PowerTorq ™ Precision Ball Spline Assemblies

PowerTorq ™ Precision Ball Spline Assemblies

PowerTorq ™ Precision Ball Spline Assemblies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

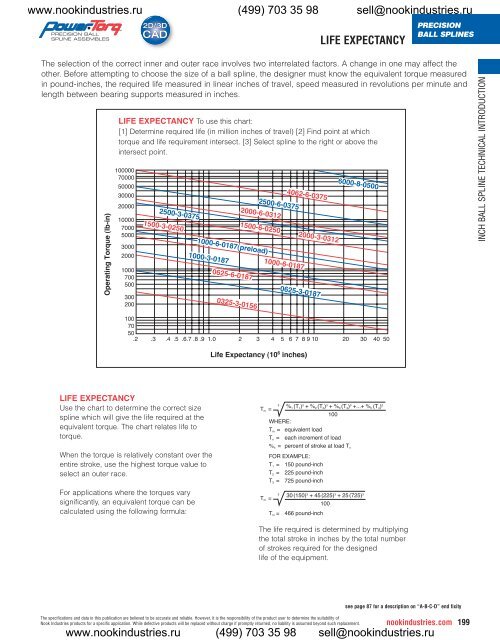

www.nookindustries.ru (499) 703 35 98 sell@nookindustries.ruPRECISION BALLSPLINE ASSEMBLESLIFE EXPECTANCYPRECISIONBALL SPLINESThe selection of the correct inner and outer race involves two interrelated factors. A change in one may affect theother. Before attempting to choose the size of a ball spline, the designer must know the equivalent torque measuredin pound-inches, the required life measured in linear inches of travel, speed measured in revolutions per minute andlength between bearing supports measured in inches.Operating Torque (lb-in)LIFE EXPECTANCY To use this chart:[1] Determine required life (in million inches of travel) [2] Find point at whichtorque and life requirement intersect. [3] Select spline to the right or above theintersect point.1000007000050000300002000010000700050003000200010007005003002002500-3-03751500-3-02502500-6-03752000-6-03124062-6-03751500-6-0250 2000-3-03121000-6-0187(preload)1000-6-01871000-3-01870625-6-01870625-3-01870325-3-01566000-8-0500INCH BALL SPLINE TECHNICAL INTRODUCTION1007050.2 .3 .4 .5 .6.7 .8 .9 1.0 2 3 4 5 6 7 8 9 10 20 30 40 50Life Expectancy (10 6 inches)LIFE EXPECTANCYUse the chart to determine the correct sizespline which will give the life required at theequivalent torque. The chart relates life totorque.When the torque is relatively constant over theentire stroke, use the highest torque value toselect an outer race.For applications where the torques varysignificantly, an equivalent torque can becalculated using the following formula:3T m =% 1 (T 1 ) 3 + % 2 (T 2 ) 3 + % 3 (T 3 ) 3 +...+ % n (T n ) 3100WHERE:T m = equivalent loadT n = each increment of load% n = percent of stroke at load T nFOR EXAMPLE:T 1 = 150 pound-inchT 2 = 225 pound-inchT 3 = 725 pound-inch3T m =30 (150) 3 + 45 (225) 3 + 25 (725) 3100T m = 466 pound-inchThe life required is determined by multiplyingthe total stroke in inches by the total numberof strokes required for the designedlife of the equipment.see page 87 for a description on “A-B-C-D” end fixityThe specifications and data in this publication are believed to be accurate and reliable. However, it is the responsibility of the product user to determine the suitability ofNook Industries products for a specific application. While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement. nookindustries.com 199www.nookindustries.ru (499) 703 35 98 sell@nookindustries.ru