NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

NA-LUBE - King Industries, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

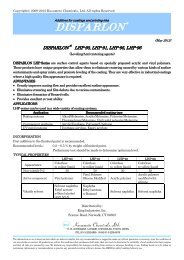

<strong>NA</strong>-<strong>LUBE</strong> ® EP 5000 Series - Extreme Pressure AdditivesPerformance of the<strong>NA</strong>-<strong>LUBE</strong> EP 5000 Series Series Performance in a ISO VG 32 Group I Base OilThe following table highlights the performance of the products in various bench tests for lubricationproperties.Tests<strong>NA</strong>-<strong>LUBE</strong>EP-5210<strong>NA</strong>-<strong>LUBE</strong>EP-5216<strong>NA</strong>-<strong>LUBE</strong>EP-5218Base Oil ISO VG 32 (Group I)Treat Level, % 5.0Four Ball Weld (ASTM D 2783)10 seconds, 25°C, 1800 rpmOK Load (kgf)Weld Load (kgf)160200200240200240<strong>NA</strong>-<strong>LUBE</strong>EP-5316200240<strong>NA</strong>-<strong>LUBE</strong>EP-5415Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpmScar Diameter (mm) 0.54 0.58 0.81 0.68 0.60Copper Corrosion(ASTM D 130, DIN 51 759)3 hours, 100ºC24 hours, 100ºC <strong>NA</strong>-<strong>LUBE</strong> EP-5210 - Concentration Effect On Properties1a2aAs shown below, with increasing concentrations of <strong>NA</strong>-<strong>LUBE</strong> EP-5210, the wear and extremepressure properties improve with no negative effects on demulsibility or copper corrosion protection.Tests2.0% <strong>NA</strong>-<strong>LUBE</strong>EP-52103a4a7.5% <strong>NA</strong>-<strong>LUBE</strong>EP-52103a4a10.0% <strong>NA</strong>-<strong>LUBE</strong>EP-5210Base Oil ISO VG 32 (Group I)Four Ball Weld (ASTM D 2783)10 seconds, 25°C, 1800 rpmOK Load (kgf)Weld Load (kgf)1201601602001602001b3b2202401b3b10.0% <strong>NA</strong>-<strong>LUBE</strong> EP-52106.0% <strong>NA</strong>-<strong>LUBE</strong> AW-6010Four Ball Wear (ASTM D 4172)1 hour, 75°C, 40 kgf, 1200 rpmScar Diameter (mm) 0.72 0.59 0.60 0.50Falex PIN & VEE (ASTM D 3233)Lbs. 890 1050 1060 950Copper Corrosion(ASTM D130, DIN 51 759)3 hours, 100ºC24 hours, 100ºCDemulsibility(ASTM D 1401,DIN 51 599Oil-Water-EmulsionTime (Minutes)1a3a39-39-2101a2a41-39-0101a2a41-39-0102002401b2a40-40-010