Heat sinks and water coolers - AMS Technologies

Heat sinks and water coolers - AMS Technologies

Heat sinks and water coolers - AMS Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

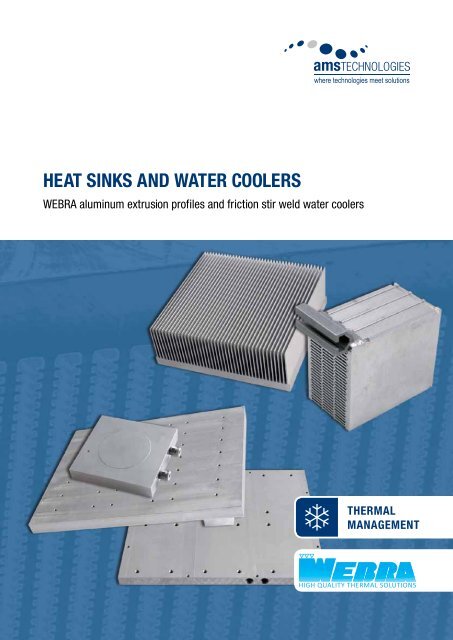

<strong>Heat</strong> <strong>sinks</strong> <strong>and</strong> <strong>water</strong> <strong>coolers</strong>WEBRA aluminum extrusion profiles <strong>and</strong> friction stir weld <strong>water</strong> <strong>coolers</strong>thermalmanagement

IndexOur commitment to you 03<strong>Heat</strong> <strong>sinks</strong> for forced convection with air 06Exceptional performance 08Safety <strong>and</strong> long life 09Dimensioning using numerical methods 10Dimensioning using performance curves 11Overview: heat <strong>sinks</strong> 12<strong>Heat</strong> sink profiles 13- 43Aluminum Cooler Plates friction stir welded……………………………… 44Cooler Plates 45-53<strong>Heat</strong> Sinks 05

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management Solutions<strong>Heat</strong> <strong>sinks</strong> for forced convection with airWebra heat sink profiles are aluminum extrusions that have proven their value in the most dem<strong>and</strong>ing industry tasks:Cooling of inverter modules in renewable energiesCooling of power semiconductormodules for traction <strong>and</strong> auxiliary powerunits in rail vehiclesCooling of frequency converters as insoft starters or in large drives06 <strong>Heat</strong> Sinks

Cooling of power amplifier components,i.e. for telecommunication or broadcastingRe-cooling of thermoelectric modules,i.e. for cooling laser diodes or reagentsCooling of batteries <strong>and</strong> Power Electronics inElectric- <strong>and</strong> Hybride Vehicles<strong>Heat</strong> Sinks 07

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsExceptional PerformanceWebra uses patented <strong>and</strong> protected technologies in order to optimize the geometry of heat sink profiles. Significantparameters for the unrivalled performance in the industry are:Surface enlargementfor heat transfer <strong>and</strong> adjusted flow crosssection for pressure drop minimizationUnhindered heat conductionfrom the heat sources to the fin surfacePerformanceverified in the wind tunnel08 <strong>Heat</strong> Sinks

Safety <strong>and</strong> long lifeThe patented heat sink profiles are manufactured froma single aluminum extrusion. They offer a significantadvantage compared to competitors’ profiles that havethermal resistances at the joints of pressed-in, rolled-inor glued-in fins <strong>and</strong> thus experience the risk of aging <strong>and</strong>performance loss.Webra’s safe construction made of a single piece is withoutrisk, its high thermal performance always remains the same.Webra’s safe constructionmade of a single piece, unhindered heat flowCompetitors’ constructionwith rolled-in fins, risk of aging, looseningof fins <strong>and</strong> performance loss<strong>Heat</strong> Sinks 09

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsDimensioning using numerical methodsThermal simulation with computational fluid dynamics (CFD)allows the engineer to dimension his system in great detail.Especially in complex systems life expectancy of electroniccomponents, space, mass <strong>and</strong> cost may be optimized.The analysis of temperatures <strong>and</strong> air flows allows to taketargeted measures such as adjusting air flow, positioningof power components, dimensioning of heat <strong>sinks</strong> <strong>and</strong> fans<strong>and</strong> others. <strong>AMS</strong> <strong>Technologies</strong> conducts thermal simulationsince 2000 <strong>and</strong> has authored more than 200 reports forcustomers.Homogeneous temperature distribution is achieved in despite of asymmetricalair flow using fine tuned air baffles. Computed with Coolit © from Daat Research.10 <strong>Heat</strong> Sinks

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsOverview: heat <strong>sinks</strong>Webra ProfileWidth x HeightW × H mm²Weightkg / mLength testheat sink mmFlow rate@Δp 1 <strong>Heat</strong> sources 2wind tunnel testRth for referenceoperationalconditions °C/WPageW-62-51-9-16 63 × 62 5.7 75 w/ 60×60 axial fan 40 x 40 mm 2 0.292 13W-91-19-7-30 92 × 26 4.7 100 8 l/s @ 70 Pa Ø 25 mm 0.225 14W-92-81-10-13 92 × 92 12.8 120 20 l/s @ 50 Pa Ø 85 mm 0.15 15W-98-19-6-38 100 × 26 4.4 100 8 l/s @ 70 Pa Ø 25 mm 0.208 16W-109-70-9-26 111 × 80 14.3 100 35 l/s @ 30 Pa Ø 52 mm 0.082 17W-137-37-10-28 137 × 47 7.3 200 50 l/s @ 240 Pa 62 × 122 (2×) 0.058 18W-148-35-10-21 150 × 46 11.6 120 25 l/s @ 70Pa Ø 52 mm (2×) 0.091 19W-150-44-11-22 150 × 55 14.2 200 35 l/s @ 150 Pa Ø 52 mm (2×) 0.065 20W-155-60-15-16 160 × 75 21.0 200 40 l/s @ 80 Pa 130 × 140 mm 2 0.053 21W-172-62-13-24 172 × 75 20.2 200 85 l/s @ 300 Pa 130 × 140 mm 2 0.030 22W-175-44-11-26 175 × 55 16.6 200 42 l/s @ 150 Pa Ø 52 mm (2×) 0.051 23W-194-60-15-20 200 × 76 26.0 200 80 l/s @ 105 Pa 182 × 146 mm 2 0.030 24W-198-62-12-28 210 × 75 23.6 200 80 l/s @ 170 Pa 182 × 146 mm 2 0.027 25W-209-60-15-22 210 × 75 26.6 200 80 l/s @ 170 Pa 182 × 146 mm 2 0.030 26W-209-60-15-34 210 × 75 26.0 200 120 l/s @ 425Pa 182 × 146 mm 2 0.022 28W-209-60-15-41 215 × 75 25.0 200 100 l/s @ 180 Pa 140 × 190 (2×) 0.019 29W-209-61-15-50 210 × 76 25.0 200 80 l/s @ 125 Pa 182 × 146 mm 2 0.028 31W-209-75-17-21 210 × 92 31.5 200 80 l/s @ 100 Pa Ø 85 mm 0.052 32W-210-60-16-18 212 × 66 24.7 200 110 l/s @ 100 Pa 182 × 146 mm 2 0.035 33W-229-50-12-29 230 × 62 19.9 200 100 l/s @ 275 Pa 190 × 140 (2×) 0.017 34W-240-64-15-23 240 × 79 26.0 400 270 l/s @ 760 Pa 90 × 270 (3×) 0.011 35W-275-73-15-26 275 × 89 38.2 200 160 l/s @ 155 Pa 130 × 142 (2×) 0.023 37W-343-35-12-40 345 × 48 26.0 200 80 l/s @ 170 Pa Ø 25 mm (9×) 0.031 38W-351-41-10-83 360 × 50 22.0 400 Ebm D2E @ 100 Pa 90 × 270 (3×) 0.015 39W-473-44-11-70 476 × 56 44.8 200 120 l/s @ 170 Pa Ø 52 mm (6×) 0.019 40W-GTM-45 152 × 45 2.6 kg/pc. 180 15 l/s @ 350 Pa Ø 100 mm (2×) 0.065 41W-GTL-75 152 × 75 3.9 kg/pc. 180 60 l/s @ 700 Pa Ø 100 mm (2×) 0.023 42W-GTK-105 152 × 105 5.25 kg/pc. 180 80 l/s @ 550 Pa Ø 100 mm (2×) 0.020 431selected values for quick selection 2uniform heat sources12 <strong>Heat</strong> Sinks

W-62-51-9-16Product DimensionsPerformance L = 75<strong>Heat</strong> Sinks 13

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-91-19-7-30Product DimensionsPerformance L = 10014 <strong>Heat</strong> Sinks

W-92-81-10-13Product DimensionsPerformance L = 1205<strong>Heat</strong> Sinks 15

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-98-19-6-38Product DimensionsPerformance L = 10016 <strong>Heat</strong> Sinks

W-109-70-9-26Product DimensionsPerformance L = 100<strong>Heat</strong> Sinks 17

W-148-35-10-21Product DimensionsPerformance L = 120<strong>Heat</strong> Sinks 19

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-150-44-11-22Product DimensionsPerformance L = 20020 <strong>Heat</strong> Sinks

W-155-60-15-16Product DimensionsPerformance L = 200<strong>Heat</strong> Sinks 21

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-172-62-13-24Product DimensionsPerformance L = 200 (Graph for L=360 available, please contact <strong>AMS</strong> <strong>Technologies</strong> sales team)22 <strong>Heat</strong> Sinks

W-175-44-11-26Product DimensionsPerformance L = 200<strong>Heat</strong> Sinks 23

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-194-60-15-20Product DimensionsPerformance L = 200 (Graph for L=300 available, please contact <strong>AMS</strong> <strong>Technologies</strong> sales team)24 <strong>Heat</strong> Sinks

W-198-62-12-28Product DimensionsPerformance L = 200<strong>Heat</strong> Sinks 25

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-209-60-15-22Product DimensionsPerformance L = 20026 <strong>Heat</strong> Sinks

W-209-60-15-22 ContinuationProduct DimensionsPerformance L = 200, L = 280, L = 360<strong>Heat</strong> Sinks 27

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-209-60-15-34Product DimensionsPerformance L = 20028 <strong>Heat</strong> Sinks

W-209-60-15-41Product Dimensions209 ± 1.5(40x) 5.176016 B efore machining210-240Performance L = 200Rth °C/kWh-aPressure dropPa7065605550500450400350300200140220190452504020035150751530100209255020040 50 60 70 80 90 100 120 140 160 200*5 10 15 20 Air velocity m/s* 20°C 1013 hPa (mbar)<strong>Heat</strong> Sinks 29

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-209-60-15-41 ContinuationPerformance L = 360Rth °C/kWh-a605040Pressure dropPa700600500400300751536014022151901Air flow200Comp. 2209301000Comp. 150 60 70 80 90 100 120 1405 10 15 20 Air velocity m/s* 20°C 1013 hPa (mbar)160*Performance L = 360 <strong>Heat</strong> sink performance compared to other W-209 profilesRth °C/kWh-a60250324041341Comp. 1Comp. 232 1 4Pressure dropPa700600500400300X Y36014022151901Air flow3050 60 70 80 90 100 120 1405 10 15 20 Air velocity m/s1602001000*209Cooler1 W-209-60-14-222 W-209-61-15-503 W-209-60-15-344 W-209-60-15-41* 20°C 1013 hPa (mbar)30 <strong>Heat</strong> Sinks

W-209-61-15-50Product DimensionsPerformance L = 200<strong>Heat</strong> Sinks 31

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-209-75-17-21Product DimensionsPerformance L = 20032 <strong>Heat</strong> Sinks

W-210-60-16-18Product DimensionsPerformance L = 200<strong>Heat</strong> Sinks 33

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-229-50-12-29Product DimensionsPerformance L = 360 (Graph for L=200 available, please contact <strong>AMS</strong> <strong>Technologies</strong> sales team)34 <strong>Heat</strong> Sinks

W-240-64-15-23Product Dimensions240.3±1.510.656416.5 B efore machining240-270Performance L = 400Rth °C/kWh-aComp. 2Comp. 3Comp. 1 120Comp. 2 110Comp. 1 1009080Air duct 2Air duct 1Pressure dropPa21001900170015001300791540090270250123Air flow7060501100900700Fan240Air duct 250Air duct 14030500300Fan400Air duct 266 66152020100110400135406080 100 120140160 180 200 240280 320 *510152025Air velocity m/s* 20°C 1013 hPa (mbar)<strong>Heat</strong> Sinks 35

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-240-64-15-23 ContinuationProduct Dimensions240.3±1.510.656416.5 B efore machining240-270Performance L = 400FanAir duct 140066FanAir duct 2110 13540066152040090270250123Rth h-a°C/kWFanRE22P-2DK.3F.1Rebm D2E135-AM47-70Pressuredrop (Pa)910280Air duct11Comp.127.439.1Comp.231.348.1Comp.334.255.1RD135-2EP.WC.2RRE22P-2DK.3F.1Rebm D2E135-AM47-709876024012256.630.244.170.932.951.379.733.153.9RD135-2EP.WC.2R942 63.8 73.6 77.3RE22P-2DK.3F.1Rebm D2E135-AM47-70RD135-2EP.WC.2R4201004033330.544.968.527.740.663.530.544.968.5Rem. Ambient air temerature before fan.7915240Air duct 250Air duct 366Fan140 120 14036 <strong>Heat</strong> Sinks

W-275-73-15-26Product DimensionsPerformance L = 200<strong>Heat</strong> Sinks 37

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-343-35-12-40Product DimensionsPerformance L = 200 (Graph for different configurations of components available, please contact <strong>AMS</strong> <strong>Technologies</strong> sales team)38 <strong>Heat</strong> Sinks

W-351-41-10-83Product Dimensions350.52±2(82x) 4.2640.512 (B efore machining)353-380Performance L = 320Rth °C/kWh-a/ Comp.Pressure dropPa706662585450045040035030041.51035150462502001404238150100Air flow2001303430500360P = 1kW / Comp.50 60 70 80 90 100 110 130 1505 10 15 Air velocity m/s** 20°C 1013 hPa (mbar)<strong>Heat</strong> Sinks 39

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-473-44-11-70Product DimensionsPerformance L = 20040 <strong>Heat</strong> Sinks

W-GTM-45Product DimensionsOptions:- A: no bus bar- B: 1 bus bar- C: 2 bus barsAnodized Nickel platedPerformance L = 180<strong>Heat</strong> Sinks 41

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsW-GTL-75Product DimensionsOptions:- A: no bus bar- B: 1 bus bar- C: 2 bus barsAnodized Nickel platedPerformance L = 18042 <strong>Heat</strong> Sinks

W-GTK-105Product DimensionsOptions:- A: no bus bar- B: 1 bus bar- C: 2 bus barsAnodized Nickel platedPerformance L = 180<strong>Heat</strong> Sinks 43

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsAluminum cooler plates friction stir weldedWater Coolers for Power SemiconductorsPower electronics engineers across Europe develop newconverter/ inverter systems for renewable energy, transportation,defense, energy transmission <strong>and</strong> industrial applications. Yourgoals of increasing power densities <strong>and</strong> utilizing newly launchedIGBT modules <strong>and</strong> innovative concepts frequently benefit fromcustomized cooling solutions. Webra <strong>and</strong> <strong>AMS</strong> <strong>Technologies</strong> areproud to offer leading edge thermal solutions <strong>and</strong> products.(6 ×) 62 mm module coolerWater <strong>coolers</strong> for IGBT modulesAluminum <strong>water</strong> <strong>coolers</strong> for IGBT modules 140x190, 130x 140,Infineon PrimePACK2 <strong>and</strong> PrimePACK3, EconoPACK3, SemikronSKiiP3 <strong>and</strong> SKiiP4, SKiM63 <strong>and</strong> 93, Semipack2, Fuji Electric HighPower 6-Pack, Mitsubishi Mega Power Dual IGBT <strong>and</strong> others areavailable in st<strong>and</strong>ard configurations. Thermo- <strong>and</strong> fluid dynamicbehavior may be tailored to your set of IGBT modules. Webra aluminum<strong>water</strong> <strong>coolers</strong> utilize modern extrusions <strong>and</strong> safe sealswith friction stir welding.PrimePack 3* coolerWater <strong>coolers</strong> for press-pack discsA uniform pressure distribution is vital for your press pack discs.Webra’s unique makes of aluminum FSW <strong>water</strong> <strong>coolers</strong> offer arigid construction, perfectly flat surfaces for ideal contact <strong>and</strong>excellent performance. The press pack <strong>coolers</strong> are suitable for4”, 5” <strong>and</strong> 6” discs. Different options for disc centering <strong>and</strong> toolsfor replacement are available.Press-pack cooler44 Cooler Plates

Cooler selection by semiconductor componentSemiconductorcomponentDrill patternWater-glycol cooler(vattenkylare-L-W-H)Number ofcomponents2Flow rate,pressure drop 1Rth K / kW / Comp(ref. temp.) 33” or 4” discs - VK-145-135-26 2 × 6 l / min, 100 kPa 5.3 (n.s.)5” or 6” discs - VK-165-150-25 2 × 10 l / min, 125 kPa 3.3 (inlet) 4662 mm housing 48 × 93EconoPACK 3” 50 × 110VK-350-150-25 2 × (2 ×) 7.5 l / min, 120 kPa 5.0 (inlet)VK-280-215-24 3 × 10 l / min, 90 kPa 16.4 (n.s.)VK-305-300-15 8 × 6 l / min, 100 kPa < 43 (inlet)VK-370-230-28 6 × 50 l / min oil, 200 kPa < 50 (n.s.)VK-440-W-33 8 × 30 l / min, 50 kPa < 20 (n.s.)VK-300-280-20 6 × 16 l / min, 27 - 32 kPa 16 - 20 (n.s.)VK-430-150-20 6 × 16 l / min, 50 - 70 kPa < 18 (outlet)EconoPACK +, 122 × 162 110 × (50 × 3) VK-1400-W-20 14 × 40 l / min, 110 kPa 5.2 (average)PrimePACK2 89 × 172 73 × (39 × 4)PrimePACK3 89 × 250SKiiP373 × (39 × 6)SpecialVK-440-200-18 3 × 10 l / min, n.s. (n.s.)VK-L-260-18 7 × 25 l / min, 65 kPa 9.2 (average)PageVK-550-180-20 6 × 16 l / min, 50 kPa 20.2 (inlet) 53VK-L-400-18 Custom 30 l / min, 50 - 100 kPa < 5 (n.s.)VK-369-299-22 3 × 7 l / min, 50 kPa < 15 (inlet)VK-370-300-22-E 3 × 20 l / min, 70 kPa 6.6 (average) 47VK-691-300-22 6 × 20 l / min, 100 - 130 kPa 6 (average) 48VK-L-400-18 Custom 30 l / min, 50 - 100 kPa < 5 (n.s.)VK-360-215-26 8 × 25 l / min, 100 kPa n.s.VK-390-215-18 4 × 12 l / min, 45 kPa 5.3 (inlet)SKiiP4 Special VK-360-215-18 4 × 12 l / min, 50 kPa 6 (inlet) 49SKiM63 120 × 160 101 × (50 × 3) VK-400-265-33 2 × 50 l / min oil, 200 kPa < 17 (inlet)SKiM93 150 × 160 137 × (50 × 3) VK-400-265-33 2 × 50 l / min oil, 200 kPa < 17 (inlet)130 × 140 124 × (57 × 2)140 × 190 124 × (57 × 3)Mitsubishi 150 × 166(contact area 150 × 129,5)137,5 × (38 - 42,5 - 38)VK-L-534-56 6 × 30 l / min, 80 kPa 7.7 (n.s.)VK-L-400-18 Custom 30 l / min, 50 - 100 kPa < 5 (n.s.)VK-280-185-21 1 × 5 l / min, 50 kPa < 6.3 (inlet)VK-430-150-22 2 × 10 l / min, 40 kPa 6.4 (outlet) 508 - 15 l / min, 70 - 200VK-480-394-22 4 ×3 - 6 (n.s.)kPaVK-500-460-24 4 × 20 l / min, 140 kPa 5 (n.s.)6 - 18 l / min, 30 - 160VK-560-222-27 2 ×3 (n.s.)kPaVK-600-400-28 8 × 30 l / min, n.s. < 10 (inlet)VK-640-570-23 6 × 30 l / min, 60 kPa < 10 (inlet)VK-852-200-20 6 × 20 l / min, 130 kPa 8.5 (average) 51VK-920-400-20 16 × 20 l / min, 220 kPa 6.6 (average) 52VK-540-150-12 4 × 20 l / min, 50 kPa < 5 (n.s.)VK-550-180-20 6 × 16 l / min, 50 kPa 13.8 (inlet) 53VK-L-200-20 Custom 20 l / min, 100 kPa < 5 (average)1 selected values for quick selection, often at 2/3 of recommended maximum flow 2 uniform heat sources 3 Rth at conditions as in (1),EasyPACK, EconoPIM, EconoPACK <strong>and</strong> PrimePACK are trademarks of Infineon <strong>Technologies</strong>SKiiP <strong>and</strong> SKiM are trademarks of SemikronDefinitionsRth h-w /Comp (inlet) = (T max, cooler – T fluid, inlet) / P (Comp)Rth h-w /Comp (average) = (T max, cooler – (T fluid, inlet + T fluid, outlet)/2) / P (Comp)Rth h-w /Comp (outlet) = (T max , cooler – T fluid, outlet) / P (Comp)Performance curves <strong>and</strong> mechanical drawings upon requestCooler Plates 45

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsVK-165-150-25-A PressPack Ø125 mm, Ø 85 mmProduct DimensionsØ24G 3/8"Ø24G 3/8"11020Ø125c 0.010901652575150PerformanceRthh-w (inlet)87.576.56°C/kWFig 1.Pressure dropkPa300250200150100Inlet <strong>water</strong> 45°CWater with 50% GlycolThermal unbalanceAbove surfaces 0.5°C/kWBetween surfacesT <strong>water</strong>25.550501655Rth °C/kWh-w (inlet)5.554.543.532.55667 8 9 10 11 1214Water flow l/minFig 2.7 8 9 10 11 1214Water flow l/minPressure dropkPa300250200150100500Side BSide A+B2Side AFig 1.Fig 2.150P1/2 PSide ASide B1/2 PComp. Ø125Comp. Ø125WaterinletComp. Ø125Recommended max. <strong>water</strong> flow 15 l/min46 Cooler Plates

VK-370-300-22 (3 ×) PrimePack 3 (89 × 250)Product Dimensions5722300292.52270(42x)M5(4x) Ø7(2x) G 1/2"267228189200150111722833227.501707.541.5114.5148.5221.5255.5328.5362.5370PerformanceRth°C/kWh-w (average)Pressure dropkPa2298220200180160G1/2"78 78 787140T1T3T512061003002501 2 380T2T4T65604037042010 12 14 16 18 20 22 26 30 Water flow l/minWater with 50% GlycolMaximum recommended flow 30 l /minMeasuredT1 - T2 = - 0.2°C / kWT3 - T4 = +0.2°C / kWT5 - T6 = +0,1°C / kWCooler Plates 47

25030022<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsVK-691-300-22 (6 ×) PrimePack 3 (89 × 250)Product Dimensions57222270300292.5267(84x)M5(4x)Ø7(2x) G 1/2"2281891502001117228337.50172207.541.5114.5148.5221.5255.5328.5362.5435.5469.5542.5576.5649.5683.5691PerformanceRth °C/kWh-w (average)987220200180160140G1/2"78 78 7878 78 7812061001 2 34 5 6805604069142010 12 14 16 18 20 22 26 30 Water flow l/minWater with 50% GlycolMaximum recommended flow 30 l /min48 Cooler Plates

VK-360-215-18 SkiiP 4* (4 - fold)Product Dimensions5300c 0.02/100034.540628489.51618(215)360(28x) M4 Djup min 8R 1/4"190.5145.7584.252168.5 93096.5102124146151.5158.5164186208213.5220.5226248270275.53109Nr ÄndringMatrealVK-360-215-18-A + -B + -C (2x) O-ring EPDM 79.5x3PerformanceDatumSkala1:2Ritad avG ErikssonDatum07 08 07ABWEBRAINDUSTRIBenämningRitningsnr.KYLAREVK-360-215-18* SkiiP is a trademark of SemikronCooler Plates 49

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsVK-430-150-22 (2 ×) 140 × 190Product Dimensions12271.60.02M6 djup11 (16x)2722M10 x 1(150)137130014.571.5128.5185.5244.5301.5358.5415.5(430)PerformanceRthh-w (outlet)10/comp °C/kWPressure drop (kPa)10022843050190615014004 5 6 7 8 9 11 13 15Water-Glycol 50-50% ( l/min )50 Cooler Plates

VK-852-200-20 (3 ×) or double sided (6 ×) (140 × 190)Product Dimensionsc 0.02 / 200791767.5729672615558534.5481424367310286.523320 1837c 0.02 / 20024852(32x) M6 through20016238055 9025 25(2x) G 1/2"151761196223.5030Kund VB : LiebherrPerformanceNr ÄndringMatrealVK-852-200-22-B + P-22-22-GA + P-200-22-GB + (2x) O-ring 84.5x3 EPDMSkalaDatum1:2Ritad avDatumG Eriksson11 10 05AB WEBRAINDUSTRIBenämningRitningsnr.KYLARÄMNEVK-852-200-22-ARthh-w (average)1211109°C/kW/ Comp. (Both sides)/ Comp. (One side)kPa320280240Cooler VK-852-200-20-A no unbalance over <strong>and</strong> between comp.852820076160140120100190(2x) G 1/2"5802001406044085210 12 14 16Inlet <strong>water</strong> 45°CWater with 50% Glycol18 20 22 26Water flow l/minRecommended max. <strong>water</strong> flow 30 l/minCooler Plates 51

<strong>AMS</strong> <strong>Technologies</strong> | Thermal Management SolutionsVK-920-400-20 (8 ×) 140 × 190 or double sided (16 ×) 140 × 190Product Dimensions(64x) M6 through400352228172480920880799742685628603546489432407350293236211154974004020G 3/4"PerformanceRth °C/kWh-w (average)/ Comp. (Both sides)/ Comp. (One side)Pressure dropInk. coupling SPT 12kPaVK-920-400-20 no unbalance over <strong>and</strong> between comp.10836032028040202406200180160140G 3/4"190140120400410012 14 16 188020 22 24Water flow l/min40880Inlet <strong>water</strong> 45°CWater with 50% GlycolRecommended max. <strong>water</strong> flow 30 l/min52 Cooler Plates

VK-550-180-20 (3 ×) or double sided (6 ×) PrimePack 2 (89 × 172) or Mitsubishi (150 × 166)Product Dimensionsc 0.020c 0.020(24x) M6 Through(30x) M5 ThroughR 3/8"180168149.25129111.2530 1209068.755130.751201020026.567140164201.5242315339376.5417490514550Performance1 Hålbild ändrad 09 10 15Nr ÄndringMatrealVK-550-180-20-BERth °C/kWh-w (inlet)252423222120Rth/Comp. between hottest point ofcooler <strong>and</strong> inlet temperature of <strong>water</strong>6050SkalaPressure dropkPa100908070Datum1:2550Ritad avDatum89G ErikssonAB09 03 20 WEBRAINDUSTRI180172C 1 + C 4C 2 + C 5C 3 + C 6Test pointBenämningRitningsnr.Kund Z2MKYLAREVK-550-180-20-BA1940183020Water outlet17161520C3 + C610C2 + C510 11 12 13 14 15 16 17 19 21 23 Water flow l/minWater with 50% Glycol (45°)Maximum recommended flow 35 l/min0C1 + C4Water inlet (45°C)3 Comp. on both side of the coolerP at test 1 kW / Comp. = 6 kWCooler Plates 53

What can we do for you?Please contact us for further informationGermany<strong>AMS</strong> <strong>Technologies</strong> AG(Headquarters)Fraunhoferstr. 2282152 Martinsried – GermanyPhone +49 (0)89 895 77 0Fax +49 (0)89 895 77 199de_info@amstechnologies.comUnited Kingdom<strong>AMS</strong> <strong>Technologies</strong> Ltd.Unit 11, St Johns Business ParkLutterworth – United KingdomLeicestershire LE17 4HBPhone: +44 (0)1455 556360Fax: +44 (0)1455 552974uk_info@amstechnologies.comFrance<strong>AMS</strong> <strong>Technologies</strong> S.A.R.L.1, avenue de l’AtlantiqueZA Courtaboeuf91976 Les Ulis Cedex – FrancePhone: +33 (0)1 64 86 46 00Fax: +33 (0)1 69 07 87 19fr_info@amstechnologies.comItaly<strong>AMS</strong> <strong>Technologies</strong> S.r.l.Via San Bernardino, 4920025 Legnano – ItalyPhone +39 0331 596 693Fax +39 0331 590 732it_info@amstechnologies.comSpain<strong>AMS</strong> <strong>Technologies</strong> S.L.C/Muntaner, 200 Atico, 4a08036 Barcelona – SpainPhone: +34 93 380 84 20Fax: +34 93 380 84 21es_info@amstechnologies.comNordic<strong>AMS</strong> <strong>Technologies</strong> NordicBalticvägen 3151 38 Södertälje – SwedenPhone +46 (0)8 55 44 24 80Fax +46 (0)8 55 44 24 99nordic_info@amstechnologies.com• Optical <strong>Technologies</strong>• Power <strong>Technologies</strong>• Thermal Managementwww.amstechnologies.com© <strong>AMS</strong> <strong>Technologies</strong>. All rights reserved.