NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

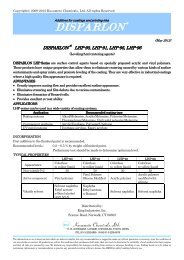

NEW <strong>NA</strong>-<strong>LUBE</strong> ® BL-1232 ELEnvironmentally Driven...Performance ProvenThroughout the world, environmentally friendly lubricants are beingdeveloped to replace older technologies that are non-renewable and arecontaminates when released into soil or water. Almost universally, thechallenge formulators face when developing these new, replacementproducts is maintaining or surpassing the performance characteristics ofthe original.Additive Packages - BlendsA particular area of focus for new greener lubricants has been hydraulicfluids, given their propensity to leak and the ensuing ground and watercontamination. Here too, the challenge has been finding additives andadditive packages that are eco-friendly and deliver the performanceneeded. In that regard <strong>King</strong> <strong>Industries</strong> is proud to introduce <strong>NA</strong>-<strong>LUBE</strong>BL-1232 EL, an ashless, multifunctional additive package specificallydesigned for use in ester based systems including hydraulic fluids.Additive Package <strong>NA</strong>-<strong>LUBE</strong> BL-1232 EL has been evaluated against thelatest European Ecolabel criteria for lubricants. Based on that evaluation,<strong>NA</strong>-<strong>LUBE</strong> BL-1232 EL, when used as a single additive, qualifies for usein a final product eligible for the European Eco-Label in a concentrationup to 1.8% by weight. <strong>NA</strong>-<strong>LUBE</strong> BL-1232 EL Performance With Saturated EstersBase Fluid Priolube 1973Saturated EsterTreat Level, % Neat With 1.8%BL-1232 ELSteel Corrosion(ASTM D 665)Procedure A (distilled H 2O)Procedure B (synthetic sea water)Demulsibility(ASTM D 1401) @ (54°C)Oil-Water-EmulsionTime (minutes)FailFail43-37-015PassPass40-40-015Radialube ® 7588Saturated EsterNeat With 1.8%BL-1232 ELFailFail43-37-025PassPassSpecificationDIN ISO 15380PassPass41-38-025 30FZG A/8.3/90(ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage n/d >12 n/d 12 10 min.Four Ball Wear (ASTM D 4172)1 hour, 22°C, 15 kgf, 1500 rpm (mm)1 hour, 22°C, 30 kgf, 1500 rpm (mm)1 hour, 75°C, 40 kgf, 1500 rpm (mm)n/d0.490.570.48n/d0.540.590.40120 max.30 max.V 104C Vane Pump(DIN EN ISO 20 763)Reported Wear Loss Ring (mg)Wear Loss Vanes (mg)n/d 4.67.5n/dn/dCopper Corrosion (ASTM D 130)3 hours, 100°C 1b 1a 1b 1a 2 max.AFNOR FiltrationDry (E 68690) FI 1.05 1.04 1.09 1.08Wet (E 68691) FI 1.28 1.08 1.33 1.12Filterability Dry (DIN ISO 13357-2)F IF II99.598.995.487.799.196.396.984.880 min.60 min.Filterability Wet (DIN ISO 13357-2)F lF ll92.583.693.885.995.082.091.779.170 min.50 min.