NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

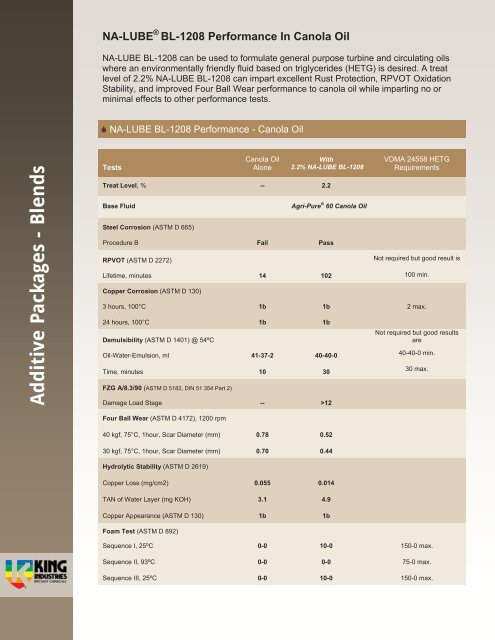

<strong>NA</strong>-<strong>LUBE</strong> ® BL-1208 Performance In Canola Oil<strong>NA</strong>-<strong>LUBE</strong> BL-1208 can be used to formulate general purpose turbine and circulating oilswhere an environmentally friendly fluid based on triglycerides (HETG) is desired. A treatlevel of 2.2% <strong>NA</strong>-<strong>LUBE</strong> BL-1208 can impart excellent Rust Protection, RPVOT OxidationStability, and improved Four Ball Wear performance to canola oil while imparting no orminimal effects to other performance tests. <strong>NA</strong>-<strong>LUBE</strong> BL-1208 Performance - Canola OilAdditive Packages - BlendsTestsCanola OilAloneWith2.2% <strong>NA</strong>-<strong>LUBE</strong> BL-1208Treat Level, % -- 2.2Base FluidSteel Corrosion (ASTM D 665)Agri-Pure ® 60 Canola OilProcedure B Fail PassRPVOT (ASTM D 2272)Lifetime, minutes 14 102Copper Corrosion (ASTM D 130)VDMA 24558 HETGRequirements3 hours, 100°C 1b 1b 2 max.24 hours, 100°C 1b 1bDemulsibility (ASTM D 1401) @ 54ºCOil-Water-Emulsion, ml 41-37-2 40-40-0Time, minutes 10 30FZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage -- >12Not required but good result is100 min.Not required but good resultsare40-40-0 min.30 max.Four Ball Wear (ASTM D 4172), 1200 rpm40 kgf, 75°C, 1hour, Scar Diameter (mm) 0.78 0.5230 kgf, 75°C, 1hour, Scar Diameter (mm) 0.70 0.44Hydrolytic Stability (ASTM D 2619)Copper Loss (mg/cm2) 0.055 0.014TAN of Water Layer (mg KOH) 3.1 4.9Copper Appearance (ASTM D 130) 1b 1bFoam Test (ASTM D 892)Sequence I, 25ºC 0-0 10-0 150-0 max.Sequence II, 93ºC 0-0 0-0 75-0 max.Sequence III, 25ºC 0-0 10-0 150-0 max.