View Data Sheet (Download PDF) - Carten Controls

View Data Sheet (Download PDF) - Carten Controls

View Data Sheet (Download PDF) - Carten Controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

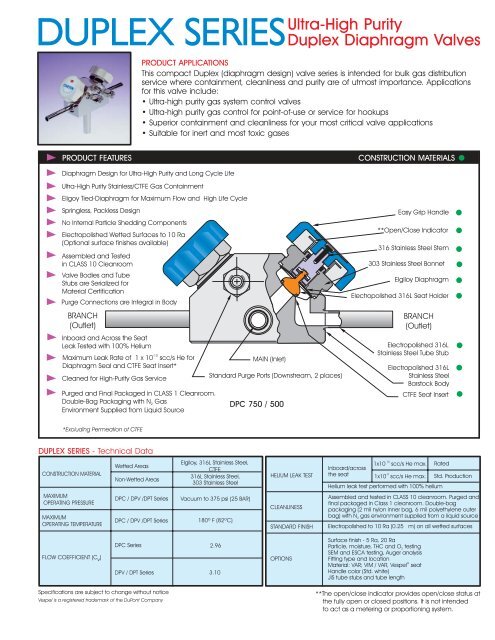

DUPLEX SERIESUltra-High PurityDuplex Diaphragm ValvesPRODUCT APPLICATIONSThis compact Duplex (diaphragm design) valve series is intended for bulk gas distributionservice where containment, cleanliness and purity are of utmost importance. Applicationsfor this valve include:• Ultra-high purity gas system control valves• Ultra-high purity gas control for point-of-use or service for hookups• Superior containment and cleanliness for your most critical valve applications• Suitable for inert and most toxic gasesPRODUCT FEATURESCONSTRUCTION MATERIALSDiaphragm Design for Ultra-High Purity and Long Cycle LifeUltra-High Purity Stainless/CTFE Gas ContainmentEligoy Tied-Diaphragm for Maximum Flow and High Life CycleSpringless, Packless DesignNo Internal Particle Shedding ComponentsElectropolished Wetted Surfaces to 10 Ra(Optional surface finishes available)Assembled and Testedin CLASS 10 CleanroomValve Bodies and TubeStubs are Serialized forMaterial CertificationPurge Connections are Integral in BodyBRANCH(Outlet)Inboard and Across the SeatLeak Tested with 100% Helium-10Maximum Leak Rate of 1 x 10 scc/s He forDiaphragm Seal and CTFE Seat Insert*Cleaned for High-Purity Gas ServicePurged and Final Packaged in CLASS 1 Cleanroom.Double-Bag Packaging with N2GasEnvironment Supplied from Liquid SourceMAIN (Inlet)Standard Purge Ports (Downstream, 2 places)DPC 750 / 500Easy Grip Handle**Open/Close Indicator316 Stainless Steel Stem303 Stainless Steel BonnetElgiloy DiaphragmElectropolished 316L Seat HolderBRANCH(Outlet)Electropolished 316LStainless Steel Tube StubElectropolished 316LStainless SteelBarstock BodyCTFE Seat Insert*Excluding Permeation of CTFEDUPLEX SERIES - Technical <strong>Data</strong>CONSTRUCTION MATERIALMAXIMUMOPERATING PRESSUREMAXIMUMOPERATING TEMPERATUREWetted AreasNon-Wetted AreasDPC / DPV /DPT SeriesDPC / DPV /DPT SeriesElgiloy, 316L Stainless Steel,CTFE316L Stainless Steel,303 Stainless SteelVacuum to 375 psi (25 BAR)180º F (82ºC)HELIUM LEAK TESTCLEANLINESSInboard/acrossthe seat1x10-10scc/s He max.-91x10 scc/s He max.RatedHelium leak test performed with 100% heliumStd. ProductionAssembled and tested in CLASS 10 cleanroom. Purged andfinal packaged in Class 1 cleanroom. Double-bagpackaging (2 mil nylon inner bag, 6 mil polyethylene outerbag) with N2gas environment supplied from a liquid sourceSTANDARD FINISH Electropolished to 10 Ra (0.25 m) on all wetted surfacesFLOW COEFFICIENT (C ) vDPC SeriesDPV / DPT Series2.963.10OPTIONSSurface finish -5Ra,20RaParticle, moisture, THC and O2testingSEM and ESCA testing, Auger analysisFitting type and location®Material: VAR; VIM / VAR, Vespel seatHandle color (Std. white)JIS tube stubs and tube lengthSpecifications are subject to change without noticeVespel is a registered trademark of the DuPont Company**The open/close indicator provides open/close status atthe fully open or closed positions. It is not intendedto act as a metering or proportioning system.

Valve Dimensions - Duplex Cross (DPC), Duplex Vertical (DPV) Valves, and Duplex Tee (DPT) ValvesHH/2Duplex Cross (DPC) and Duplex Tee (DPT)G OPENØCDBRANCHBRANCHJØABSeeDuplex TeeNoteF2.982PL.<strong>View</strong>-XMounting HolesBottom <strong>View</strong>Cross, Tee & VerticalXE/21.25±0. 12K2.50EX0.631.25MAIN0.250-20 UNCX 0.38 DP4PL.1.711.241.002.00±0. 12L2.982PL.DUPLEX TEE NOTE: This tube stub is not applicablefor the DPT version.DPV TubeLocationOnlyHH/2Duplex Vertical (DPV)G OPENØCDBRANCHBRANCHJF2.982PL.BE/2K ±0.12MAINEØ ANote: Additional main and branch tube sizes are available on request.Approx.Catalog No. A* B* C* D* E F G H J K LWeightDPC4.16 0.75 3.80 1.50 1.92 10.12 7.96750/500DPV0.750 0.065 0.500 0.0496.3 Lb(105.6mm) (19.1mm) (96.5mm) (38.1mm) (48.8mm) (257.0mm) (202.2mm) (2.85 Kg)DPC4.16 0.75 3.80 1.50 1.92 10.12 7.96750/750DPV0.750 0.065 0.750 0.0656.3 Lb(105.6mm) (19.1mm) (96.5mm) (38.1mm) (48.8mm) (257.0mm) (202.2mm) (2.85 Kg)DPC4.16 0.75 3.80 1.50 1.92 10.12 7.961000/5006.3 LbDPV1.000 0.065 0.500 0.049 (105.6mm) (19.1mm) (96.5mm) (38.1mm) (48.8mm) (257.0mm) (202.2mm) (2.85 Kg)DPC4.16 0.75 3.80 1.50 1.92 10.12 7.961000/7506.3 LbDPV1.000 0.065 0.750 0.065 (105.6mm) (19.1mm) (96.5mm) (38.1mm) (48.8mm) (257.0mm) (202.2mm) (2.85 Kg)DPC4.86 1.25 4.40 2.00 2.67 10.58 8.461500/50010.2 LbDPV1.500 0.065 0.500 0.049 (118.4mm) (31.7mm) (111.8mm) (50.8mm) (67.8mm) (268.7mm) (214.9mm) (4.62 Kg)DPC4.86 1.25 4.40 2.00 2.67 10.58 8.461500/75010.2 LbDPV1.500 0.065 0.750 0.065 (118.4mm) (31.7mm) (111.8mm) (50.8mm) (67.8mm) (268.7mm) (214.9mm) (4.62 Kg)DPC4.66 1.25 4.40 2.00 2.67 10.58 8.462000/500 2.000 0.065 0.500 0.04910.2 LbDPV(118.4mm) (31.7mm) (111.8mm) (50.8mm) (67.8mm) (268.7mm) (214.9mm) (4.62 Kg)DPC4.66 1.25 4.40 2.00 2.67 10.58 8.462000/750 2.000 0.065 0.750 0.06510.2 LbDPV(118.4mm) (31.7mm) (111.8mm) (50.8mm) (67.8mm) (268.7mm) (214.9mm) (4.62 Kg)*Metric tube sizes and wall thicknesses are available on request.REV. 99-1NOTE 1: All tolerances are ± 0.06 in. unless otherwise statedNOTE 2: Dimensional drawings shown are for reference only. Please contact the manufacturerCARTEN CONTROLS INC.for customer drawings showing updated dimensions.1.711.24 2.981.002.00