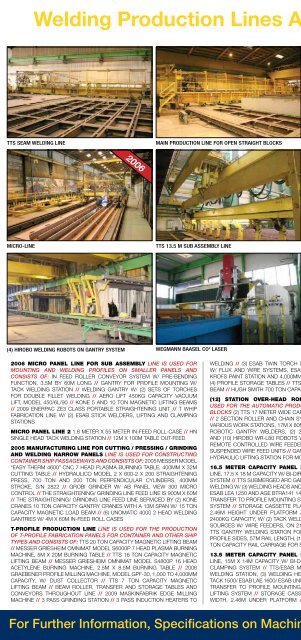

Welding production lines available For Immediate Sale200620052004TTS SEAm WElDING lINE mAIN pRODuCTION lINE fOR OpEN STRAIGHT BlOCKS BuRNING mACHINES (12) WElDING ROBOTS ON lARGE GANTRy SySTEmmICRO-lINETTS 13.5 m SuB ASSEmBly lINElINE fOR CuTTING, STRAIGHTENING & GRINDINGCOmplETE lINES fOR pANElS(4) HIROBO WElDING ROBOTS ON GANTRy SySTEm WEGmANN BAASEl CO 2 lASERT-pROfIlE lINE ESAB WElDING mANIpulATORS2006 MICRo PANEL LINE FoR SUB ASSEMBLy Line is used formounting and weLding profiLes on smaLLer paneLs andconsists of: IN FeeD ROLLeR CONveyOR SySTeM w/ PRe-beNDINGFUNCTION, 3.5M by 60M LONG // GANTRy FOR PROFILe MOUNTING w/TACK weLDING STATION // weLDING GANTRy w/ (2) SeTS OF TORCHeSFOR DOUbLe FILLeT weLDING // AeRO LIFT 450KG CAPACITy vACUUMLIFT, MODeL 450/6L/90 // KONe 5 AND 10 TON MAGNeTIC LIFTING beAMS// 2009 eNeRPAC ze3 CLASS PORTAbLe STRAIGHTeNING UNIT // T wHIPFAbRICATION LINe w/ (2) eSAb STICK weLDeRS, LIFTING AND CLAMPINGSTATIONSMICRo PANEL LINE 2 1.8 MeTeR x 55 MeTeR IN-FeeD ROLL-CASe // HNSINGLe HeAD TACK weLDING STATION // 12M x 100M TAbLe OUT-FeeD2005 MANUFACTURING LINE FoR CUTTING / PRESSING / GRINDINGAND WELDING NARRoW PANELS Line is used for constructingcontainer ship passageways and consists of: 2005 MeSSeR MODeL“eASy THeRM 4600” CNC 7 HeAD PLASMA bURNING TAbLe, 400MM x 32MCUTTING TAbLe // HyDRAULICO MODeL 2 x 600-2 x 200 STRAIGHTeNINGPReSS, 700 TON AND 200 TON PeRPeNDICULAR CyLINDeRS, 400MMSTROKe, S/N 2822 // GRObI GRINDeR w/ Ab PANeL vIew 300 MICROCONTROL // THe STRAIGHTeNING/ GRINDING LINe FeeD LINe IS 900M x 60M// THe STRAIGHTeNING/ GRINDING LINe FeeD LINe SeRvICeD by (2) KONeCRANeS 10 TON CAPACITy GANTRy CRANeS wITH A 13M SPAN w/ 15 TONCAPACITy MAGNeTIC LOAD beAM // (6) UNOMATIC 4000 2 HeAD weLDINGGANTRIeS w/ 4M x 60M IN-FeeD ROLL CASeST-PRoFILE PRoDUCTIoN LINE Line is used for the productionof t-profiLe fabrication paneLs for container and other shiptypes and consists of: TTS 20 TON CAPACITy MAGNeTIC LIFTING beAM// MeSSeR GRIeSHeIM OMNIMAT MODeL S6000P 7 HeAD PLASMA bURNINGMACHINe, 5M x 20M bURNING TAbLe // TTS <strong>16</strong> TON CAPACITy MAGNeTICLIFTING beAM // MeSSeR GRIeSHeIM OMNIMAT MODeL S4800P <strong>16</strong> HeADACeTyLeNe bURNING MACHINe, 2.5M x 8.5M bURNING TAbLe // 2006GRAebeNeR PROFILe MILLING MACHINe, MODeL GPF-30, 1,000 TO 4,000MMCAPACITy, w/ DUST COLLeCTOR // TTS 7 TON CAPACITy MAGNeTICLIFTING beAM // beAM ROLLeR, TRANSFeR AND STORAGe TAbLeS ANDCONveyORS THROUGHOUT LINe // 2009 MASKINFAbRIK eDGe MILLINGMACHINe // 3 PASS GRINDING STATION // 3 PASS INDUCTION HeATeRS TOweLDING // (3) eSAb TwIN TORCH SUbMeRGeD ARC weLDING SySTeMSw/ FLUx AND wIRe SySTeMS, eSAb LAe 1250 weLDeRS // AAbO TyPeKROFS PAINT STATION AND 4,000MM x <strong>14</strong>,500MM TUNNeL DRyING LINe //(4) PROFILe STORAGe TAbLeS // TTS 20 TON CAPACITy MAGNeTIC LIFTINGbeAM // HUGH SMITH 700 TON CAPACITy FRAMe beNDeR, S/N 27030(12) STATIoN ovER-HEAD RoBoTIC GANTRy SySTEM Line isused for the automatic production of Large, open straightbLocks (2) TTS 17 MeTeR wIDe CAPACITy ONe-SIDe weLDING MACHINeS// 2 SeCTION ROLLeR AND CHAIN SySTeM TO MOve, LIFT AND PLACe TOvARIOUS wORK STATIONS, 17M x 80M AND 15M x 30M // (12) INDePeNDeNTRObOTIC GANTRy weLDeRS, (2) 2009 HIRObO wR-L80 111y RObOTSAND (10) HIRObO wR-L80 RObOTS w/ HITACHI weLDeRS // (8) eSAb MeHReMOTe CONTROLLeD wIRe FeeDeRS ON jIb CRANeS // (17) MIGAMATICSUSPeNDeD wIRe FeeD UNITS // GANTRy CAPACITy: x-32M/ y-<strong>16</strong>M/ z-6M //HyDRAULIC LIFTING STATION FOR MObILe TRANSPORTS<strong>16</strong>.5 METER CAPACITy PANEL LINE consists of: PANeL FeeDINGLINe, 17.5 x 18 M CAPACITy w/ bI-DIReCTIONAL MOveMeNT AND CLAMPINGSySTeM // TTS SUbMeRGeD ARC GANTRy weLDING STATION FOR ONe SIDeweLDING w/ (3) weLDING HeADS AND FLUx LOAD SySTeM, eSAb TACK 1500/eSAb LeA 1250 AND AGe bTRA<strong>14</strong>1 <strong>14</strong>00A weLDING SOURCeS // (4) SeCTIONTRANSFeR TO PROFILe MOUNTING STATION, 17 x 86 M, HyDRAULIC LIFTINGSySTeM // STORAGe CASSeTTe PLATFORM, 17.8M LeNGTH, 3.8M wIDTH,2.46M HeIGHT UNDeR PLATFORM // TTS PROFILe MOUNTING STATION,2400KG CAPACITy, w/ (2) TACK weLDING STATIONS, eSAb LAe 315 POweRSOURCeS w/ wIRe FeeDeRS, ON 21M x 57 M RAIL TRANSFeR SySTeM //TTS GANTRy weLDING STATION FOR SIMULTANeOUS weLDING OF bOTHPROFILe SIDeS, 57M RAIL LeNGTH, (<strong>16</strong>) eSAb TF 6L-500 AMP weLDeRS // 40TON CAPACITy RAIL CARRIAGe FOR SUb ASSeMbLy TRANSPORT13.5 METER CAPACITy PANEL LINE consists of: PANeL FeeDINGLINe, 15M x <strong>14</strong>M CAPACITy w/ bI-DIReCTIONAL MOveMeNT, 2 SeCTIONS,CLAMPING SySTeM // TTS/eSAb MODeL A6 SUbMeRGeD ARC GANTRyweLDING STATION, (3) weLDING HeADS AND FLUx LOAD SySTeM, eSAbTACK 1500/ eSAb LAe <strong>16</strong>00/ eSAb UNITOR weLDING SOURCeS // (4) SeCTIONTRANSFeR TO PROFILe MOUNTING STATION, 13.5M x 75M, HyDRAULICLIFTING SySTeM // STORAGe CASSeTTe PLATFORM, <strong>16</strong>M LeNGTH, 3.8MwIDTH, 2.46M UNDeR PLATFORM // TTS PROFILe MOUNTING STATION,200KG CAPACITy, w/ TACK weLDING STATION, eSAb LAe 315 AND wIReFeeDeR, ON 15M x 50M RAIL TRANSFeR SySTeM // HeDe NIeLSeN 4 HeADweLDING GANTRy FOR SIMULTANeOUS weLDING OF (2) PROFILeS, 50MLeNGTH GANTRy w/ eUROMASTeR 500 e-1 weLDING POweR SOURCeS(2) TTS/ HEIDE NIELSEN CURvED PANEL PRoDUCTIoN LINES Linesare used for production of curved paneL sections up to 12 x10m and consist of: (5) MOveAbLe PLATFORMS eACH w/ 187 HeIGHTADjUSTAbLe POLeS. POLeS SUPPORT THe CURveD PANeL // SUbMeRGeDARC TACK weLDING OF ONe SIDe FOR ONe SIDe weLDING // HyDRAULICHANDLING TOOL FOR MOUNTING OF PROFILeS // SIMULTANeOUS weLDINGOF bOTH PROFILe SIDeS // (CURveD PANeL LINeS ARe DISASSeMbLeD ANDIN STORAGe)SUB-ASSEMBLy PRoFILE MoUNTING AND WELDING MACHINE 1995combined profiLe mounting and weLding machine consistingof: MAGNeTIC LIFTING beAM FOR x-y PLACING OF PROFILe PLACeMeNT,MAx PROFILe SIze .5 x 3.2 M // HN AUTOMATIC GANTRy weLDING SySTeMFOR SIMULTANeOUS AUTOMATIC weLDING, CO2 MIG MAG weLDING wITH(2) eUROMASTeR 700 e-1 POweR SOURCeS // CONveyOR FeeD TAbLe IS3.5M x 20M LONG // RATeD weLDING SPeeD IS 700MM PeR MINUTe // (LINeIS PARTLy DISASSeMbLeD AND STOReD)GANTRy (4) RoBoTIC WELDING SySTEM (4) HIRObO weLDING RObOTSON INDIvIDUAL RAILS // 20 TON CAPACITy ON TURNING FIxTURe // TOTALGANTRy SySTeM IS x-60M, y-4M, z-1.5M // (4) HITACHI MIG MAG TS-ARC-Rx500 weLDING SOURCeS // ReMOTe PROGRAMMAbLe(2) 2005 ESAB 2 HEAD GANTRy WELDING SySTEMS for gantryweLding of container ship paneLs consisting of: (2) eSAbReMOTe CONTROLLeD weLDING HeADS // 2 MeTeR PeR MINUTe weLDINGCAPAbILITy // FLUx SySTeM // eSAb TAF POweR SOURCeS // ReMOTeCONTROLLeD, eSAb A2-A6 CONTROLLeR1997 WEGMANN BAASEL 12KW LASER CUTTING AND WELDINGLINE 17.5M x 4M CAPACITy CUTTING TAbLe // CUTTING CAPACITy TO28MM, CUTTING SPeeD 250-1800 MM/ MIN. // weLDING CAPACITy TO 15MMTO 2800MM/MIN. // QUICK CHANGe HyDRAULIC TAbLe // 12Kw LASeRPRoDUCTIoN vIDEoS AvAILABLE oN MoST LINESFor Further Information, Specifications on Machinery & Equipment or to Download a brochure, pleas