MAJOR 3-DAY AUCTION JUNE 14-16, 2011 SHIPYARD

MAJOR 3-DAY AUCTION JUNE 14-16, 2011 SHIPYARD

MAJOR 3-DAY AUCTION JUNE 14-16, 2011 SHIPYARD

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

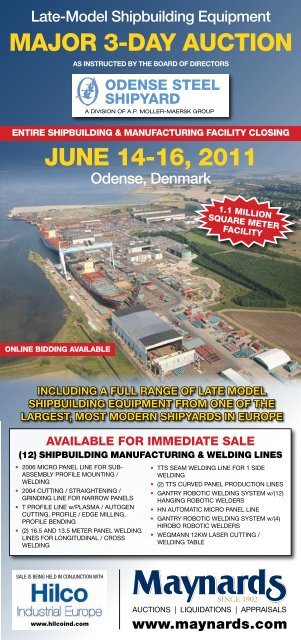

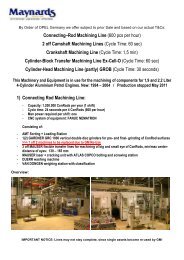

Late-Model Shipbuilding Equipment<strong>MAJOR</strong> 3-<strong>DAY</strong> <strong>AUCTION</strong>aS InStRucted by the boaRd oF dIRectoRSODENSE STEEL<strong>SHIPYARD</strong>A DIVISION OF A.P. MOLLER-MAERSK GROUPENTIRE SHIPBUILDING & MANUFACTURING FACILITY CLOSING<strong>JUNE</strong> <strong>14</strong>-<strong>16</strong>, <strong>2011</strong>Odense, Denmark1.1 MILLIONSQUARE METERFACILITYONLINE BIDDING AVAILABLEIncludIng a Full Range oF late ModelShIpbuIldIng equIpMent FRoM one oF thelaRgeSt, MoSt ModeRn ShIpyaRdS In euRopeAVAILABLE FOR IMMEDIATE SALE(12) SHIPBUILDING MANUFACTURING & WELDING LINES• 2006 MICRO PANEL LINE FOR SUB-ASSEMBLY PROFILE MOUNTING /WELDING• 2004 CUTTING / STRAIGhTENING /GRINDING LINE FOR NARROW PANELS• T PROFILE LINE w/PLASMA / AUTOGENCUTTING, PROFILE / EDGE MILLING,PROFILE BENDING• (2) <strong>16</strong>.5 AND 13.5 METER PANEL WELDINGLINES FOR LONGITUDINAL / CROSSWELDING• TTS SEAM WELDING LINE FOR 1 SIDEWELDING• (2) TTS CURvED PANEL PRODUCTION LINES• GANTRY ROBOTIC WELDING SYSTEM w/(12)hANGING ROBOTIC WELDERS• hN AUTOMATIC MICRO PANEL LINE• GANTRY ROBOTIC WELDING SYSTEM w/(4)hIROBO ROBOTIC WELDERS• WEGMANN 12KW LASER CUTTING /WELDING TABLESALE IS BEING HELD IN CONJUNCTION WITHwww.hilcoind.com<strong>AUCTION</strong>S | LIQUIDATIONS | APPRAISALSwww.maynards.com

Welding production lines available For Immediate Sale200620052004TTS SEAm WElDING lINE mAIN pRODuCTION lINE fOR OpEN STRAIGHT BlOCKS BuRNING mACHINES (12) WElDING ROBOTS ON lARGE GANTRy SySTEmmICRO-lINETTS 13.5 m SuB ASSEmBly lINElINE fOR CuTTING, STRAIGHTENING & GRINDINGCOmplETE lINES fOR pANElS(4) HIROBO WElDING ROBOTS ON GANTRy SySTEm WEGmANN BAASEl CO 2 lASERT-pROfIlE lINE ESAB WElDING mANIpulATORS2006 MICRo PANEL LINE FoR SUB ASSEMBLy Line is used formounting and weLding profiLes on smaLLer paneLs andconsists of: IN FeeD ROLLeR CONveyOR SySTeM w/ PRe-beNDINGFUNCTION, 3.5M by 60M LONG // GANTRy FOR PROFILe MOUNTING w/TACK weLDING STATION // weLDING GANTRy w/ (2) SeTS OF TORCHeSFOR DOUbLe FILLeT weLDING // AeRO LIFT 450KG CAPACITy vACUUMLIFT, MODeL 450/6L/90 // KONe 5 AND 10 TON MAGNeTIC LIFTING beAMS// 2009 eNeRPAC ze3 CLASS PORTAbLe STRAIGHTeNING UNIT // T wHIPFAbRICATION LINe w/ (2) eSAb STICK weLDeRS, LIFTING AND CLAMPINGSTATIONSMICRo PANEL LINE 2 1.8 MeTeR x 55 MeTeR IN-FeeD ROLL-CASe // HNSINGLe HeAD TACK weLDING STATION // 12M x 100M TAbLe OUT-FeeD2005 MANUFACTURING LINE FoR CUTTING / PRESSING / GRINDINGAND WELDING NARRoW PANELS Line is used for constructingcontainer ship passageways and consists of: 2005 MeSSeR MODeL“eASy THeRM 4600” CNC 7 HeAD PLASMA bURNING TAbLe, 400MM x 32MCUTTING TAbLe // HyDRAULICO MODeL 2 x 600-2 x 200 STRAIGHTeNINGPReSS, 700 TON AND 200 TON PeRPeNDICULAR CyLINDeRS, 400MMSTROKe, S/N 2822 // GRObI GRINDeR w/ Ab PANeL vIew 300 MICROCONTROL // THe STRAIGHTeNING/ GRINDING LINe FeeD LINe IS 900M x 60M// THe STRAIGHTeNING/ GRINDING LINe FeeD LINe SeRvICeD by (2) KONeCRANeS 10 TON CAPACITy GANTRy CRANeS wITH A 13M SPAN w/ 15 TONCAPACITy MAGNeTIC LOAD beAM // (6) UNOMATIC 4000 2 HeAD weLDINGGANTRIeS w/ 4M x 60M IN-FeeD ROLL CASeST-PRoFILE PRoDUCTIoN LINE Line is used for the productionof t-profiLe fabrication paneLs for container and other shiptypes and consists of: TTS 20 TON CAPACITy MAGNeTIC LIFTING beAM// MeSSeR GRIeSHeIM OMNIMAT MODeL S6000P 7 HeAD PLASMA bURNINGMACHINe, 5M x 20M bURNING TAbLe // TTS <strong>16</strong> TON CAPACITy MAGNeTICLIFTING beAM // MeSSeR GRIeSHeIM OMNIMAT MODeL S4800P <strong>16</strong> HeADACeTyLeNe bURNING MACHINe, 2.5M x 8.5M bURNING TAbLe // 2006GRAebeNeR PROFILe MILLING MACHINe, MODeL GPF-30, 1,000 TO 4,000MMCAPACITy, w/ DUST COLLeCTOR // TTS 7 TON CAPACITy MAGNeTICLIFTING beAM // beAM ROLLeR, TRANSFeR AND STORAGe TAbLeS ANDCONveyORS THROUGHOUT LINe // 2009 MASKINFAbRIK eDGe MILLINGMACHINe // 3 PASS GRINDING STATION // 3 PASS INDUCTION HeATeRS TOweLDING // (3) eSAb TwIN TORCH SUbMeRGeD ARC weLDING SySTeMSw/ FLUx AND wIRe SySTeMS, eSAb LAe 1250 weLDeRS // AAbO TyPeKROFS PAINT STATION AND 4,000MM x <strong>14</strong>,500MM TUNNeL DRyING LINe //(4) PROFILe STORAGe TAbLeS // TTS 20 TON CAPACITy MAGNeTIC LIFTINGbeAM // HUGH SMITH 700 TON CAPACITy FRAMe beNDeR, S/N 27030(12) STATIoN ovER-HEAD RoBoTIC GANTRy SySTEM Line isused for the automatic production of Large, open straightbLocks (2) TTS 17 MeTeR wIDe CAPACITy ONe-SIDe weLDING MACHINeS// 2 SeCTION ROLLeR AND CHAIN SySTeM TO MOve, LIFT AND PLACe TOvARIOUS wORK STATIONS, 17M x 80M AND 15M x 30M // (12) INDePeNDeNTRObOTIC GANTRy weLDeRS, (2) 2009 HIRObO wR-L80 111y RObOTSAND (10) HIRObO wR-L80 RObOTS w/ HITACHI weLDeRS // (8) eSAb MeHReMOTe CONTROLLeD wIRe FeeDeRS ON jIb CRANeS // (17) MIGAMATICSUSPeNDeD wIRe FeeD UNITS // GANTRy CAPACITy: x-32M/ y-<strong>16</strong>M/ z-6M //HyDRAULIC LIFTING STATION FOR MObILe TRANSPORTS<strong>16</strong>.5 METER CAPACITy PANEL LINE consists of: PANeL FeeDINGLINe, 17.5 x 18 M CAPACITy w/ bI-DIReCTIONAL MOveMeNT AND CLAMPINGSySTeM // TTS SUbMeRGeD ARC GANTRy weLDING STATION FOR ONe SIDeweLDING w/ (3) weLDING HeADS AND FLUx LOAD SySTeM, eSAb TACK 1500/eSAb LeA 1250 AND AGe bTRA<strong>14</strong>1 <strong>14</strong>00A weLDING SOURCeS // (4) SeCTIONTRANSFeR TO PROFILe MOUNTING STATION, 17 x 86 M, HyDRAULIC LIFTINGSySTeM // STORAGe CASSeTTe PLATFORM, 17.8M LeNGTH, 3.8M wIDTH,2.46M HeIGHT UNDeR PLATFORM // TTS PROFILe MOUNTING STATION,2400KG CAPACITy, w/ (2) TACK weLDING STATIONS, eSAb LAe 315 POweRSOURCeS w/ wIRe FeeDeRS, ON 21M x 57 M RAIL TRANSFeR SySTeM //TTS GANTRy weLDING STATION FOR SIMULTANeOUS weLDING OF bOTHPROFILe SIDeS, 57M RAIL LeNGTH, (<strong>16</strong>) eSAb TF 6L-500 AMP weLDeRS // 40TON CAPACITy RAIL CARRIAGe FOR SUb ASSeMbLy TRANSPORT13.5 METER CAPACITy PANEL LINE consists of: PANeL FeeDINGLINe, 15M x <strong>14</strong>M CAPACITy w/ bI-DIReCTIONAL MOveMeNT, 2 SeCTIONS,CLAMPING SySTeM // TTS/eSAb MODeL A6 SUbMeRGeD ARC GANTRyweLDING STATION, (3) weLDING HeADS AND FLUx LOAD SySTeM, eSAbTACK 1500/ eSAb LAe <strong>16</strong>00/ eSAb UNITOR weLDING SOURCeS // (4) SeCTIONTRANSFeR TO PROFILe MOUNTING STATION, 13.5M x 75M, HyDRAULICLIFTING SySTeM // STORAGe CASSeTTe PLATFORM, <strong>16</strong>M LeNGTH, 3.8MwIDTH, 2.46M UNDeR PLATFORM // TTS PROFILe MOUNTING STATION,200KG CAPACITy, w/ TACK weLDING STATION, eSAb LAe 315 AND wIReFeeDeR, ON 15M x 50M RAIL TRANSFeR SySTeM // HeDe NIeLSeN 4 HeADweLDING GANTRy FOR SIMULTANeOUS weLDING OF (2) PROFILeS, 50MLeNGTH GANTRy w/ eUROMASTeR 500 e-1 weLDING POweR SOURCeS(2) TTS/ HEIDE NIELSEN CURvED PANEL PRoDUCTIoN LINES Linesare used for production of curved paneL sections up to 12 x10m and consist of: (5) MOveAbLe PLATFORMS eACH w/ 187 HeIGHTADjUSTAbLe POLeS. POLeS SUPPORT THe CURveD PANeL // SUbMeRGeDARC TACK weLDING OF ONe SIDe FOR ONe SIDe weLDING // HyDRAULICHANDLING TOOL FOR MOUNTING OF PROFILeS // SIMULTANeOUS weLDINGOF bOTH PROFILe SIDeS // (CURveD PANeL LINeS ARe DISASSeMbLeD ANDIN STORAGe)SUB-ASSEMBLy PRoFILE MoUNTING AND WELDING MACHINE 1995combined profiLe mounting and weLding machine consistingof: MAGNeTIC LIFTING beAM FOR x-y PLACING OF PROFILe PLACeMeNT,MAx PROFILe SIze .5 x 3.2 M // HN AUTOMATIC GANTRy weLDING SySTeMFOR SIMULTANeOUS AUTOMATIC weLDING, CO2 MIG MAG weLDING wITH(2) eUROMASTeR 700 e-1 POweR SOURCeS // CONveyOR FeeD TAbLe IS3.5M x 20M LONG // RATeD weLDING SPeeD IS 700MM PeR MINUTe // (LINeIS PARTLy DISASSeMbLeD AND STOReD)GANTRy (4) RoBoTIC WELDING SySTEM (4) HIRObO weLDING RObOTSON INDIvIDUAL RAILS // 20 TON CAPACITy ON TURNING FIxTURe // TOTALGANTRy SySTeM IS x-60M, y-4M, z-1.5M // (4) HITACHI MIG MAG TS-ARC-Rx500 weLDING SOURCeS // ReMOTe PROGRAMMAbLe(2) 2005 ESAB 2 HEAD GANTRy WELDING SySTEMS for gantryweLding of container ship paneLs consisting of: (2) eSAbReMOTe CONTROLLeD weLDING HeADS // 2 MeTeR PeR MINUTe weLDINGCAPAbILITy // FLUx SySTeM // eSAb TAF POweR SOURCeS // ReMOTeCONTROLLeD, eSAb A2-A6 CONTROLLeR1997 WEGMANN BAASEL 12KW LASER CUTTING AND WELDINGLINE 17.5M x 4M CAPACITy CUTTING TAbLe // CUTTING CAPACITy TO28MM, CUTTING SPeeD 250-1800 MM/ MIN. // weLDING CAPACITy TO 15MMTO 2800MM/MIN. // QUICK CHANGe HyDRAULIC TAbLe // 12Kw LASeRPRoDUCTIoN vIDEoS AvAILABLE oN MoST LINESFor Further Information, Specifications on Machinery & Equipment or to Download a brochure, pleas

auctIon #1 - June <strong>14</strong>-<strong>16</strong>, <strong>2011</strong>Ship building yard and Support equipment2003<strong>MAJOR</strong> 3-<strong>DAY</strong> <strong>AUCTION</strong>Late-Model Shipbuilding Equipment<strong>JUNE</strong> <strong>14</strong>-<strong>16</strong>, <strong>2011</strong>Odense, DenmarkODENSE STEEL<strong>SHIPYARD</strong>A DIVISION OF A.P. MOLLER-MAERSK GROUPGROVE 70 TON CRANESupply plATfORmS (uNuSED/7 Off) ATlAS-COpCO XRHS 366GENIE mANlIfTSlAyHER & OTHER SCAffOlDING100’S Of lOTS - yARD / plANT SuppORT EQuIpmENTMoBILE EqUIPMENTOveR (30) MAN LIFTS by GeNIe / jLG TO 34 M CAPACITy • GROve 70 TON MObILe CRANe • TRUCK CRANeS •TANSPORT LORRy’S • OveR (30) 70 TON CAPACITy beD TRAILeRS • SeMI-TRAILeRS • PORTAbLe COMPReSSORSTO 800 CFMCRANES / HoISTS(2) 1996 20 TON yARD GANTRy CRANeS • (2) 17.5 TON yARD GANTRy CRANeS • (15) OveR-HeAD AND jIb TyPeCRANeS • SCANCLIMbING PLATFORMS FOR COveReD SHIP wORK • New AND USeD SHIP-bUILDING PLATFORMSFOR MULTI-FUNCTION PRePAReD FOR AIR / weLDING / veNTILATIONSCAFFoLDING (HUGE oFFERING)OveR (10,000) bRACKeTS • OveR (3,000) RAILINGS • OveR (500) HANGING FRAMeS • OveR (17,000) SCePTeRS• OveR (20,000’) OF DeCKING FROM 4’ TO 11’ • OveR (2,500) SCAFFOLDING LADDeRS AND STeP-LADDeRS •OveR 6000’ OF SCAFFOLDING wOOD • layheR ModulaR ScaFFoldIng - oveR 61,000 pIeceS oF WheelS,SpIndleS, tubeS, deckS, gIRdeRS, laddeRS, u-RaIl etc.PAINT / SANDBLASTING EqUIPMENTPORTAbLe AIRLeSS SPRAy UNITS, SeLF-CONTAINeD • OveR (50) AIRLeSS SPRAyeRS • LARGe QTy OF SPRAyGUNS AND HOSe • OveR (10) PORTAbLe SAND bLAST MACHINeS • SPONGe AND DRy ICe bLAST SySTeMSELECTRICAL AND AIR SUPPoRT EqUIPMENTOveR (50) TRANSFORMeRS AND ReCTIFIeRS • OveR (250) DC bReAKeR PANeLS • OveR (300) AC bReAKeRPANeLS • OveR (40) PRe-HeATING UNITS FOR STeeL • OveR (400) COMPReSSeD AIR UNITS • OveR (150) OxyGeN/ ACeTyLeNe UNITS • OveR (200) CLeANAIR FILTeRS AND exHAUST/ veNTILATION UNITS • TRANSPORTAbLe AIRTANKS • THOUSAND OF MeTeRS OF OxyGeN / ACeTyLeNe / COMPReSSeD AIR / CO2 HOSe • THOUSANDS OFMeTeRS OF eLeCTRICAL CAbLeWELDING EqUIPMENTOveR (500) ARC / STUD / MIG weLDeRS by eSAb, FRONIUS, HObART, KeMPPI, MIGATRONIC • OveR (1,000)wIRe FeeDeRS • OveR (50) bUG-O-TRACK TRACK weLDING CUTTeRS • weLDING ReMOTe CONTROL UNITS •THOUSANDS OF MeTeRS OF weLDING CAbLeTRANSPoRT MEANS / HEAvy SUPPoRT STRUCTURESOveR (100) 60 TO 100 TON CAPACITy STeeL SUPPORT STRUCTUReS • OveR (100) 1.74 MeTeR STeeL SUPPORTTRIPODS FROM 60 TO 250 TON CAPACITy • OveR (200) PORTAL SUPPORTS FOR SeA FASTeNING • OveR (60) HeAvyGIRDeRS • OveR (70) TRANSPORT CRADLeS • OveR (25) SUPPORT PILLARS FROM 200 TO 500 TON CAPACITy •OveR (15) SUPPORT PILLARS FROM 30 TO 60 TON CAPACITyovER (200) PoWER HAND TooLSHUNDReDS eACH OF: ANGLe AND HOLe GRINDeRS • DRILLS • IMPACT GUNS • De-SLAGGING TOOLS • PORTAbLeCUT-OFF AND bANDSAwS • beLT SANDeRS • LIFTING MAGNeTS AND CLAMPS • AIR AND HyDRAULIC HOISTS •PORTAbLe HyDRAULIC jACKS AND PUMPS • MeASURING TOOLSSURPLUS MATERIALSLARGe QTy OF bOLTS / SCRewS / THReADeR bAR / NUTS eTC • LARGe QTy OF OTHeR PeRISHAbLe TOOLING ANDSUPPLIeS (TO be DeTeRMINeD)SCRAP METAL INvENToRyAPPROxIMATeLy 3,000 TONS THROUGH-OUT SHIPyARD TO be SOLD AT <strong>AUCTION</strong>GENERALOveR (40) SeA CONTAINeRS 20-40’ • MObILe RePAIR, MACHINING AND CARPeNTRy eQUIPMeNT • (4) MeTALSTORAGe / wORK bUILDINGSe visit www.maynards.com or www.hilcoind.comOVER5000LOtS!IncLuDIng a FuLL RangE OF LatE MODELShIpbuILDIng EquIpMEnt FROM OnE OF thELaRgESt, MOSt MODERn ShIpyaRDS In EuROpEAuction DatesTUES<strong>DAY</strong>, WEDNES<strong>DAY</strong> & ThURS<strong>DAY</strong>, <strong>JUNE</strong> <strong>14</strong>, 15 & <strong>16</strong>, <strong>2011</strong>BEGINNING AT 10AM LOCAL TIME EACh <strong>DAY</strong>Preview DatesMON<strong>DAY</strong>, <strong>JUNE</strong> 13, <strong>2011</strong> FROM 9AM-4PM OR BY PRIORAPPOINTMENTAuction & Preview LocationLINDOALLEEN 150, ODENSE, MUNKEBO, DENMARKDirectionsSITE IS APPROXIMATELY 1½ hOURS BY TRAIN AND LESS ThAN2 hOURS BY CAR FROM COPENhAGEN AIRPORTPlease visit the OSS Listing onwww.maynards.com for the following:• TRAvEL INFORMATION• BUYERS PREMIUMS• BIDDING REQUIREMENTS• TERMS AND CONDITIONSFoR FURTHER INFoRMATIoN,SPECIFICATIoNS oN MACHINERy & EqUIPMENToR To DoWNLoAD CoMPLETE, DETAILED oNLINEBRoCHURE, vISIT WWW.MAyNARDS.CoMCoNTACT: Andreas Matuszczak % 49 8151 973420 | oss@maynards.comUNITED KINGDoM: Daniel Gray % 44 (0) 8453 130 185NoRTH AMERICA: Mike McIntosh % 1 (4<strong>16</strong>) 242-3560