FAQ's - sebaKMT

FAQ's - sebaKMT

FAQ's - sebaKMT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FAQ’s<br />

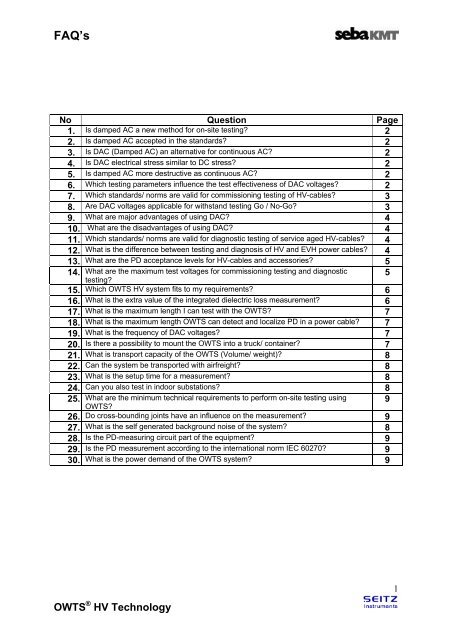

No Question Page<br />

1. Is damped AC a new method for on-site testing? 2<br />

2. Is damped AC accepted in the standards? 2<br />

3. Is DAC (Damped AC) an alternative for continuous AC? 2<br />

4. Is DAC electrical stress similar to DC stress? 2<br />

5. Is damped AC more destructive as continuous AC? 2<br />

6. Which testing parameters influence the test effectiveness of DAC voltages? 2<br />

7. Which standards/ norms are valid for commissioning testing of HV-cables? 3<br />

8. Are DAC voltages applicable for withstand testing Go / No-Go? 3<br />

9. What are major advantages of using DAC? 4<br />

10. What are the disadvantages of using DAC? 4<br />

11. Which standards/ norms are valid for diagnostic testing of service aged HV-cables? 4<br />

12. What is the difference between testing and diagnosis of HV and EVH power cables? 4<br />

13. What are the PD acceptance levels for HV-cables and accessories? 5<br />

14. What are the maximum test voltages for commissioning testing and diagnostic<br />

testing?<br />

5<br />

15. Which OWTS HV system fits to my requirements? 6<br />

16. What is the extra value of the integrated dielectric loss measurement? 6<br />

17. What is the maximum length I can test with the OWTS? 7<br />

18. What is the maximum length OWTS can detect and localize PD in a power cable? 7<br />

19. What is the frequency of DAC voltages? 7<br />

20. Is there a possibility to mount the OWTS into a truck/ container? 7<br />

21. What is transport capacity of the OWTS (Volume/ weight)? 8<br />

22. Can the system be transported with airfreight? 8<br />

23. What is the setup time for a measurement? 8<br />

24. Can you also test in indoor substations? 8<br />

25. What are the minimum technical requirements to perform on-site testing using<br />

OWTS?<br />

9<br />

26. Do cross-bounding joints have an influence on the measurement? 9<br />

27. What is the self generated background noise of the system? 8<br />

28. Is the PD-measuring circuit part of the equipment? 9<br />

29. Is the PD measurement according to the international norm IEC 60270? 9<br />

30. What is the power demand of the OWTS system? 9<br />

OWTS ® HV Technology<br />

1

FAQ’s<br />

1. Is damped AC a new method for on-site testing?<br />

NO: The damped alternating voltage (DAC) is an oscillating switching impulse<br />

voltage (OSI) of quite low damping (

FAQ’s<br />

c) number of DAC voltage excitations appears to be an important parameter; the<br />

breakdown voltage decreases as the number of excitations increases;<br />

d) The DAC voltage charging time does not seem to have an important influence on<br />

the breakdown processes;<br />

7. Which standards/ norms are valid for commissioning testing of HV-cables?<br />

Looking for standards important for on-site testing we have to make a distinction<br />

between HV and EHV cables, HV cables are standardized as cables with a rated<br />

voltage between 30kV and 150kV, EHV for cables with a rated voltage for 150kV and<br />

higher.<br />

Standards for (E) HV cable design and testing are: IEC 60060-3 High Voltage test<br />

techniques –Part 3: Definitions and requirements for on-site testing<br />

[1] IEEE 400 Guide for Field Testing and Evaluation of the Insulation of Shielded<br />

Power Cable Systems<br />

[2] IEEE 400.3 Guide for PD Testing of Shielded Power Cable Systems in a Field<br />

Environment<br />

[3] IEC 60840 Power cables with extruded insulation and the accessories for rated<br />

voltages above 30kV up to 150kV Test methods and requirements;<br />

[4] IEC 62067 Power cables with extruded insulation and the accessories for rated<br />

voltages above 150kV.<br />

In addition with regard to PD detection the following standards are of importance<br />

[5] IEC 60270, Partial Discharges Measurements, 2000<br />

[6] IEC 885-3 Test methods for Partial Discharges measurements on lengths of<br />

extruded power cable<br />

Moreover with regard to on-site testing and diagnosis several Cigre documents have been<br />

published in the past e.g.<br />

[7] CIGRE Electra 176, 1998, ‘’Diagnostic Methods for HV Paper Cables and<br />

Accessories’’<br />

[8] CIGRE Electra 208 Electra, 2003. “Experiences in partial discharge detection of<br />

distribution power cable systems”<br />

[9] CIGRE Brochure 226, 2004, ‘’Knowledge rules for partial discharge diagnosis in<br />

service’’<br />

[10] CIGRE Electra 226, 2006, ‘’Practical aspects of the detection and location of<br />

partial discharges in power cables’’<br />

8. Are DAC voltages applicable for withstand testing Go / No-Go?<br />

YES: Applying DAC withstand test the cable section can be stressed with a selected<br />

DAC voltage stress for selected time duration and the cable section can be rejected if<br />

a breakdown has occurred.<br />

Due to shorter duration of the excitations and decaying characteristic of the voltage it<br />

is not directly comparable to withstand voltage testing with continuous AC.<br />

OWTS ® HV Technology<br />

3

FAQ’s<br />

9. What are major advantages of using DAC?<br />

Application of DAC voltages has the following advantages:<br />

1. Since several years accepted for on-site testing and PD measurements of all<br />

types and lengths of power cables.<br />

2. Simple, lightweight, cost effective equipment with very low input power<br />

requirements and able to stress long cable lengths.<br />

3. With regard to partial discharges similar AC electrical stresses as during factory<br />

testing and service operation.<br />

4. During over-voltage application the small number of cycles reduces the risk of<br />

damage to the cable system.<br />

5. Analyzing the damped AC voltage attenuation provides information about<br />

dielectric losses (tan δ, ∆ tanδ).<br />

10. What are the disadvantages of using DAC?<br />

Actually there are no serious disadvantages in using DAC voltages. A number of<br />

limitations can be mentioned:<br />

1. Due to short duration of the excitations and decaying characteristic of the damped<br />

AC voltage the breakdown field strengths are not directly comparable to the<br />

breakdown stresses of withstand voltage testing with continuous AC.<br />

2. To obtain PD occurrence conditions (e.g. PD inception, PD level) similar to 50<br />

(60) Hz AC voltage stresses, the DAC frequency has to be below approx. 500 Hz.<br />

3. Use of fixed inductor at different cable capacitances results in variation in<br />

resonance frequencies.<br />

4. In the case of very short cable length an additional capacitive load is<br />

recommended.<br />

5. The damped AC voltage decay characteristic depends on the actual dielectric loss<br />

behavior of a particular cable section.<br />

11. Which standards/ norms are valid for diagnostic testing of service aged HVcables?<br />

Generally taken there are no standards/ norms for diagnosing HV-cables. However<br />

experiences from diagnostic testing in the MV-network of over 10 years have proven<br />

the need for diagnosis. When performing diagnostic testing one can monitor the<br />

condition of the insulation, in other words follow the ageing processes of the<br />

insulation. In the HV-application this is very useful to monitor oil-filled, oil-pressurized<br />

or gas pressurized cables. From this type of cable it is generally known that they<br />

show higher dielectric losses due to ageing and are reaching the end of there<br />

estimated life time, so what to do with these cables?<br />

12. What is the difference between testing and diagnosis of HV and EVH power<br />

cables?<br />

With regard to testing the following is important:<br />

1. To detect insulation defects in HV and EHV power cables during on-site testing<br />

voltages higher than Uo (over-voltages) can be used.<br />

2. Voltage tests up to e.g. 1.7Uo to demonstrate that<br />

OWTS ® HV Technology<br />

4

FAQ’s<br />

a. the insulation is healthy (defect-free and/or non-aged) and that insulation<br />

can withstand a high voltage stress level,<br />

b. insulation is aged and/or consists of insulation defects should<br />

have lower level of withstand voltage.<br />

With regard to diagnosis the following is important:<br />

1. PD detection up to e.g. 1.7Uo to demonstrate that the insulation is PD free by<br />

determining the PDIV. The margin between PDIV and the Uo is a reliability<br />

indicator of a particular cable circuit.<br />

2. With regard to service aged power cables the dielectric loss measurement in<br />

function of the test voltage up to e.g. 1.7Uo is very valuable indicator about the<br />

thermal stability of a particular cable circuit (OF cables).<br />

13. What are the PD acceptance levels for HV-cables and accessories?<br />

Generally speaking HV-XLPE cables and accessories must be PD-free, not only in<br />

case of newly installed cables but also for service aged cables.<br />

Oil filled cables should be also PD-free, but at field tests some test objects have<br />

shown PD in terminations and cable insulation. Today no threshold values for<br />

acceptable PD level in oil filled cables are known.<br />

14. What are the maximum test voltages for commissioning testing and<br />

diagnostic testing?<br />

When testing in accordance to the IEC 60840 for cables rated up to 150kV the<br />

specified test voltages are listed below:<br />

OWTS ® HV Technology<br />

5

FAQ’s<br />

For cables rated higher then 150kV the test voltage has to be selected in accordance<br />

to IEC 62067<br />

or with 1.7U0, depending on practical operational conditions.<br />

15. Which OWTS HV system fits to my requirements?<br />

Depending on the maximum test voltages of a particular cable type a system can be<br />

selected from the table below<br />

OWTS ® HV Technology<br />

Applicability for testing different power cable ratting voltages<br />

Power cable rated Uo [kV] OWTS HV 150 OWTS HV 250 OWTS HV 350<br />

voltages [kV]<br />

X Uo<br />

X Uo<br />

X Uo<br />

66 38,1 2,8<br />

110 63,5 1,7 2,8<br />

132 76,2 1,4 2,3<br />

150 86,6 1,2 2.0 2,8<br />

220 127 0.8 1,4 1,9<br />

330 190,5 0.9 1,3<br />

380 219,4 1,1<br />

16. What is the extra value of the integrated dielectric loss measurement?<br />

The estimation of the dielectric losses which has been integrated in the OWTS<br />

determines the condition of the insulation and is therefore for HV-cables of major<br />

importance. Especially for HV-cables with paper insulation such as; oil filled cables,<br />

oil-pressurized or gas-pressurized cables, the dielectric losses (absolute and tip-up)<br />

is an important parameter.<br />

6

FAQ’s<br />

17. What is the maximum length I can test with the OWTS?<br />

OWTS HV technology is standard tested for capacitive loads of cable lengths up to<br />

30km) and longer. On request larger capacitive loads can also be also energized.<br />

Depending on the type of cable the capacitance per kilometre differs. For instance a<br />

XLPE insulated cable with a specific capacitance of 200 nF/km can have a length of<br />

40 km.<br />

18. What is the maximum length OWTS can detect and localize PD in a power<br />

cable?<br />

A distinction has to be made between PD-detection and PD-localisation. The OWTS<br />

is the only an integrated system available which is able to energize and detect PD<br />

from cables up to capacitive load of cable lengths to 30km) and longer.<br />

Using IEC60270 PD detection principles OWTS is the best system to detect on-site in<br />

[pC] very sensitively PD in all type of power cables.<br />

To localize PD sites in a power cable OWTS uses the time domain reflectometry<br />

method. It is known that TDR effectiveness depends on several factors e.g.<br />

a) HF-impedance characteristic of the particular cable system<br />

b) PD site position in the cables<br />

c) PD level and intensity<br />

d) actual background noise,<br />

e) PD level etc.<br />

Therefore it is not possible to give a fixed number of max. length to localize PD sites.<br />

It is advisable in the case of long cables to perform PD detection form both cable<br />

ends.<br />

19. What is the frequency of DAC voltages?<br />

OWTS uses large PD-free and low losses inductors specially developed for testing<br />

power cables. Depending on the type of OWTS system the inductors may vary<br />

between 4H and 8H. As a result the frequency of the DAC wave will be between<br />

20Hz and 300Hz, which is the normalized frequency according to the IEC standards<br />

IEC 62067 and IEC 60840. The particular DAC frequency is depending on the length<br />

of the cable section under test. In particular after charging the cable section up to<br />

selected voltage level the LC circuit as obtained from the cable capacitance and the<br />

external inductance (7H) As a result system produces sinusoidal damped AC<br />

voltages in the range of 20Hz-300Hz, depending on cable capacitance.<br />

Examples of typical damped ac voltage frequencies for different lengths of two typical 150kv<br />

power cables<br />

Length [km] XLPE (C=154pF/m) [Hz] Oil filled (C=373pF/m) [Hz]<br />

0.25 300 194<br />

0.5 213 137<br />

1 151 97<br />

2 107 69<br />

4 76 49<br />

8 53 34<br />

16 38 24<br />

20 34 22<br />

20. Is there a possibility to mount the OWTS into a truck/ container?<br />

YES: The OWTS has been originally designed to be transportable, that’s why the<br />

components have been packed in transportation boxes. However mounting the<br />

OWTS 150kV in a container must be possible.<br />

7<br />

OWTS ® HV Technology

FAQ’s<br />

For the other two systems (HV250 and HV350) this will bring implications since the<br />

height of the system + clearance will be more then 4m, which makes transportation<br />

on road or by rail problematic.<br />

The systems can be mounted on a trailer of sufficient length. In this case extra<br />

measures have to be taken to support the individual components during transport.<br />

21. What is transport capacity of the OWTS (Volume/ weight)?<br />

In the table listed below the total volume of each system has been given. When<br />

compared with a resonance test set this is almost nothing.<br />

OWTS HV 150kV 10 m 3<br />

OWTS HV 250kV 12 m 3<br />

OWTS HV 350kV 20 m 3<br />

E.g. for the OWTS HV 150 system for transportation purpose the minimal cubic size<br />

must be 10m3 Vans like: Mercedes Sprinter 311, Opel Movano L2H2<br />

Component Height (cm) Width (cm) Length (cm) Net weight<br />

3 x coil box 65 75 75 45kg<br />

Bas unit box 91 130 85 35kg<br />

HV source box 137 105 75 85kg<br />

PD divider box 115 70 70 45kg<br />

22. Can the system be transported with airfreight?<br />

YES: all system of the OWTS technology can be transported with airfreight.<br />

Since the weight and size of the equipment are both relatively small it is possible to<br />

transport the system by airfreight. Something that isn’t possible with a resonance test<br />

set).<br />

23. What is the setup time for a measurement?<br />

The setup of the system is one of the most important aspects of the entire<br />

measurement and must therefore be done carefully. Generally it takes up to 2 hours<br />

to setup the system, required that all other work like de-energizing the cable and<br />

making the termination free for connecting the OWTS on it, is performed on forehand.<br />

E.g. Un-packing/packing OWTS HV 150 components and connection to the test<br />

object: approx. 2.0 hrs.<br />

Measuring (one phase) depending on max test voltage applied, e.g. starting from 10<br />

kV (peak) to 150 kV (peak) with steps 10kV, testing/measurement takes: approx.<br />

0.5hrs/phase. Changing between particular cable phases approx. 2x 0.5hrs<br />

Total duration: Depending on cable section detailed information, logistics and on-site<br />

local situation and the amount of diagnostic data to be collected for 3-phase cable<br />

approx. 5-8 hrs.<br />

24. Can you also test in indoor substations?<br />

YES: One of the big advantages of the OWTSHV Technology is the compactness of<br />

the system. Since the dimensions of the OWTS HV series are relatively small, it is<br />

absolutely no problem to measure indoor. Each component has been packed in a<br />

portable transportation box on wheels which makes it possible to easily transport the<br />

equipment to the measurement side.<br />

OWTS ® HV Technology<br />

8

FAQ’s<br />

25. What are the minimum technical requirements to perform on-site testing<br />

using OWTS?<br />

There are no special or extraordinary requirements regarding testing using OWTS.<br />

Preparing the on-site test the following has to be considered:<br />

1. At the location a power supply of 220Vac 50(60Hz and rated for at least 5kW has<br />

to be available.<br />

2. The access to the test object (connection point between the OWTS system and<br />

the cable terminations) has to be below 7m height.<br />

3. The test object has fully be disconnected from the network and other components<br />

e.g. transformers, surge arrestors etc.<br />

4. In the case of GIS connection the specific tools (inserts, bushings, etc) needed to<br />

connect the test system has to be provided and installed by the customer.<br />

5. Tent of other solution needed to protect the test system against the rainwater.<br />

6. In case of an higher position of the termination (more than 5-7m) a special pd free<br />

connecting cable is required.<br />

26. Do cross- bonding joints have an influence on the measurement?<br />

YES: Cross-bonding joints have an influence on the signal quality of the travelled PD<br />

pulses. Cross links must therefore be removed and sheaths must be connected<br />

normal during PD-testing.<br />

27. What is the self generated background noise of the system?<br />

Since the voltage source is disabled during the PD measuring, DAC principle, the self<br />

generated background-noise of the system can be assumed as