Current Developments in the Hydrometallurgical Treatment of ...

Current Developments in the Hydrometallurgical Treatment of ...

Current Developments in the Hydrometallurgical Treatment of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesThe <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper ConcentratesDavid Dreis<strong>in</strong>gerUniversity <strong>of</strong> British ColumbiaVancouver, Canada

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCopper Ore/Concentrate <strong>Treatment</strong>‣Focus on Sulfate Processes‣Variety <strong>of</strong> Process Options Available‣Key Factors– Copper Leach Extraction– Iron Precipitation– Precious Metal Recovery– Sulfur Deportment– Cost!

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesProcess Options‣Copper Leach<strong>in</strong>g Issues;– Copper leach<strong>in</strong>g controlled by copperm<strong>in</strong>eral leach k<strong>in</strong>etics– Chalcopyrite passivates under mildconditions– Liquid sulfur wets unreacted m<strong>in</strong>erals andstops leach<strong>in</strong>g

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesChalcopyrite Passivation‣Eh – pH Diagram Shows Many Phasesbetween CuFeS 2 (solid) andCuSO 4 (aqueous)‣Chalcopyrite Passivates by an Iron-Deficient Copper Sulfide (CuS n ) <strong>in</strong>Sulfate Based Leach<strong>in</strong>g Processes

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCu-Fe-S-H 2 O Diagram

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesChalcopyrite Oxidation and SulfurElemental Sulfur Reaction Product4CuFeS 2 + 5O 2 (g) + 10H 2 SO 4 =4CuSO 4 + 2Fe 2 (SO 4 ) 3 + 10H 2 O + 20S(0.63 t O 2 /t Cu leached)Sulfate Sulfur Reaction Product4CuFeS 2 + 15O 2 (g) + 2H 2 O =4CuSO 4 + 2Fe 2 (SO 4 ) 3 + 2H 2 SO 4(1.89 t O 2 /t Cu leached)

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesSulfur Chemistry‣Sulfur is formed from sulfide m<strong>in</strong>eralsdur<strong>in</strong>g leach<strong>in</strong>g‣Three temperature regimes‣Low T: < 119.3 C – SOLID (S 8 )‣Medium T: 119.3 C to 159 C – LIQUID(S 8 )‣High T: +159 C – LIQUID/POLYMER (S n )

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesLOW T Leach<strong>in</strong>g‣Elemental sulfur forms porous productlayer‣K<strong>in</strong>etics can be slow due to diffusionthrough sulfur product layer

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesMedium Temperature Leach<strong>in</strong>g‣Molten sulfur is dispersed by addition <strong>of</strong>a sulfur dispersant/surface active agent‣Lign<strong>in</strong> sulfonate and Quebracho are twocommon agents.‣Sulfide m<strong>in</strong>eral becomes sulfophobicand hydrophilic‣Sulfur liquid droplets are dispersed

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesApparatus for <strong>in</strong>terfacial measurementPressure gaugeGas <strong>in</strong>letPlungerOutlet for gas bleed<strong>in</strong>gGlass tipLiquorsulfurScrew-drive syr<strong>in</strong>geThermowellSta<strong>in</strong>less steel bombGlass tipOpticalglass cellM<strong>in</strong>eralsampleAdjustable holderLightsourceLensSapphirew<strong>in</strong>dowOpticalglass cellAdjustableholderSapphirew<strong>in</strong>dowLensLensDigitalcamera

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesSulfur Droplets <strong>in</strong> Acid Solution (150 C)0.05 g/L lign<strong>in</strong> sulfonate 0.1 g/L lign<strong>in</strong> sulfonate0.5 g/L lign<strong>in</strong> sulfonateSurfactant-free0.05 g/L Quebracho0.1 g/L Quebracho 0.5 g/L Quebracho

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCalculated Sulfur/AqueousInterfacial Tensions (γ SA )Concentration / g L -1 0 0.05 0.1 0.2 0.3 0.4 0.5Lign<strong>in</strong> sulfonate / mN m -1 55 43 35 31 29 29 29Quebracho / mN m -1 55 45 38 37 37 37 37

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesSulfur Droplets <strong>in</strong> Acid Solution onChalcopyrite M<strong>in</strong>eral Surface (150 °C)0.05 g/L lign<strong>in</strong> sul<strong>of</strong>nate 0.1 g/L lign<strong>in</strong> sul<strong>of</strong>nate 0.5 g/L lign<strong>in</strong> sul<strong>of</strong>nateSurfactant-free0.05 g/L Quebracho 0.1 g/L Quebracho0.5 g/L Quebracho

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesContact Angles (Θ)Concentration / g L -1 0 0.05 0.1 0.2 0.3 0.4 0.5Lign<strong>in</strong> sulfonate / 76 142 152 155 156 157 158Quebracho / 76 155 157 158 159 160 161Wa = γ SA (1+cos(Θ))Work <strong>of</strong> Adhesion (Wa)Concentration / g L -1 0 0.05 0.1 0.2 0.3 0.4 0.5Lign<strong>in</strong> sulfonate / mJm -2 68.3 9.1 4.1 2.9 2.5 2.3 1.9Quebracho / mJ m -2 68.3 4.3 3.0 2.7 2.4 2.2 2.0

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesIron Precipitation‣ Dissolved iron will be oxidized andprecipitated as ferric hydroxide (undesirable),jarosite, goethite or hematite‣ Goethite forms at less than 140 C withhematite form<strong>in</strong>g above 140 C‣ Jarosite can form over wide temperaturerange‣ Basic ferric sulfate processes (Sepon)precipitate iron at high free acid and high T(220 C). Iron forms basic ferric sulfateswhich <strong>the</strong>n re-dissolve at atmospheric T+P.

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesPrecious Metal Recovery‣ Au may be recovered by cyanidation <strong>of</strong> copper leachresidues.‣ However if S present <strong>the</strong>n form SCN and <strong>in</strong>crease<strong>the</strong> cost <strong>of</strong> Au recovery.‣ Ag <strong>of</strong>ten forms Ag-jarosite under copper leach<strong>in</strong>gconditions. May have to use lime boil to decomposeAg-jarosite prior to cyanidation.‣ Alternative strategy to use o<strong>the</strong>r reagents (eg. S 2 O 32-,SCN - or Cl - /Br - )‣ PGM Recoveries difficult from residues but possibledirectly (PLATSOL)

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesS Deportment and Impurities‣ S oxidation forms sulfuric acid‣ Sulfuric acid may be a by-product as a weaksulfuric acid solution (economic credit)‣ Sulfuric acid neutralization consumeslimestone or lime (expense).‣ Impurities are generally removed byoxidation/pH adjustment as part <strong>of</strong> <strong>the</strong> leachor iron residue.

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesProcess Examples‣GALVANOX‣Anglo American Corporation/University<strong>of</strong> British Columbia Process‣PLATSOL‣SEPON Copper Process

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesGALVANOX‣Process developed by David Dixon andAla<strong>in</strong> Tshilombo <strong>of</strong> University <strong>of</strong> BritishColumbia‣Atmospheric leach<strong>in</strong>g <strong>of</strong> chalcopyriteconcentrates under mild, “galvanic”conditions to avoid passivation‣Follow<strong>in</strong>g slides from David Dixon

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and Concentrates‣ Atmospheric Leach (~80 C)‣ No microbes‣ Pure sulphate medium (no chloride)‣ No f<strong>in</strong>e gr<strong>in</strong>d<strong>in</strong>g‣ Generates elemental sulfur (> 95%), low oxygen demand‣ No surfactantsGALVANOX FEATURES‣ Selective for chalcopyrite over pyrite (can cost-effectively treat lowgrade concentrates down to 9% copper or less)‣ Complete copper recovery, typically <strong>in</strong> less than 12 hours, andsometimes <strong>in</strong> as little as 4 hours‣ Fully compatible with conventional SX-EW‣ Conventional materials <strong>of</strong> construction

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and Concentrates

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesGALVANOX CHEMISTRY‣ GALVANOX takes advantage <strong>of</strong> <strong>the</strong> galvanic effect betweenchalcopyrite and pyrite.‣ Chalcopyrite is a semiconductor, and <strong>the</strong>refore corrodeselectrochemically <strong>in</strong> oxidiz<strong>in</strong>g solutions.‣ In ferric sulphate media, <strong>the</strong> overall leach<strong>in</strong>g reaction is as follows:CuFeS 2 + 2 Fe 2 (SO 4 ) 3 → CuSO 4 + 5 FeSO 4 + 2 S 0‣ This reaction may be represented as a comb<strong>in</strong>ation <strong>of</strong> anodic andcathodic half-cell reactions:Anodic: CuFeS 2 → Cu 2+ + Fe 2+ + 2 S 0 + 4 e –Cathodic: 4 Fe 3+ + 4 e – → 4 Fe 2+

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesUNASSISTED CHALCOPYRITE LEACHINGSoCu2+4 e-4 Fe3+Fe2+CuFeS24 Fe2+Anodic SiteCathodic Site

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesUNASSISTED CHALCOPYRITE LEACHING

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesGALVANOX CHEMISTRY‣ Typically, chalcopyrite surfaces are passivated (i.e., <strong>the</strong>ybecome resistant to electrochemical breakdown) <strong>in</strong> ferric sulfatesolutions at even modest solution potential levels.‣ It is widely held that this results from <strong>the</strong> formation <strong>of</strong> some sort<strong>of</strong> passivat<strong>in</strong>g film on <strong>the</strong> m<strong>in</strong>eral surface that most likelyconsists <strong>of</strong> an altered, partially Fe-depleted sulfide layer.‣ Because <strong>of</strong> this, most <strong>in</strong>vestigators have assumed that it is <strong>the</strong>anodic half-cell reaction that limits <strong>the</strong> overall rate <strong>of</strong> leach<strong>in</strong>g.‣ However, we discovered that it is primarily <strong>the</strong> cathodic half-cellreaction (i.e., ferric reduction) that is slow on <strong>the</strong> chalcopyritesurface.

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesGALVANOX CHEMISTRY‣ The presence <strong>of</strong> pyrite facilitates chalcopyrite leach<strong>in</strong>g byprovid<strong>in</strong>g an alternative catalytic surface for ferric reduction <strong>in</strong>electrical contact with <strong>the</strong> chalcopyrite‣ This essentially elim<strong>in</strong>ates cathodic passivation <strong>of</strong> chalcopyrite <strong>in</strong>ferric sulfate solutions.‣ Also, by ensur<strong>in</strong>g that chalcopyrite oxidation is rapid relative t<strong>of</strong>errous oxidation, <strong>the</strong> solution potential is ma<strong>in</strong>ta<strong>in</strong>ed at a levellow enough to prevent anodic passivation <strong>of</strong> <strong>the</strong> chalcopyrite‣ This also prevents anodic breakdown <strong>of</strong> <strong>the</strong> pyrite, whichrema<strong>in</strong>s more or less completely <strong>in</strong>ert.

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesGALVANICALLY-ASSISTEDCHALCOPYRITE LEACHINGCu2+PyCp4 Fe3+4 e-4 e -4 Fe 2+Fe 2+Anodic SiteSoPyCathodic Site

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesGALVANICALLY-ASSISTEDCHALCOPYRITE LEACHINGPartially leached particleCompletely leached particles

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesGALVANOX CHEMISTRY‣ The ferric required for GALVANOX leach<strong>in</strong>g is regenerated <strong>in</strong> situ withoxygen gasFerric leach<strong>in</strong>g <strong>of</strong> chalcopyrite:CuFeS 2 + 2 Fe 2 (SO 4 ) 3 → CuSO 4 + 5 FeSO 4 + 2 S 0Oxidation <strong>of</strong> ferrous with dissolved oxygen gas:4 FeSO 4 + O 2 + 2 H 2 SO 4 → 2 Fe 2 (SO 4 ) 3 + 2 H 2 OOverall leach<strong>in</strong>g reaction:CuFeS 2 + O 2 + 2 H 2 SO 4 → CuSO 4 + FeSO 4 + 2 S 0 + 2 H 2 O

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCu RecoveryCHALCOPYRITE CONCENTRATE – 35% CuEffect <strong>of</strong> pyrite addition (50 g con, 65 g acid, 470 mV, 80 C)100%90%80%70%60%50%40%30%20%10%0%0 4 8 12 16 20 24Time (h)Py = 150 g (K5)Py = 100 g (K9)Py = 50 g (K6)Py = 25 g (K10)Py = 0 g (K1)

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCu RecoveryCHALCOPYRITE CONC 2 – 23.6% CuEffect <strong>of</strong> pyrite addition (30 g con, 120 g Py, 30 g acid, 480 mV, 80 C)100%90%80%70%60%50%40%30%20%10%0%Galvanox Leach<strong>in</strong>gNo Pyrite0 4 8 12 16 20 24Time (h)

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and Concentrates

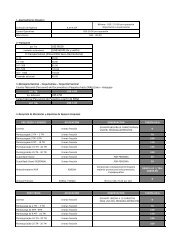

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCONTINUOUS PILOT PLANT RESULTSStageOperat<strong>in</strong>gHoursM<strong>in</strong>imum CuRecovery (%)Maximum Curecovery (%)Average CuRecovery (%)Plant Setup 0 -125 56.8 93.4 82.1100% Recycle40 hrsresidence time100% Recycle20 hrsresidence time200% Recycle20 hrsresidence timeEntire runexclud<strong>in</strong>g plantsetup125-325 92.7 97.1 95.3325-405 88.4 95.4 91.6405-464 96.6 97.9 97.3125-464 88.4 97.9 94.6

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesAnglo American Corporation/University <strong>of</strong>British Columbia Process‣Chalcopyrite concentrates are f<strong>in</strong>elyground (

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCopper Extraction as a Function <strong>of</strong> Initial Particle Size150 C Leach<strong>in</strong>g <strong>of</strong> Chalcopyrite Concentrate with Surfactant AdditionCopper Extraction (%)100.0095.0090.0085.0080.0075.0070.00F<strong>in</strong>er Size5.28 um10.01 um13.04 um17.93 um65.0060.0055.0050.000 0.5 1 1.5 2 2.5 3 3.5 4Tim e (hr)

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesFreeport-McMoRan <strong>Developments</strong> <strong>in</strong>Copper Concentrate Leach<strong>in</strong>g‣ John O. Marsden and John C. Wilmot‣ Freeport-McMoRan M<strong>in</strong><strong>in</strong>g Co.‣ Selected Slides from Copper 2007 Short Course,Toronto, August 2007

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesMorenci “MT-DEW-SX” FlowsheetConcentrate1,000 mtpdPLV Conditions:~160 C200 psi O 2 overpressureLE Added to PLVWaterSlurryFormationSuper F<strong>in</strong>eGr<strong>in</strong>d<strong>in</strong>gPressureLeach<strong>in</strong>gLeanto PLV24331901.8Heap/Stockpile/Tank*Leach<strong>in</strong>gLeanBleedFeedFlashLet DownCoolantStreamsSolutionExtractionWaterLimeSolid/LiquidSeparationSolidsSolid/LiquidSeparation/WashSolids113110221.9SPLSWPLSElectrow<strong>in</strong>n<strong>in</strong>g1534.71.51.1Precious MetalsLeach<strong>in</strong>g/RecoveryGold/SilverBullion(optional)NeutralizationTail<strong>in</strong>gsDisposalLEGEND:Flow (m3/hr)Cu (g/L)H2SO4 (g/L)Fe (gpl)*Tank <strong>in</strong>cludes vat or agitatedor stirred leach<strong>in</strong>g vesselCathodeCopper

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesMorenci Concentrate Leach Plant

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesPLATSOL‣ PLATSOL Process– Simple process for one-step dissolution <strong>of</strong> baseand precious metals– Add 5-10 g/L Chloride to AC solution– Invented at Lakefield Research for BulkConcentrate <strong>Treatment</strong>– Tested via Batch and Cont<strong>in</strong>uous AutoclavePrograms at Lakefield– High levels <strong>of</strong> base (+95-99%) and preciousmetals (90-95%) recovery

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesPressure Oxidation: Conventional andPLATSOL Metal Extractions (220 C)Element Conventional PLATSOL**Cu 99.3 99.6Ni 95.9 98.9Co >92 96Fe 11.5 11.5S 91.5 91.5Pt ~0 96Pd 61.1 94.6Au ~0 89.4** ACTUAL PILOT PLANT RESULTS FROM SGS LAKEFIELD

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesAutoclave Leach<strong>in</strong>g Base MetalsChloride – Assisted Total Pressure OxidationChalcopyrite Oxidation/Iron Hydrolysis:CuFeS 2 + 4.25O 2 + H 2 O = CuSO 4 + 0.5Fe 2 O 3 +H 2 SO 4Pyrite Oxidation:FeS 2 + 3.75O 2 + 2H 2 O = 0.5Fe 2 O 3 + 2H 2 SO 4Pyrrhotite OxidationFe 7 S 8 + 16.25O 2 + 8H 2 O = 3.5Fe 2 O 3 + 8H 2 SO 4Nickel Sulfide Oxidation:NiS + 2O 2 = NiSO 4Basic Ferric Sulfate Formation:Fe O + 2H SO = 2Fe(OH)SO + H O

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesAutoclave Leach<strong>in</strong>g Precious MetalsGold Oxidation/Chlorocomplex Formation:Au + 0.75O 2 + 4HCl = HAuCl 4 + 1.5H 2 OPlat<strong>in</strong>um Oxidation/ChlorocomplexFormation:Pt + O 2 + 6HCl = H 2 PtCl 6 + 2H 2 OPalladium Oxidation/ChlorocomplexFormation:Pd + 0.5O 2 + 4HCl = H 2 PdCl 4 + H 2 OTemperature <strong>of</strong> 220 to 230 C.

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesBase and Precious Metal Recovery‣ Copper– Copper Solvent Extraction and Electrow<strong>in</strong>n<strong>in</strong>g toProduce LME Grade Copper Metal Cathode‣ Nickel/Cobalt– Variety <strong>of</strong> Processes Possible– Mixed Hydroxide Precipitation <strong>of</strong> Nickel and Cobalt– Nickel and Cobalt Hydroxide Ref<strong>in</strong>ed “Off Site”– SX-EW or SX-Hydrogen Reduction to Metal‣ Au-PGM– Precipitate under reduc<strong>in</strong>g conditions to make highvalue precipitate for ref<strong>in</strong><strong>in</strong>g

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesBulk ConcentrateRegr<strong>in</strong>d<strong>in</strong>gPLATSOL ®NaClLSLeach ResiduePGM’s NaSH PrecipPGM ConcCu SX/EWBleed(Ni-Co recovery)

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesApplications to O<strong>the</strong>rCu/Ni/PGM ConcentratesConcentrate TypesElementsD F G H I J K L MCu % 5.8 12.0 4.2 2.4 5.5 3.9 0.9 0.2 0.7Ni% 4.1 3.01 7.7 0.9 10.3 14.9 0.1 0.1 0.3Fe% 17.1 33.9 35.9 19.2 - 27.9 32.7 16.6 28.7S% 16.3 24.5 34.1 - 25.3 28.8 0.8 0.5

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesApplications to O<strong>the</strong>rCu/Ni/PGM ConcentratesElements% RecoveryConcentrate TypeD F G H I J K L MCu 99.9 99.3 99.0 99.3 99.7 99.6 99.3 85.0 99.2Ni 99 93.8 99.6 98.7 98.9 98.7 96.7 - 95.5Au 99 97.1 84.3 96.0 97.9 82.9 91.5 96.4 53.6Pt 95 97.4 98.2 99.0 97.9 93.9 93.9 99.1 95.3Pd 94 98.1 93.9 98.4 96.2 95.6 94.9 96.3 96.3

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesApplications to O<strong>the</strong>r Feeds‣Cu/Au concentrates‣Refractory Au Concentrates‣Cu/Ni/PGE mattes‣Pt Laterites‣Automobile catalysts

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesO<strong>the</strong>r ApplicationsCu - Au concentrate(28.9% Cu,5.8 g/t Au)‣ PLATSOL TMrecovery99.7% Cu95.9% Au‣ No cyanide!

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesO<strong>the</strong>r ApplicationsRefractory Au ores-concentrates(non-pregrobbers)FeS 2 - FeAsS conc19.9 Au, 19.4 g/t Ag‣ PLATSOL TM recoveryAu 96%, Ag 99.5%‣ No cyanide!

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesSEPON Copper Process‣ Atmospheric leach<strong>in</strong>g process for whole oreto leach copper oxides/carbonates/secondary sulfides‣ After CCD wash, pyrite and sulfur are floatedas a concentrate and sent to a hightemperature autoclave for oxidation.‣ Autoclave is <strong>the</strong> “chemical eng<strong>in</strong>e” for <strong>the</strong>Sepon plant produc<strong>in</strong>g acid, ferric sulfate andheat to susta<strong>in</strong> <strong>the</strong> atmospheric leachprocess.

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesAutoclave and Post-Autoclave ChemistryAutoclave formation <strong>of</strong> basic ferric sulfate (22O C)‣ 2FeS 2 (s) + 7.5O 2 + H 2 O = Fe 2 (SO 4 ) 3 + H 2 SO 4‣ S + 1.5O 2 + H 2 O = H 2 SO 4‣ Fe 2 (SO 4 ) 3 + 2H 2 O = 2Fe(OH)SO 4 (s) + H 2 SO 4Post Autoclave Re-Leach <strong>of</strong> Basic Ferric Sulfate(100 C)‣ 2Fe(OH)SO 4 (s) + H 2 SO 4 = Fe 2 (SO 4 ) 3 + 2H 2 O

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesSEPONLOCALITYMAP

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesCRUSHINGEXCESSPYRITEMILLINGWASHWATERPOX LEACHAUTOCLAVESTEAMSURGEDIRECT HEXSEPONPROCESS BLOCKFLOWSHEETFILTERFe AcidADDNSURGEATM LEACHSURGEHEXCOOLING TWRCLARIFICATIONSXEWRAF CCDWASH CCDWASHWATERCATHODEFLOTATIONWASH CCDFe AcidCu LOSSNEUTRALISATIONTAILINGS

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> Next <strong>of</strong> Step Copper – ConstructionOres and ConcentratesExample: Sepon Copper and Gold OperationKhanong Copper OrebodyGold OperationPadan CampCopper Operation

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesSepon Copper Ramp Up Plant designed for 60 ktpa Cu productionCommission<strong>in</strong>g commenced Oct 2004 Ore commission<strong>in</strong>g Feb 2005 First cathode harvested March 2005 2005 Production: 644kt milled, 30.5kt stripped 2006 Production: 1,231kt milled, 60.8kt stripped 2007 Production: 60-63kt Q1 2009 Second POX circuit on l<strong>in</strong>e

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesConclusions‣ <strong>Hydrometallurgical</strong> <strong>Treatment</strong> <strong>of</strong> Copper Oresand Concentrates is Cont<strong>in</strong>u<strong>in</strong>g to Develop‣ New Chemistries and Process OptionsEmerg<strong>in</strong>g‣ Central use <strong>of</strong> SX-EW for Copper Recovery‣ Theory and Practice are Work<strong>in</strong>g toge<strong>the</strong>rHand-<strong>in</strong>-Hand

<strong>Current</strong> <strong>Developments</strong> <strong>in</strong> <strong>the</strong> <strong>Hydrometallurgical</strong><strong>Treatment</strong> <strong>of</strong> Copper Ores and ConcentratesThank You!Questions?