NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

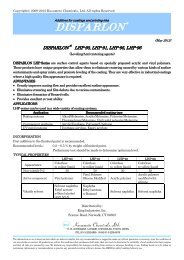

K-CORR ® SA-300Ashless Rust InhibitorK-CORR ® SA-300 - Ashless Rust InhibitorK-CORR SA-300 is an ashless rust inhibitor based upon organic acid/ester chemistry. The additiveis highly efficient and may be used at treat levels as low as 0.03% to pass the ASTM D 665B test inR&O circulating oils and HF-2 hydraulic oils. In addition, it is recommended for formulating highperformance ashless steam turbine oils, paper machine oils, industrial and automotive gear oils,greases, and rust preventive fluids.Advantages:AshlessOutstanding rust and corrosion protectionExcellent demulsificationGood thermal and hydrolytic stabilitySoluble in highly paraffinic and synthetic base oilsEffective at very low treat levelsExcellent compatibility with all types of conventional functional additivesThe following table shows that the addition of a low treat level of K-CORR SA-300 imparts excellentsteel corrosion protection to an oil already containing antioxidants. In addition, K-CORR SA-300exhibits no adverse effects on other performance tests including copper corrosion, demulsibility, androtating pressure vessel oxidation. Further addition of a low treat level of an ashless yellow metaldeactivator to the formulation significantly increases the oxidation resistance of the oil as indicatedby rotating pressure vessel oxidation testing.Tests0.125% <strong>NA</strong>-<strong>LUBE</strong> AO-1300.125% <strong>NA</strong>-<strong>LUBE</strong> AO-2420.125% <strong>NA</strong>-<strong>LUBE</strong> AO-1300.125% <strong>NA</strong>-<strong>LUBE</strong> AO-2420.070% K-CORR SA-300Base Oil ISO VG 46 (Group II ) *0.125% <strong>NA</strong>-<strong>LUBE</strong> AO-1300.125% <strong>NA</strong>-<strong>LUBE</strong> AO-2420.070% K-CORR SA-3000.050% K-CORR NF-200Steel Corrosion(ASTM D 665, DIN 51 585)A & B Fail Pass PassCopper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 135°C1b1b1b1b1b1bDemulsibility(ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (Minutes)40-40-0540-40-0540-40-05RPVOT(ASTM D 2272)Lifetime (Minutes) 218 222 463* Compared to solvent refined HVI oils, Group II oils are more difficult to inhibit because the natural antioxidants (sulfur, nitrogen,and oxygen-containing compounds) have been removed by the refining process. The current industry trend is towardsGroup II and Group III base oils.