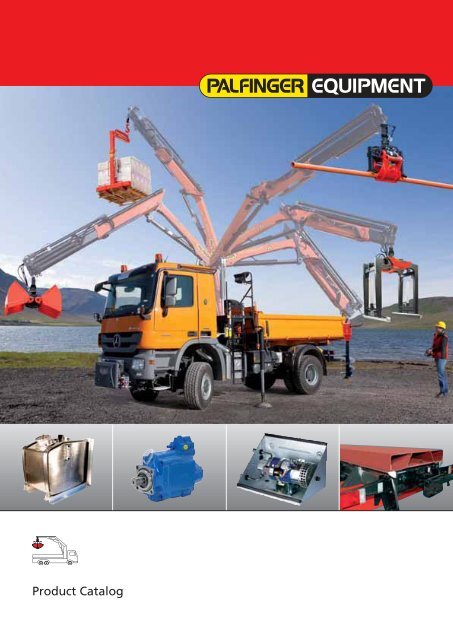

PEC 2010_Umschlag_engl - Palfinger

PEC 2010_Umschlag_engl - Palfinger

PEC 2010_Umschlag_engl - Palfinger

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Product Catalog

Contents1. PALFINGER made by Kinshofer ........ 4-37Rotators ........................................................................ 4-5Accessories for Rotators .............................................. 6-7HPX-E Standard ............................................................ 8-9HPX Standard .......................................................... 10-11HPX Heavy Duty ...................................................... 12-13Clamshell Buckets .................................................... 14-17High Volume Clamshell Buckets .............................. 18-19Universal Buckets .......................................................... 20Accessories for Clamshell Buckets ................................ 21Orange Peel Grapples .............................................. 22-23Brick Stack Grapples ..................................................24-26Pallet Forks .............................................................. 27-31Universal Forks .............................................................. 32Bottle-Bank Discharge Units .................................... 33-34Manipulators ................................................................ 35Barrier Lifter .................................................................. 36Special Solutions ............................................................ 372. PK-Small Crane Grapples .................... 389. Vacuum Lifting Device ........................ 4910. Pumps .............................................. 50-61Bosch Rexroth ........................................................ 50-53Hydro Leduc ............................................................ 54-58Sunfab ...................................................................... 59-6111. Hydraulic Power Units ........................ 6212. Oil Coolers ...................................... 63-6413. Oil Tanks .......................................... 65-67Steel ................................................................................ 65Aluminum ...................................................................... 66Accessories .................................................................... 6714. Mounting Kits ................................ 68-71Rear Demountable Consoles .................................. 68-69Coupling Extension and Underride Protection ............70Subframes ...................................................................... 713. Crane Box ............................................ 394. Augers ............................................ 40-415. Workman-Baskets .......................... 42-436. Pull-In-Parts .......................................... 447. Car Lifting Devices .......................... 45-468. Weight-Measuring Systems .......... 47-4815. Additional Stabilizers .................... 72-79Mounting Frames for PC-Cranes ............................ 72-73New Additional Stabilizers ...................................... 74-76Additional Stabilizers .............................................. 77-78Accessories .................................................................... 7916. Top Seat Cover, Seat Cover, High Stand 8017. Automatic Hooks ................................ 8118. Automatic Uncoupling System ...... 82-83Businesspartners fromebner-Abschlepptechnik3

Accessories for RotatorsKinshoferUpper suspensions between rotator and craneAn upper suspension is a cardan link between rotator and crane. It is available for all common models of cranes.Please specify dimensions when ordering.BAEUpper Upper Lower Lower Length Rotators Crane Selfwidth pin-Ø width pin-Ø weightType A (mm) B (mm) C (mm) D (mm) E (mm) (kg)UL045 71 30 85 30 263 PZR450(G,GF) Compact crane 10UL045K 71 30 85 30 173 PZR450(G,GF) Compact crane 10UL045L 71 30 85 30 400 PZR450(G,GF) Compact crane 10UL045-42 71 42 85 30 253 PZR450(G,GF) Compact crane 10UL090K 72 30 77 25 173 PZR450(G,GF) Compact crane 12UL090 72 30 76 25 245 PZR450(G,GF) Compact crane 12UL134 22 25 85 30 173 PZR450(G,GF) Compact crane 10UL135 72 30 85 40 278 PZR601(G,GF) Compact crane 15UL135K 72 30 85 40 173 PZR601(G,GF) Compact crane 15UL135-42 71 42 85 40 268 PZR601(G,GF) Compact crane 15UL153 71 30 80 35 270 PZR1000GF Compact crane 25UL153K 71 30 80 35 245 PZR1000GF Compact crane 25UL153-42 71 42 80 35 370 PZR1000GF Compact crane 25UL144 79 40 85 30 150 PZR450(G,GF) EPSILON cranes 10UL136 79 40 85 30 240 PZR450(G,GF) Wallboard cranes 10UL137 108 30 86 40 185 PZR601(G,GF) Wallboard cranes 15UL138 79 40 86 40 185 PZR601(G,GF) EPSILON cranes 15UL152 80 40 137 52 240 PZR1000GF EPSILON cranes 15UL154 80 40 80 35 150 PZR1000GF EPSILON cranes 25UL155 80 40 80 35 240 PZR1000GF EPSILON cranes 25N00267 with double pendulum brake* PZR450(G,GF) EPSILON cranes 20N00597 with pendulum brake* PZR450GF Compact crane 20N00629 with pendulum brake* PZR601GF Compact crane 20*) please specify dimensions when orderingCDHose protectionsThe hose protection is a metal bow, which is attached onto the rotator. It is designed to protect the hosesof the rotator from damage i.e. from protruding branches.TypeN00101N00369For rotatorPZR450 (G,GF)PZR601 (G,GF)Reduction links between rotator and attachmentA reduction link adapts a shaft type rotator to an attachment with a standard hole pattern fora flange rotator.6TypeDescriptionN00072-XX*between shaft rotator and attachmentN00072-68-59 reduction link 68 mm for 59 mmN00417intermediary between flange and shaft 58 mm*) specify Ø shaft when ordering (59, 62, 63, 68, 69)

Quick change system for shaft rotatorsThe quick change system enables an easy exchange between different attachments. The mechanical couplingand locking is achieved by the turning motion of the rotator. You simply disconnect quick couplingsand disengage the locking device manually. Upper elements of the quick change system are available for allshaft rotators. The system can be used on most attachments, which allows the versatility to quickly changethe application with a minimum of down-time. It is not suitable for heavy duty work.KinshoferDescription Flange attachment Self weightType Hole pattern of flange (mm) (kg)N00074* complete, incl. hydraulic couplings (BL981-L, BL981-F) 4 x Ø18 / ■ 140 12N00076* upper element (fitted to rotator) 5N00077 lower element (mounted onto attachment) 4 x Ø18 / ■ 140 7N00075 rigid suspension link with non-rotating hook to connectto the upper element instead of the lower element e.g. for attaching pallet forks 7N00414 intermediary between PZP-W and N00074*) specify type of rotator when orderingN00074N00076N00077N00075Connecting hoses and hydraulic quick change kit for hosesTypeBL462BL462-RBL463BL513BL462-MFBL513-MFDescriptionconnecting hoses between rotator and crane 900 mm ; 4 pcs.connecting hoses between rotator and crane 900 mm ; 2 pcs.connecting hoses between rotator and attachment 500 mm; 2 pcs.connecting hoses between rotator and crane version D and E 1200 mm; 4 pcs.connecting hoses between rotator and crane 900 mm; (4 pcs.), multi-fasterconnecting hoses between rotator and crane version D and E 1200 mm (4 pcs.), multi-fasterBL981-LBL981-FN00090mobile part of hydraulic quick coupling for fitting to the hose (Ø 10 mm, 2 pieces)fixed part of hydraulic quick coupling for fitting to the rotator (Ø 10 mm, 2 pieces)hydraulic quick change kit incl. mobile and fixed parts, 2 pieces each,mounted with adapters to rotatorAccessories for attaching pallet forks etc.TypeDescriptionN00070** rigid suspension link with pin for all shaft-type rotatorsN00071-XX* non-rotating hook for all shaft-type rotatorsN00071-SB safety latch for N00071-XX* (3 pieces)N00070-62 rigid suspension link with pin for shaft rotator, shaft 62 mm*) specify Ø shaft when ordering (59, 62, 63, 68, 69) **) specify model of the crane fork when orderingN00360 rigif hook 6 t for PZR601GF flange rotatorN00328-68 rigid hook 6 t for PZR601G shaft rotator, shaft 68 mmN00372 non-rotating oscillating hook for PZR1000GF flange rotator7

HPX-E Standard Quick Change SystemKinshoferThe HPX-Edrive as an allround drive unit with integrated rotator and jawquick change system is perfect for the daily routine jobs. The advantagesof the revolutionary HPXdrive-technology – the constant high closingforce and the compact design – are combined with the speed advantageof the HPX-E jaw quick change system in just one single device. As soonas a new demand on site arises, the right attachment for excavating,landscaping, laying pipes, logging, rail track handling etc. can be exchangedin four minutes and the new application can commence.• Efficiency: only the attachments are replaced. One-man-exchange is possible• Quickness: trouble-free exchange of the linchpin from the change-over systemwithin 4 minutes, no hydraulic work necessary• Robust technics: compact design through the integrated rotator.Robust shell bearings with coexisting change mechanismPZHP04E-GF HPXdrive standard with flange rotator and HPX-EPackage consists of: upper suspension UL045K, flange rotator PZR450GF, long connecting hosesBL462, drive unit HPXdrive standard with pressure relief valve, non-return valveand HPX-E jaw quick change system, exchange aidsSettle bucket or gripper withclosed shells.Self weight:Height:210 kg480 mmMount exchange aids and loosentwo linchpins with extraction tool.HPX-E jaw quick change systemSmall volumeclamshell bucketsClamshellbucketsRemove the linchpins.Loosen the locking unit hydraulically.Lift the carrier.Position the carrier over the new attachmentand close the locking unit hydr.RockgrapplesHPX-Equick changing moduleMulti purposegrapplesInsert two linchpins and fasten thepin retainers.TimbergrapplesExchangeaidsHay- andwood grapples8Remove the exchange aids.Ready for use.Please note: The drive unit HPXdrive standard can only be used in combination with PALFINGER-rotatorand HPX shells or HPX-E system. We reserve the right to amend specifications without prior notice.

HPX-E Exchangeable ShellsDue to the HPX-E quick exchange system the replacement of shells orgrippers mounted to the HPXdrive standard is very easy and fast. Withoutscrews, simply by loosening and setting the linchpins, different tools forvarious applications can be fitted onto the drive unit, e.g. clamshellbuckets, rock grapples, timber grapples, hay- and forestry grapples ormulti purpose clamshells. Other types of shells are available on request.KinshoferThe interchangeable shells or grippers are delivered with an exchange aid, whichguarantees that the HPXdrive can be positioned onto the shells with ease.Package consists of: exchangeable shells, bolt-on teeth (for PZWS04E), exchange aid kitVolume Width Opening max. Number of Self weightType (litre) (mm) (mm) teeth/tines (kg)Exchangeable shells clamshell buckets for HPX-EPZWS04E-200 200 400 1395 4 143PZWS04E-250 250 500 1395 4 153PZWS04E-325 325 600 1395 6 163PZWS04E-350 350 650 1395 6 168PZWS04E-450 450 800 1395 6 183Exchangeable shells small clamshell buckets for HPX-EPZWS04E-95 95 400 900 4 108PZWS04E-100 100 450 900 4 103PZWS04E-150 150 600 900 6 123Exchangeable shells clamshell buckets with open shells for HPX-EPZWS4UE-250 250 570 1595 - 228PZWS4UE-300 300 670 1595 - 248PZWS4UE-400 400 820 1595 - 268PZWS4UE-500 500 1020 1595 - 298optional available with bolt on teeth and side plates (N00385, N00385-10)Exchangeable shells rock grapples for HPX-EPZWS13E-016 0,16 m 2 400 1230 - 88Exchangeable shells timber grapples for HPX-EPZWS32E-016 0,16 m 2 400 1225 - 88Exchangeable shells hay- and forestry grapples for HPX-EPZWS41E-02 0,20 m 2 670 1200 7 108PZWS41E-04 0,40 m² 940 1695 7 1739

HPXdrive Standard – Drive UnitsKinshoferThe HPXdrive standard as an allround unit is perfect forthe daily routine jobs. The advantages of the HPXdrivetechnology– the constant high closing force and thecompact design – guarantee a long life and rentability.UppersuspensionThe standard rotator of the HPXdrive standard is the rotatorwith flange PZR450GF. The combination with the shaft rotatorenables a quick exchange to a hook.▲Rotatorwith flange▲Rotatorwith shaft▲ ▲ ▲Technical information HPXdrive standardNonrotatinghookQuickchangesystemReductionlink▲NonrotatinghookTorque (at 26 MPa):Operating pressure:Pump capacity:12000 Nm26 to 32 MPa (approx. 260 to 320 bar)25 to 75 l/min▲ ▲PZHP04-GF HPXdrive standard with flange rotatorPackage consists of: upper suspension UL045K, rotator PZR450GF, long hoses BL462, drive unitHPXdrive standard with pressure relief valve and non-return valveSelf weight:Height:160 kg480 mmPZHP04-502 HPXdrive standard/N00072 with shaft rotator and reduction linkPackage consists of: upper suspension UL045K, rotator PZR450G-68, reduction link N00072-68,long hoses BL462, drive unit HPXdrive standard with pressure relief valve andnon-return valveSelf weight:Height:165 kg535 mmPZHP04-505 HPXdrive standard/N00074 with shaft rotator and quickchange systemPackage consists of: upper suspension UL045K, rotator PZR450G-68, quick change system N00074,long hoses BL462, drive unit HPXdrive standard with pressure relief valve andnon-return valveSelf weight:Height:170 kg575 mm10Please note: The drive unit HPXdrive standard can only be used in combination with PALFINGER rotator and PALFINGER shells.

HPXdrive Standard – Exchangeable ShellsThe shells of the HPXdrive standard are easily exchangeableby loosening the retaining screws. Different typesof shells for various applications can be refitted ontothe driving unit, e.g. clamshell buckets, rock grapples,timber grapples, hay- and forestry grapples and multipurpose clamshells. Other types of shells are availableon request.KinshoferThe exchangeable shells are delivered with an exchange aid,which guarantees that the HPXdrive standard can bepositioned with ease.Package consists of: exchangeable shells, bolt-on teeth (for PZHP04), exchange aid kitVolume Width Opening max. Number of Self weightType (litre) (mm) (mm) teeth/tines (kg)Exchangeable shells clamshell buckets for PZHP04PZWS04-200 200 400 1395 4 125PZWS04-250 250 500 1395 4 140PZWS04-325 325 600 1395 6 150PZWS04-350 350 650 1395 6 155PZWS04-450 450 800 1395 6 170Exchangeable shells clamshell buckets with open shells for PZHP04PZWS4U-250 250 570 1595 - 215PZWS4U-300 300 670 1595 - 235PZWS4U-400 400 820 1595 - 255PZWS4U-500 500 1020 1595 - 285optional available with bolt on teeth and side plates (N00385, N00385-10)Exchangeable shells rock grapples for PZHP04PZWS13-016 0,16 m 2 400 1230 - 75Exchangeable shells timber grapples for PZHP04PZWS32-016 0,16 m 2 400 1225 - 75Exchangeable shells hay- and forestry grapples for PZHP04PZWS41-02 0,20 m 2 670 1200 7 95PZWS41-04 0,40 m 2 940 1695 7 160Load capacity Closing force Width Self weightType (kg) (kN) (mm) (kg)Exchangeable shells guard rail grapples for PZHP04PZWS04-VG / Vario guard 1500 25 2200 415PZWS04-MG / Mini guard 1500 25 820 25011

HPXdrive Heavy Duty – Drive UnitsKinshoferThe HPXdrive heavy duty is a powerful version fordifficult tasks. The advantages of the HPXdrivetechnology– the constant high closing force and thecompact design – guarantee a long life and rentability.UppersuspensionThe standard rotator of the HPXdrive heavy duty is the rotatorwith flange PZR450GF. The combination with the shaft rotatorenables a quick exchange to a hook.▲Rotatorwith flange▲Rotatorwith shaft▲ ▲ ▲Technical information HPXdrive heavy dutyTorque (at 32 MPa): 21000 NmOperating pressure: 26 to 32 MPa (approx. 260 to 320 bar)Pump capacity:40 to 90 l/minNonrotatinghookQuickchangesystem▲ ▲Reductionlink▲NonrotatinghookPZHP05-GF HPXdrive heavy duty with flange rotatorPackage consists of: upper suspension UL045K, rotator PZR450GF, long hoses BL462,drive unit HPXdrive heavy duty with pressure relief valve and non-return valveSelf weight:Height:195 kg510 mmPZHP05-502 HPXdrive heavy duty/N00072 with shaft rotatorand reduction linkPackage consists of: upper suspension UL045K, rotator PZR450G-68, reduction link N00072-68,long hoses BL462, drive unit HPXdrive heavy duty with pressure relief valveand non-return valveSelf weight:Height:200 kg565 mmPZHP05-505 HPXdrive heavy duty/N00074 with shaft rotator and quickchange systemPackage consists of: upper suspension UL045K, rotator PZR450G-68, quick change system N00074,long hoses BL462, drive unit HPXdrive heavy duty with pressure relief valve andnon-return valveSelf weight:Height:205 kg605 mm12Please note: The drive unit HPXdrive heavy duty can only be used in combination with PALFINGER rotator and PALFINGER shells.

HPXdrive Heavy Duty – Exchangeable ShellsThe shells of the HPXdrive heavy duty are easily exchangeableby loosening the retaining screws. Different types ofshells for various applications can be refitted onto thedriving unit, e.g. clamshell buckets, rock grapples, timbergrapples, hay- and forestry grapples and multi purposeclamshells. Other types of shells are available on request.KinshoferThe exchangeable shells are delivered with an exchangeaid which guarantees that the HPXdrive heavy duty can bepositioned onto the shells with ease.Package consists of: exchangeable shells, bolt-on teeth (for PZHP05), exchange aid kitVolume Width Opening max. Number of Self weightType (litre) (mm) (mm) teeth/tines (kg)Exchangeable shells heavy duty clamshell buckets for PZHP05PZWS05-200 200 400 1420 4 135PZWS05-250 250 500 1420 4 165PZWS05-350 350 650 1420 6 190PZWS05-450 450 800 1420 6 215PZWS05-550 550 1000 1420 8 250Exchangeable shells heavy duty clamshell buckets with open shells for PZHP05PZWS5U-250 250 570 1545 5* 220PZWS5U-300 300 670 1545 5* 240PZWS5U-400 400 820 1545 7* 260PZWS5U-450 450 920 1545 7* 275PZWS5U-500 500 1020 1545 9* 295*) optional available with bolt-on teeth and side pates (N00385, N00385-10)Exchangeable shells heavy duty rock grapples for PZHP05PZWS13-035S 0,35 m 2 400 1705 - 135Exchangeable shells heavy duty timber grapples for PZHP05PZWS32-016S 0,16 m 2 400 1290 - 90Exchangeable shells heavy duty hay- and forestry grapples for PZHP05PZWS41-04S 0,40 m 2 940 1720 7 19513

Clamshell Buckets with Horizontal Hydraulic CylinderKinshoferThe bucket is the ideal solution for light weight loader cranes in dailyroutine work – robust, effective, cost efficient.• Maximum loading height is achieved through the compact designwith the horizontal hydraulic cylinder• Long life is ensured through the use of 500 HB steel in the manufacture ofthe cutting edges and a generously dimensioned bearing system• Synchronized opening and closing through a sturdy compensation bar• Bolt-on digging teeth are delivered with each clamshell bucket• Excellent digging characteristics are the result of high closing forces(20 kN at 26 MPa operating pressure)Package clamshell buckets PZG-GPKVolume Width Opening max. Number of Self weight Closing force LoadB teeth capacityType (litre) (mm) (mm) (kg) (kN) (kg)PZG150GPK 150 325 1390 3 210 20 3000PZG250GPK 250 500 1390 5 255 20 3000PZG350GPK 350 650 1390 5 275 20 3000PZG450GPK 450 800 1390 9 280 20 3000PZG550GPK 550 1000 1390 9 310 20 3000Package consists of: clamshell bucket, bolt-on teeth, rotator PZR450GF, connecting hoses BL462 and BL463, upper suspension UL045,non-return valveClamshell buckets PZG-GPZG150G 150 325 1390 3 185 20 3000PZG200G 200 400 1390 3 195 20 3000PZG250G 250 500 1390 5 220 20 3000PZG325G 325 600 1390 5 235 20 3000PZG350G 350 650 1390 5 240 20 3000PZG450G 450 800 1390 9 275 20 3000PZG550G 550 1000 1390 9 290 20 3000Package consists of: clamshell bucket, bolt-on teeth, non-return valveAccessoriesTechnical drawingsTypePZR450GFPZR450G-XX*N00074N00072-XX*N00143N00130N00129N00173N00048N00049PZ102-7000Descriptionrecommended flange rotator- load capacity 4500 kgshaft rotator - load capacity 4500 kgquick change system for shaft rotatorsreduction link between rotator and grapplescraper - indicate type of grapple when orderingwelded hookswear plates to protect horizontalcutting edges (2 pieces)adapters for mounting of compression railscompression rails – length 720 mm (2 pieces)compression rails – length 1000 mm (2 pieces)bolt-on teeth cpl., incl. screws and nuts220889Ø3084*) specify Ø shaft when orderingRequirements of truck crane14Operating pressure: 26 to 32 MPa (260 to 320 bar)Pump capacity: 25 to 75 l/min1392 B

Heavy Duty Clamshell Buckets with Horizontal Hydraulic CylinderThe rugged clamshell bucket is a successfulcomposition of design, function and performance.Kinshofer• Maximum loading height is achieved through the compact designwith the horizontal hydraulic cylinder• Long life is ensured through the use of 500 HB steel in the manufactureof the cutting edges and a generously dimensioned bearing system• Synchronized opening and closing through a sturdy compensation bar• Bolt-on digging teeth are delivered with each clamshell bucket• Excellent digging characteristics are the result of high closing forces(30 kN at 26 MPa operating pressure)Package clamshell buckets PZG-G-1PVolume Width Opening max. Number of Self weight Closing force LoadB teeth capacityType (litre) (mm) (mm) (kg) (kN) (kg)PZG200G-1P 200 400 1430 3 285 30 3000PZG250G-1P 250 500 1430 5 320 30 3000PZG350G-1P 350 650 1430 5 345 30 3000Package consists of: clamshell bucket, bolt-on teeth, rotator PZR450GF, connecting hoses BL462 and BL463, upper suspension UL045,non-return valveClamshell buckets PZG-G-1PZG200G-1 200 400 1430 3 265 30 3000PZG250G-1 250 500 1430 5 285 30 3000PZG350G-1 350 650 1430 5 310 30 3000PZG450G-1 450 800 1430 9 340 30 3000PZG550G-1 550 1000 1430 9 375 30 3000PZG650G-1 650 1200 1430 9 410 30 3000Package consists of: clamshell bucket, bolt-on teeth, non-return valveAccessoriesTechnical drawingsTypeDescriptionPZR450GF recommended flange rotator- load capacity 4500 kgPZR450G-XX* shaft rotator - load capacity 4500 kgN00074 quick change system for shaft rotatorN00072-XX* reduction link between rotator and grappleN00143 scraper - indicate type of grapple when orderingN00130 welded hooksN00129 wear plates to protect horizontal cuttingedges (2 pieces)N00173 adapters for mounting of compression railsN00048 compression rails – length 720 mm (2 pieces)N00049 compression rails – length 1000 mm (2 pieces)PZ102-7000 bolt-on teeth cpl., incl. screws and nuts*) specify Ø shaft when ordering220900Ø3084Requirements of truck craneOperating pressure: 26 to 32 MPa (260 to 320 bar)Pump capacity: 25 to 75 l/min1430 B15

Reinforced Heavy Duty Clamshell Buckets with Horizontal Hydraulic CylinderKinshoferThe rugged clamshell bucket is the reinforced version of the PZG-G-1.The shell frame, cutting edges and shells are reinforced.• Maximum loading height is achieved through the compact designwith the horizontal hydraulic cylinder• Long life is ensured through the use of 500 HB steel in the manufacture ofthe cutting edges and a generously dimensioned bearing system• Synchronized opening and closing through a sturdy compensation bar• Bolt-on digging teeth are delivered with each clamshell bucket• Excellent digging characteristics are the result of high closing forces(30 kN at 26 MPa operating pressure)Clamshell buckets PZG-GS-1Volume Width Opening max. Number of Self weight Closing force LoadB teeth capacityType (litre) (mm) (mm) (kg) (kN) (kg)PZG200GS-1 200 400 1430 3 315 30 3000PZG250GS-1 250 500 1430 5 335 30 3000PZG350GS-1 350 650 1430 5 365 30 3000AccessoriesTechnical drawingsType DescriptionPZR450GF recommended flange rotator – depending on application– load capacity 4500 kgPZR601GF recommended flange rotator – depending on application– load capacity 6000 kgPZR450G-XX*shaft rotator – up to 4500 kg load capacityN00074 quick change system for shaft-type rotatorsN00072-XX* reduction link between rotator and grappleN00143 scraper - indicate type of grapple when orderingN00130 welded hooksN00129 wear plates to protect horizontal cutting edges (2 pieces)N00173 adapters for mounting of compression rails(non-return valve necessary)N00048 compression rails – length 720 mm (2 pieces)N00049 compression rails – length 1000 mm (2 pieces)BL463 short connecting hoses*) specify Ø shaft when ordering252900Ø408416Requirements of truck craneOperating pressure:26 to 32 MPa (260 to 320 bar)Pump capacity:25 to 75 l/min1430 B

Clamshell Buckets with Vertical Hydraulic CylinderThe clamshell bucket is a proven grapple for daily routine work – ideal for excavatingfoundations, trenches and other similar applications in civil engineering. The closelypositioned shell pivots ensure good digging behaviour and high closing pressure.Kinshofer• Good digging behaviour through the closely positioned shell pivots• Longevity is ensured through the use of 500 HB steel in the manufacture of cutting edgesand the generously dimensioned bearing system. The enclosed hydraulic cylinder (in a hubunit) and short hydraulic connection hoses lower the risk of damage and down-time• Maximum loading height is achieved through the compact design• Special model with scraper and special bucket shape for excavating foundationsand graves• Special model with round buckets for digging well shafts etc.• Bolt-on digging teeth are delivered with each clamshell bucket• Excellent digging characteristics are the result of high closing forces(20 kN at an operating pressure of 26 MPa)Clamshell buckets PZG-GVVolume Width Opening max. Number of Self weight Closing force LoadB teeth capacityType (litre) (mm) (mm) (kg) (kN) (kg)PZG150GV 150 325 1390 3 260 20 3000PZG200GV 200 400 1390 3 275 20 3000PZG250GV 250 500 1390 5 295 20 3000PZG325GV 325 600 1390 5 315 20 3000PZG350GV 350 650 1390 5 320 20 3000PZG450GV 450 800 1390 9 355 20 3000Special grapples incl. scraper PZG-GVF or round shells PZG-GVRPZG100GVF 100 600 800 5 280 30 3000PZG125GVF 125 760 800 7 315 30 3000PZG150GVF 150 600 1000 5 275 30 3000PZG190GVF 190 760 1000 7 305 30 3000PZG200GVF 200 600 1000 5 295 30 3000PZG030GVR 30 - Ø 460 4 210 30 3000PZG050GVR 50 - Ø 600 5 225 30 3000PZG150GVR 150 - Ø 900 5 240 30 3000AccessoriesTypeDescriptionPZR450GF recommended flange rotator– load capacity 4500 kgPZR450G-XX* shaft rotator – up to 4500 kg load capacityN00074 quick change system for shaft-type rotatorsN00072-XX* reduction link between rotator and grappleN00143 scraper - indicate type of grapple when orderingN00130 welded hooksN00129 wear plates to protect horizontalcutting edges (2 pieces)N00173 adapters for mounting of compression railsN00048 compression rails – length 720 mm (2 pieces)N00049 compression rails – length 1000 mm (2 pieces)*) specify Ø shaft when ordering2201316Technical drawings35 84Ø40Requirements of truck craneOperating pressure: max. 26 MPa (260 bar)Pump capacity: 25 to 75 l/min1392B17

Heavy Duty Universal Buckets with Horizontal Hydraulic CylinderKinshoferThe universal bucket is a robust clamshell bucket and versatile tool for handlingrefuse material. The open sides of the grapple enables the handling ofbulk material.• Compact design with a horizontal hydraulic cylinder achieves a maximum loading height• Long life due to the use of 500 HB steel in the manufacture of the cutting edges anda generously dimensioned bearing system• Synchronized opening and closing through a sturdy compensation bar• Safety is assured in case of an unexpected pressure drop due to the integratednon-return valve• Additional wear plates (useable on both sides) and welded hooks are deliveredon each grapple• Powerful operation due to high closing force (28 kN at an operating pressure of 26 MPa)Package universal buckets PZG-UPVolume Width Opening max. Number of Self weight Closing force LoadB teeth capacityType (litre) (mm) (mm) (kg) (kN) (kg)PZG250UP 250 570 1545 5 375 28 3000PZG300UP 300 670 1545 5 390 28 3000PZG450UP 450 920 1545 7 425 28 3000Package consists of: clamshell bucket, rotator PZR450GF, upper suspension UL045, wear plates N00129, welded hooks N00130 (2 pieces),connecting hoses BL462 and BL463, non-return valveUniversal buckets PZG-UPZG250U 250 570 1545 5 340 28 3000PZG300U 300 670 1545 5 355 28 3000PZG400U 400 820 1545 7 380 28 3000PZG450U 450 920 1545 7 390 28 3000PZG500U 500 1020 1545 9 410 28 3000PZG600U 600 1220 1545 9 440 28 3000Package consists of: high volume clamshell bucket, non-return valveAccessoriesTechnical drawingsTypeDescriptionPZR450GF recommended flange rotator– load capacity 4500 kgPZR450G-XX* shaft rotator – up to 4500 kg load capacityN00074 quick change system for shaft-type rotatorsN00072-XX* reduction link between rotator and grappleN00173 adapters for mounting of compression railsN00048 compression rails – length 720 mm (2 pieces)N00049 compression rails – length 1000 mm (2 pieces)N00385 side plates, 8 mm, bolted, for easy diggingtasks (4 pieces)N00385-10 side plates, 10 mm, bolted, for easydigging tasks (4 pieces)*) specify Ø shaft when ordering5196141080497Requirements of truck crane20Operating pressure:26 to 32 MPa (260 to 320 bar)Pump capacity:25 to 75 l/min115115451659B

Accessories for Clamshell BucketsScraperThe scraper for clamshell buckets with narrow widths clears the inside of the shells of stickymaterials such as clay, during each opening. The design varies depending on the grapple.KinshoferTypeN00143please indicate bucket type when orderingN00143Adapter for compression railsThe adapter enables mounting of compression rails or support for concrete rings, for handlingpaving slabs, curbstones, concrete rings etc. The adapter can only be used with a non-return valve.It is not suitable for the use with a scraper.N00173N00173N00048N00049adapter for compression railscompression rails – length 720 mm (2 pieces)compression rails – length 1000 mm (2 pieces)Central lifting device, welded hooks or welded eyesN00130The central lifting device is for the HPXdrive, welded eyes or welded hooks serve for lifting chainsor slings. The max. capacity per eye or hook is 1000 kg.PZHP04ZAPZHP05ZAN00130central lifting device for PZHP04central lifting device for PZHP05welded hooks (2 pcs.)PZHP04ZA; PZHP05ZAcentral liftingdevice only forHPXdrivewelded hookwelded eyeon demand(not for HPXdrive)Wear plates (2 pieces)N00129wear plates, please indicate bucket type when orderingN00129Extension for excavating with the HPXdrive standard or the HPXdrive heavy dutyPZHP450VPZHP450VPZHP2000Vextension for excavating;- for canal construction and civil engineering – 450 mm (30 kg)extension for excavating;- for canal construction and civil engineering – 2000 mm (97 kg)Please note: • Other lengths available on request21

Orange Peel Grapples Light Duty with 120-240 Litres CapacityKinshoferThe robust orange peel grapple light duty is used for the handling of bulky scrap,building materials and handling facilities. Depending on the task, it is available withdifferent tine shapes and volumes (120l, 180l, 240l).• Versatility: 3 different tine shapes of the PZG-P light duty series with 4 or 5 tines toaccommodate handling a variety of materials: PZG-PV: fully closing tines for handlingswarf, loose waste, soil, gravel etc. PZG-PH: half closing tines (closing at lower part ofsegments) for handling swarf, scrap, rubbish, waste paper etc. PZG-PS: pointed tines forbulky scrap, car bodies, bundled waste paper etc• A lifting-eye on the centre section acts as an additional stop• Long life due to a solid design: the hydraulic cylinder pistons are protected by the grippingarms and the hydraulic hoses, oil distributor and connections are positioned in the robustcentre section. Special wear resistant material of 400HB Brinell used in the production ofthe gripping arms and oversized bearings ensure a long service life for these sturdy grapples• Powerful operation with high closing force (11 kN to 13 kN at an operating pressure of 26 MPa)Orange peel grapples PZG-P light dutyNumber of Volume Opening max. Width Height B Self weight Load Closingtines A (closed) (closed, incl. rotator) (w/o rotator) capacity forceType (litre) (mm) (mm) (mm) (kg) (kg) (kN)PZG120PV4 4 120 1360 1065 800 330 2000 13PZG180PV4 4 180 1450 1070 850 345 2000 12PZG240PV4 4 240 1720 1125 985 380 2000 11PZG120PV5 5 120 1360 1065 800 350 2000 13PZG180PV5 5 180 1450 1070 850 365 2000 12PZG240PV5 5 240 1720 1125 985 415 2000 11PZG120PH4 4 120 1360 1065 800 260 2000 13PZG180PH4 4 180 1450 1070 850 270 2000 12PZG240PH4 4 240 1720 1125 985 300 2000 11PZG120PH5 5 120 1360 1065 800 300 2000 13PZG180PH5 5 180 1450 1070 850 305 2000 12PZG240PH5 5 240 1720 1125 985 340 2000 11PZG120PS4 4 120 1360 1065 800 230 2000 13PZG180PS4 4 180 1450 1070 850 235 2000 12PZG240PS4 4 240 1720 1125 985 250 2000 11PZG120PS5 5 120 1360 1065 800 275 2000 13PZG180PS5 5 180 1450 1070 850 285 2000 12PZG240PS5 5 240 1720 1125 985 300 2000 11Package consists of: orange peel grapple, non-return valve, connecting hoses BL463AccessoriesTypePZR450GFPZR601GFDescriptionrecommended flange rotator– load capacity 4500 kgflange rotator - up to 6000 kg load capacitydepending on applicationRequirements of truck craneOperating pressure:max. 26 MPa (260 bar)Pump capacity:30 to 75 l/minTechnical drawingsBC22DA

Orange Peel Grapples Heavy Duty with 250-500 Litres CapacityThe robust orange peel grapple heavy duty is used for the handling of bulky scrap,building materials and handling facilities and depending on the task available withdifferent tine shapes and volumes (250l, 350l, 500l).Kinshofer• Versatility: 3 different tine shapes of the PZG-P heavy duty series with 4 or 5 tines toaccommodate handling a variety of materials: PZG-PV: fully closing tines for handling swarf,loose waste, soil, gravel etc. PZG-PH: half closing tines (closing at lower parts of segments)for handling swarf, scrap, rubbish, waste paper etc. PZG-PS: pointed tines for bulky scrap,car bodies, bundled waste paper etc.• A lifting-eye on the centre section acts as an additional stop• Long life due to a solid design: the hydraulic cylinder pistons are protected by the gripping armsand the hydraulic hoses, oil distributor and connections are positioned in the robust centre section.Special wear resistant materials of 400HB Brinell used in the production of the gripping arms andoversized bearings ensure a long service life for these sturdy grapples• Powerful operation with high closing force (13 kN to 18 kN at an operating pressure of 26 MPa)Orange peel grapples PZG-P heavy dutyNumber of Volume Opening max. Width Height B Self weight Load Closingtines A (closed) (closed, incl. rotator) (w/o rotator) capacity forceType (litre) (mm) (mm) (mm) (kg) (kg) (kN)PZG250PV4 4 250 1550 1285 1015 445 2500 18PZG350PV4 4 350 1720 1260 1100 470 3000 16PZG500PV4 4 500 2155 1320 1350 555 3000 13PZG250PV5 5 250 1550 1285 1015 520 2500 18PZG350PV5 5 350 1720 1260 1100 545 3000 16PZG500PV5 5 500 2155 1320 1350 635 3000 13PZG250PH4 4 250 1550 1285 1015 425 2500 18PZG350PH4 4 350 1720 1260 1100 440 3000 16PZG500PH4 4 500 2155 1320 1350 505 3000 13PZG250PH5 5 250 1550 1285 1015 505 2500 18PZG350PH5 5 350 1720 1260 1100 520 3000 16PZG500PH5 5 500 2155 1320 1350 595 3000 13PZG250PS4 4 250 1550 1285 1015 390 2500 18PZG350PS4 4 350 1720 1260 1100 395 3000 16PZG500PS4 4 500 2155 1320 1350 435 3000 13PZG250PS5 5 250 1550 1285 1015 470 2500 18PZG350PS5 5 350 1720 1260 1100 480 3000 16PZG500PS5 5 500 2155 1320 1350 525 3000 13Package consists of: orange peel grapple, non-return valve, connecting hoses BL463AccessoriesTypePZR450GFPZR601GFDescriptionrecommended flange rotator – depending onapplication – load capacity 4500 kgflange rotator - depending on applicationup to 6000 kg load capacityBRequirements of truck craneOperating pressure: max. 26 MPa (260 bar)Pump capacity: 30 to 80 l/minDA23

Brick Stack Grapples with Parallel SqueezeKinshoferThe technically unique brick stack grapple is a versatile tool for palleted andnon-palleted materials.• Rigid or adjustable plunge depth with parallel opening and closing clampingarms hydraulically operated• Versatile tool through opening ranges of 400 mm to 1400 mm i.e. for handling ofsingle concrete products like curbstones, or handling of brick packs• Easy operation due to durable and replaceable rubber inserts in the compression rails• Adjustable plunge depth of PZSV-1 can match the size of the stack-easy adaptionwith a mechanical latch• Precise synchronisation of the arms as a result of two in series double actinghydraulic cylinders• Safety through internal pressure relief valve (independent from crane pressure) andnon-return valve (safe clamping force at pressure drop)• Long life due to generously dimensioned bearings, integrated grease reservoir,automatic wear compensation of main bearing, spherical central bearing for the cylindersPackage brick stack grapples PZS-V-1PPlunge depth A Load capacity at Gripping Height B Selfmin./max. plunge depth min./max. (incl. rotator) weightType (mm) (kg) (mm) (mm) (kg)PZS110V-1PK* 1100 – 1650 1900 – 1350 400 – 1400 1315 – 1865 355PZS110V-1P** 1100 – 1650 1900 – 1350 400 – 1400 1315 – 1865 355PZS110V-1PS*** 1100 – 1650 1900 – 1350 400 – 1400 1315 – 1865 355*) incl. PZR450GF **) incl. PZR450G-68 and tilting device PZSUKVW ***) incl. PZR450G-68 und quick change system N00074Package consists of: brick stack grapple, rotator, connecting hoses BL463 and BL462, upper suspension UL045,compression rails PZS100A-1 (length 1000 mm), pressure relief valve, non-return valveBrick stack grapples PZS-1 and PZS-V-1PZS085-1 850 2200 400 – 1400 1065 240PZS100-1 1000 2000 400 – 1400 1215 250PZS130-1 1300 1600 400 – 1400 1515 260PZS110V-1 1100 – 1650 1900 / 1350 400 – 1400 1315 – 1865 295Please note: • The load capacity listed in the table depends on the load (the surface conditions, the size of individual stones,stack size and kind of bundling). The capacity listed does not apply to stacks of low-profile and unbundled items• The price does not include the compression rails• Wider opening ranges 400 – 1800 mm are available on request720/81024PZR450GFrecommended flange rotator– load capacity 4500 kgRequirements of truck craneOperating pressure:20 bis 26 MPa (200 bis 260 bar), a built-inpressure relief valve also allows the useof higher operating pressurePump capacity:25 to 75 l/minB = max.B = min.4001400A = min.A = max. 215720/1000/1250

Accessories for Brick Stack GrapplesCompression railsDescription Length Self weightType (mm) (kg)PZS072A-1 compression rails with smooth rubber inserts (2 pcs.) 720 17PZS100A-1 compression rails with smooth rubber inserts (2 pcs.) 1000 24N00180 compression rails with smooth rubber inserts (2 pcs.) 1100 26PZS125A-1 compression rails with smooth rubber inserts (2 pcs.) 1250 28KinshoferN00177N00162N00136compression rails with two rubber inserts, upper insert contoured,lower insert smooth (2 pcs.) 720 24compression rails with two rubber inserts, upper insert contoured,lower insert smooth (2 pcs.) 1000 33compression rails with two rubber inserts, upper insert contoured,lower insert smooth (2 pcs.) 1250 40N00054 spring loaded rails with parallel-action teeth (2 pcs.) 1000 62N00055 spring loaded rails with parallel-action teeth (2 pcs.) 1250 76Quick change system and other accessoriesN00074 quick change system 12N00078 suspension with pendulum brake – up to 4500 kg load capacity 15N00076 upper element (fitted to rotator) 4N00077 lower element (mounted onto attachment) 8N00075 rigid suspension link with non-rotating hook 5Other opening ranges: grapples with opening ranges not listed are available on requestOther plunge depths: grapples with plunge depths not listed are available on requestOther optionsPZSUKVW tilting device to reduce overall height for shaft rotators 12PZSUKVF of the equipment in transport for flange rotators 18PZSKAF height reduction link to reduce the overall height for flange rotators 15PZSKAW of the equipment in transport for shaft rotators 15N00305spring loaded guide rails for stabilizing the top layer of the stackN00245 adapter to reduce gripping range by 200 mm 16N00109 adapter for concrete pipes with diameters from 800 to 1350 mm 6025

Brick Stack Grapples with Scissor GrabKinshoferThe robust brick stack grapple handles loads up to 2000 kg.• Fixed plunge depth with pivot clamping arms – hydraulically operated• Versatile tool through opening ranges of 40 mm to 1500 mm i.e. for handling of singleconcrete products like curbstones, or handling of brick packs• Synchronised function of clamping arms due to sturdy gear-toothed quadrants• Safety through internal pressure relief valve (independent from crane pressure) and nonreturn valve (safe clamping force at pressure drop)• Reduced overall height in comparison to the plunge depth due to lower rotator position• Compression rails with durable and replaceable rubber insertsPackage brick stack grapples PZS-SPPlunge depth A Load capacity Gripping min./max. G Height B Self weightType (mm) (kg) (mm) (mm) (kg)PZS100SP 1000 2000 200 – 1420 1565 315PZS110SP 1100 2000 160 – 1450 1665 320PZS120SP 1200 1800 98 – 1475 1765 325PZS130SP 1300 1600 40 – 1500 1865 330PZS100SHP with 12 hooks 1000 2000 220 – 1420 1565 333(welded above and below, at the exterior at the lower edge)Package consists of: brick stack grapple, rotator PZR450GF, connecting hoses BL462, BL463, upper suspension UL045K,compression rails N00436 (length 1000 mm), pressure relief valve, non-return valvePlease note:• The load capacity listed in the table depends on the load (the surface conditions, the size of individual stones,stack size and type of bundling). The capacity listed does not apply to stacks of low-profile and unbundled items• Full plunge depth A decreases with opening ranges over 1100 mm (see technical drawings)AccessoriesType Description Self weight (kg)N00078 upper suspension with pendulum brake 15N00425 compression rails – 720 mm (2 pieces) 29N00436 compression rails – 1000 mm (2 pieces) 40N00184 compression rails – 1250 mm (2 pieces) 52N00442welded hooks (4 pcs.)Please note:• Non-standard compression rails with length not listed are available on request• Non-standard plunge depth not listed are available on request• Alternatively with shaft rotator and reduction linkRequirements of truck craneTechnical drawingsOperating pressure: 20 to 32 MPa (200 to 320 bar)Pump capacity: 25 to 75 l/min1430380AB26G = minOptimum opening range with full plunge depthG = max 1000Max. opening range with reduced plunge depth

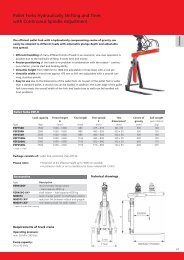

Pallet Forks Hydraulically Shifting and Tineswith Continuous Spindle AdjustmentThe efficient pallet fork with a hydraulically compensating centre of gravity caneasily be adapted to different loads with adjustable plunge depth and adjustabletine spread.Kinshofer• Efficient handling of many different kinds of loads in an economic, one-man operation ispossible due to the hydraulic shifting. It saves time and money• Precise positioning of the loads is no problem in combination with the rotator – continuousrotation, precise start and braking ability• Versatile height from 1000 mm to 1600 mm adjustable in three steps with a lock pin• Versatile width of tines from approx. 475 mm to 815 mm adjustable with a smooth running,stainless spindle• Easy to use due to the dimensions of the pallet fork. As no part of the pallet fork is widerthan a standard pallet, a second row can be loaded. In addition, the outer edge of the palletfork tines meets the overall width of the fork and loads close to walls can be handled withoutproblemsPallet forks PZP-HLoad capacity Throat height Tine length Tine spread Tine Centre of Self weightA Z dimensions* gravity (w/o rotator)Type (kg) (mm) (mm) (mm) (mm) (mm) (kg)PZP150H 1500 1000 – 1600 980 475 – 815 80 x 35 500 120PZP200H 2000 1000 – 1600 980 495 – 835 100 x 35 500 135PZP250H 2500 1000 – 1600 980 490 – 830 100 x 50 500 160PZP150HL 1500 1000 – 1600 1150 495 – 835 100 x 35 600 155PZP200HL 2000 1000 – 1600 1150 500 – 840 100 x 50 600 170PZP250HL 2500 1000 – 1600 1150 510 – 850 120 x 50 600 235*) width x heightPackage consists of: pallet fork, protection chain PZP-SKPlease note:• Extension of the effective height up to 3000 mm possible• A protection trellis or net is mandatory for loose material (EN 13155)AccessoriesTechnical drawingsTypeDescriptionPZR450GFrecommended flange rotator– load capacity 4500 kgPZR450G-XX* shaft rotator – load capacity 4500 kgN00074quick change system for shaft-type rotatorsN00072-XX* reduction link between rotator and grappleN00071-XX* non-rotating hook for shaft rotator*) specify Ø shaft when ordering500/600ARequirements of truck craneOperating pressure:max. 26 MPa (260 bar)Pump capacity:20 to 40 l/minZ minZ max 980(500)/1150(600)27

Pallet Forks Self Balancing and Tines with Continuous Spindle AdjustmentKinshoferThe efficient pallet fork with spring loaded centre of gravity compensation caneasily be adapted to different loads with adjustable plunge depth and adjustabletine spread.• Efficient handling of many different kinds of loads in an economic, one-man operationis possible due to the automatic shifting of the fork to a preset position. Compressionsprings return the slide to initial position• Variable height from 1000 mm to 1600 mm adjustable in three steps with a lock pin• Variable tine spread from approx. 475 mm to 815 mm adjustable with a smooth running,stainless spindle• Easy to use due to the dimensions of the pallet fork. As no part of the pallet fork is widerthan a standard pallet, a second row can be loaded. In addition, the outer edge of thepallet fork tines meets the overall width of the fork and loads close to walls can be handledwithout problemsPallet forks PZP-VLoad capacity Throat height Tine length Tine Tine Centre of Self weightA spread Z dimensions* gravity (w/o rotator)Type (kg) (mm) (mm) (mm) (mm) (mm) (kg)PZP150V 1500 1000 – 1600 980 475 – 815 80 x 35 500 120PZP200V 2000 1000 – 1600 980 495 – 835 100 x 35 500 135PZP250V 2500 1000 – 1600 980 490 – 830 100 x 50 500 160PZP300V 3000 1000 – 1600 980 510 – 850 120 x 50 500 200PZP150VL 1500 1000 – 1600 1150 495 – 835 100 x 35 600 155PZP200VL 2000 1000 – 1600 1150 500 – 840 100 x 50 600 170PZP250VL 2500 1000 – 1600 1150 510 – 850 120 x 50 600 235*) width x heightPackage consists of: pallet fork, protection chain PZP-SK, 2 chain elements for suspensionPlease note: • Protection trellis or net is mandatory for handling of loose material (EN 13155)• Automatic compensation of centre of gravity functions with a min. package weight of approx. 250 to 500 kg• Extension of the effective height up to 3000 mm possibleAccessoriesTechnical drawingsTypeDescriptionPZR450G-XX* shaft rotator up to 4500 kgload capacity for precisepositioning of the loadN00070rigid suspension link with pinfor shaft rotatorN00071-XX* non-rotating hook for shaft rotator*) specify Ø shaft when ordering500/600AZ min980(500)/1150(600)Z max28

Pallet Forks Self Shifting and Tines with Lock Pin AdjustmentThe robust pallet fork with spring loaded centre of gravity compensationcan easily be adapted to different loads with adjustable plunge depth andadjustable tine spread.Kinshofer• Efficient handling of many different kinds of loads in an economic, one-man operationis possible due to the automatic shifting to a preset position. Compression springs returnthe slide to initial position• Throat height adjustable in steps from 1000 mm to 1600 mm with a lock pin• Tine spread adjustable in steps from 320 mm to 930 mm with a lock pinPallet forks PZP-VSLoad capacity Throat height Tine length Tine spread Tine Centre of Self weightA Z dimensions* gravity (w/o rotator)Type (kg) (mm) (mm) (mm) (mm) (mm) (kg)PZP100VS 1000 1000 – 1600 980 325 – 920 80 x 35 500 145PZP125VS 1250 1400 – 2000 980 310 – 930 70 x 40 500 145PZP150VS 1500 1000 – 1600 980 325 – 920 80 x 35 500 145PZP200VS 2000 1000 – 1600 980 345 – 940 100 x 35 500 150PZP250VS 2500 1000 – 1600 980 355 – 945 90 x 40 500 170PZP300VS 3000 1000 – 1600 980 385 – 975 120 x 50 500 205PZP125VSL 1250 1050 – 1650 1150 310 – 930 70 x 40 600 170PZP150VSL 1500 1000 – 1600 1150 345 – 940 100 x 35 600 170PZP200VSL 2000 1000 – 1600 1150 355 – 945 90 x 40 600 180PZP250VSL 2500 1000 – 1600 1150 385 – 975 120 x 50 600 185PZP300VSL 3000 1000 – 1600 1150 385 – 975 130 x 50 600 220*) width x heightPackage consists of: pallet fork, protection chain PZP-SK, 2 chain elements for suspensionPlease note: • Protection trellis or net is mandatory for handling of loose material (EN 13155)• Automatic compensation of centre of gravity functions with a min. package weight of approx. 250 to 500 kg• Extension of the effective height up to 3000 mm possibleAccessoriesTechnical drawingsTypeDescriptionPZR450G-XX* shaft rotator up to 4500 kgload capacity for precisepositioning of the loadN00070rigid suspension link with pinfor shaft rotatorN00071-XX* non-rotating hookfor shaft rotator*) specify Ø shaft when orderingA500/600Z minZ max 980(500)/1150(600)29

Pallet Forks with Manual Shifting and Tines with Lock Pin AdjustmentKinshoferThe robust pallet fork with a manual centre of gravity compensation isbecause of its versatile useability an economic alternative.• Manual change of position of shifting collar by the operator enables thehandling of different loads, e.g. protection trellies or brick stacks• Connection plate for flange rotator, shaft rotator or for a crane hook is includedin the package• Throat height adjustable in steps from 1000 mm to 1600 mm with a lock pin• Tine spread adjustable in steps from 320 mm to 930 mm with a lock pinPallet forks PZPLoad capacity Throat height Tine length Tine spread Tine Centre of Self weightA Z dimensions* gravity (w/o rotator)Type (kg) (mm) (mm) (mm) (mm) (mm) (kg)PZP100 1000 1050 – 1650 980 310 – 930 70 x 35 500 80PZP125 1250 1000 – 1600 980 325 – 920 80 x 35 500 100PZP150 1500 1000 – 1600 980 325 – 920 80 x 35 500 120PZP200 2000 1000 – 1600 980 345 – 940 100 x 35 500 130*) width x heightPackage consists of: pallet fork, protection chain PZP-SKPlease note: • A protection trellis or net is mandatory for loose material (EN 13155)• Extension of the effective height up to 3000 mmAccessoriesTechnical drawingsTypeDescriptionPZR450G -XX* shaft rotator up to 4500 kgload capacity for precisepositioning of the loadN00070 rigid suspension link with pin for shaft rotatorN00071-XX* non-rotating hook for shaft rotator*) specify Ø shaft when ordering1430 - 2030A50030980Z minZ max

Pallet Forks with Manual Shifting and Tines with Lock Pin AdjustmentThe robust pallet fork with manual centre of gravity compensation is aneconomic alternative because of its versatile uses.Kinshofer• Manual change of position of shifting collar by the operator enables handling ofdifferent loads, e.g. protection trellies or brick stacks• Connection plate for flange rotator, shaft rotator or for a crane hook is included inthe package• Throat height adjustable in steps from 1000 mm to 1600 mm with a lock pin• Tine spread adjustable in steps from 320 mm to 930 mm with a lock pinPallet forks PZP-MLoad capacity Throat height Tine length Tine spread Tine Centre of Self weightA Z dimensions* gravity (w/o rotator)Type (kg) (mm) (mm) (mm) (mm) (mm) (kg)PZP125M 1250 1000 – 1600 980 325 – 920 80 x 35 500 100PZP150M 1500 1000 – 1600 980 325 – 920 80 x 35 500 120PZP200M 2000 1000 – 1600 980 345 – 940 100 x 35 500 130PZP250M 2500 1000 – 1600 980 355 – 945 90 x 40 500 170PZP300M 3000 1000 – 1600 980 385 – 975 120 x 50 500 200PZP150ML 1500 1000 – 1600 1150 345 – 940 100 x 35 600 150PZP200ML 2000 1000 – 1600 1150 355 – 945 90 x 40 600 180PZP250ML 2500 1000 – 1600 1150 385 – 975 120 x 50 600 235PZP300ML 3000 1000 – 1600 1150 385 – 975 130 x 50 600 265* width x heightPackage consists of: pallet fork, protection chain PZP-SKPlease note: • A protection trellis or net is mandatory for loose material (EN 13155)• Extension of the effective height up to 3000 mm possibleAccessoriesTypeDescriptionPZR450GF flange rotator - load capacity 4500 kgfor precise positioning of the loadPZR450G-XX* shaft rotator - load capacity 4500 kgfor precise positioning of the loadN00074 quick change system forshaft-type rotatorsN00072-XX* reduction link betweenrotator and grappleN00070 rigid suspension link with pinfor shaft rotatorN00071-XX* non-rotating hook for shaft rotator*) specify Ø shaft when orderingTechnical drawingsB AC1250-1850A: 1050-1650Connecting plate for:A* crane hookB* shaft rotatorC* flange rotator*) specify type of connecting plate when ordering500/600Z minZ max980(500)/1150(600)31

Universal ForksKinshoferThe universal fork for loader cranes handles wallboards and other lying deliveredbuilding materials up to a size of 1250 mm height and 460 mm depth.• Different tine spreads, besides the standard tine spread of 640-1600 mm are available up to1000, 1830 or 2130 mm, depending on the sheets that have to be handled• Safe transport of sheets of wallboard in the hinged lower section. The boards can be lifted andfolded into a vertical position and clamped between the tines and frame, preventing them fromsliding during handling• Protection of the sheets during unloading through semi-tapered forged tines, equipped withrollers and pads. A standard centre slide gives an additional support point for the loads• Security is assured even in case of a drop in pressure due to the integrated counterbalance valvethat prevents the fork from opening unintentionally. The hydraulic cylinder is equipped with apressure relief valve to prevent overload• Accurate positioning of the load is ensured by the tilt cylinder and the rotator• The special version of the universal fork PZP150WA with a second suspension point on themain beam enables the unloading of lying boards through narrow openings in the wallPackage universal fork PZP-WPLoad capacity Tine spread A Height of load max. Depth of load max. Self weightType (kg) (mm) (mm) (mm) (kg)PZP150WP* 1500 640 – 1600 1250 460 400PZP200WP* 2000 640 – 1600 1250 460 410*) specify tine spread when orderingPackage consists of: universal fork, rotator PZR450G-68, connecting hoses BL462, BL463, upper suspension UL045, quick change systemN00074, rigid hook N00075, pressure relief valve, counterbalance valveUniversal forks PZP-WPZP080W 800 600 – 1000 1250 460 280PZP100W 1000 640 – 1600 1250 460 340PZP150W 1500 640 – 1600 1250 460 380PZP200W 2000 640 – 1600 1250 460 390PZP250W 2500 640 – 1600 1250 460 400PZP150WA 1500 640 – 1600 1250 460 390Please note:• The universal fork PZP080W is delivered with an integrated rack and an upper suspension for a shaft rotator• PZP150WA: delivered with a second suspension point on the main beamAccessoriesTechnical drawingsType Description Self weight (kg)PZR450GF recommended flange rotator - load capacity 4500 kg 26PZR450G-XX* shaft rotator - load capacity 4500 kg 26N00074 quick change system for shaft-type rotators 12N00072-XX* reduction link between rotator and grapple 3PZP001 adjustable clamping device to securesingle sheets of smaller packs 14PZP002 rack for safe and easy handling offolded universal fork (for load capacity over 1000 kg) 9N00414 intermediary between PZP-W and N00074*) specify Ø shaft when ordering91516751312 22546018078110°32Requirements of truck craneOperating pressure: 20 to 32 MPa (200 – 320 bar)Pump capacity: 40 to 75 l/minA540 12507°

Bottle-Bank Discharge UnitsThe container discharge attachments with ring system are characterised by short cycle times and an attractiveacquisition price. Containers can be emptied even faster and more cost effectively with a one-man operation.KinshoferBottle-bank discharge unit for container with ring system and a low overall height• Low overall height due to compact design• Rugged engineering with steel cords operation• Constraining guide of the closing hook when container is lifted• Precise positioning with rotator• Protection against damage of container by automatic lift stop361Lift of the Load capacity Height Self weight Operating Pumphook max. (incl. rotator) pressure max. capacityType (mm) (kg) (mm) (kg) (MPa(bar)) max. (l/min)PZC220R 500 2200 955 170 21 (210) 60Package consists of: bottle-bank discharge unit, rotator PZR450GF, short connecting hoses BL463, upper suspension with pendulumbrake N00078, non-return valve, pressure relief valveBottle-bank discharge unit for container with ring system• Robust mechanics with few moving parts and guided lifting hook• Precise positioning with rotator, due to the use of a rotator with vertical oilducts no externally installed hydraulic hoses are necessary• Pressure relief valve ensures independence of crane operating pressure• Protection against damage of container by automatic lift stop1400max 500833952Lift of the Load capacity Height Self weight Operating Pumphook max. (incl. rotator) pressure max. capacityType (mm) (kg) (mm) (kg) (MPa(bar)) max. (l/min)PZC250R 500 2500 1400 175 32 (320) 60Package consists of: bottle-bank discharge unit, rotator PZR450GF, short connecting hoses BL463, upper suspension with pendulum brakeN00078, pressure relief valve, non-return valveAccessoriesmax 312Type Description Tilting angle (degree) Self weight (kg)PZCDD docking device for bottle-bank discharge units: 90 70it allows the discharge unit to be hydraulically dockedand locked onto the crane extension. When unlocked,acts as a hydraulic pendulum brake. A solenoid valvefor switch-over between the hydraulic circuits isincluded. Please indicate crane model when ordering.Operating pressure 28 MPa (280 bar)33

Bottle-Bank Discharge Units for ContainerKinshoferThe container discharge attachments with the fast, patented mushroom system are characterised by short cycle timesand an attractive acquisition price. Containers can be emptied even faster and more cost effectively with a one-manoperation.Bottle-bank discharge unit for container with mushroom system• Robust mechanics with self centring hydraulic interlocking• Precise positioning with rotator, direct hose routing• Independence of crane operating pressure due to the pressurerelief valve• Protection against damage of container by automatic lift stopand an additional height control system1489Lift of the Load capacity Height Self weight Operating Pumphook max. (incl. rotator) pressure max. capacityType (mm) (kg) (mm) (kg) (MPa(bar)) max. (l/min)PZC250P 500 2500 1490 175 32 (320) 60Package consists of: bottle-bank discharge unit, rotator PZR450GF, short connecting hoses BL463, upper suspension with pendulum brakeN00078, pressure relief valve and non-return valveBottle-bank discharge unit for container with mushroom and ring system424• Combination model: without any adjustments both types of containerscan be handled – with mushroom system or ring system• Low overall hight due to compact design• Robust mechanics with self locking spindle• Precise positioning with rotator• Pressure relief valve ensures independence of crane operating pressure• Protection against damage of container by automatic lift stop and anadditional height control system500215840Lift of the Load capacity Height Self weight Operating Pumphook max. (incl. rotator) pressure max. capacityType (mm) (kg) (mm) (kg) (MPa(bar)) max. (l/min)PZC250PR 500 2500 1055 170 32 (320) 60Package consists of: bottle-bank discharge unit, rotator PZR450GF, short connecting hoses BL463, upper suspension with pendulum brakeN00078, pressure relief valve and non-return valveAccessories34Type Description Tilting angle (degree) Self weight (kg)PZCDD docking device for bottle-bank discharge units: it 90 70allows the discharge unit to be hydraulically dockedand locked onto the crane extension. When unlocked, acts as ahydraulic pendulum brake. A solenoid valve for switch-over betweenthe hydraulic circuits is included. Please indicate crane model whenordering. Operating pressure 28 MPa (280 bar)N00413 ring hook and support for PZC250PN00426 ring hook and support for PZC250PR

ManipulatorsA hydraulically operated attachment used for positioning tubes or poles.It is flanged on the boom extension of the crane.Kinshofer• Mobility through three hydraulic functions such as gripping, turning and tilting(three hydraulic circuits are necessary). Unlimited angle of rotation• Heavy loads of 500 kg up to 3000 kg can be handled by the manipulators• Precise positioning guaranteed by the rotator equipped with mechanicallyoperating, hydraulic pilot controlled brake for the rotary motion,to prevent unintentional rotationManipulators PZMLoad capacity Gripping Ø Width Number of Self weight Closing(min./max.) B tines forceType (kg) (mm) (mm) (kg) (kN)PZM0500 500 100 / 300 785 1 235 11PZM1000 1000 100 / 300 1275 2 310 23PZM2000 2000 250 / 600 1365 4 865 25PZM3000 3000 250 / 600 1630 6 1085 39Package consists of: manipulator, rotator, hydraulic pilot controlled brake, non-return valvePlease note:• Tubes or poles always have to be grabbed in the centre of gravity• Special manipulators with different gripper attachments and an additional motion axis available upon requestAccessoriesTypePZMMVDescriptionsolenoid valve adds-on an oil circuit to change over to 3 circuits (for gripping, turning, tilting), when only 2 circuits areavailable (incl. hose guard) – 12 V / 24 V, working pressure max. 25 MPa, oil flow 60 l/min.Requirements of truck craneOperating pressure:20 MPa (200 bar)Pump capacity:20 to 40 l/minTechnical drawingsBBBBPZM0500 PZM1000 PZM2000 PZM300035

Barrier LiftersKinshoferThe barrier lifter is a mechanical grapple for fast and convenient handling ofconcrete barriers and blocks.• Efficiency: the fully integrated, mechanically operated “latch & release” systemallows the unit to function independently, without assistance from a ground man.The elimination of slings and chains means more cycles can be achieved per hour• Safety: carbide gripping pads ensure safe operation, even on wet orcoated surfaces• Versatility: multi-position arms are a standard feature. This means that one unitcan achieve different gripping ranges by simply changing a pin position• For both barrier lifters the gripping range can be adjusteddue to the use of a lock pinBarrier lifters PZBGripping A Self weight Load capacity(min./max.)max.Type (mm) (kg) (kg)PZB932-6/10 100 – 310 150 6580PZB932-12/14 285 – 400 115 6580Ø 28,625,4Technical drawings141-15889449759 APZB932-6/1025,41000’’Adjustment ofopening rangewith pin2121-135clamping rangeopening range123Arm 136PZB932-12/14

Special solutionsWood chips grapple for light materialKinshoferThe wood chips grapple is a combination of the proven clamshell bucket PZG-S andthe sturdy timber grapple KM634 for loading and restacking wood chips or otherlight bulk material.• Large volume with low self weight• Precise positioning of the load because of the mounted rotator• Integrated load holding valve• Recommended rotator is N00377; 6 t; especially develloped for lifting andloading wood, incl. hose protectionVolume Width Opening Closing Load Selfmax. force capacity weightType (Litre) (mm) (mm) (kN) (kg) (kg)PZG1500SL 1500 1500 2260 23 2000 550Load Hole pattern Upper Torque Moment of Selfcapacity of flange connection* deflection weightType (kg) (mm) (mm) (Nm) max. (Nm) (kg)N00377 6000 ø 173 81 x 35 1000 8500 34*) width x Ø shaftPipe grapple with a diameter of 70 - 410 mm• With block valve panel suitable for the 4,5 t flange rotator N00330 with 2 oil ductsat the bottomLoad Pipe Width Opening Closing Selfcapacity diameter max. force weightType (kg) (mm) (mm) (mm) (kN) (kg)PZG400R 2000 70 – 410 933,5 1200 23 280Load Hole pattern Upper Torque Moment of Selfcapacity of flange connection* deflection weightType (kg) (mm) (mm) (Nm) max. (Nm) (kg)N00330 4500 140 84x30 850 3000 26*) width x Ø shaftMetallic grids grapple• For grids 2400 x 4800 mm with lattice spacing 100x200 or 200x200 or 100x400 mm• Differential cylinder with end balance for synchronisation unit• Non-return valve and hydraulic accumulator• Height stop• Shackle centered and on the gripping railLoad Clamping Effective Width Number Operating Selfcapacity dim. depth of hooks pressure weightType (kg) (mm) (mm) (mm) (Stk.) max. (bar) (kg)PZG1600SGG 1600 1500 – 2650 130 1200 4 280 300recommended rotator: PZR450GFHay- and forestry grappleVolume Load Width Opening Number of Selfcapacity max. teeth weightType (Litre) (kg) (mm) (mm) (Stk.) (kg)PZG1000HFG 200 1000 668,5 1245 3 / 4* 95recommended rotator: PZR450GF*) narrow gripping arm 3, wide gripping arm 437

Grapples for Small Cranes PK 2900 – PK 4200These grapples are ideal for gardening or for tasks in the municipal sector.PK-CraneGrapples• For small excavation works• Compact design• Efficient handling• Universal grapple is ideal for bulk material• Universal grapple with perforated shells is ideal for works in wetareas or in the water• Max. operating pressure 200 bar• Complete solution with rotator, suspension and hosesPackage clamshell buckets PZG-PVolume Width Opening max. Height SelfL B (incl. rotator) C weightType (Litre) (mm) (mm) (mm) (kg)PZG050P 50 330 894 880 52PZG095P 90 350 1100 960 85PZG125P 125 450 1200 1060 134CPackage consists of: clamshell bucket; 3,5 t rotator; suspension, hosesPackage universal grapples PZG-UPVolume Width Opening max. Height SelfL B (incl. rotator) C weightType (Litre) (mm) (mm) (mm) (kg)PZG095UP 90 350 1100 1006 85PZG125UP 125 450 1200 1105 134Package consists of: universal grapple; 3,5 t rotator; suspension, hosesBPackage universal grapples with perforated shells PZG-UPPVolume Width Opening max. Height SelfL B (incl. rotator) C weightType (Litre) (mm) (mm) (mm) (kg)PZG095UPP 90 350 1100 1006 81PZG125UPP 125 450 1200 1105 130Package consists of: universal grapple; 3,5 t rotator; suspension, hoses38L

Crane BoxThe crane box is an ideal solution for conveying bulk materials witha truck. It is used in the areas of building construction, landscaping,roofing company, agricultural and municipal work.• For bulk materials like sand, gravel, grit, fertilizer, building waste,cobblestones and more• One truck can load different materials• Easy emptying• Precise dosage• Bulk materials can be unloaded directly at the processing location• Time saving handling of goods at the building site• Cost effective multi way big bagCrane BoxCrane box for pickup with brick stack grapple-pickup PZKRABO-AVolume Length Width Height Load capacity Self weightType (Litre) (mm) (mm) (mm) (kg) (kg)PZKRABO500-A 450 1167 1012 998 1300 210PZKRABO700-A 700 1167 1012 1272 1700 244Crane box for hook-pickup with bent lever PZKRABO-BVolume Length Width Height Load capacity Self weightType (Litre) (mm) (mm) (mm) (kg) (kg)PZKRABO500-B 450 1167 1012 998 1300 219PZKRABO700-B 700 1167 1012 1272 1700 253Technical drawings11671272101010447921012Bulk container with lever and locking39

AugersThe PALFINGER augers provide the highest drilling performances and durability,thus the PALFINGER crane becomes a multipurpose tool. The respectively optimisedteeth and centering tips are suitable for earth and gravel layers as well as for soft rock.AugersMany manufacturers fasten the teeth friction-locked, so the teeth can easily get lost while drilling.This means costly replacement of the teeth and downtimes. The „shock-lock“ system thatis used for earth and Tungsten augers guarantees that the teeth do not get lost during drillingthanks to a locking bolt. This bolt can easily be removed when changing the teeth. The cushioningrubber ensures that the Tungsten tooth will not break, even under the harshest conditions.The teeth of the rock augers are fixed with a taper lock. The use of rock augers is recommended,when drilling in stony soil or soft rock.40Augers (incl. centering tip)Dimension Height of Distance Ø D Self RecommendedA slope gradient between weight drive unitType (mm) B (mm) spirals C (mm) (mm) (kg)EBG 150E 1200 750 120 150 29 BEG30EBG 150TEBG 150REBG 200E 1200 750 150 200 33 BEG30EBG 200TEBG 200REBG 225E 1200 750 150 225 36 BEG30EBG 225TEBG 225REBG 250E 1200 750 150 250 42 BEG50EBG 250TEBG 250REBG 300E 1200 700 200 300 47 BEG50EBG 300TEBG 300REBG 350E 1200 675 225 350 52 BEG50EBG 350TEBG 350REBG 400E 1200 625 250 400 54 BEG50EBG 400TEBG 400REBG 450E 1200 625 250 450 64 BEG50EBG 450TEBG 450REBG 500E 1200 625 250 500 75 BEG80EBG 500TEBG 500REBG 600E 1200 600 300 600 82 BEG80EBG 600TEBG 600REBG 750E 1200 550 350 750 107 BEG80EBG 800E 1200 525 350 800 109 BEG80EBG 800TEBG 800REBG 900E 1200 525 350 900 143 BEG80EBG 900TEBG 900RE Earth auger T Tungsten auger R Rock augerREPlease note:Other dimensions available on requestCDBAT

Drive Units for AugersKey features• High-strength forged hood ears• No loss of clips with the unique hood pin• High quality of the planetary gearbox• NDS - Non-Dislodgement Shaft - no rip away of the shaft• Intgral service bungs for quick and easy oil changes• Overflow oil line not necessaryAugersDrive units for augersRange Operating Speed Shaft of Torque of Oil Selfof drilling pressure of turn drive unit drive unit flow weightType (mm) (bar) (U/min) (mm 2 ) at 260 bar (Nm) (l/min) (kg)BEG 30 150 - 600 260 68 57 3,007 20 - 50 108BEG 50 150 - 750 260 41 57 5,012 20 - 50 112BEG 80 150 - 900 260 27 57 7,517 20 - 50 116in operationRope wind hitchThe rope wind hitch was especially designed for PALFINGER cranes. It simplifies thesecure storage and reduces down times of removal and reinstallation of the auger atthe beginning and the completion of work.TypeSelf weight (kg)BEGAV20* apt for cranes up to 20 mt 140*) specify crane type and dimensions of the extension boom when orderingAuger extensionsLength Pole length Shaft exit SelfType (mm) (mm) (mm) weight (kg)BEG12-500 500 114 57 - square 18BEG12-1000 1000 114 57 - square 25BEG12-2000 2000 114 57 - square 30BEG12-3000 3000 114 57 - square 57in transportPull in partsFor arm dimensionsSelf weightType (mm) (kg)UL025 296 x 133 49,3UL026 259 x 115 44,1UL027 221 x 97 39,5UL028 185 x 80 34,7UL146 123 x 62 31,8UL147 155 x 79 34,2UL148 188 x 96 36,9UL149 224 x 116 41,6UL150 260 x 136 45,941

New Workman Baskets 2011The new workman baskets from PALFINGER are especially developed forcorresponding the demanding market requirements and are ready to fulfil theEN280 workman basket standard. In addition to the low self weight due tothe steel-aluminium design, the new workman baskets feature optimizedspace and the smooth levelling.WorkmanBasketsFurther advantages:• Low self weight for maximum operating distance• Smooth levelling due to optimised recirculation ball steering• Emergency switch in the basket• Integrated tool box 704 x 202 x 209 mm• All around protected handrail• Simple mechanical and electrical mounting on the crane due to a quick coupling system• Functional design• Optionally in desired colour availableWorkman basketsDescription Load capacity Floor space Self weight Width/ Depth/ HeightType (kg) (m 2 ) (kg) (mm)BB040 2 persons workman basket 200 0,98 200 1400 x 700 x 1160slewing angle 360°automatic levelling accordingto EN280BB041 1 person workman basket 120 0,60 172 850 x 700 x 1160slewing angle 360°automatic levelling accordingto EN280Technical drawingsEAHBTDCDimensionsA B C D E T HType (mm) (mm) (mm) (mm) (mm) (mm) (mm)BB040 1375 1400 1890 940 480 700 1180BB041 1375 850 1340 940 480 700 1180Accessories42TypePZBB01PZBB02KSS001B03HXE3003HXE3004Descriptionsafety harness (EN361)safety belt 1,5 m with automatic snap hook and shock absorberbracket for big Scanreco radio remote controlbracket for small Scanreco radio remote controlbracket for Hetronic radio remote control

Workman BasketsOur workman baskets have been developed as additional tool forhydraulic loader cranes.Areal platforms are subject to different safety regulations and instructionsdepending on the country, which have to be considered for the equipmentof a crane with workman basket.BB014AWorkman basketsDescription Load capacity Self weight Entry Electr.hydr.width deviceType (kg) (kg) (mm) (V)BB014A automatic performed according 300 272 830 24to machine guideline,(2 personspositively controlled, incl. aggregate,and tools)emergency stop switch, coded plug,connected at the basket, according to EN280BB004B with weight levelling performed 280 190 520 24according to machine guideline,(2 personsincl. emergency stop switch, coded plug, and tools)disc brake, connected at the basket,not according to EN280BB004 with weight levelling, 280 188 520 –no CE-version, without electrical(2 personsparts at the basketand tools)BB030 1 man safety cage, fold-away, 150 116 800 24according to EN280, incl. emergency(1 personstop switch, coded plug, connectedand tools)at the basketWorkmanBaskets1226 mmBB004BB0302197 mm694 (2’ 3 5/16’’)1190 (3’ 10 13/16’’752 (2’ 5 5/8’’)826 (2’ 8 9/16’’)1285 (4’ 2 9/16’’)1192 (46.93’’)860 (33.85’’)1246 mm04/20061001 (39.40’’)Dok Nr.: bb030555 mm800 mm<strong>Palfinger</strong> – EuropeA 5101 Bergheim–Salzburg/AustriaFranz – W. – Scherer Straße 24www.palfinger.com43

Pull In PartsPull in parts for workman baskets BB004 and BB004BTypeBB013-10V1BB013-15V1BB013-16V1BB013-17AV1BB013-18V1Dimensions - extension booms (inner dimensions)123 x 62 mm155 x 79 mm188 x 96 mm224 x 116 mm260 x 136 mmBB004-3BB007-3BB009-3BB011-3C016221 x 97 mm150 x 63 mm185 x 80 mm259 x 115 mm117 x 48 mmPull-InPartsQuick change flangeBZ456for BB004, BB004BPull in parts for workman baskets BB014A, BB030, BB040, BB041TypeBB013-5V1BB013-6V1BB013-7V1BB013-8V1BB013-9V1BB013-20V1BB013-24V1Dimensions - extension booms (inner dimensions)123 x 62 mm155 x 79 mm188 x 96 mm224 x 116 mm260 x 136 mm296 x 156 mm335 x 176 mmBB013-3BB013-4150 – 221 x 63-97 mm259 – 295 x 115 mmOverview to extension boom dimensionsInner height Inner width BB004, BB004, BB004B, BB030, BB014A, Earth(mm) (mm) BB004B + BZ456 BB040, BB041 auger335 176 - BB013-24V1 BB013-24V1 -296 156 - BB013-20V1 BB013-20V1 -260 136 BB013-18V1 BB013-9V1 BB013-9V1 UL150224 116 BB013-17AV1 BB013-8V1 BB013-8V1 UL149188 96 BB013-16V1 BB013-7V1 BB013-7V1 UL148155 79 BB013-15V1 BB013-6V1 BB013-6V1 UL147123 62 BB013-10V1 BB013-5V1 BB013-5V1 UL14644

Car Lifting Devices3,5 t Lifting system PZLG35 / PZLG35Hwith rotary servo connection or hook connection adjustedhydraulically from 400 mm up to 700 mm• Torsion resistant version• Adjustment of center of gravity 400 mm to 700 mm• Weight: 175 kg• Easy handling due to a spring latch with pull button• Material: steel• Surface: galvanized version• Mounting of PZR450GF flange rotator possible(not included in delivery!)• Mounting bracket PZLG35BHook connection / PZLG35H2 t Lifting system with ring connection / PZLG20H mechanicalCar LiftingDevices• Torsion resistant version• Width: 2,2 m• Weight: 75 kg• Surface: galvanized version• Easy handling• Usable only with hook• Mounting bracket PZLG20BWith ring connection / PZLG20HWith welded plate / PZLG20SWith bolted plate / PZLG20PWheel clamps PZTC01Scope of delivery: set with 4 pieces• Secure lifting of vehicles• Load capacity 900 kg per wheel clamp• For wheel width up to 295 mm• For wheel size 12 to 19 Zoll• Many adjustment possibilities• Torsion resistant• Weight: 16 kg• Material: steel• Surface: yellow galvanizedNew improved version!Wheel clamps PZTC01-1Scope of delivery: set with 4 pieces• Load capacity 900 kg per wheelclamp• For wheel size 12 to 19 inches• For wheel width up to 355 mm• Better, easier adjustmentpossibilities45

Car Lifting DevicesWheel clamp straps PZLS01Scope of delivery: set with 4 pieces• Length adjustable: 1,3 / 1,5 / 1,7 m• Width: 50 mm• Load capacity: 892 kg per pieceWheel clamp straps PZLS02• Length adjustable: 4,2 - 5,1 m• Width: 300 mm• Load capacity: 2,5 t per pieceCar LiftingDevicesRoller window / PZ0001• Window opening 210 x 20 mm• Hole pattern: 365 mm• Usage: rope guidance (stem at winch)Recovery kit / PZ0002• Usage: rear side mounting on plateaus for better recoverypossibilityAccessoriesDeflection pulley (hinged) with eye whirl / PZ0004• Roll diameter: 50 to 100 mm• Rope diameter: 10 to 12 mm• Load capacity: 2000 to 4000 kg• Not apt for winch ropes made of synthetic fibre• Usage: better recovery possibilitiesDeflection pulley / PZ0003• Roll diameter: 100 mm• Rope diameter: 12 mm• Usage: additional switching point for recovery of cars46

Weight Measuring Systems for Hook OperationThe load measuring tool consists of a CROSBY-standard shackle withintegrated measuring cell and a transmitter with antenna and battery.This extremely robust version is especially apt for tasks in difficultenvironments, where a cable connection to the data transmission isnot possible.Within the cage for the transmission, mounted laterally to the measuring axis,there is also an easily exchangeable battery. On the opposite side an additionallyinstalled counterbalance provides an optimal shackle position even whenthe charge is small. This weighing system is optionally available with an aluminiumcase.• Accuracy ± 1% based on final value• Not calibratable• Transmission from the emitter to the seperate hand receiver• One-button with integrated LED, which flashes while data transmission• Battery conditions shown in the display of the receiverB*CHØ 92AD50EWeight measuring systemsLoad A B C D E H WeightType (t) (mm) (mm) (mm) (mm) (mm) (mm) (kg)EZ2631-03 3 37 58 22 25 55 97 2,8EZ2631-06 6,3 37 58 22 25 55 97 2,8EZ2631 8,5 43 68 26 28 61 109 3,8EZ2631-13 13,5 57 92 35 38 84 153 8,2EZ2631-17 17 60 98 38 41 92 166 10,5EZ2631-BOX transport boxmeasurements of the emitter are identical for all versionsWeight-MeasuringDescription of the receiving unitThe load data are transmitted to the hand receiver and displayed. This receiver consists of a waterproof case with a big, well legibleLCD display. The complete handling can be made by 3 buttons. An easily changeable battery provides the necessary operationalvoltage. The LCD display can be switched off in order to safe energy. Especially mentionable is the tare possibility of the loaddisplay.• Tare and weight calibration• Stable weight measuring (display)• Choice of serial exit• Battery conditions of emitter and receiver are shownin the display• All functions programmable via keypad and can be savedbattery conditionTechnical dataReceiver frequency:868,3 MHzData display:7 segment display, 5 signs,sign height 12 mmKeypad:2 push- and 1 on-buttonDisplay resolution:step size 1-2-5 / 10-20-50 kgWorking temperature:-10 to +50°CStock temperature:-20 to +70°CProtection class: IP 65Number transmissions:2 / secondVoltage feed-in:3 batteries 1,5 V type “AA”Dimensions:110 x 68 x 31 mmnet weightKeyON/OFF: switch on/off receiverfunctions: TARE: tare load displayMODE: switch on/off of LCD display47

Weight Measuring Systems with Integrated PrinterThe compact, precise and robust wireless-weight measuring system isequipped with a shackle and a hook and can be operated 30 - 40 hours incontinous duty application.The remote control allows an operation from the distance. Depending on the requirementsthe IHG wireless-weighing system is available with different capacitiesand for various applications like dynamic weighing or check weighing.• Display of cross and net weight• Auto-stop function• Calibration• Integrated micro-printer• Weighing unit KG/LB• Weight accumulation function 3000 data• Easy insertion of the battery• Taring function over the entire weight range• Rechargeable battery / auto-sleep• Included printerWeight-MeasuringWeight measuring systemsLoad capacity / partition A B C Ø D E Self weightType (kg) (mm) (mm) (mm) (mm) (mm) (kg)PZWMS-05 5000 / 2 680 210 170 270 240 30PZWMS-10 10000 / 5 840 230 200 270 320 35Technical dataTechnical drawingsAccuracy:Continous work:Max. load:Operating temperature:Operating humidity:Frequency:Protection class:+/- 0,03% based on final value60 hours120% F.S.-10°C - +40°C90° relative humidity433MHzIP54ACE BØ D48