NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>.Lubricant Additives DivisionSpecialty Additives and Synthetic Base Oilsfor Industrial & Automotive Lubricants, Greases,Metalworking Fluids and Rust Preventives<strong>NA</strong>-<strong>LUBE</strong> ® KR SeriesAlkylated NaphthaleneSynthetic Basestocks<strong>NA</strong>-<strong>LUBE</strong> ® ADTCAshless Dialkyldithiocarbamate<strong>NA</strong>-<strong>LUBE</strong> ® AO SeriesAntioxidants<strong>NA</strong>-<strong>LUBE</strong> ® AW SeriesAntiwear Additives<strong>NA</strong>-<strong>LUBE</strong> ® EP SeriesExtreme Pressure AdditivesK-CORR ® G SeriesSpecialty Additives for Grease<strong>NA</strong>-SUL ®Rust & Corrosion InhibitorsK-CORR ®Rust & Corrosion Inhibitors<strong>NA</strong>-<strong>LUBE</strong> ® BL SeriesAdditive Blends & PackagesPerformance Products Backed ByUnsurpassed Technical Service

<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>.Lubricant Additives Division<strong>King</strong> <strong>Industries</strong> offers a broad range of products for use in formulating high performanceindustrial and automotive lubricants, greases, metalworking fluids, and rust preventives.<strong>King</strong>’s product lines include:Synthetic Base Oils & Base Oil Modifiers<strong>NA</strong>-<strong>LUBE</strong> ® KR Series - Alkylated Naphthalene Base Oils and Base Oil Modifiers:The <strong>NA</strong>-<strong>LUBE</strong> KR Series represents the industry’s broadest range of alkylated naphthalenesynthetic basestocks. With decades of experience in alkylation, <strong>King</strong> offers a diverse range ofproducts with viscosities from 22 cSt to 190 cSt (40°C).Specialty Additives<strong>NA</strong>-<strong>LUBE</strong> ® EP 5000 Series - Extreme Pressure Additives:A series of light-colored, low odor sulfurized fatty acid esters/triglycerides, and sulfurized olefins/triglycerides for industrial and automotive lubricants, greases, and metalworking fluids. When usedin combination with ash-containing or ashless phosphorus-type antiwear and lubricity additives,these additives are outstanding alternatives to chlorinated paraffins in metalworking fluids.<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 Series - Antiwear Additives:These additives are based on amine salts of phosphoric acid and dithiophosphoric acid derivatives.Some of these additives are formulated with other components, offering synergistic antiwear,extreme pressure, and rust and corrosion protection.<strong>NA</strong>-<strong>LUBE</strong> ® ADTC - Ashless Dialkyldithiocarbamate:A multifunctional additive offering extreme pressure, antioxidant, and antiwear properties when usedin industrial and automotive lubricants and greases.<strong>NA</strong>-<strong>LUBE</strong> ® AO - Primary Antioxidants:Phenolic and aminic antioxidants that are effective stabilizers for a broad range of industrial andautomotive lubricants and greases. All products are ashless and non-corrosive, and offer excellentsolubility in petroleum and synthetic base oils.<strong>NA</strong>-SUL ® - Rust and Corrosion Inhibitors:A broad range of high performance rust and corrosion inhibitors based on dinonylnaphthalenesulfonic acid. They are supplied as metal or ashless salts in a variety of liquid and solid diluents.Applications include industrial and automotive lubricants, greases, metalworking fluids, and rustpreventives.K-CORR ® - Rust and Corrosion Inhibitors:Non-sulfonate rust and corrosion inhibitors that are effective in a broad range of industrial andautomotive lubricants, greases, and rust preventives. K-CORR inhibitors have demonstratedsynergistic performance with select antiwear/extreme pressure additives.K-CORR ® G Series - Rust Inhibitor Systems for Grease:The K-CORR G Series was specifically designed for greases subjected to severe conditions andoffers excellent rust protection and enhanced AW/EP properties.<strong>NA</strong>-<strong>LUBE</strong> ® BL - Blends - Multifunctional Additive Packages:Several specialized additive blends offering an alternative to individual component formulations.A complete overview of product offerings including new developmental products as well as technicaland application brochures can be found at <strong>King</strong>’s website:www.kingindustries.com

Table of ContentsIntroduction/<strong>King</strong> <strong>Industries</strong> Page 2<strong>NA</strong>-<strong>LUBE</strong> KR Series - Alkylated Naphthalenes Page 3<strong>NA</strong>-<strong>LUBE</strong> AW Series - Antiwear Additives Page 7<strong>NA</strong>-<strong>LUBE</strong> AO Series - Primary Antioxidants Page 12<strong>NA</strong>-<strong>LUBE</strong> ADTC - Ashless Dialkyldithiocarbamate Page 14<strong>NA</strong>-<strong>LUBE</strong> EP Series - Extreme Pressure Additives Page 15<strong>NA</strong>-SUL Rust & Corrosion Inhibitors Page 19<strong>King</strong> Product and Application ChartCenterfoldK-CORR Rust & Corrosion Inhibitors Page 32K-CORR G Series - Rust Inhibitor Systems for Grease Page 35HX-1 Registered Products Page 38<strong>NA</strong>-<strong>LUBE</strong> Blends Page 41Technical Support Page 49KING FACILITIESUSAWorld Headquarters<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>.Science RoadNorwalk, CT 06852Phone: 203-866-5551Fax: 203-866-0425E-mail:lad@kingindustries.comEUROPETechnical Sales Office<strong>King</strong> <strong>Industries</strong>International, <strong>Inc</strong>.Noordkade 642741 EZ WaddinxveenThe NetherlandsPhone: +31 182-631360Fax: +31 182-621002E-mail:dgartz@kingindustries.comASIA/PACIFICTechnical Service LabDr. Zhiqiang HeSynlico Tech(Zhongshan) Co., Ltd.106 Chuangye Building,Kang Le Ave.Torch DevelopmentZone,Zhongshan, ChinaPhone: +760-88229866Fax: +760-88229896E-mail:alex.he@kingindustries.com<strong>King</strong> <strong>Industries</strong>“Our passion has always been to provide innovative additive technology andvalue-added customized solutions to our customers worldwide.”- Richard S. <strong>King</strong>, PresidentFor close to eight decades, <strong>King</strong> <strong>Industries</strong> has been owned and operated by the <strong>King</strong> family inNorwalk, Connecticut. In the 1940’s, R. Gardner <strong>King</strong> and associate George Thielcke pioneeredthe development of a unique chemical, dinonlynaphthalenesulfonic acid, the salts of whichexhibited excellent rust inhibiting properties. Since then, <strong>NA</strong>-SUL sulfonate technology has beenunsurpassed with respect to rust and corrosion inhibition and demulsification properties inhigh-tech lubricants and greases.In the mid-1990’s, <strong>King</strong> <strong>Industries</strong> expanded its product offerings with the development ofK-CORR non-sulfonate rust and corrosion inhibitor technology and an extensive <strong>NA</strong>-<strong>LUBE</strong>product portfolio consisting of extreme pressure, antiwear, and antioxidant additives, as well asalkylated naphthalene base oils and multifunctional/synergistic blends.By offering comprehensive solutions to lubricant problems and a growing portfolio of the mostadvanced additive technologies, <strong>King</strong> <strong>Industries</strong> strives to provide its worldwide customers withthe ability to formulate the most cost-effective premium products in the marketplace.<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong> is proud to be:ISO 9001, 14001 and 18001 Certified

<strong>NA</strong>-<strong>LUBE</strong> ® KR Series - Alkylated NaphthalenesSynthetic Base Oils and Base Oil Modifiers<strong>NA</strong>-<strong>LUBE</strong> ® KR-Series - Alkylated NaphthalenesFor over 50 years, <strong>King</strong> has been a leader in the alkylation of naphthalenes, and today <strong>King</strong> is theproducer of the world’s broadest line of alkylated naphthalene synthetic fluids. Designated the<strong>NA</strong>-<strong>LUBE</strong> KR Series, these products are the ideal choice for use as base stocks to meet theindustry’s highest performance standards where high temperatures degrade petroleum basedproducts or as modifiers for non-polar base stocks, such as Group II oils, Group III oils, and PAO’s.Whether working to develop an innovative new product or to improve an existing product, the<strong>NA</strong>-<strong>LUBE</strong> KR Series can help formulators meet today’s ever-increasing demands placed onlubricants. This includes three new NSF HX-1 registered products that meet the requirements forincidental food contact as prescribed by FDA 21 CFR 178.3570 - <strong>NA</strong>-<strong>LUBE</strong> KR-006FG, KR-015FGand KR-029FG.<strong>NA</strong>-<strong>LUBE</strong> KR alkylated naphthalenes provide superior thermo-oxidative stability, excellent hydrolyticstability, and greater film thickness compared to alternative base fluids (see comparison tablebelow). In addition, the non-polar nature of the <strong>NA</strong>-<strong>LUBE</strong> KR products makes them superior to othersynthetic fluids in that there is no surface competition with additives.PROPERTY<strong>NA</strong>-<strong>LUBE</strong>KR SeriesPAOEstersMineral Oils(Group II & III)Thermo-Oxidative Stability Excellent Good Good to Excellent GoodThermal Stability Excellent Excellent Excellent ExcellentHydrolytic Stability Excellent Excellent Good ExcellentSeal Swell Good to Excellent Poor Excellent PoorViscosity Index Good Excellent Excellent Good to ExcellentAdditive Solubility Good to Excellent Poor Excellent PoorFilm Thickness Excellent Good Good Fair<strong>NA</strong>-<strong>LUBE</strong> ® KR Series Products - Typical Properties<strong>NA</strong>-<strong>LUBE</strong>Viscosity@ 40°CASTM D 445Viscosity@ 100°CASTM D 445ViscosityIndexCalculatedAnilinePointASTM D 611NoackVolatilityCEC L40PourPointASTM D 97FlashPointASTM D 92KR-007A 21.8 cSt 3.8 cSt 22 40°C 39%

Applications and Product CustomizationAs can be seen from the Typical Properties Chart, <strong>King</strong> <strong>Industries</strong> offers a range of products withdiverse viscosity and polarity (aniline point) that leads to their use in a multitude of applications.Ranging from low viscosity for automotive lubricants to high viscosity for industrial lubricants andgreases - all <strong>NA</strong>-<strong>LUBE</strong> KR Series products offer exceptional performance in thermal and oxidativestability, hydrolytic stability, low volatility, good solvency and seal swell capability.MonoestersDiestersPolyol Esters<strong>NA</strong>-<strong>LUBE</strong>KR-007ARelative Aniline Points of Various Base Oils<strong>NA</strong>-<strong>LUBE</strong>KR-008<strong>NA</strong>-<strong>LUBE</strong>KR-015<strong>NA</strong>-<strong>LUBE</strong>KR-019PAOGroup II and IIIMineral Oils-7 to 5°C 40°C 42°C 94°C 103°C 115 to 135°CAUTOMOTIVE LUBRICANTS<strong>NA</strong>-<strong>LUBE</strong> KR-007A KR-008 KR-015 KR-019Transmission Fluids • •Crankcase OilsApplicationsAutomotive Lubricants•Gear Oils • • •INDUSTRIAL LUBRICANTSApplicationsIndustrial LubricantsGreases<strong>NA</strong>-<strong>LUBE</strong> KR-007A KR-008 KR-015 KR-019 KR-023Chain Oils • • •Compressor Oils • •Gear Oils • •<strong>NA</strong>-<strong>LUBE</strong> ® KR-Series - Alkylated NaphthalenesGreases • • •Heat Transfer Oils • •H-1 Fluids KR-006FG, KR-015FG & KR-029FGHydraulic FluidsLow Temperature Applications••Paper Machine Oils • • •Pages 3-4Turbine OilsVacuum Oils••

<strong>NA</strong>-<strong>LUBE</strong> KR-Series Performance as a Base Oil<strong>NA</strong>-<strong>LUBE</strong> ® KR-Series - Alkylated NaphthalenesThe performance characteristic that sets the <strong>NA</strong>-<strong>LUBE</strong> KR-Series apart from other base oils is theirsuperior thermal-oxidative stability. Thermal-oxidative stability results from both the CEC-L-48-A-95Modified Bulk Oxidation Test and ASTM D 6186 Pressure Differential Scanning Calorimetry (PDSC)are shown to illustrate this point. Thermal-Oxidative Stability - Modified CEC-L-48-A-95 Bulk Oxidation Test<strong>NA</strong>-<strong>LUBE</strong> KR-015 and a variety of other base fluids were subjected to heat and oxygen in thepresence of metal catalysts. <strong>Inc</strong>reases in acid number and viscosity were monitored over time. Anincrease in acid number is indicative of oxidation and degradation of the base oil. As shown in thegraph below on the left, <strong>NA</strong>-<strong>LUBE</strong> KR-015 was the most stable of the six base oils tested. Likewise,it maintained its original viscosity better than all the other fluids tested including a 7 cSt Group IIIbase oil containing an antioxidant (graph on the right).Acid # (mg KOH/g)706050403020100<strong>Inc</strong>rease in Acid ValueColor Key to Base Oils:<strong>NA</strong>-<strong>LUBE</strong> KR-0150 20 40 60 80Time (hour) Thermal-Oxidative Stability - PDSC - (ASTM D 6168)PDSC - Induction Time With O 2Modified Bulk Oxidation Test ConditionsBase Oil PAO Group I Group II Group III500 grams @ 160°C for 72 hours with solubleFe and Cu catalysts and air purge at 15L/hr10009008007006005004003002001000% <strong>Inc</strong>rease in Viscosity0 20 40 60 80Time (hour)<strong>NA</strong>-<strong>LUBE</strong> KR-015 and KR-019 (neat) when tested at 200°C and 210°C using 500 psig O 2 resulted inthe following performance compared to other base stocks:<strong>NA</strong>-<strong>LUBE</strong>KR-015<strong>NA</strong>-<strong>LUBE</strong>KR-019Minutes @ 200°C

<strong>NA</strong>-<strong>LUBE</strong> KR-Series Performance as a Base Oil ModifierWhen used as base oil modifiers, the <strong>NA</strong>-<strong>LUBE</strong> KR Series can:Offer dramatic improvements in thermal-oxidative stability when used alone or in conjunctionwith antioxidantsBoost RPVOT performance of formulations containing highly refined mineral oilsImprove thermal stabilityThe first graph below compares the thermal-oxidative stability performance of <strong>NA</strong>-<strong>LUBE</strong> KR-015and a variety of other synthetic base oil modifiers when used at a 20% level in a 7 cSt Group III oil.RPVOT Rotating Pressurized Vessel Oxidation Test (ASTM D 2272) data follow showing theinfluence of modification levels and the addition of some common antioxidants. Thermal-Oxidative Stability - PDSC - (ASTM D 6186)PDSC Oxidation Induction Times(Isothermal at 160°C with 150 psi air pressure)2520151050No Modifier KR-015 Diester Polyol Ester PAO Thermal-Oxidative Stability - RPVOT - (ASTM D 2272)Induction TimeBlends of 20% Synthetic Base Oils in 7 cSt Group III OilRPVOT of <strong>NA</strong>-<strong>LUBE</strong> KR-015in a 7 cSt Group III Oil90807060504030201000 25% 50% 75% 100%% <strong>NA</strong>-<strong>LUBE</strong> KR-015Induction Time600500400300200100The chart to the left shows oxidativeinduction times for blends containing20% of various synthetic base oils and<strong>NA</strong>-<strong>LUBE</strong> KR-015 in a 7 cSt Group IIIoil as measured by PDSC - PressureDifferential Scanning Calorimetry.As can be seen, <strong>NA</strong>-<strong>LUBE</strong> KR-015significantly outperforms the other fluidstested - PAO, diester and polyol esterbase oils.0Effect of 0.2% Antioxidant AdditionNoneDTBP<strong>NA</strong>-<strong>LUBE</strong>AO-210ZnDTPDPA<strong>NA</strong>-<strong>LUBE</strong>AO-1427 cSt Group III <strong>NA</strong>-<strong>LUBE</strong> KR-015<strong>NA</strong>-<strong>LUBE</strong> ® KR-Series - Alkylated NaphthalenesAs shown above, <strong>NA</strong>-<strong>LUBE</strong> KR-015 was testedat various concentrations in a 7 cSt Group IIIbase oil to track its influence on RPVOTperformance.<strong>NA</strong>-<strong>LUBE</strong> KR-015 can impart dramaticimprovements in thermo-oxidative stability whenused as a base oil modifier. Testing was donewithout the addition of additives or stabilizers.Both <strong>NA</strong>-<strong>LUBE</strong> KR-015 and a 7 cSt Group III oilwere tested to determine the effect of adding0.2% of various antioxidants to the base oils.As shown in the graph above, significantimprovements to the thermal-oxidative stability(induction time) were obtained using the<strong>NA</strong>-<strong>LUBE</strong> KR-015.Pages 5-6

<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 Series - Ashless Antiwear Additives<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 SeriesAshless Multifunctional Antiwear AdditivesThe <strong>NA</strong>-<strong>LUBE</strong> AW 6000 Series consists of light-colored, 100% active antiwear additives basedon various phosphorous, nitrogen and sulfur chemistries. With the exception of AW-6010, all aremultifunctional in terms of providing excellent antiwear properties in combination with other propertyenhancing functions as shown in the chart that follows. Performance details are shown on pages9-11.Product % P % N % S Description Functions<strong>NA</strong>-<strong>LUBE</strong>AW-6010<strong>NA</strong>-<strong>LUBE</strong>AW-6110<strong>NA</strong>-<strong>LUBE</strong>AW-6110P<strong>NA</strong>-<strong>LUBE</strong>AW-6220<strong>NA</strong>-<strong>LUBE</strong>AW-6310<strong>NA</strong>-<strong>LUBE</strong>AW-6330<strong>NA</strong>-<strong>LUBE</strong>AW-6360<strong>NA</strong>-<strong>LUBE</strong>AW-6400FG5.3 4.8 -8.2 1.8 -5.3 3.7 -4.5 5.7 -4.2 3.0 9.14.5 - 10.05.0 2.6 10.88.3 2.4 -Amine phosphate with excellent antiwear properties atvery low treat levels.Amine phosphate with excellent antiwear properties andexcellent rust protection. Imparts outstanding FZGperformance (higher than 12 load stages) at low treatlevels (0.10 – 0.15%).Amine phosphate with excellent antiwear properties andexcellent rust protection. Can be used with <strong>NA</strong>-<strong>LUBE</strong>EP-5216 as an alternative to chlorinated paraffins.Complex composition of amine phosphate chemistrieswith excellent antiwear properties, excellent rustprotection and yellow metal deactivating functionality.Outstanding FZG performance at low treat levels.Multifunctional composition with excellent extremepressure/antiwear properties, excellent rust protection,yellow metal deactivating functionality and demulsificationproperties. Imparts outstanding FZG performance(higher than 12 load stages) at low treat levels(0.15 – 0.20%).Multifunctional additive with excellent extreme pressure/antiwear and antioxidation properties. Can be used asan ashless alternative to zinc dialkyldithiophosphates inindustrial lubricants, greases, and metalworking fluids.Multifunctional additive with excellent extreme pressure/antiwear and outstanding steel corrosion inhibitingproperties.NSF HX-1 approved multifunctional additive - please seepage 40 for details.AWAW, CIAW, CIAW, CI, YMDAW, CI, YMDEP/AW, AO, CIEP/AW, CIEP/AW, CI<strong>NA</strong>-<strong>LUBE</strong> AW technology offers excellent antiwear and FZGperformance coupled with rust and corrosion inhibition.Photos:Far Left: Base Oil without any additivesImmediate Left: Base Oil with <strong>NA</strong>-<strong>LUBE</strong> AW technologyThe <strong>NA</strong>-<strong>LUBE</strong> AW 6000 product line of unique ashless chemistries exhibits the following properties: Excellent antiwear and extreme pressure (FZG) performance Good rust and corrosion inhibition Protection of non-ferrous metals Good to excellent demulsification Solubility in a wide range of base oils, including silicone fluids Synergy with other additives(e.g., <strong>King</strong> <strong>Industries</strong>’ <strong>NA</strong>-<strong>LUBE</strong> EP and K-CORR Series) Good hydrolytic stability

Because of their multifunctionality, the <strong>NA</strong>-<strong>LUBE</strong> AW 6000 Products are used in:SolubilityScrew Compressor Oils <strong>NA</strong>-<strong>LUBE</strong> AW-6310 is strongly recommended for high performance screwcompressor oils.Rust and Oxidation OilsAutomotive Gear OilsIndustrial Gear Oils <strong>NA</strong>-<strong>LUBE</strong> AW-6110 in combination with well selected sulfur carriers (SIBtechnology/sulfurized esters) has proven to be an excellent antiwear additivefor formulating industrial gear oils requiring excellent performance in theFAG-FE8 test. <strong>NA</strong>-<strong>LUBE</strong> AW-6310 is strongly recommended for industrial gear oils.Automatic and Manual Transmission FluidsSlide Way OilsHydraulic Fluids <strong>NA</strong>-<strong>LUBE</strong> AW-6310 is strongly recommended for ashless HF-2 typehydraulic fluids.GreasesApplications for the<strong>NA</strong>-<strong>LUBE</strong> AW 6000 SeriesFood Grade Lubricants <strong>NA</strong>-<strong>LUBE</strong> AW-6400FG is NSF HX-1 registered and complies withFDA 21 CFR 178.3750.“Neat Oil” Metalworking Fluids The <strong>NA</strong>-<strong>LUBE</strong> AW 6000 Series can also be used in combination with the<strong>NA</strong>-<strong>LUBE</strong> EP 5000 Series for formulating heavy-duty chlorine-free “neatoil” metalworking fluids. <strong>NA</strong>-<strong>LUBE</strong> AW-6010 and AW-6220 are specifically designed for “neat oil”metalworking fluids, such as high-speed grinding fluids based on mineraloil or synthetic esters.Multifunctional Fluids (Hydraulic/Metalworking Fluids) <strong>NA</strong>-<strong>LUBE</strong> AW-6310 in combination with inactive sulfurized products andaminic/phenolic antioxidants can be used to formulate multifunctional fluids(hydraulic fluid/metalworking fluid) based on Group I-V base oils, includingcanola and sunflower oils.The <strong>NA</strong>-<strong>LUBE</strong> AW 6000 Series exhibits excellent solubility in a wide range of base oils, includingnaphthenic oils, solvent refined Group I base oils, hydrotreated Group II base oils, Group III baseoils, polyalphaolefins, synthetic diesters, and silicone fluids (i.e., Dow Corning 200, 510, and 550).<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 Series - Ashless Antiwear AdditivesPages 7-8

<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 Series - Ashless Antiwear Additives Performance in a Paraffinic ISO VG 46 Base OilThe following table shows the performance of <strong>NA</strong>-<strong>LUBE</strong> AW-6010, AW-6110, and AW-6220 whenadded to a paraffinic ISO VG 46 base oil.TestsBase Oil0.25%AW-60100.10%AW-6110ISO VG 46 (Group II)0.10%AW-6220Steel Corrosion (ASTM D 665, DIN 51 585) A & B Not Applicable Pass PassDemulsibility (ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (Minutes)Copper Corrosion (ASTM D 130, DIN 51 759)3 hours, 100°C24 hours, 100°C3 hours, 135°C42-38-0101a1b1b41-39-0101a1b1b41-39-05FZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage >12 >12 12Four Ball Wear (ASTM D 4172)1 hour, 75°C, 1200 rpm, 30 kgf, Scar Diameter (mm)1 hour, 75°C, 1200 rpm, 40 kgf, Scar Diameter (mm)Performance of the<strong>NA</strong>-<strong>LUBE</strong> AW 6000 Series0.460.640.320.50 Performance of <strong>NA</strong>-<strong>LUBE</strong> AW-6220 as a Yellow Metal Deactivator<strong>NA</strong>-<strong>LUBE</strong> AW-6220 also acts as a yellow metal deactivator. The table below compares theperformance of <strong>NA</strong>-<strong>LUBE</strong> AW-6220 to the performance of two common yellow metal deactivators.As the data show, at a treat level of 0.10%, <strong>NA</strong>-<strong>LUBE</strong> AW-6220 provides excellent yellow metalprotection while also providing steel corrosion protection with good antiwear properties.Tests --Base OilISO VG 46 * +100 ppm Sulfur**0.10% DMTD***DerivativeISO VG 46 +100 ppm Sulfur0.10%TolytriazoleISO VG 46 +100 ppm Sulfur1a1b1b0.400.430.10%<strong>NA</strong>-<strong>LUBE</strong> AW-6220ISO VG 46 +100 ppm SulfurSteel Corrosion(ASTM D 665, DIN 51 585) A & B Fail Fail Fail PassCopper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 120ºC24 hours, 120ºC3 hours, 135ºC24 hours, 135°C4a4b4b4b4bFour Ball Wear(ASTM D 4172)Scar Diameter (mm)1 hour, 75°C, 1200 rpm, 40 kgf 0.75 0.66 0.71 0.50Four Ball Weld Load(ASTM D 2783)10 second, 25ºC, 1800 rpmOK Load (kgf)Weld Load (kgf)1001201b1b3a1b3b1401601b1b3a1b3a1401601b1b3a1b3a140160* Hydrotreated paraffinic oil (Group II) with less than 0.03% natural sulfur ** Elemental sulfur soluble in Group II oil***Dimercaptothiadiazole

Enhancing the Antiwear Performance of Extreme Pressure Agents<strong>NA</strong>-<strong>LUBE</strong> AW-6010 in Combination with <strong>NA</strong>-<strong>LUBE</strong> EP-5218Sulfurized EP agents typically provide very good extreme pressure properties and moderateantiwear properties when used alone. One of the unique performance characteristics of an aminephosphate, such as <strong>NA</strong>-<strong>LUBE</strong> AW-6010, is the ability to improve the antiwear performance of wellselected sulfurized extreme pressure agents. As depicted below, the addition of 2.0% <strong>NA</strong>-<strong>LUBE</strong>AW-6010, reduces the scar diameter from 0.81 mm to 0.51 mm. However, additional <strong>NA</strong>-<strong>LUBE</strong>AW-6010 to approximately 6% is required to return the weld load back to the starting level of>300 kgf.Different Levels of <strong>NA</strong>-<strong>LUBE</strong> AW-6010 in Group II Oil containing 10% <strong>NA</strong>-<strong>LUBE</strong> EP-5218Four Ball Wear Test (ASTM D 4172) - 1 hour, 75ºC, 40 kgf, 1200 rpm, - Four Ball Weld (ASTM D 2783) - 10 seconds, 25°C, 1800 rpmWeld Load (kgf)3503002502001501005000% 1% 2% 3% 4% 5% 6% 7% 8% 9% 10%% <strong>NA</strong>-<strong>LUBE</strong> AW-6010 <strong>NA</strong>-<strong>LUBE</strong> AW-6330 as an Ashless Alternative to Zinc Dialkyldithiophosphates<strong>NA</strong>-<strong>LUBE</strong> AW-6330 Comparison to ZnDTPAs shown below, <strong>NA</strong>-<strong>LUBE</strong> AW-6330 is an excellent ashless alternative to zinc dialkyldithiophosphates. Itoffers outstanding performance in Group I, II and synthetic base stocks.TestsBase Oil1.0%AW-63301.0%ZnDTP*WeldWear1.0% AW-63300.35% Blend**Steel Corrosion (ASTM D 665, DIN 51 585) A & B Pass Pass PassDemulsibility (ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (Minutes)Copper Corrosion (ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 135°C42-38-052a2a41-39-0102a2aISO VG 46 (Group I)42-38-051b1b0.90.80.70.60.50.40.30.20.10Average ScarDiameter (mm)1.0% ZnDTP0.35% Blend**Pass43-35-2301a-<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 Series - Ashless Antiwear AdditivesFZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage 12 12 1212Four Ball Wear (ASTM D 4172)1 hour, 75°C, 1500 rpm, 30 kgf, Scar Diameter (mm)1 hour, 75°C, 1800 rpm, 40 kgf, Scar Diameter (mm)0.42-0.37--0.54-0.45Pages 9-10* ZnDTP based on 2-ethylhexanol (stabilized) ** 0.35% Blend of yellow metal deactivator, aminic and phenolic antioxidants

<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 Series - Ashless Antiwear Additives Performance of the Unique <strong>NA</strong>-<strong>LUBE</strong> AW-6310<strong>NA</strong>-<strong>LUBE</strong> AW-6310 is an innovative extension of the other <strong>NA</strong>-<strong>LUBE</strong> AW products. It is aproprietary composition containing unique sulfur/phosphorus/nitrogen chemistries.<strong>NA</strong>-<strong>LUBE</strong> AW-6310 exhibits the following properties:Superior FZG performanceOutstanding rust inhibitionExcellent demulsificationGood hydrolytic stabilityGood thermal stabilityOutstanding synergy with the <strong>NA</strong>-<strong>LUBE</strong> AO SeriesExcellent solubility in a wide range of base oils, including some silicon fluids<strong>NA</strong>-<strong>LUBE</strong> AW-6310 is used in screw compressor oils, railroad type non-mineral oil (Group V)greases, industrial gear oils, and automotive gear oils. It can also be used for formulating extremelyeffective ashless HF-2 type hydraulic fluids as shown below:TestsBase OilDemulsibility (ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (Minutes)Steel Corrosion (ASTM D 665, DIN 51 585) A & B0.15% <strong>NA</strong>-<strong>LUBE</strong> AW-63100.20% <strong>NA</strong>-<strong>LUBE</strong> AO-2100.10% <strong>NA</strong>-<strong>LUBE</strong> AO-1300.03% K-CORR NF-20040-40-010PassAFNOR Wet Filtration (E 68691)Filterability Index 1.17Copper Corrosion (ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 135°CFZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage >12CM Thermal Stability (ASTM D 2070)CM Color Class: CopperSteelViscosity Change, %Acid Number Change (mg KOH/g)Total Sludge (mg/100 ml)Hydrolytic Stability (ASTM D 2619)Copper Loss (mg/cm²)Total Acidity of Water Layer (mg KOH)Copper Appearance (ASTM D 130)ISO VG 46 (Group II)1b1b530.510.0314.80<strong>NA</strong>-<strong>LUBE</strong> AW-6310 also exhibits very good performance in greases. The table below depicts theperformance of <strong>NA</strong>-<strong>LUBE</strong> AW-6310 in a synthetic lithium complex grease.Tests Without Additive <strong>NA</strong>-<strong>LUBE</strong> AW-63100.003.473bTreat Level, % — 2.0Base GreaseSynthetic Lithium ComplexTest Water5% Synthetic Sea WaterEMCOR Rust Test (ASTM D 6138, IP 220) 2,2 0,0Four Ball Wear (ASTM D 2266)1 hour, 75˚C, 40 kgf, 1200 rpmScar Diameter (mm) 0.73 0.48

R1H׀NR2<strong>NA</strong>-<strong>LUBE</strong> ® AO SeriesPrimary Antioxidants<strong>NA</strong>-<strong>LUBE</strong> AO-130& <strong>NA</strong>-<strong>LUBE</strong> AO-142t-ButylProduct<strong>NA</strong>-<strong>LUBE</strong>AO-130<strong>NA</strong>-<strong>LUBE</strong>AO-142<strong>NA</strong>-<strong>LUBE</strong>AO-210<strong>NA</strong>-<strong>LUBE</strong>AO-242OHHt-Butyl<strong>NA</strong>-<strong>LUBE</strong> AO-210t-ButylHOt-ButylOC 3OR3<strong>NA</strong>-<strong>LUBE</strong> AO-242For R 1, R 2, and R 3, seechemical descriptions below.ChemicalDescriptionFormNitrogenApprox.(%)Flash Point,COC(ASTM D 92)Approx.(°C)Dinonyldiphenylamine Liquid 3.5 165Octyl/butyldiphenylamine2,6 Ditertbutylphenol2,6 DitertbutylphenolDerivativeThe <strong>NA</strong>-<strong>LUBE</strong> AO product line is a series of phenolic and aminicantioxidants that is used in a broad range of industrial lubricants, engineoils, and greases. These products retard the oxidation of lubricants thusreducing sludge formation and viscosity increase, providing economicand ecological benefits. The <strong>NA</strong>-<strong>LUBE</strong> antioxidants exhibit the followingphysical and performance properties:Liquid 4.5 185Solid at< 36° CAshlessNon-corrosiveExcellent solubility in a wide range of base fluidsEnhanced thermal and oxidative stabilityBoth solid and liquid <strong>NA</strong>-<strong>LUBE</strong> AO products are available to offermaximum formulating flexibility.<strong>NA</strong>-<strong>LUBE</strong> ADTC is a unique multifunctional additive that not onlyprovides outstanding antioxidant properties but also extreme pressureand antiwear properties.— >100Liquid — 148DescriptionExcellent antioxidant with outstandingproduct stability at low temperatures.Excellent antioxidant that is in compliancewith the Food and Drug AdministrationRegulation 21 CFR 178.3570 (lubricantswith incidental food contact) up to a treatlevel of 0.5% by weight. HX-1 registered# 140584.General purpose antioxidant with verylow volatility compared to BHT.High temperature antioxidant with lowvolatility and low viscosity. Providesreduced sludge formation.<strong>NA</strong>-<strong>LUBE</strong> ® AO Series - Primary AntioxidantsProductChemicalDescriptionSulfurApprox.(%)NitrogenApprox.(%)Flash Point,COC(ASTM D 92)Approx.(°C)Description<strong>NA</strong>-<strong>LUBE</strong>ADTCMethylene-bisdibutyldithiocarbamate30.0 6.5 180<strong>NA</strong>-<strong>LUBE</strong> ADTC is a unique ashlessdithiocarbamate offering extremepressure, antiwear and antioxidantproperties.Pages 11-12

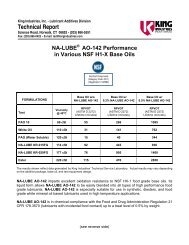

Synergistic Effects of Aminic and Phenolic AO Combinations<strong>NA</strong>-<strong>LUBE</strong> ® AO Series - Primary AntioxidantsAminic and phenolic antioxidants impart excellent oxidation stability to formulated functional fluids.Each type provides excellent protection as the sole antioxidant, or they can be used in combinationto take advantage of their synergistic strength to provide outstanding long-term protection. Below isan example of the synergistic effect.Synergy of <strong>NA</strong>-<strong>LUBE</strong> AO-142 and <strong>NA</strong>-<strong>LUBE</strong> AO-2425004003002001000Rotating Pressure Vessel Oxidation Test(ASTM D 2272)RPVOT (minutes)5004003002001000Base Oil: ISO VG 46 Group II0.20% AO-242 0.20% AO-142 0.10% AO-2420.10% AO-1420.10% AO-2420.10% AO-1420.05% K-CORR NF-200 <strong>NA</strong>-<strong>LUBE</strong> AO-142 Performance in Various HX-1 Base OilsFORMULATIONSBase OilTestViscosity@40°CBase Oil Without<strong>NA</strong>-<strong>LUBE</strong> AO-142Turbine Oil Oxidation Test(ASTM D 943)TOST (hours to TAN > 2 mg KOH/g)Base Oil With0.2% <strong>NA</strong>-<strong>LUBE</strong> AO-1425004003002001000.10% AO-2420.10% AO-1420.05% K-CORR NF-2000.05% K-CORR 1031RPVOT - Rotating Pressure Vessel Oxidation Test(ASTM D 2272) Lifetime - MinutesBase Oil With0.5% <strong>NA</strong>-<strong>LUBE</strong> AO-142PAO 10 66 cSt 55 266 1095White Oil 110 cSt 31 141 762PAG (Water Soluble) 120 cSt 15 40 344<strong>NA</strong>-<strong>LUBE</strong> KR-015FG 114 cSt 92 443 930<strong>NA</strong>-<strong>LUBE</strong> KR-029FG 177 cSt 76 905 1400Ester 220 cSt 115 470 2650

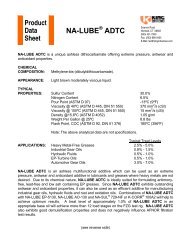

<strong>NA</strong>-<strong>LUBE</strong> ® ADTCMultifunctional Ashless Dialkyldithiocarbamate<strong>NA</strong>-<strong>LUBE</strong> ADTC is a unique, ashless dialkyldithiocarbamate additive that offers excellent extremepressure, antiwear, and antioxidant properties. <strong>NA</strong>-<strong>LUBE</strong> ADTC has well-defined chemistry withsulfur and nitrogen present in the same molecule. Performance of <strong>NA</strong>-<strong>LUBE</strong> ADTC - Ashless Hydraulic Fluid PackageThe table below shows the performance capabilities of <strong>NA</strong>-<strong>LUBE</strong> ADTC in an ashless hydraulic fluidpackage containing K-CORR 1031, an amino acid derived rust inhibitor.TestsProduct<strong>NA</strong>-<strong>LUBE</strong> ADTCCompositionMethylene-bisdibutyldithiocarbamate<strong>NA</strong>-<strong>LUBE</strong> ADTC exhibits the followingproperties:Excellent extreme pressure andantiwearExcellent oxidation inhibitionOutstanding demulsificationGood thermal stabilityExcellent solubility in highlyparaffinic base stocksASHLESS PACKAGE: <strong>NA</strong>-<strong>LUBE</strong> ADTC, <strong>NA</strong>-<strong>LUBE</strong> AO-130,<strong>NA</strong>-<strong>LUBE</strong> AW-6220, K-CORR 1031Treat Level of Additive Package, % 0.5 1.0Base Oil ISO VG 32 (Group I)Demulsibility (ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (Minutes)SulfurApprox.(%)C 4 H 9 SN CC 4 H 9 S CH 242-38-010NitrogenApprox.(%)41-38-110Steel Corrosion (ASTM D 665B, DIN 51 585) Pass PassCopper Corrosion (ASTM D 130, DIN 51 759)3 hours, 135°C 1a 1aRPVOT* (ASTM D 2272) Lifetime (Minutes) 495 1260Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpm, Scar Diameter (mm) 0.50 0.47AFNOR Wet Filtration (E 68691)Filterability Index 1.25 1.10FZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage Not Determined >12Viscosity @ 100°C(ASTM D 445)Approx. mm 2 /s (cSt)30 6.5 15SCSDue to its multifunctionality, <strong>NA</strong>-<strong>LUBE</strong> ADTC isused in:N<strong>NA</strong>-<strong>LUBE</strong> ADTCPROPERTIES & USESC 4 H 9C 4 H 9Heavy Metal-free GreasesRust and Oxidation OilsAutomotive and Industrial Gear OilsExtreme Pressure Turbine OilsHydraulic OilsEngine OilsMetalworking Fluids<strong>NA</strong>-<strong>LUBE</strong> ® ADTC - Ashless DialkydithiocarbamatePages 13-14* Rotating Pressure Vessel Oxidation Test

<strong>NA</strong>-<strong>LUBE</strong> ® EP 5000 Series - Extreme Pressure Additives<strong>NA</strong>-<strong>LUBE</strong> ® EP 5000 SeriesExtreme Pressure / Antiwear AdditivesThe <strong>NA</strong>-<strong>LUBE</strong> EP 5000 Series consists of low odor, light-colored fatty acid esters, sulfurized fattyacid esters/triglycerides, and sulfurized α-olefins/triglycerides.Light-colored, low odor sulfur-containing additives are primarily produced by using hydrogen sulfideand elemental sulfur. The reaction is usually performed under high pressure and high temperatureconditions. Light-colored, low odor sulfur-containing additives have improved properties over thewell-known “black” sulfur-containing additives, including significantly improved oxidative stability andbetter solubility in highly paraffinic base oils.Sulfur-containing additives are commonly known in the lubricant and grease industry as “sulfurcarriers”. The different raw materials used for the production of these additives have a significantimpact on the properties and performance of the different sulfur carriers. Products based on shortchainolefins, such as isobutylene, can be called “dry” sulfur carriers because they only provideEP/AW properties; while those based on esters and triglycerides (fatty oils) can be called “wet”sulfur carriers because they also improve boundary lubrication.One of the most important characteristics of sulfur carriers is sulfur activity as measured inaccordance with the ASTM D 1662 test. The active sulfur content primarily depends on thepolysulfide chain length in the molecule. Sulfur-containing additives with a very low active sulfurcontent (6%) primarilyprovide extreme pressure properties.The <strong>NA</strong>-<strong>LUBE</strong> EP 5000 Series is manufactured from carefully selected raw materials to optimizeproduct quality and performance. Precisely controlled manufacturing processes result in productsthat are of light color and low odor.Product<strong>NA</strong>-<strong>LUBE</strong>EP-5210<strong>NA</strong>-<strong>LUBE</strong>EP-5216<strong>NA</strong>-<strong>LUBE</strong>EP-5218<strong>NA</strong>-<strong>LUBE</strong>EP-5310<strong>NA</strong>-<strong>LUBE</strong>EP-5316<strong>NA</strong>-<strong>LUBE</strong>EP-5415% TotalSulfur% ActiveSulfurViscosity@ 40ºC(cSt)10

The <strong>NA</strong>-<strong>LUBE</strong> EP 5000 Series consists of a variety of novel sulfur-containing additives with totalsulfur content ranging from approximately 10% to 65% and the active sulfur content ranging from

<strong>NA</strong>-<strong>LUBE</strong> ® EP 5000 Series - Extreme Pressure AdditivesPerformance of the<strong>NA</strong>-<strong>LUBE</strong> EP 5000 Series Series Performance in a ISO VG 32 Group I Base OilThe following table highlights the performance of the products in various bench tests for lubricationproperties.Tests<strong>NA</strong>-<strong>LUBE</strong>EP-5210<strong>NA</strong>-<strong>LUBE</strong>EP-5216<strong>NA</strong>-<strong>LUBE</strong>EP-5218Base Oil ISO VG 32 (Group I)Treat Level, % 5.0Four Ball Weld (ASTM D 2783)10 seconds, 25°C, 1800 rpmOK Load (kgf)Weld Load (kgf)160200200240200240<strong>NA</strong>-<strong>LUBE</strong>EP-5316200240<strong>NA</strong>-<strong>LUBE</strong>EP-5415Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpmScar Diameter (mm) 0.54 0.58 0.81 0.68 0.60Copper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100ºC24 hours, 100ºC <strong>NA</strong>-<strong>LUBE</strong> EP-5210 - Concentration Effect On Properties1a2aAs shown below, with increasing concentrations of <strong>NA</strong>-<strong>LUBE</strong> EP-5210, the wear and extremepressure properties improve with no negative effects on demulsibility or copper corrosion protection.Tests2.0% <strong>NA</strong>-<strong>LUBE</strong>EP-52103a4a7.5% <strong>NA</strong>-<strong>LUBE</strong>EP-52103a4a10.0% <strong>NA</strong>-<strong>LUBE</strong>EP-5210Base Oil ISO VG 32 (Group I)Four Ball Weld (ASTM D 2783)10 seconds, 25°C, 1800 rpmOK Load (kgf)Weld Load (kgf)1201601602001602001b3b2202401b3b10.0% <strong>NA</strong>-<strong>LUBE</strong> EP-52106.0% <strong>NA</strong>-<strong>LUBE</strong> AW-6010Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpmScar Diameter (mm) 0.72 0.59 0.60 0.50Falex PIN & VEE (ASTM D 3233)Lbs. 890 1050 1060 950Copper Corrosion(ASTM D130, DIN 51 759)3 hours, 100ºC24 hours, 100ºCDemulsibility(ASTM D 1401,DIN 51 599Oil-Water-EmulsionTime (Minutes)1a3a39-39-2101a2a41-39-0101a2a41-39-0102002401b2a40-40-010

<strong>NA</strong>-<strong>LUBE</strong> EP-5415 Metalworking Performance Data<strong>NA</strong>-<strong>LUBE</strong> EP-5415 imparts good extreme pressure performance for metalworking fluids and can beused to replace chlorinated paraffins as shown in the chart below.TestsAs shown below, tapping torque tests were conducted to compare the performance of <strong>NA</strong>-<strong>LUBE</strong>EP-5415 versus the performance of a commonly used chlorinated paraffin. The tests wereconducted using 4340 alloy steel under varying machining speeds.4340 Alloy SteelBase Oil: Paraffinic ISO VG 3210% Chlorinated ParaffinAverage Peak Torque(inch - pounds)10% <strong>NA</strong>-<strong>LUBE</strong> EP-5415Average Peak Torque(inch - pounds)% Efficiency40 sfm* (407rpm) 68.8 70.79 97.248 sfm (488rpm) 69.2 71.32 97.058 sfm (586rpm) 71.0 69.88 101.669 sfm (703rpm) 71.7 72.05 99.583 sfm (844rpm) 69.1 70.95 97.4*sfm = surface feet per minuteAdditionally, <strong>NA</strong>-<strong>LUBE</strong> EP-5415 can be used to formulate premium quality machine tool slide waylubricants. Various treat levels of <strong>NA</strong>-<strong>LUBE</strong> EP-5415 in combination with 0.5% tackifier in an ISOVG 68 oil meet the requirements of the Cincinnati Lamb P-47 Heavy-Medium Way Oil specification.Tests1.5% <strong>NA</strong>-<strong>LUBE</strong> EP-54150.5% Tackifier5.0% <strong>NA</strong>-<strong>LUBE</strong> EP-54150.5% TackifierCincinnati LambP-47 SpecificationBase Oil ISO VG 68 ISO VG 68 cSt @ 40ºC:61.6-74.8SUS @ 100ºF:317-389Flash Point (ASTM D 92)COC (ºF) >380 >380 330 MinimumFire Point (ASTM D 92)COC (ºF) >380 >380 360 MinimumAcid Number (ASTM D 974)(mg KOH/g) 0.07 0.10 1.7 MaximumCincinnati Lamb Stick-Slip(μs/μK)* 0.0710 / 0.0982 = 0.72 0.0783 / 0.1009 = 0.78 0.80 MaximumThermal Stability TestProcedure B: 24 hours, 101ºCCM Color ClassRod Weight of Deposit (mg)Rod Metal Loss (mg)Acid Number Change (mg KOH/g)PrecipitateSteel Copper1 30.30 1.00.2 0.40.07None10% Mid-chain ChlorinatedParaffin (C 14-17 >50% Cl)Base Oil ISO VG 32 (Group I)Four Ball Weld (ASTM D 2783)10 seconds, 25°C, 1800 rpmOK Load (kgf)Weld Load (kgf)160180Steel Copper1 30.35 1.20.3 0.40.07None10% <strong>NA</strong>-<strong>LUBE</strong>EP-5415Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpm 0.80 0.75Copper Corrosion (ASTM D 130, DIN 51 759)3 hours, 100ºC 1a 1b320340Maximum LimitsSteel Copper1 53.5 --1.0 5.05--<strong>NA</strong>-<strong>LUBE</strong> ® EP 5000 Series - Extreme Pressure AdditivesPages 17-18* Ratio of static to kinetic friction

<strong>NA</strong>-SUL ®Rust & Corrosion InhibitorsSince the introduction of the first products in 1952, the <strong>NA</strong>-SUL trade name has been synonymouswith high quality, cost-effective rust protection. After 50 years of continuous improvement andinnovation, these unique synthetic sulfonates continue to be recognized as the premium rust andcorrosion inhibitors for industrial and automotive lubricants, greases, metalworking fluids, and rustpreventives.<strong>NA</strong>-SUL ® Rust & Corrosion InhibitorsThe <strong>NA</strong>-SUL line is based upon salts of dinonylnaphthalenesulfonic acid. Controlled alkylation ofnaphthalene with nonene produces dinonylnaphthalene. This is then sulfonated to produce thebuilding block sulfonic acid that becomes a <strong>NA</strong>-SUL when neutralized to form various salts. <strong>NA</strong>-SULproducts use a wide variety of neutralizing metals and amines resulting in the world’s broadest lineof sulfonates.The <strong>NA</strong>-SUL line provides excellent rust and corrosion protection in addition to other uniqueperformance properties. <strong>King</strong>’s process of direct neutralization produces sulfonates with no chlorine,resulting in enhanced rust protection and resistance to staining.PerformanceRust & Corrosion ProtectionThe <strong>NA</strong>-SUL line consistently outperforms other synthetic orpetroleum sulfonates, thus offering:Better performance at equal or lower concentrationsHigher maximum performanceFerrous and non-ferrous metal protectionSynergy with other anti-rust additivesUnsurpassed Demulsibility<strong>NA</strong>-SUL Inhibitors OfferSuperior PerformanceASTM D 665 B0.025% 0.05% 0.05% 0.05%<strong>NA</strong>-SUL COMP. COMP. COMP.729 A B CPerformance BeyondRust & Corrosion ProtectionIn addition to superior rust and corrosioninhibition, <strong>NA</strong>-SUL inhibitors impart otherdesirable performance properties to industriallubricants and rust preventive applications,including:Unsurpassed demulsibilityEnhanced oxidation stabilityExcellent filterabilityExcellent additive compatibilityExcellent solubilityCalciumDinonylnaphthaleneSulfonate<strong>NA</strong>-SUL 729CalciumPetroleumSulfonateSyntheticCalciumSulfonate ASyntheticCalciumSulfonate B

Acid # (mg KOH/g)2.50.5Enhanced Oxidation Stability of <strong>NA</strong>-SUL 72921.510<strong>Inc</strong>rease in Acid Value vs. TimeFORMULATION0.25% <strong>NA</strong>-SUL 7290.25% Phenolic Antioxidant99.5% Paraffinic Oil0 20 40 50 60 80 100 120 140Hours in ASTM D 4636 @ 150ºC<strong>NA</strong>- SUL 729 Didodecylbenzene Sulfonate Oil + AO w/o SulfonateImproved FilterabilityAFNOR Filtration (Wet) - ISO VG 46 Group II OilTreat LevelFORMULATIONHF-0 Type Package*Without <strong>NA</strong>-SUL 7290.8% of Additive Package*Package: ZnDTP (Primary C8), Yellow Metal Deactivator and AntioxidantsEnhanced OxidativeStabilityIn addition to unsurpassedrust and corrosion protectionand demulsibility, <strong>NA</strong>-SULsulfonates can enhance oxidativestability performanceas shown in the graph to theleft.<strong>NA</strong>-SUL Sulfonates can also improve filterability. The table below compares the Wet AFNORFiltration when <strong>NA</strong>-SUL 729 was incorporated into a Denison HF-0 type package at 9.0% replacingoil so that the concentration of all other additives was held constant. This package was then addedto the oil at a treat level of 0.8%, resulting in a final <strong>NA</strong>-SUL 729 concentration in the oil of 720ppm. The package without <strong>NA</strong>-SUL 729 plugged the filter, while the package with the <strong>NA</strong>-SUL 729passed the AFNOR Filtration. A good AFNOR Filterability Index is

<strong>NA</strong>-SUL Rust & Corrosion Inhibitors - Types<strong>NA</strong>-SUL TYPE PRIMARY USES PAGE <strong>NA</strong>-SUL TYPE PRIMARY USES PAGENeutral Metal Salts Ind. Lubes/RP’s 21 Specialty Grades Ind. Lubes/RP’s 22Amine Salts Ind. Lubes/Fuel/RP’s 21 RP Concentrates RP’s 27<strong>NA</strong>-SUL ® Rust & Corrosion InhibitorsBasic Metal Salts Lubricants/RP’s 22 Aqueous RP’s/Cleaners 31RSO 3Neutral dinonylnaphthalenesulfonates are used in almost all applications where premium rust andcorrosion inhibitors are required. The divalent metal salts also exhibit excellent demulsibility.Several of the neutral metal sulfonates are available in a variety of diluents.Product<strong>NA</strong>-SUL 707<strong>NA</strong>-SUL 729<strong>NA</strong>-SUL BSN<strong>NA</strong>-SUL MG<strong>NA</strong>-SUL SS<strong>NA</strong>-SUL ZSRMM M = Ca, = Ca, Ba, Ba, Mg, Mg and or ZnRSO 32Metal DNNS Salt*(Metal Approx. %)R. R'NH 32Lithium(0.76)Calcium(2.1)Barium(6.6)Magnesium(1.3)Sodium(2.4)Zinc(2.8)<strong>NA</strong>-SUL Neutral Metal SaltsDescriptionLow ash rust inhibitor with good high temperature stability in industrial oilsand greases. Retards bleeding in lithium soap greases.Premium rust inhibitor for petroleum and synthetic lubricants, hydraulic fluidsand circulating oils. Outstanding water resistance properties, includingdemulsibility, wet filterability, and hydrolytic stability.Premium rust inhibitor for industrial lubricants, greases, rust preventivefluids, and metalworking specialties. Excellent water resistance properties.Non-staining to metal surfaces. Widely used in gear oils and greases.Lowest ash premium rust inhibitor. Particularly effective in rust preventiveapplications exposed to water, such as ballast tank coatings.High molecular weight sodium sulfonate. Not an emulsifier, but excellentadditive to enhance rust preventive properties of emulsions.Premium rust inhibitor for industrial oils, greases, and hydraulic fluids,particularly when used in combination with zinc dithiophosphates.<strong>NA</strong>-SUL Amine Salts (Ashless)RSO 3. MM=Lior NaRNeutralization with amines, instead of metals, produces ashless sulfonates. The base strength andvolatility of the amine chosen influences the properties and applications.Product<strong>NA</strong>-SUL AS<strong>NA</strong>-SUL DTA<strong>NA</strong>-SUL EDSAmine DNNS Salt*(Nitrogen Approx. %)Ammonia(1.5)Diethylenetriamine(0.5)Ethylenediamine(0.7)DescriptionAshless rust inhibitor used in a wide range of petroleum fluids, includingdistillate fuels. May be used as a supplemental additive withother rust inhibitors.Stable ashless rust inhibitor with good demulsibility in petroleum andsynthetic lubricants.Ashless rust inhibitor for lubricants, distillate fuels, and mild-duty rustpreventives. Diluent is 70°C flash aliphatic solvent.* Diluent is light Mineral Oil with the exception of <strong>NA</strong>-SUL EDS.

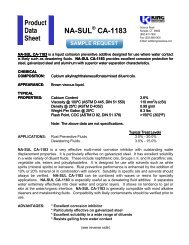

<strong>NA</strong>-SUL Basic Metal SaltsRRCa·CaCO3SO 32Basic sulfonates find application as rust inhibitors in lubricants, greases and metalworking specialtieswhere alkalinity is desirable to neutralize mild acid contamination, thus improving oxidationstability. They are also used in rust preventives to improve performance when applied overcontaminated substrates.Product<strong>NA</strong>-SUL 611<strong>NA</strong>-SUL BSB<strong>NA</strong>-SUL CA-50Several specialty <strong>NA</strong>-SUL grades have evolved for applications with different requirements than thesulfonates alone can provide. Various complexes take advantage of synergisms to enhanceproperties.Product<strong>NA</strong>-SUL 729-NF<strong>NA</strong>-SUL CA-770FG<strong>NA</strong>-SUL BSN-HT<strong>NA</strong>-SUL CA-1089Metal DNNS Salt*(Metal Approx. %)Barium(11.7)Barium(12.0)Calcium(3.2)DNNS Salt Derivative*(Metal Approx. %)Calcium with YMD**(1.9)Calcium(1.7)Barium Complex(8.7)Calcium Complex(2.2)DescriptionApproximate TBN is 45 mg KOH/g as barium carbonate. Particularlyeffective in polyglycol/ester based compressor fluids.Approximate TBN is 45 mg KOH/g as barium hydroxide. Versatile rustinhibitor additive for rust preventives, greases and lubricants containingacidic components.Approximate TBN is 50 mg KOH/g as calcium carbonate. Excellentresistance to salt water environments, particularly in greases and rustpreventive fluids. Also used in high performance military hydraulic fluids.<strong>NA</strong>-SUL Grades for Specialty LubricantsDescriptionComplexes andHX-1 RegisteredSynergistsPremium ferrous rust inhibitor plus yellow metal deactivatorfor non-ferrous corrosion protection.Calcium based sulfonate in PAO specifically designed for usein food grade applications. NSF HX-1 Registration # 143718.Synergistic rust inhibitor with excellent thermal stability.Particularly suited for high temperature applications.Exceptional additive providing excellent rust protection,demulsibility, filterability (dry and wet), and thermal stability.Makes excellent RP fluids and dewatering fluids because ofits superior water resistance.<strong>NA</strong>-SUL ® Rust & Corrosion Inhibitors<strong>NA</strong>-SUL CA-HT3Calcium Complex(2.5)Excellent rust inhibitor with thermal stability and gooddemulsibility required for applications such as paper machineoils and high temperature circulating fluids.<strong>NA</strong>-SUL MG-HTMagnesium Complex(1.7)Synergistic rust inhibitor with good thermal stability.Particularly effective at neutralizing the corrosivity andstaining of chlorinated paraffins.<strong>NA</strong>-SUL ZS-HTZinc Complex(3.8)Excellent rust inhibitor, particularly in systems with other zinccontaining additives. Exhibits antioxidation synergism withprimary antioxidants in petroleum and PAO base fluids.Pages 21-22* Diluent is light Mineral Oil with the exception of <strong>NA</strong>-SUL CA-770 FG, ** YMD = Yellow metal deactivator

<strong>NA</strong>-SUL CA-1089Hydraulic Fluid Performance Data<strong>NA</strong>-SUL ® Rust & Corrosion Inhibitors<strong>NA</strong>-SUL CA-1089 is a calcium sulfonate/carboxylate complex that imparts outstanding steelcorrosion protection, demulsibility and filtration performance to formulated functional fluids. Hydraulicfluids meeting the Denison HF-0 specification can be developed using <strong>NA</strong>-SUL CA-1089 as thecorrosion inhibitor/demulsifier portion of the formulation. <strong>NA</strong>-SUL CA-1089 Performance in a Denison HF-0 Type Hydraulic Fluid PackageHF-0 Type Package w/o <strong>NA</strong>-SUL w/ 2.0% <strong>NA</strong>-SULTestsCA-1089 CA-1089Treat Level of Additive Package, % 0.8Base OilISO VG 46 (Group II)w/ 4.5% <strong>NA</strong>-SULCA-1089Additive Package Color Light Amber Light Amber Light AmberSteel Corrosion (ASTM D 665, DIN 51 585)A & B Fail Pass PassDemulsibility (ASTM D 1401, DIN 51 599)Oil-Water-EmulsionTime (Minutes)41-34-53040-39-11039-39-210Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpmScar Diameter (mm) 0.42 0.41 0.40Copper Corrosion (ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 135°C3 hours, 160°CCincinnati Milacron Thermal Stability (ASTM D 2070)CM Color Class: CopperSteelViscosity Change, %Acid Number Change (mg KOH/g)Rod Weight of Deposit, Steel / Copper (mg/200ml)Rod Metal Loss, Steel / Copper (mg/200ml)Total Sludge (mg/100 ml)Whatman Precipitate (mg/100 ml)Millipore Precipitate (mg/100 ml)Hydrolytic Stability (ASTM D 2619)Copper Loss (mg/cm 2 )Total Acidity of Water Layer (mg KOH)Copper Appearance (ASTM D 130)1b1b1b1.51.51.80.230.1 / 0.10.2 / 0.65.52.72.80.290.912a1b1b1b1.01.52.10.360.2 / 0.70.0 / 0.13.60.72.80.050.701b1b1b1b1.01.51.30.300.2 / 0.30.0 / 0.21.70.41.20.301.101bAFNOR Wet Filtration (E 68691)Filterability Index Plugged 1.34 1.27FZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage 12 12 12This table compares the performance of a Denison HF-0 type package for hydraulic fluids with andwithout <strong>NA</strong>-SUL CA-1089. <strong>NA</strong>-SUL CA-1089 was incorporated into the package at 2.0% and 4.5%replacing the oil. The concentrations of all other additives were held constant. Testing wasconducted at a package treat level of 0.8% in an ISO VG 46 Group II oil resulting in final <strong>NA</strong>-SULCA-1089 concentrations of 0.036% and 0.016% in the oil. The package without <strong>NA</strong>-SUL CA-1089failed the steel corrosion, demulsibility, and AFNOR filtration tests and resulted in notable copper lossin the hydrolytic stability test. <strong>Inc</strong>lusion of <strong>NA</strong>-SUL CA-1089 in the formulation imparted excellentsteel corrosion protection, demulsibility, and AFNOR filtration performance and greatly reduced theamount of copper loss in the hydrolytic stability test when tested at the lower concentration. Theimproved AFNOR filtration performance is attributed to the excellent dispersancy characteristics of<strong>NA</strong>-SUL CA-1089. <strong>NA</strong>-SUL CA-1089 also exhibited no adverse effects on other performance tests,including four ball wear, copper corrosion, Cincinnati Milacron thermal stability and FZG.

<strong>NA</strong>-SUL CA-1089Performance In Rust Preventives<strong>NA</strong>-SUL CA-1089 is not only an excellent rust inhibitor for industrial lubricants, as shownpreviously in the hydraulic fluid example, but is also highly effective in a broad range ofrust preventive applications where it offers:Remarkable non-staining performance in stacked stain testing in all oils tested, makingit an outstanding barium sulfonate replacement. Highly recommended for protection ofcoiled steel and closely stacked steel parts.Exceptional performance in both cyclic and constant humidity testing, making it anexcellent choice for most parts storage applications.Outstanding water displacement and demulsibility performance, including acidic andbasic aqueous fluids. A perfect choice for difficult dewatering fluids.Excellent solubility in paraffinic oils, PAO, esters and vegetable oils. A versatileadditive that can be used in a variety of products using different base stocks. <strong>NA</strong>-SUL CA-1089 Performance in a Paraffinic ISO VG 32 Base OilTests2.0% CA-108998.0% Oil #15.0% CA-108995.0% Oil #110.0% CA-108990.0% Oil #1Average Film ThicknessMeasured by Weight (m) 2.8 2.8 3.0Salt Fog (ASTM B 117)Average Hours to Failure 3-5 5-10 12-15Humidity Cabinet (ASTM D 1748)Average Hours to Failure 100-125 300-350 450-500 <strong>NA</strong>-SUL CA-1089 Performance in a Solvent/Oil Based System*Tests3.0% CA-108920.0% Oil #177.0% Solvent5.0% CA-108920.0% Oil #175.0% Solvent10.0% CA-108920.0% Oil #170.0% SolventAverage Film ThicknessMeasured by Weight (m) 1.8 2.0 2.4Salt Fog (ASTM B 117)Average Hours to Failure 5-10 5-10 16-20Humidity Cabinet (ASTM D 1748)Average Hours to Failure 230-300 400-500 500-600* Solvent: 40°C Mineral Spirits, Oil: Paraffinic ISO VG 32 (150 SUS)“Hours to failure” is defined as rust more than 1.5 cm from the top panel edge or more than 0.5 cm from either side edge.<strong>NA</strong>-SUL ® Rust & Corrosion Inhibitors <strong>NA</strong>-SUL CA-1089 Performance - Accelerated Stacked Stain Test10.0% CA-108990.0% Oil #15.0% CA-108995.0% Oil #2Stack Stain7-Day Accelerated Pass PassOil #1 - Paraffinic Group I - ISO VG 32 (150 SUS)Oil #2 - Paraffinic Group II - ISO VG 46 (220 SUS)5% <strong>NA</strong>-SUL CA-108995% Group II ParaffinicISO VG 46 (220 SUS)5% Commercial RP95% Group II ParaffinicISO VG 46 (220 SUS)Pages 23-24

<strong>King</strong> <strong>Industries</strong>, <strong>Inc</strong>. - Lubricant Additives DivisionPRODUCTS & APPLICATIONS CHART*CHART KEY:ApplicationsColored Box = RecommendedTR= Technical Report AvailableCirculatingOilsCompressorOilsGearOilsGreaseHydraulicFluidsPowerTransferTurbineOilsGearOilsEngineOilsSolubleOilsCuttingOilsOil/SolventBasedAqueousEmulsionAqueousSolution<strong>NA</strong>-<strong>LUBE</strong> EP ExtremePressure Additives<strong>NA</strong>-<strong>LUBE</strong> EP-5210<strong>NA</strong>-<strong>LUBE</strong> EP-5216<strong>NA</strong>-<strong>LUBE</strong> EP-5218<strong>NA</strong>-<strong>LUBE</strong> EP-5310<strong>NA</strong>-<strong>LUBE</strong> EP-5316<strong>NA</strong>-<strong>LUBE</strong> EP-5415<strong>NA</strong>-<strong>LUBE</strong> EP-5425<strong>NA</strong>-<strong>LUBE</strong> EP-5665<strong>NA</strong>-<strong>LUBE</strong> ADTC <strong>NA</strong>-<strong>LUBE</strong> ADTC TR TR<strong>NA</strong>-<strong>LUBE</strong> AW-6010<strong>NA</strong>-<strong>LUBE</strong> AWAntiwear Additives<strong>NA</strong>-<strong>LUBE</strong> AW-6110<strong>NA</strong>-<strong>LUBE</strong> AW-6110P<strong>NA</strong>-<strong>LUBE</strong> AW-6220 TR TR<strong>NA</strong>-<strong>LUBE</strong> AW-6310 TR TR<strong>NA</strong>-<strong>LUBE</strong> AW-6330<strong>NA</strong>-<strong>LUBE</strong> AW-6360 TR TR<strong>NA</strong>-<strong>LUBE</strong> AW-6400FGIndustrial Lubricants Automotive Metalworking Rust Preventive SystemsTRTRTRTRTRTRTRTRTR<strong>NA</strong>-<strong>LUBE</strong> AOAntioxidants<strong>NA</strong>-SULNeutral Metal Salts<strong>NA</strong>-SULBasic Metal Salts<strong>NA</strong>-SULAshless / Amine Salts<strong>NA</strong>-SULConcentratesfor Oil & Oil/SolventRust Preventive Systems<strong>NA</strong>-SULAdditives forAqueous Systems<strong>NA</strong>-SULAdditives forSpecialty LubricantsK-CORR<strong>NA</strong>-<strong>LUBE</strong> AO-130<strong>NA</strong>-<strong>LUBE</strong> AO-142<strong>NA</strong>-<strong>LUBE</strong> AO-210<strong>NA</strong>-<strong>LUBE</strong> AO-242<strong>NA</strong>-SUL 707TR<strong>NA</strong>-SUL 729 TR TR TR TR<strong>NA</strong>-SUL BSN TR TR<strong>NA</strong>-SUL MGTR<strong>NA</strong>-SUL SS TR TR<strong>NA</strong>-SUL ZS<strong>NA</strong>-SUL 611<strong>NA</strong>-SUL BSB<strong>NA</strong>-SUL CA-50<strong>NA</strong>-SUL AS<strong>NA</strong>-SUL DTA<strong>NA</strong>-SUL EDS<strong>NA</strong>-SUL CA-1082TR<strong>NA</strong>-SUL CA-1089 TR TR<strong>NA</strong>-SUL CA-1183<strong>NA</strong>-SUL CA-1259<strong>NA</strong>-SUL CA/W1146<strong>NA</strong>-SUL CA/W1177<strong>NA</strong>-SUL CA/W1213<strong>NA</strong>-SUL TEA/LB<strong>NA</strong>-SUL 1019A<strong>NA</strong>-SUL 437<strong>NA</strong>-SUL 420KX450<strong>NA</strong>-SUL BSN-HT<strong>NA</strong>-SUL CA-770FGTR<strong>NA</strong>-SUL CA-1089 TR TR<strong>NA</strong>-SUL CA-HT3 TR TR TR<strong>NA</strong>-SUL MG-HT TR TR<strong>NA</strong>-SUL ZS-HT TR TR<strong>NA</strong>-SUL 729-NF TR TRK-CORR 100 TR TRK-CORR 100A2K-CORR 1031K-CORR G-1086AK-CORR G-1107K-CORR G-1270K-CORR ZN-510K-CORR NF-200 TR TRK-CORR NF-410TRTRTRTRK-CORR SA-300 TR TR TRTRTRTRTRTRTRTRTR* See inside back cover for information regarding recommendations and product uses.

Technical Assistance: (203) 866-5551 lad@kingindustries.comApplicationsCharacteristicsHotMeltWaxThickFilmPostTensioningGreaseDemulsibilityDispersancyOxidativeStabilityThermalStabilityWaterDisplacementAcidAtmosphere Anti-StainWaterSolubleWaterEmulsifiableNonferrousAshlessProtectionSulfurCarrier,ActiveSulfurCarrier,InactivePhosphorusPhenolicAOAminicAORust Preventive SystemsTRTRTRTR TR TRTRTRTRTRTRTRTRTRTRTRTR

<strong>NA</strong>-SUL Rust and CorrosionPreventive Additives<strong>NA</strong>-SUL ® Rust & Corrosion Inhibitors<strong>King</strong> <strong>Industries</strong>’ rust preventive additives are generally based on salts of dinonylnaphthalenesulfonatewith additional polar compounds chosen to provide rust preventive synergy. This results inextremely hydrophobic rust preventive coatings that effectively exclude water and air from reachingthe metal surface. The resulting performance advantage provides levels of metal protection thatcompetitive additives cannot achieve and/or reductions in additive use levels that result in significantformulation savings.<strong>NA</strong>-SUL Rust Preventive Concentrates for Oil and Oil/Solvent SystemsProduct<strong>NA</strong>-SUL CA-1089<strong>NA</strong>-SUL CA-1183Formerly KX1183<strong>NA</strong>-SUL CA-1259Formerly KX1259<strong>NA</strong>-SUL CA/W1146<strong>NA</strong>-SUL CA/W1177Formerly KX1177<strong>NA</strong>-SUL CA/W1213Formerly KX1213<strong>NA</strong>-SUL CA-HT3Form(% Calcium)Liquid(2.2%)ViscousLiquid(2.6%)Liquid(1.6%)Very ViscousLiquid(2.0%)ViscousLiquid(1.4%)ViscousLiquid(1.4%)Liquid(2.5%)DescriptionExcellent general purpose rust preventive additive. Good dewateringproperties. Good performance after water contamination. Recommendedfor medium to long term indoor storage.Provides excellent corrosion protection for steel, galvanized steel andaluminum with good water separation characteristics. Designed for usewhere water contact is likely, such as dewatering fluids.High performance rust and corrosion inhibitor for rust preventives anddewatering fluids. Excellent solubility (should be verified) in a wide rangeof mineral oils, esters, and vegetable oils. Particularly recommendedwhere water displacement is important.Recommended for heavy duty applications, such as sheltered outdoorstorage and marine environments. Best in naphthenic oils. Effective inacid atmospheres. Not recommended if water contamination will occurbefore application on metals.Specifically designed for use where water contact is likely, such asdewatering fluids. It combines excellent corrosion protection with goodwater separation characteristics.Specifically designed for formulating rust preventive fluids for use inharsh environments, such as salt fog exposure. Also recommended forhigh humidity and normal indoor storage.Excellent solubility in a wide range of diluents. Effective in salt andhumidity tests at low treat levels. Not recommended if watercontamination will occur before application on metals.<strong>NA</strong>-SUL CA-1082Liquid(1.4%)Excellent for long term warehouse storage. Best in Group I paraffinic ornaphthenic oils. Good water separation character. Avoid contaminationwith strong alkaline materials.Film CharacteristicsThese additives should be used with 10% to 30% mineral oil in oil/solvent formulations forbest corrosion protection. This results in thin, slightly oily coatings. If oil is not used withsolvent, these additives may produce a slightly tacky coating particularly at higher additivelevels. ,<strong>NA</strong>-SUL CA/W1213, CA/W1177, and CA/W1146 will be almost dry at low treatlevels.

Selection Guide - <strong>NA</strong>-SUL Additives forOil/Solvent Based Rust PreventivesThere are many rust preventive additives available from <strong>King</strong> <strong>Industries</strong> that are used for formulatingoil or oil/solvent based rust preventives. The following selection guide is designed to help chosefrom among them based on specific performance requirements. Multiple requirements can bedetermined using the respective scales (0 to 4) to optimize formulations.RequirementSolubility (Oil)Tolerance of fluidto water exposure(Dewatering)Ease of useIndoor storageOutdoor shelteredstorageMarineenvironment0NotRecommendedCA/W11461 2 3 4HighlyRecommendedCA-HT3CA-1089Acid atmosphere CA-1089 CA-HT3CA/W1146CA/W1177CA/W1213CA/W1146CA/W1177CA/W1213CA-HT3CA-HT3CA-1082CA/W1177CA-1183CA-1082CA/W1213CA-1183CA/W1146CA/W1213CA-HT3CA/W1146CA-1089CA-1082CA-1082CA/W1177CA-1259CA-1259CA-1082CA-1089CA-HT3CA-1183CA-1089CA/W1177CA-1183CA-1259CA-1089CA-1082CA-HT3CA-1259CA-1089CA-1082CA/W1177CA-1183CA-1259CA-1259CA-1183CA/W1177CA/W1146CA/W1213CA/W1146CA/W1213<strong>NA</strong>-SUL ® Rust & Corrosion InhibitorsTolerance tostrongly basicmaterialsCA/W1146CA-1082CA-HT3CA/W1213CA-1259CA-1089CA-1183Let <strong>King</strong>’s rust preventivelaboratory assist you indeveloping highperformance RP products.Call 203-866-5551or emaillad@kingindustries.comPages 27-28

Performance - <strong>NA</strong>-SUL CA-1259in Rust Preventives<strong>NA</strong>-SUL ® Rust & Corrosion Inhibitors<strong>NA</strong>-SUL CA-1259 is a high performance liquid rust and corrosion inhibitor specifically designed forrust preventives and dewatering fluids. It offers excellent solubility in a wide range of mineral oils,esters, solvents, and vegetable oils with excellent rust protection as shown below. However, it isrecommended to verify the solubility in the base oils/fluids used and compatibility with otheradditives.<strong>NA</strong>-SUL CA-1259 contains a minimal amount of wax giving good barrier properties. It is less viscousthan many other additives of its type and often can be cold blended into oils.It has an exceptional ability to help separate water from oil and oil/solvent solutions making it verysuitable for dewatering fluid applications. In addition to its water displacement characteristics,<strong>NA</strong>-SUL CA-1259 resists gelling in the presence of bulk water making it ideal for high moistureapplications, such as rust preventives associated with wet parts. <strong>NA</strong>-SUL CA-1259 Salt Fog Performance in Oil Based Formulations on SteelSalt Fog(ASTM B 117)Average Hrs to Failure5.0% CA-125995.0% Group IISO VG 32 Oil28 (Polished)18 (Matte)10.0% CA-125990.0% Group IISO VG 32 Oil30 (Polished)50 (Matte)10.0% CA-125990.0% Group IIISO VG 22 Oil40 (Polished)32 (Matte)10.0% CA-125990.0% NaphthenicISO VG 46 Oil72 (Polished)60 (Matte) <strong>NA</strong>-SUL CA-1259 Salt Fog Performance in Oil/Solvent Formulations on SteelSalt Fog(ASTM B 117)Average Hrs to Failure5.0% CA-125920.0% Group IISO VG 32 Oil75.0% MS*85 (Polished)80 (Matte)5.0% CA-125920.0% Group IISO VG 32 Oil75.0% ISOPAR ® H**90 (Polished)110 (Matte)20.0% CA-125930.0% Group IISO VG 32 Oil50.0% ISOPAR ® H**105 (Polished)240 (Matte)10.0% CA-125920.0% Group IISO VG 32 Oil70.0% Exxsol ® D-40**90 (Polished)95 (Matte) <strong>NA</strong>-SUL CA-1259 Performance in Vegetable Oil Based Formulations on Steel2.0% CA-125998.0% Soy BaseFluid4.0% CA-125996.0% Soy BaseFluid10.0% CA-125990.0% Canola Oil15.0% CA-125930.0% Canola Oil55.0% MethylSoyateSalt Fog(ASTM B 117)Average Hrs to Failure10 (Polished)8 (Matte)14 (Polished)10 (Matte)20 (Polished)14 (Matte)22 (Polished)18 (Matte)*MS - Mineral Spirits, **ISOPAR ® H and Exxsol ® D-40 are registered trademarks of ExxonMobil.“Hrs to failure” is defined as rust more than 1.5 cm from the top panel edge or more than 0.5 cm from either side edge.

<strong>NA</strong>-SUL Additives PerformanceIn Oil Based Rust PreventivesThe following data show the relative performance of three widely used rust preventive additives from<strong>King</strong> <strong>Industries</strong>. <strong>NA</strong>-SUL CA-1089 is not as effective at preventing rust in salt environments asCA/W1177 or especially CA-1259. CA-1089 does have exceptional anti-staining properties, as shownon page 24. The data below show that the addition of a minor quantity of CA/W1177 significantlyboosts salt fog performance. This combination even approaches the performance of CA-1259 onsome surfaces while maintaining the outstanding anti-staining properties of CA-1089. <strong>NA</strong>-SUL RP Additives In Oil Based SystemsTestsTests5% CA-108995% Naph Oil*10% CA-108990% Naph Oil5% CA/W117795% Naph Oil10% CA/W117790% Naph Oil4% CA-10891% CA/W117795% Naph Oil8% CA-10892% CA/W117790% Naph Oil5% CA-125995% Naph OilAverage Film ThicknessMeasured by Weight (μm) 2.0 2.1 2.6 1.5Salt Fog (ASTM B 117)Average Hours to Failure(P) (M) (SB)8 6 20Photo 1 - 50 Hours Salt Fog Exposure10% <strong>NA</strong>-SUL CA-1259, 90% Naphthenic Oil(P) Polished (M) Matte (SB) Sand Blasted(P) (M) (SB)32 20 16(P) (M) (SB)14 10 36(P) (M) (SB)30 30 72Photo 2 - 50 Hours Salt Fog Exposure10% <strong>NA</strong>-SUL CA/W1177, 90% Naphthenic Oil(P) Polished (M) Matte (SB) Sand Blasted10% CA-125990% Naph Oil<strong>NA</strong>-SUL ® Rust & Corrosion InhibitorsAverage Film ThicknessMeasured by Weight (μm) 2.6 2.8 3.3 1.9Salt Fog (ASTM B 117)Average Hours to Failure(P) (M) (SB)14 8 28(P) (M) (SB)44 30 50(P) (M) (SB)24 16 72(P) (M) (SB)72 48 80* 200 SUS Naphthenic Oil(P) = polished surface (M) = matte surface (SB) = sand blasted surface“Hours to failure” is defined as rust more than 1.5 cm from the top panel edge or more than 0.5 cm from either side edge.Pages 29-30

<strong>NA</strong>-SUL AqueousRust & Corrosion Inhibitors<strong>NA</strong>-SUL ® Rust & Corrosion Inhibitors<strong>NA</strong>-SUL rust inhibitors for aqueous applications contain ingredients that allow the hydrophobicdinonylnaphthalenesulfonate molecule to be used in water systems. Depending on the additivechosen, the result is either a clear solution or an emulsion. These formulations can often achieveresults similar to oil or solvent based systems.ProductAmine/Metal DNNSSaltAppearance<strong>NA</strong>-SUL TEA/LB Triethanolamine Stable dispersion<strong>NA</strong>-SUL 437<strong>NA</strong>-SUL 1019ATriethanolamine/diethylethanolamineTriethanolamine/diethylethanolamineClear solutionClear solution<strong>NA</strong>-SUL 420 Sodium EmulsionKX450 Calcium Dark Brown LiquidRequirementWater SolubleSystemsWaterEmulsifiable0NotRecommended420KX450DescriptionGood coupling agent. Short to medium termindoor storage. Building block for waterbased corrosion inhibitors. Easy to use.Short to long term indoor storage. Aerosolcan protection. Easy to use. Hard watertolerant.Improved iron chip test results. Short to longterm indoor storage. Hard water tolerant.General purpose aqueous rust preventive.Easy to use. Medium to long term indoorstorage. Short term outdoor shelteredstorage.Liquid rust preventive concentrate that easilyforms stable emulsions when added to waterwith moderate stirring. Excellent rust protectionfor steel parts during storage and transportation.Selection Guide - Aqueous Corrosion Inhibitors1 2 3 4HighlyRecommended4371019A4371019A420KX450Ease of Use420, 4371019AKX450Indoor Storage4371019AKX450420MarineEnvironment4371019A420KX450Aerosol CansProtection420KX4504371019AStacking WetParts420437KX4501019A

K-CORR ® NF SeriesYellow Metal DeactivatorsK-CORR NF-200 is a premium ashless liquid yellow metal deactivator for industrial and automotive lubricants,greases, and rust preventive fluids. It complies with FDA 21 CFR 178.3570 standards and is NSF HX-1registered.K-CORR NF-410 is a multifunctional additive that provides extreme pressure properties in addition to yellowmetal protection. It can be used with K-CORR NF-200 to achieve higher levels of non-ferrous metal protection.TestProduct Composition DescriptionK-CORR NF-200K-CORR NF-410ADVANTAGES:Base OilProprietary HeterocyclicDerivativeSulfur & NitrogenChemistryExcellent thermal and hydrolytic stabilityGood demulsificationOutstanding solubility in mineral oil and syntheticbase stocksGood compatibility with other additivesLow viscosityEnhanced oxidation stabilityK-CORR NF-200 is used in all types of lubricants and greases wherecopper and copper-alloy machine parts need to be protected fromcorrosion.The table below shows the ability of K-CORR NF-200 to protect copperagainst the corrosive effects of active sulfur. The incorporation of activesulfur into an ISO VG 32 oil results in severe corrosion of the copperstrips in the ASTM D 130 test. Addition of a low treat level of K-CORRNF-200 offsets the detrimental effects of the active sulfur.No AdditiveISO VG 32*+ 50 ppm Sulfur**Premium ashless liquid yellow metal deactivator forindustrial and automotive lubricants, greases, and rustpreventive fluids. HX-1 registered - # 141124.Premium ashless liquid multifunctional additive providingextreme pressure and yellow metal protecting properties byscavenging active sulfur.0.05%K-CORR NF-200ISO VG 32+ 50 ppm SulfurNo AdditiveISO VG 32+ 100 ppm Sulfur1a4aASTM D 130Copper0.05%K-CORR NF-200ISO VG 32+ 100 ppm SulfurK-CORR ® NF Series - Yellow Metal DeactivatorsCopper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 135°C3a4a1a1b4a4c1b1b* Solvent refined paraffinic Group I oil, ** Elemental sulfurAdditional formulations containing K-CORR NF-200 and K-CORR NF-410 can be found on pages11, 13, 34, 35, 36, 37, 40 and 50 of this product guide.Pages 31-32

O OHO R NOOR''OR''K-CORR ® 100 SeriesAshless Rust InhibitorsR'OK-CORR ® Ashless Rust & Corrosion InhibitorsThe K-CORR 100 Series is based on a unique amino acid derivative and is effective in a broadrange of industrial lubricants and functional fluids. In addition to excellent rust protection at lowadditive levels, the K-CORR 100 inhibitors offer a variety of performance advantages in specificsystems, including:Neutral behavior in FZG testingExcellent thermal stabilityGood hydrolytic stabilityGood demulsibility and water separationAntiwear synergism with selected EP/AW additivesEnhanced oxidation stabilityProductChemical BasisAcid Value(mg KOH/g)DescriptionK-CORR 100 Amino Acid Derivative ~105 Ashless rust inhibitor and intermediateK-CORR 100A2K-CORR 1031Amino Acid Derivativewith AmineAmino Acid Derivativewith Amine~80Ashless rust inhibitor with improvedsolubility~95 Premium ashless rust inhibitorImproving Antiwear Performanceof Extreme Pressure Agents with K-CORR 100 Series ProductsAntiwear agents and rust inhibitors compete for sites on the substrate and typically are antagonistictowards each other. The K-CORR 100 Series rust inhibitors are unique because they aresynergistic with a variety of EP/AW agents including phosphate esters, sulfurized olefins, triphenylphosphorothionate (TPPT), and ashless dialkyldithiocarbamates.Scar Diameter: Four Ball Wear (ASTM D 4172) 1 hour, 75ºC, 40 kgf, 1200 rpm0.90.80.70.60.50.40.30.2WithoutK-CORR 1031With 0.25%K-CORR 10310.10Paraffinic Base OilISO VG 320.75% TPPT 1.00% PhosphateEster1.00% SulfurizedOlefin

K-CORR 1031 and<strong>NA</strong>-<strong>LUBE</strong> ADTC SynergyC 4 H 9 SN CC 4 H 9 S CH 2SCS<strong>NA</strong>-<strong>LUBE</strong> ADTCNC 4 H 9C 4 H 9At various additive treat levels in an ISO VG 32paraffinic oil, K-CORR 1031 improves the lowload antiwear performance of an additive normallychosen for high load extreme pressure effectiveness.The graph to the right shows an example of theantiwear synergism of K-CORR 1031 with theextreme pressure agent <strong>NA</strong>-<strong>LUBE</strong> ADTC (anashless dialkyldithiocarbamate).K-CORR 1031 Industrial Lubricant PerformanceTestsBase Oil0.35% K-CORR NF-410 0.35% K-CORR NF-4100.06% K-CORR 1031ParaffinicISO VG 32ParaffinicISO VG 320.35% K-CORR NF-4100.25% K-CORR 1031ParaffinicISO VG 32Steel Corrosion(ASTM D 665, DIN 51 585) A & B Fail Pass PassDemulsibility(ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (minutes)Copper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100°C24 hours, 100°C3 hours, 135°C42-38-0101a1a1aASTM D 4172 Four Ball Wear Test1 hour, 75°C, 40 kgf, 1200 rpm43-37-015FZG A/8.3/90 (DIN 51 354 Part 2)Damage Load Stage 9 9 91b1b1b41-39-015Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpmScar Diameter (mm) 0.75 0.76 0.610.80.60.40.20Without K-CORRWith 0.25% K-CORR 10310.0 0.5 1.0 1.5 2.0Weight % <strong>NA</strong>- <strong>LUBE</strong> ADTCK-CORR 1031 imparts outstanding steel corrosion protection and demulsibility to formulated fluids.The table below shows the typical performance of K-CORR 1031 in an oil containing a dimercaptothiadiazolederivative.Average Scar Diameter1a1a1aK-CORR ® Ashless Rust & Corrosion InhibitorsK-CORR 1031 at 0.06% in this base oil passes the standard steel corrosion tests without detractingfrom other test requirements. At an increased level of 0.25% K-CORR 1031, improvement in theFour Ball Wear performance, similar to that shown on the previous page, is demonstrated.Additive CompatibilityA concern exists regarding the compatibility of ashless and metal-containing (primarily zinc)lubricants and functional fluids. Formulations containing K-CORR 100 Series rust inhibitors,particularly K-CORR 1031, are tolerant of contamination with zinc dithiophosphate-based fluids.Studies showing this behavior are available.Pages 33-34