NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

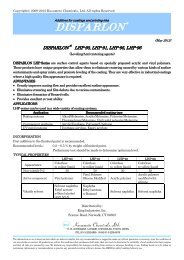

<strong>NA</strong>-<strong>LUBE</strong> ® AW 6000 Series - Ashless Antiwear Additives Performance in a Paraffinic ISO VG 46 Base OilThe following table shows the performance of <strong>NA</strong>-<strong>LUBE</strong> AW-6010, AW-6110, and AW-6220 whenadded to a paraffinic ISO VG 46 base oil.TestsBase Oil0.25%AW-60100.10%AW-6110ISO VG 46 (Group II)0.10%AW-6220Steel Corrosion (ASTM D 665, DIN 51 585) A & B Not Applicable Pass PassDemulsibility (ASTM D 1401, DIN 51 599)Oil-Water-EmulsionSeparation Time (Minutes)Copper Corrosion (ASTM D 130, DIN 51 759)3 hours, 100°C24 hours, 100°C3 hours, 135°C42-38-0101a1b1b41-39-0101a1b1b41-39-05FZG A/8.3/90 (ASTM D 5182, DIN 51 354 Part 2)Damage Load Stage >12 >12 12Four Ball Wear (ASTM D 4172)1 hour, 75°C, 1200 rpm, 30 kgf, Scar Diameter (mm)1 hour, 75°C, 1200 rpm, 40 kgf, Scar Diameter (mm)Performance of the<strong>NA</strong>-<strong>LUBE</strong> AW 6000 Series0.460.640.320.50 Performance of <strong>NA</strong>-<strong>LUBE</strong> AW-6220 as a Yellow Metal Deactivator<strong>NA</strong>-<strong>LUBE</strong> AW-6220 also acts as a yellow metal deactivator. The table below compares theperformance of <strong>NA</strong>-<strong>LUBE</strong> AW-6220 to the performance of two common yellow metal deactivators.As the data show, at a treat level of 0.10%, <strong>NA</strong>-<strong>LUBE</strong> AW-6220 provides excellent yellow metalprotection while also providing steel corrosion protection with good antiwear properties.Tests --Base OilISO VG 46 * +100 ppm Sulfur**0.10% DMTD***DerivativeISO VG 46 +100 ppm Sulfur0.10%TolytriazoleISO VG 46 +100 ppm Sulfur1a1b1b0.400.430.10%<strong>NA</strong>-<strong>LUBE</strong> AW-6220ISO VG 46 +100 ppm SulfurSteel Corrosion(ASTM D 665, DIN 51 585) A & B Fail Fail Fail PassCopper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100°C3 hours, 120ºC24 hours, 120ºC3 hours, 135ºC24 hours, 135°C4a4b4b4b4bFour Ball Wear(ASTM D 4172)Scar Diameter (mm)1 hour, 75°C, 1200 rpm, 40 kgf 0.75 0.66 0.71 0.50Four Ball Weld Load(ASTM D 2783)10 second, 25ºC, 1800 rpmOK Load (kgf)Weld Load (kgf)1001201b1b3a1b3b1401601b1b3a1b3a1401601b1b3a1b3a140160* Hydrotreated paraffinic oil (Group II) with less than 0.03% natural sulfur ** Elemental sulfur soluble in Group II oil***Dimercaptothiadiazole