NEW K-FLEX® XM-332 - King Industries, Inc.

NEW K-FLEX® XM-332 - King Industries, Inc.

NEW K-FLEX® XM-332 - King Industries, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

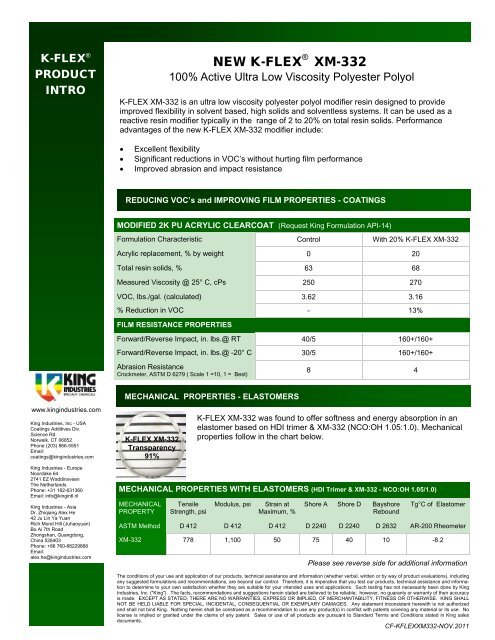

K-FLEX ®PRODUCTINTRO<strong>NEW</strong> K-FLEX ® <strong>XM</strong>-<strong>332</strong>100% Active Ultra Low Viscosity Polyester PolyolK-FLEX <strong>XM</strong>-<strong>332</strong> is an ultra low viscosity polyester polyol modifier resin designed to provideimproved flexibility in solvent based, high solids and solventless systems. It can be used as areactive resin modifier typically in the range of 2 to 20% on total resin solids. Performanceadvantages of the new K-FLEX <strong>XM</strong>-<strong>332</strong> modifier include:Excellent flexibilitySignificant reductions in VOC’s without hurting film performanceImproved abrasion and impact resistanceREDUCING VOC’s and IMPROVING FILM PROPERTIES - COATINGSMODIFIED 2K PU ACRYLIC CLEARCOAT (Request <strong>King</strong> Formulation API-14)Formulation Characteristic Control With 20% K-FLEX <strong>XM</strong>-<strong>332</strong>Acrylic replacement, % by weight 0 20Total resin solids, % 63 68Measured Viscosity @ 25° C, cPs 250 270VOC, lbs./gal. (calculated) 3.62 3.16% Reduction in VOC - 13%FILM RESISTANCE PROPERTIESForward/Reverse Impact, in. lbs.@ RT 40/5 160+/160+Forward/Reverse Impact, in. lbs.@ -20° C 30/5 160+/160+Abrasion ResistanceCrockmeter, ASTM D 6279 ( Scale 1 =10, 1 = Best)8 4MECHANICAL PROPERTIES - ELASTOMERSwww.kingindustries.com<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong> - USACoatings Additives Div.Science Rd.Norwalk, CT 06852Phone (203) 866-5551Email:coatings@kingindustries.comK-FLEX <strong>XM</strong>-<strong>332</strong>Transparency91%K-FLEX <strong>XM</strong>-<strong>332</strong> was found to offer softness and energy absorption in anelastomer based on HDI trimer & <strong>XM</strong>-<strong>332</strong> (NCO:OH 1.05:1.0). Mechanicalproperties follow in the chart below.<strong>King</strong> <strong>Industries</strong> - EuropeNoordake 642741 EZ WaddinxveenThe NetherlandsPhone: +31 182-631360Email: info@kingintl.nl<strong>King</strong> <strong>Industries</strong> - AsiaDr. Zhiqiang Alex He42 Ju Lin Ya YuanRich Mond Hill (Juhaoyuan)Bo Ai 7th RoadZhongshan, Guangdong,China 528403Phone: +86 760-88229866Email:alex.he@kingindustries.comMECHANICAL PROPERTIES WITH ELASTOMERS (HDI Trimer & <strong>XM</strong>-<strong>332</strong> - NCO:OH 1.05/1.0)MECHANICALPROPERTYTensileStrength, psiModulus, psiStrain atMaximum, %Shore A Shore D BayshoreReboundTg°C of ElastomerASTM Method D 412 D 412 D 412 D 2240 D 2240 D 2632 AR-200 Rheometer<strong>XM</strong>-<strong>332</strong> 778 1,100 50 75 40 10 -8.2Please see reverse side for additional informationThe conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of product evaluations), includingany suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and informationto determine to your own satisfaction whether they are suitable for your intended uses and applications. Such testing has not necessarily been done by <strong>King</strong><strong>Industries</strong>, <strong>Inc</strong>. ("<strong>King</strong>"). The facts, recommendations and suggestions herein stated are believed to be reliable; however, no guaranty or warranty of their accuracyis made. EXCEPT AS STATED, THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS OR OTHERWISE. KING SHALLNOT BE HELD LIABLE FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES. Any statement inconsistent herewith is not authorizedand shall not bind <strong>King</strong>. Nothing herein shall be construed as a recommendation to use any product(s) in conflict with patents covering any material or its use. Nolicense is implied or granted under the claims of any patent. Sales or use of all products are pursuant to Standard Terms and Conditions stated in <strong>King</strong> salesdocuments.CF-KFLEX<strong>XM</strong><strong>332</strong>-NOV.2011

SYSTEMSSB HS SL<strong>NEW</strong> K-FLEX ® <strong>XM</strong>-<strong>332</strong>K-FLEX <strong>XM</strong>-<strong>332</strong> is designed for use as a modifier for solventborne,high solids and solventless systems. It is recommended for use inair dry/force dry 2-component polyurethanes, blocked isocyanateand melamine baking systems.APPLICATIONS Coatings Adhesives Cast ElastomersGeneral IndustrialAutomotive OEM/RefinishPlastic CoatingsStructural AdhesivesElectronicsCast Elastomer PrepolymersSOLUBILITYK-FLEX <strong>XM</strong>-<strong>332</strong> SOLUBILITYAlcohols Soluble t-butyl acetate* SolubleGlycols Soluble Acetone* SolubleKetones Soluble Oxsol ® 100* SolubleEsters Soluble Aromatic Hydrocarbons SolubleK-FLEX <strong>XM</strong>-<strong>332</strong> &OXSOL ® 100*RATIO: 1:1Glycol ethers Soluble Aliphatic HydrocarbonsWaterInsolubleInsoluble*Exempt Solvents; Oxsol ® 100 is a of Makhteshim-Agan ofNorth America <strong>Inc</strong>.TYPICALPROPERTIESTYPICAL PROPERTIESAppearance Light colored liquid Hydroxyl # 260Active, % 100 Viscosity, cPs, 25°C 450APHA Color 30 Pounds per Gallon 9.0KINGFORMULATIONSAVAILABLE FORMULATIONFORMULATION API-142K PU ClearcoatRequest by emailing:coatings@kingindustries.comorinfo@kingintl.nlVisit <strong>King</strong>’s Coatings Additives Division at: www.kingindustries.com