Park City Case Study - Siemens Water Technologies

Park City Case Study - Siemens Water Technologies

Park City Case Study - Siemens Water Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

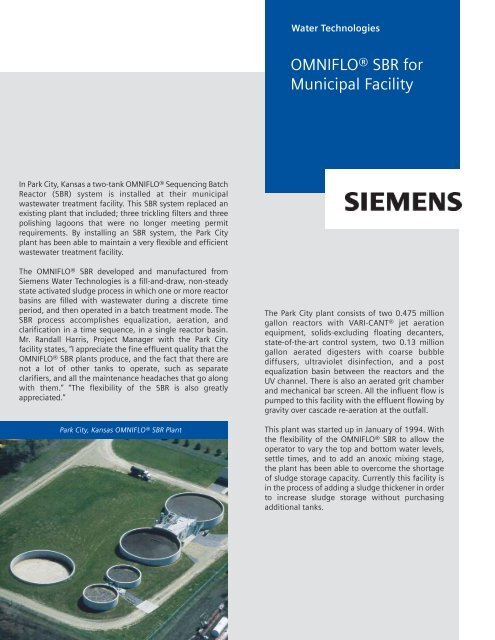

<strong>Water</strong> <strong>Technologies</strong>OMNIFLO® SBR forMunicipal FacilityIn <strong>Park</strong> <strong>City</strong>, Kansas a two-tank OMNIFLO® Sequencing BatchReactor (SBR) system is installed at their municipalwastewater treatment facility. This SBR system replaced anexisting plant that included; three trickling filters and threepolishing lagoons that were no longer meeting permitrequirements. By installing an SBR system, the <strong>Park</strong> <strong>City</strong>plant has been able to maintain a very flexible and efficientwastewater treatment facility.The OMNIFLO® SBR developed and manufactured from<strong>Siemens</strong> <strong>Water</strong> <strong>Technologies</strong> is a fill-and-draw, non-steadystate activated sludge process in which one or more reactorbasins are filled with wastewater during a discrete timeperiod, and then operated in a batch treatment mode. TheSBR process accomplishes equalization, aeration, andclarification in a time sequence, in a single reactor basin.Mr. Randall Harris, Project Manager with the <strong>Park</strong> <strong>City</strong>facility states, “I appreciate the fine effluent quality that theOMNIFLO® SBR plants produce, and the fact that there arenot a lot of other tanks to operate, such as separateclarifiers, and all the maintenance headaches that go alongwith them.” “The flexibility of the SBR is also greatlyappreciated.”<strong>Park</strong> <strong>City</strong>, Kansas OMNIFLO® SBR PlantThe <strong>Park</strong> <strong>City</strong> plant consists of two 0.475 milliongallon reactors with VARI-CANT® jet aerationequipment, solids-excluding floating decanters,state-of-the-art control system, two 0.13 milliongallon aerated digesters with coarse bubblediffusers, ultraviolet disinfection, and a postequalization basin between the reactors and theUV channel. There is also an aerated grit chamberand mechanical bar screen. All the influent flow ispumped to this facility with the effluent flowing bygravity over cascade re-aeration at the outfall.This plant was started up in January of 1994. Withthe flexibility of the OMNIFLO® SBR to allow theoperator to vary the top and bottom water levels,settle times, and to add an anoxic mixing stage,the plant has been able to overcome the shortageof sludge storage capacity. Currently this facility isin the process of adding a sludge thickener in orderto increase sludge storage without purchasingadditional tanks.

InfluentPlant LayoutBar ScreenAerated Grit ChamberAerobicDigesterAerobicDigesterDisposalFloating SolidsExcludingDecanterWASBlowersID/SCAirLineDry-PitMotivePumpsEffluentHoldingTankUV DisinfectionEffluentPERFORMANCE PARAMETERS:FLOWBOD TSS AMMONIADesignActual(startup throughApril 2000)AverageFlow (MGD)1.080.613Influentmg/l241197Effluentmg/l* The permitted weekly average ammonia levels vary seasonally from 2.0 - 9.0 mg/l.307Influentmg/l241206Effluentmg/l3012Influentmg/l3626Effluentmg/l2 - 9*0.5Mr. Harris states, “I am very pleased withthe performance of the OMNIFLO® SBRand would recommend them to anymunicipality looking to build or retrofit afacility.”The information provided in this literature contains merely general descriptions orcharacteristics of performance which in actual case of use do not always apply asdescribed or which may change as a result of further development of the products.An obligation to provide the respective characteristics shall only exist if expresslyagreed in the terms of the contract.OMNIFLO and VARI-CANT are trademarks of <strong>Siemens</strong>, its subsidiaries or affiliates.<strong>Siemens</strong><strong>Water</strong> <strong>Technologies</strong>1051 BlakeEdwardsville, KS 66111913.422.7600 phone913.422.7667 faxwww.usfilter.com© 2006 <strong>Siemens</strong> <strong>Water</strong> <strong>Technologies</strong> Corp.JT-PC-CS-0906