Supply Chain Management Factsheet - Constructing Excellence

Supply Chain Management Factsheet - Constructing Excellence

Supply Chain Management Factsheet - Constructing Excellence

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

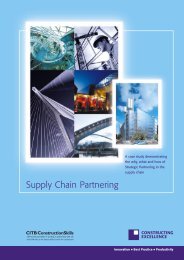

<strong>Supply</strong> <strong>Chain</strong> <strong>Management</strong>How do we get started?Whether the supply chain is being established for awhole project or by a group of companies wishing tomarket their specialisms, the following principles apply:It is likely to be impractical to establish long-termrelationships with all members of the supply chain.So you should start by establishing relationships withthose suppliers and sub-contractors who are critical toyour delivery to the market of better products at lowercost and higher quality. These are your strategicsupply chain partners or ‘first tier suppliers’. It is vitalthat you take time and care to establish whichcompanies fulfil the criteria that you set (or have thepotential to do so) and that they have similar intereststo you in developing long term relations. A successfulsupply chain of first tier suppliers is a manageableobjective. In time you may plan for each of yoursuppliers to have similar chains, but don’t try toconquer the world in one go.Evaluate and compare potential first tier suppliers’strengths and capabilities in the following areas:- the strength of the existing relationship- technical capability and reputation- design capability and innovation record- size and market position- management styleconstruction professionals. Developing successfulsupply chains will therefore be difficult and take timebut the rewards will be worthwhile.Involving the designer in the supply chain isessential to long-term success.For a whole project supply chain, there may be anumber of professional design teams (architect,structural engineer, services engineer) that need to beinvolved. On the other hand, where the supply chain isestablished to deliver a component, the designer maybe embedded within one of the supply chain partners.Either way, the designer’s role is central to delivering:• Optional functionality• Lowest cost of ownership through a value formoney focus on lowest through-life cost• Safe construction using least amount labourand minimum waste.Managing CostCentral to successful collaborative relationships is theapproach to cost management. The most enlightenedclients accept they will obtain best value if the supplychain’s margins are offered some protection. That willallow the supply chain to focus on delivering value tothe client rather than using its efforts to protectmargins.Remember you are seeking partners capable ofreliably supplying you with products and services atcompetitive prices. Success will deliver mutualcommercial benefit through greater success in themarket, based on increasingly satisfied clients. Allparties in the supply chain must be committed toworking for the long term on the basis of continuousimprovement and innovation. If anyone is inclined toquit when the going gets tough, the supply chain willfail.Ring-fenceManage out(risk management)Optimise –target costingsupported byVM/VEMarginsRisk allowancesComponent andprocess costs}PRICEMuch of the success of supply chains rests onpersonal relations so look at the guidance that isavailable on Partnering (see fact sheet).Key personal actions are to be proactive, lessadversarial, and to learn from others. Neitherpartnering nor supply chain management are easy.The parties do not need to be good friends, however.Relationships need to be fair but firm, based on a teamapproach which involves regular contact and mutualrespect. Learning to work in this way is new for mostEven where the supply chain cannot get suchagreements from a client, it is still essential that costsare understood and managed. The principle of sharingrisk and reward underpins the whole process ofcollaborating for mutual benefit. Passing all risk downthe supply chain does not lead to the lowest cost andcertainly does not lead to best value for the client.Gain/pain sharing incentive schemes will often ensurethe continuing delivery of optimum value to the client.Published by <strong>Constructing</strong> <strong>Excellence</strong> T 0845 605 55 56 F 01923 664690 E helpdesk@constructingexcellence.org.uk www.constructingexcellence.org.uk2 <strong>Supply</strong> <strong>Chain</strong> <strong>Management</strong>: 19/3/04