View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

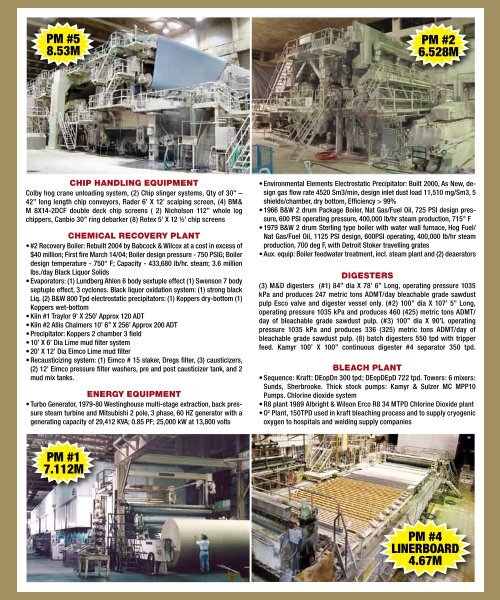

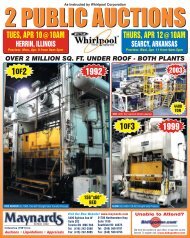

PM #58.53MPM #26.528MCHIP HANDLING EQUIPMENTColby hog crane unloading system, (2) Chip slinger systems, Qty of 30” –42” long length chip conveyors, Rader 6’ X 12’ scalping screen, (4) BM&M 8X14-2DCF double deck chip screens ( 2) Nicholson 112” whole logchippers, Canbio 30” ring debarker (8) Rotex 5’ X 12 ½’ chip screensCHEMICAL RECOVERY PLANT• #2 Recovery Boiler: Rebuilt 2004 by Babcock & Wilcox at a cost in excess of$40 million; First fire March 14/04; Boiler design pressure - 750 PSIG; Boilerdesign temperature - 750° F; Capacity - 433,680 lb/hr. steam; 3.6 millionlbs./day Black Liquor Solids• Evaporators: (1) Lundberg Ahlen 6 body sextuple effect (1) Swenson 7 bodyseptuple effect, 3 cyclones. Black liquor oxidation system: (1) strong blackLiq. (2) B&W 800 Tpd electrostatic precipitators: (1) Koppers dry-bottom (1)Koppers wet-bottom• Kiln #1 Traylor 9’ X 250’ Approx 120 ADT• Kiln #2 Allis Chalmers 10’ 6” X 256’ Approx 200 ADT• Precipitator: Koppers 2 chamber 3 field• 10’ X 6’ Dia Lime mud filter system• 20’ X 12’ Dia Eimco Lime mud filter• Recausticizing system: (1) Eimco # 15 slaker, Dregs filter, (3) causticizers,(2) 12’ Eimco pressure filter washers, pre and post causticizer tank, and 2mud mix tanks.energy equipment• Turbo Generator, 1979-80 Westinghouse multi-stage extraction, back pressuresteam turbine and Mitsubishi 2 pole, 3 phase, 60 HZ generator with agenerating capacity of 29,412 KVA; 0.85 PF; 25,000 kW at 13,800 volts• Environmental Elements Electrostatic Precipitator: Built 2000, As New, designgas flow rate 4520 Sm3/min, design inlet dust load 11,510 mg/Sm3, 5shields/chamber, dry bottom, Efficiency > 99%• 1966 B&W 2 drum Package Boiler, Nat Gas/Fuel Oil, 725 PSI design pressure,600 PSI operating pressure, 400,000 lb/hr steam production, 715° F• 1979 B&W 2 drum Sterling type boiler with water wall furnace, Hog Fuel/Nat Gas/Fuel Oil, 1125 PSI design, 600PSI operating, 400,000 lb/hr steamproduction, 700 deg F, with Detroit Stoker travelling grates• Aux. equip: Boiler feedwater treatment, incl. steam plant and (2) deaeratorsDIGESTERS(3) M&D digesters (#1) 84” dia X 78’ 6” Long, operating pressure 1035kPa and produces 247 metric tons ADMT/day bleachable grade sawdustpulp Esco valve and digester vessel only. (#2) 100” dia X 107’ 5” Long,operating pressure 1035 kPa and produces 460 (425) metric tons ADMT/day of bleachable grade sawdust pulp. (#3) 100” dia X 90’L operatingpressure 1035 kPa and produces 336 (325) metric tons ADMT/day ofbleachable grade sawdust pulp. (8) batch digesters 550 tpd with tripperfeed. Kamyr 100’ X 100” continuous digester #4 separator 350 tpd.BLEACH PLANT• Sequence: Kraft: DEopDn 300 tpd; DEopDEpD 722 tpd. Towers: 6 mixers:Sunds, Sherbrooke. Thick stock pumps: Kamyr & Sulzer MC MPP10Pumps. Chlorine dioxide system• R8 plant 1989 Albright & Wilson Erco R8 34 MTPD Chlorine Dioxide plant• O 2 Plant, 150TPD used in kraft bleaching process and to supply cryogenicoxygen to hospitals and welding supply companiesPM #17.112MPM #4LINERBOARD4.67M