View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

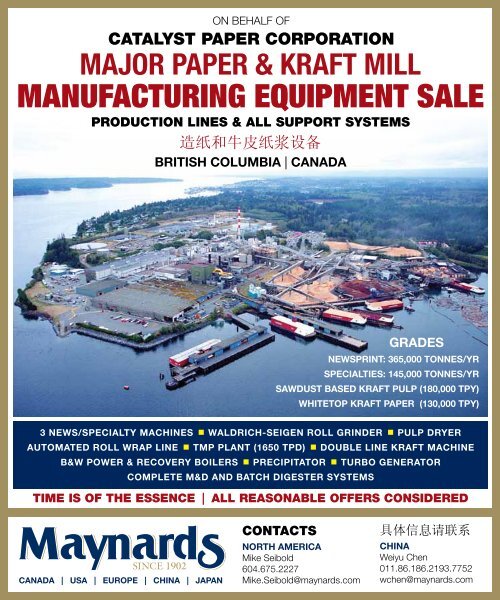

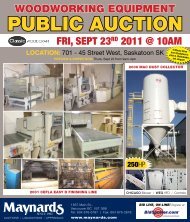

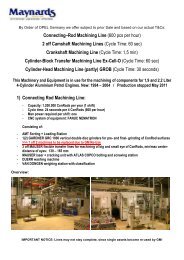

On behalf ofCatalyst Paper CorporationMAJOR PAPER & KRAFT MILLMANUFACTURING EQUIPMENT SALEPRODUCTION LINES & ALL SUPPORT SYSTEMS造 纸 和 牛 皮 纸 浆 设 备BRITISH COLUMBIA | CANADAGRADESNewsprint: 365,000 tonnes/yrSpecialties: 145,000 tonnes/yrSawdust based Kraft pulp (180,000 tpy)Whitetop Kraft paper (130,000 tpy)3 NEWS/SPECIALTY MACHINES n WALDRICH-SEIGEN ROLL GRINDER n PULP DRYERAUTOMATED ROLL WRAP LINE n TMP PLANT (1650 TPD) n DOUBLE LINE KRAFT MACHINEB&W POWER & RECOVERY BOILERS n PRECIPITATOR n TURBO GENERATORCOMPLETE M&D AND BATCH DIGESTER SYSTEMSTIME IS OF THE ESSENCE | ALL REASONABLE OFFERS CONSIDEREDCANADA | USA | EUROPE | CHINA | JAPANContactSNorth AmericaMike Seibold604.675.2227Mike.Seibold@maynards.com具 体 信 息 请 联 系CHINAWeiyu Chen011.86.186.2193.7752wchen@maynards.com

Andritz & Sunds RefinersPulp ProcessingKraft knotters: I-R & Jonsson. (5) Black Clawson selectifier screens,Cleaners (1) 4 stage Celleco. (1) Black Clawson chemiwasher SoftwoodSawdust Sulphate pulp, production 600 A.D T/D average. Right hand, wirewidth 246”, Headbox pond 240” W, design speed 160FPM, wire slacktension 40PLI. (4) 8’ X 12’ Dorr-Oliver Long, (4) 12’ X 16’ Kamyr bleach,(3) 13.5 X 24’ Coru-Deck. Deckers (1) Sherbrooke, (3) Dorr-Oliver-LongTMP PLANT(3) line plant consisting of: Sunds Defibrators (6) Mod RLP-58 (3) primary(3) secondary 120 ton air dry per day, (8) Sunds Defibrators Mod CD-70S (4)primary (4) secondary 300 ton air dry per day, (3) Sunds Mod RGP 60 rejectrefiner @ 190 ADT/day, 6000 hp motors, (13) Hooper primary and secondaryscreens, (3) Celleco Disc filters, (6) IR Centrisorter screens, (3) CE Bauer 575-28 reject presses, (4) CE Bauer 575-28-5 wash presses, (2) Thune SP45LScrew PressesNEWSPRINT LINESPM#5 1982 Valmet Metso Twin wire blue white newsprint anddirectory machine: basis weight 35, 8-52G/sq.m most common grade48,8 G/sq.m, 9.05 M (356.3)” headbox pond width, 8.53 M (336”) trim, 340”IMPCO DISC FILTERSwidth of paper web on the reel, 4300 fpm design speed, normal operatingspeed, 4000 fpm, 8500 fpm balancing speed, dimensioning production 740metric tons/day (816 short tons/day) on reel w/ 100% efficiency caculated per48,8 G/m2 (30 lbs/3000 sq.ft.), 1997 Voith headbox upgrade to a WA-Jetmitmodule jet, size SW12500-module jet pond width 9050mm 141 module, ABBSmart Platform scannerPM#1 Dominion Valmet Symformer on base Dominion Engineeringfourdrinier newsprint machine, basis weight 40-52 G/M2, 288” wire width,7.112 M (280”) headbox pond width, 6.81 M (268”) trim, 3500 fpm balancingspeed, left hand, furnish 80 to 85% TMP - freeness range 75 to 95 degreesCSF, 15 to 20% SBK-freeness range 550 to 700 degrees CSF broke up to 25%,upgraded automatic slice control, edge injection, headbox heater (2001),Beloit twinver press, Measurex 4000 scanner, Beloit double drum ModL-26-G-50 slitter rewinder systemPM#2 Beloit Bel Baie III Horizontal newsprint and groundwoodspecialties machine: Valmet twin wire former, 6.528 M (257”) headboxpond width, 6.2 M (244”) trim, 420-480 TPD, 3450 fpm, twinver press,Kleinewefers 2 stage soft nip calendar, Measurex 4000 scanner, 1991Jagenberg Varistep Mod VS-90 slitter rewinder system3JAGENBERG VARISTEP SLITTER REWINDERM & D DIGESTERS

1OF2TRANFORMERSBLACK CLAWSON SCREENSWHOLE LOG CHIPPERSSAVANT GUIDED VEHICLE1OF6JAGENBERG VARISTEPMCCs STARCH COOLER SUNDS DEFIBRATORFLAKT DRYER1990 Flakt airborne sheet cooler system bleached kraft 820ADMTPD operating speed 421 FPM, width of sheet entering194”, Wet end and dry end Accuray scanners, disc thickener,economizer, 3rd press pulper, Cutter-Layboy system with air floattable into dry end beater.BALING LINEThere is a complete small and large bale systems consisting of 2 bale presses (1)Hymac 1200 ton and (1) Dominion 1200 ton, (2) Bale stacker systems, (3) wire tyingsystems all transfers and conveyors, Duowrap dispensing and folding systems, baleUnityer system. Automatic James Brinkley/ Hymac BHK (Bleached Hardwood Kraft),and DLK (Deinked Linerboard Kraft) bale handling and beatering systems$12 MILLION INVENTORY OF NEW SPARE PARTSPartial Listing Available at www.maynards.com

PM #58.53MPM #26.528MCHIP HANDLING EQUIPMENTColby hog crane unloading system, (2) Chip slinger systems, Qty of 30” –42” long length chip conveyors, Rader 6’ X 12’ scalping screen, (4) BM&M 8X14-2DCF double deck chip screens ( 2) Nicholson 112” whole logchippers, Canbio 30” ring debarker (8) Rotex 5’ X 12 ½’ chip screensCHEMICAL RECOVERY PLANT• #2 Recovery Boiler: Rebuilt 2004 by Babcock & Wilcox at a cost in excess of$40 million; First fire March 14/04; Boiler design pressure - 750 PSIG; Boilerdesign temperature - 750° F; Capacity - 433,680 lb/hr. steam; 3.6 millionlbs./day Black Liquor Solids• Evaporators: (1) Lundberg Ahlen 6 body sextuple effect (1) Swenson 7 bodyseptuple effect, 3 cyclones. Black liquor oxidation system: (1) strong blackLiq. (2) B&W 800 Tpd electrostatic precipitators: (1) Koppers dry-bottom (1)Koppers wet-bottom• Kiln #1 Traylor 9’ X 250’ Approx 120 ADT• Kiln #2 Allis Chalmers 10’ 6” X 256’ Approx 200 ADT• Precipitator: Koppers 2 chamber 3 field• 10’ X 6’ Dia Lime mud filter system• 20’ X 12’ Dia Eimco Lime mud filter• Recausticizing system: (1) Eimco # 15 slaker, Dregs filter, (3) causticizers,(2) 12’ Eimco pressure filter washers, pre and post causticizer tank, and 2mud mix tanks.energy equipment• Turbo Generator, 1979-80 Westinghouse multi-stage extraction, back pressuresteam turbine and Mitsubishi 2 pole, 3 phase, 60 HZ generator with agenerating capacity of 29,412 KVA; 0.85 PF; 25,000 kW at 13,800 volts• Environmental Elements Electrostatic Precipitator: Built 2000, As New, designgas flow rate 4520 Sm3/min, design inlet dust load 11,510 mg/Sm3, 5shields/chamber, dry bottom, Efficiency > 99%• 1966 B&W 2 drum Package Boiler, Nat Gas/Fuel Oil, 725 PSI design pressure,600 PSI operating pressure, 400,000 lb/hr steam production, 715° F• 1979 B&W 2 drum Sterling type boiler with water wall furnace, Hog Fuel/Nat Gas/Fuel Oil, 1125 PSI design, 600PSI operating, 400,000 lb/hr steamproduction, 700 deg F, with Detroit Stoker travelling grates• Aux. equip: Boiler feedwater treatment, incl. steam plant and (2) deaeratorsDIGESTERS(3) M&D digesters (#1) 84” dia X 78’ 6” Long, operating pressure 1035kPa and produces 247 metric tons ADMT/day bleachable grade sawdustpulp Esco valve and digester vessel only. (#2) 100” dia X 107’ 5” Long,operating pressure 1035 kPa and produces 460 (425) metric tons ADMT/day of bleachable grade sawdust pulp. (#3) 100” dia X 90’L operatingpressure 1035 kPa and produces 336 (325) metric tons ADMT/day ofbleachable grade sawdust pulp. (8) batch digesters 550 tpd with tripperfeed. Kamyr 100’ X 100” continuous digester #4 separator 350 tpd.BLEACH PLANT• Sequence: Kraft: DEopDn 300 tpd; DEopDEpD 722 tpd. Towers: 6 mixers:Sunds, Sherbrooke. Thick stock pumps: Kamyr & Sulzer MC MPP10Pumps. Chlorine dioxide system• R8 plant 1989 Albright & Wilson Erco R8 34 MTPD Chlorine Dioxide plant• O 2 Plant, 150TPD used in kraft bleaching process and to supply cryogenicoxygen to hospitals and welding supply companiesPM #17.112MPM #4LINERBOARD4.67M

ALSO AVAILABLE FOR PURCHASEAPPROX.$100 MILLIONINVESTEDSINCE 1991PAPER RECYCLING FACILITYVancouver, British Columbia | Canada1991 Paper Recycling Division 480 ADMTPD of market ONP/OMG DIP•Pulper Voith High Density HDC 60 Batch pulper (1250 HP)• Detrashers Contaminex Voith CMS 40, 10 mm hole size (200 HP)• High Density Cleaners 5 Krebs P15GP-1713 Cleaners• Coarse Hole Screens Voith 3 stages holes:Coarse hole Primary Stage 2- 20Spectro Screens (1.4 mm holes and 200 HP), Primary Rejects: CombisorterSize 12: (125HP with 2.6 mm and 3.0 mm hole size),Coarse hole 2nd Stage:1-20 Spectro Screens (1.4 mm holes and 150 HP), Coarse hole 3rd Stage:10W Spectro Screen ( 1.4 mm holes and 75 HP), Coarse Slot Screens Voith3 stage slots (0.25 mm slot baskets), Primary Screens: 3 –Voith Model 20Pressure Screens (75 HP), Secondary Screen: 1 – Voith Model 20 PressureScreen (75 HP), Tertiary Screen: 1 – Voith Model 10W Minisorter (50 HP),Fine Slot Screens Voith 3 stage slots (0.15 mm slot baskets): Primaryscreens: 2 – Voith model 20 screens (100 HP) 1 – Voith VPS35 screen (150HP) Secondary screens: 2 – Voith model 20 screens (100 HP), Tertiaryscreen: 1 – Voith model 20 screen (100 HP) (Installed in October 2006)• Flotation Cells 2 – Voith E-cells: 6 – 3 m primary cells and 2- 2m secondarycells, Secondary cells upgraded with Eco-injectors, 1 – Voith E-cell customdesign post flotation cell, 4 – 5 m primary cells and 2 – 2m secondary cells,Secondary cells upgraded with Ecoinjectors.• Disc Filters 4 Beloit Polydisc filters• Screw Presses 2 Andritz – 3620 Screw Presses (250 HP each)• Pulp Drying 2 - Andritz Double Wire Presses DWP4 (2.6 m wide),1 x righthand drive, 1 x left hand drive, 2 – Andritz Heavy Duty Press HDP3 (2.6 mwide) 1 x right hand drive, 1 x left hand drive• 2- Andritz Cutter Lay Boy CLB (2.4 m wide), 1 x right hand drive, 1 x left handdrive• Sludge Presses 2 Andritz 3628 Screw Presses (300 HP)• Gravity Tables 2 Andritz 2 m Gravity Belt Thickeners• Wire Tyers 1 Cranston Bale Line• Process Water Clarifiers 5 – 316LSS Flakt Dispersion Units, 5 – Flaktdissolved air flotation units• Secondary Treatment Plant 1 – Eimco Activated Sludge Reactor, 1 – EimcoSecondary Clarifier (20m)• Forward Cleaners 2 stages of Beloit Posiflow Cleaners, 4 banks of 100primary cleaners, 1 bank of 20 secondary cleaners• Dispersers 1 Voith 350 tpd Dispersion unit 1250 HP Manual Gap adjustment• Disk Filters 2 Beloit Polydiscs• Package Boilers (2) Superior: 4-X-1276-S150-CF Boilers Capacity: 4630 kg/hour steam each Pressure rating: 1034 kPa (1) Boiler modified to burn bothnatural gas and landfill gas.CONTACTS: 具 体 信 息 请 联 系North America | Mike Seibold, 604.675.2227, Mike.Seibold@maynards.comCHINA | Weiyu Chen, 1.86.2193.7752, wchen@maynards.comLAND AVAILABLE FOR SUBLEASE (6.3 HECTARES)Sign up at www.maynards.com to receive email notificationsof upcoming sales in your industry!Please email us at info@maynards.com if your mailing information has changed, or if you have received this brochure in error.