High Level Virtual Prototyping with Hardware in the Loop

High Level Virtual Prototyping with Hardware in the Loop

High Level Virtual Prototyping with Hardware in the Loop

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

International Workshop on <strong>Virtual</strong> and Intelligent Measurement Systems29-30 April 2000, Annapolis, MD, USA<strong>High</strong> <strong>Level</strong> <strong>Virtual</strong> <strong>Prototyp<strong>in</strong>g</strong> <strong>with</strong> <strong>Hardware</strong> <strong>in</strong> <strong>the</strong> <strong>Loop</strong>A. Monti ( + ), R. Dougal ( ++ ), B. Pettus ( ++ ), E. Santi ( ++ )( + ) Dip. di Elettrotecnica, Politecnico di Milano, Milano, Italy( ++ ) Dep. of Electrical Eng<strong>in</strong>eer<strong>in</strong>g, University of South Carol<strong>in</strong>a, Columbia (SC), USAAbstract<strong>Virtual</strong> prototyp<strong>in</strong>g of complex systems presents <strong>in</strong>terest<strong>in</strong>gchallenges, especially <strong>with</strong> regard to systems <strong>in</strong> whichsome components are represented by software models ando<strong>the</strong>rs are present as real hardware. We describe here oneapproach to solv<strong>in</strong>g such a problem. In this <strong>in</strong>stance, twomotors were controlled by a dSpace general-purposecontroller board that was coupled to <strong>the</strong> <strong>Virtual</strong> Test Bedsoftware environment for system simulation.I. IntroductionSimulation of complex systems where manycomponents <strong>in</strong>teract presents peculiar challenges. Considerthat a particular system might be analyzed differently bydifferent users, each one of <strong>the</strong>m focus<strong>in</strong>g on a differentaspect of <strong>the</strong> system performance and each one hav<strong>in</strong>g adifferent metric for what is important. Consider that <strong>the</strong>complexity of <strong>the</strong> system may bridge several areas oftechnical expertise, and that users <strong>in</strong> each of thosetechnical areas traditionally work <strong>with</strong> <strong>the</strong>ir own set ofdesign and simulation tools. Consider also that some partsof <strong>the</strong> system may be already available while o<strong>the</strong>r partsare still be<strong>in</strong>g designed. To <strong>the</strong> extent possible, one maywish to substitute real components for <strong>the</strong>ir models everytime that a new component becomes available. Such anapproach keeps <strong>the</strong> design/simulation "alive", promotesiteration, allows an opportunity to validate models, and<strong>in</strong>troduces at <strong>the</strong> earliest possible time potentiallycomplicat<strong>in</strong>g nuances that were not orig<strong>in</strong>ally accountedfor <strong>in</strong> <strong>the</strong> component models. The cost of this approach isthat it requires a sophisticated capability for work<strong>in</strong>g <strong>with</strong><strong>Hardware</strong> In <strong>the</strong> <strong>Loop</strong> (HIL) [1-2]. All of <strong>the</strong>seconsiderations suggest <strong>the</strong> desirability of a new high-level<strong>in</strong>terface that allows many types of users to be comfortable<strong>with</strong> <strong>the</strong> virtual prototyp<strong>in</strong>g tool. An attempt to developsuch a tool has been underway at <strong>the</strong> University of SouthCarol<strong>in</strong>a for several years now under <strong>the</strong> program name<strong>Virtual</strong> Test Bed. We have just recently begun <strong>the</strong> processof <strong>in</strong>corporat<strong>in</strong>g hardware <strong>in</strong> <strong>the</strong> loop.II.The VTB ProjectThe <strong>Virtual</strong> Test Bed (VTB) is software for virtualprototyp<strong>in</strong>g of multi-technical dynamic systems. With<strong>in</strong><strong>the</strong> context of "virtual prototyp<strong>in</strong>g" we <strong>in</strong>clude not onlysimulation of system dynamics, but also solid model<strong>in</strong>g of<strong>the</strong> system, and visualization of <strong>the</strong> system dynamics. Oneof <strong>the</strong> project goals is to extend <strong>the</strong> context of virtualprototyp<strong>in</strong>g to <strong>in</strong>clude operation of hybrid systems --where some of <strong>the</strong> parts exist as real hardware and o<strong>the</strong>rparts exist as simulation models. The work reported <strong>in</strong> thispaper focuses on our approach to achiev<strong>in</strong>g that goal. Tobetter understand <strong>the</strong> context of our work, we present firstan overview of <strong>the</strong> <strong>Virtual</strong> Test Bed projectThe <strong>Virtual</strong> Test Bed project is dedicated to develop<strong>in</strong>g anew environment for simulation and virtual prototyp<strong>in</strong>g ofpower electronic systems [3-4]. One of its challenges is tofully accommodate <strong>the</strong> breadth of discipl<strong>in</strong>es that powerelectronics encompasses, <strong>in</strong>clud<strong>in</strong>g analog electronics,digital electronics, power systems, controls, electromechanics,and mechanical systems. We have addressed<strong>the</strong>se challenges by choos<strong>in</strong>g to support:Multiformalism: Different languages can be use to buildmodels of <strong>the</strong> different components that make up a system.This allows an <strong>in</strong>dividual to build models us<strong>in</strong>g <strong>the</strong>language preferred <strong>with</strong><strong>in</strong> his or her discipl<strong>in</strong>e. Inparticular <strong>the</strong> system now <strong>in</strong>tegrates dynamic modelsdef<strong>in</strong>ed by such widely used tools such asMatlab/Simul<strong>in</strong>k, SPICE, and ACSL [5-7-8].<strong>High</strong>ly <strong>in</strong>teractive environment: Users can change <strong>the</strong>system topology or parameters while a simulationexecutes. This allows <strong>the</strong> user to rapidly <strong>in</strong>vestigate<strong>in</strong>teractions between components or to explore <strong>the</strong><strong>in</strong>fluence of design parameters on system performance.<strong>High</strong>-level visualization: Visualization models of <strong>the</strong>system can be easily created and l<strong>in</strong>ked to live simulation

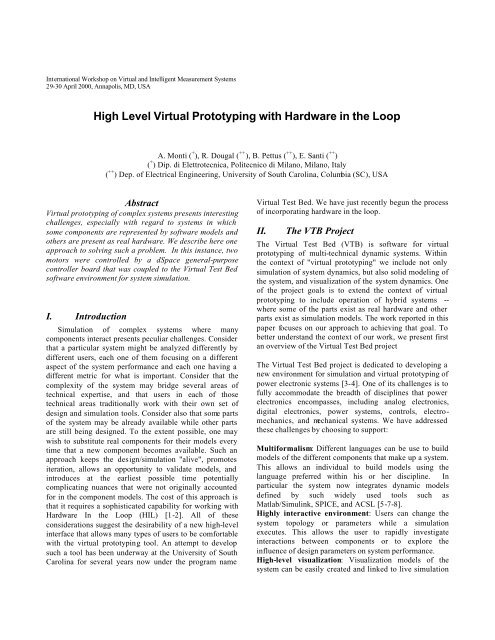

data. Visualization aids <strong>the</strong> user to rapidly comprehend <strong>the</strong>system performance. Visual outputs <strong>in</strong>clude data-drivenanimation of <strong>the</strong> motion of solid objects, imposition on topof <strong>the</strong> solid objects of novel representations of abstractsimulation data, or simply oscilloscope-like graphs.Distributed computation: Large or complicated systemsrequire that computational load be distributed across anetwork <strong>in</strong> order to achieve speeds suitable for <strong>in</strong>teractiveexplorations. This naturally supports hardware-<strong>in</strong>-<strong>the</strong>-loopoperations.The structure here <strong>in</strong>troduced is well summarized <strong>in</strong> Figure1. Let us now go <strong>in</strong>to details about <strong>the</strong> component structureto better appreciate <strong>the</strong> system design.PC1VTBSocketPC2DOSMatlab Eng<strong>in</strong>eThe VTB has o<strong>the</strong>r significant strengths, <strong>in</strong>clud<strong>in</strong>gautomatic enforcement of physical constra<strong>in</strong>ts (such asensur<strong>in</strong>g that <strong>the</strong> sum of currents at a node is zero).MatlabPC busDspaceBoardIII.Demonstration SystemOur HIL capability was developed <strong>with</strong> reference to aspecific laboratory setup so as to focus our effort and toallow immediate test<strong>in</strong>g of <strong>the</strong> system. The hardwaresystem amounted to a two-axis DC motor drive. Our<strong>in</strong>terest was <strong>in</strong> design<strong>in</strong>g <strong>the</strong> higher-level logic to control<strong>the</strong> motors <strong>in</strong> coord<strong>in</strong>ation <strong>with</strong> software models of o<strong>the</strong>rcomponents of <strong>the</strong> system. Work<strong>in</strong>g <strong>in</strong> this way, we wereable to directly verify <strong>the</strong> consequences of <strong>the</strong> commandsignals sent to <strong>the</strong> drive and to use a real oscilloscope toobserve <strong>the</strong> system operation. At <strong>the</strong> same time, <strong>the</strong>advanced visualization capabilities of <strong>the</strong> <strong>Virtual</strong> Test Bedshowed on a PC screen <strong>the</strong> operation of <strong>the</strong> entire system.The motor control system was based on a dSpace board[9], which could be easily programmed us<strong>in</strong>gMatlab/Simul<strong>in</strong>k. The authors added a custom <strong>in</strong>terface toMatlab to exchange data <strong>with</strong> <strong>the</strong> control board work<strong>in</strong>g <strong>in</strong>real time. The system is based on <strong>the</strong> Matlab Eng<strong>in</strong>e [6]<strong>in</strong>terface and allows one to send data to and receive datafrom <strong>the</strong> Matlab workspace. A set of custom Matlabcommands (developed by <strong>the</strong> authors) allowscommunication <strong>with</strong> <strong>the</strong> real time dSpace board. The dataexchange <strong>with</strong> VTB was implemented via a socketcommunication channel. This arrangement allows hav<strong>in</strong>gVTB and <strong>the</strong> dSpace board runn<strong>in</strong>g on differentcomputers, if so desired. This feature adds flexibility to <strong>the</strong>virtual simulation environment.From <strong>the</strong> VTB po<strong>in</strong>t of view, <strong>the</strong> external system is adevice that receives virtual data from <strong>the</strong> simulationenvironment and that sends back real data from <strong>the</strong>hardware environment. This is reasonably transparent to<strong>the</strong> user, who has only to def<strong>in</strong>e <strong>the</strong> parameters for <strong>the</strong>socket communication (<strong>the</strong> name of <strong>the</strong> PC hav<strong>in</strong>g <strong>the</strong>DSP board) and <strong>the</strong> number of <strong>the</strong> <strong>in</strong>put/output channel. In<strong>the</strong> demonstration case two data are sent from <strong>the</strong>simulation environment to <strong>the</strong> hardware (<strong>the</strong> two axisposition references) and two are sent back from <strong>the</strong>hardware to <strong>the</strong> simulation environment (<strong>the</strong> real positionof <strong>the</strong> two motors).Digital and Analog I/OControlledFigure 1: Diagram of <strong>the</strong> HIL system, <strong>in</strong>clud<strong>in</strong>gtwo motor drives, <strong>the</strong> <strong>in</strong>terfaces, <strong>the</strong> PC and <strong>the</strong>DSPACE boardIV.The Matlab-dSPACE InterfaceThe heart of <strong>the</strong> communication protocol <strong>with</strong> <strong>the</strong>dSPACE board is <strong>the</strong> Matlab eng<strong>in</strong>e. The Matlab eng<strong>in</strong>eallows data exchange between Matlab and C customsoftware.The ma<strong>in</strong> program is a DOS application runn<strong>in</strong>g on <strong>the</strong>PC connected to <strong>the</strong> dSPACE system. The structure of <strong>the</strong>application is well summarized <strong>in</strong> <strong>the</strong> follow<strong>in</strong>g:• wait for VTB startup• start Matlab Eng<strong>in</strong>e• set up <strong>the</strong> communication <strong>with</strong> Matlab def<strong>in</strong><strong>in</strong>g <strong>the</strong> setof shared data• select <strong>the</strong> dSpace board to be used <strong>in</strong> <strong>the</strong> experiment• wait for VTB dataAt every cycle <strong>the</strong> follow<strong>in</strong>g set of operations isperformed:• send <strong>the</strong> data from VTB to dSpace system us<strong>in</strong>g <strong>the</strong>Matlab eng<strong>in</strong>e• acquire from dSPACE <strong>the</strong> feedback data• send <strong>the</strong> feedback data through <strong>the</strong> socketcommunication channel to VTBThis set of data exchange is guaranteed thanks to a set ofuser def<strong>in</strong>ed new Matlab commands that run through <strong>the</strong>Matlab eng<strong>in</strong>e:HW

• [xf, yf] = placexy(x,y): it sends <strong>the</strong> new reference xand y to <strong>the</strong> motor controllers and receives back <strong>the</strong>real xf and yf position• enable_motor(num): it enables <strong>the</strong> position and speedcontrol of <strong>the</strong> motor num• disable_motor(num):it disables <strong>the</strong> position and speedcontrol of <strong>the</strong> motor numThe gun visualization is shown <strong>in</strong> Figure 2. The gunangular position and pitch are given by <strong>the</strong> actual angularposition of <strong>the</strong> two motors. VTB receives <strong>the</strong> actual motorposition from <strong>the</strong> dSpace board and animates <strong>the</strong> gun. Thegun itself is placed aboard <strong>the</strong> ship shown <strong>in</strong> Figure 3. Thereference angle for <strong>the</strong> two motors could come from <strong>the</strong>position of an “enemy” airplane, which could also be partof <strong>the</strong> VTB visualization.V. The VTB Interface and VisualizationCapabilityVTB allows advanced data visualization. The purpose is tohelp <strong>the</strong> user understand <strong>the</strong> simulation results and to put<strong>the</strong>m <strong>in</strong> a visual form that may be more familiar andmean<strong>in</strong>gful to <strong>the</strong> user. In particular VTB allows datadrivenanimations. In <strong>the</strong> case of <strong>the</strong> two-axis motorcontrol presented here, an animation has been implementedshow<strong>in</strong>g a possible application of <strong>the</strong> two-axis motorcontroller. The application is <strong>the</strong> two-axis position controlof a gun <strong>in</strong> a ship.Figure 2: VTB visualization of a gun whoseposition is controlled by <strong>the</strong> two-axis motorsystem. The gun is aboard a ship.åFigure 3: VTB visualization of <strong>the</strong> ship carry<strong>in</strong>g<strong>the</strong> gun. The arrow shows <strong>the</strong> position of <strong>the</strong> gun.VI. The Distributed Environment andNetwork SupportCommunication at <strong>the</strong> computer-to-computer level (PC1 toPC2 <strong>in</strong> figure 1) is handled by use of W<strong>in</strong>dows/NTsockets. This is a generic technique and functionalequivalents exist for o<strong>the</strong>r environments. The connectionto <strong>the</strong> <strong>in</strong>dividual PC’s is a 10 Mbit E<strong>the</strong>rnet, creat<strong>in</strong>g apotential bottleneck although <strong>the</strong> highest communicationbandwidth achieved <strong>in</strong> our system is currently only onethird of <strong>the</strong> available network bandwidth (<strong>in</strong> <strong>the</strong> best caseof unidirectional communication from VTB to <strong>the</strong> dSpaceboard). However, <strong>the</strong> variable latency times are potentiallymore troublesome than <strong>the</strong> bandwidth. A next -generationversion of <strong>the</strong> system will have a dedicated connection,result<strong>in</strong>g <strong>in</strong> predictable performance.It is possible to compensate for some of <strong>the</strong> effects of(variable) delays <strong>in</strong> <strong>the</strong> network. For <strong>in</strong>stance, <strong>the</strong>re are anumber of distributed clock algorithms that can keep localclocks synchronized <strong>in</strong> <strong>the</strong> presence of significant networkdelays. Reference [10] has a good discussion of <strong>the</strong>sealgorithms. Current network response times are sufficientfor distributed large subsystems hav<strong>in</strong>g slow responsetimes but improvements may be needed for device-levelconnections hav<strong>in</strong>g faster response times.VII.ResultsThe data protocol has been implemented and tested.Figure 4 shows an <strong>in</strong>terest<strong>in</strong>g result. The position of onemotor is fed to <strong>the</strong> horizontal <strong>in</strong>put of <strong>the</strong> oscilloscope,while <strong>the</strong> position of <strong>the</strong> o<strong>the</strong>r motor is fed to <strong>the</strong> vertical<strong>in</strong>put. A VTB model runn<strong>in</strong>g on ano<strong>the</strong>r computergenerates <strong>the</strong> reference signals for <strong>the</strong>se movements.Figure 5 shows <strong>the</strong> commanded position and actualposition of one motor. The delay is two VTB time steps.This can be seen from <strong>the</strong> figure: <strong>the</strong> commanded positionat time step #171 has a numerical value of 106.393 and <strong>the</strong>actual position reaches a value close to it (106.535) at timestep #173.The delay is mostly due to network delay. This can beseen from Figure 6, which shows <strong>the</strong> actual motor positionand <strong>the</strong> commanded motor position measured at <strong>the</strong> DSPboard. This allows look<strong>in</strong>g at <strong>the</strong> motor controller response

time separately from <strong>the</strong> network delay: <strong>the</strong> dSpace boardreceives <strong>the</strong> new commanded position and <strong>the</strong> controlleradjusts <strong>the</strong> actual motor position to follow it. The twowaveforms are substantially <strong>in</strong> phase, which <strong>in</strong>dicates that<strong>the</strong> delay measured by VTB (Figure 5) is due to <strong>the</strong>network connection. The response time to a step referencechange of <strong>the</strong> dSpace position controller is approximately120ms.The communication bandwidth is approximately threedata po<strong>in</strong>ts per second <strong>in</strong> <strong>the</strong> case of bi-directionalcommunication between VTB and <strong>the</strong> dSpace board. In <strong>the</strong>case of unidirectional communication (no real position sentback to VTB) <strong>the</strong> speed was approximately twenty timeshigher. At this po<strong>in</strong>t <strong>the</strong> reason for this deterioration ofcommunication speed <strong>in</strong> <strong>the</strong> case of bi-directionalcommunication is not clear.Figure 6: Oscilloscope measurement show<strong>in</strong>gactual motor position <strong>in</strong> <strong>the</strong> upper trace andcommanded position <strong>in</strong> <strong>the</strong> lower trace (timescale 2s/div).Attempts to speed up communication are under way. Apromis<strong>in</strong>g approach is open<strong>in</strong>g a direct communicationchannel between VTB and <strong>the</strong> dSpace board bypass<strong>in</strong>gMatlab (see Figure 1).Figure 4: The real position of <strong>the</strong> motor as shown<strong>in</strong> x-y mode <strong>in</strong> <strong>the</strong> scope (<strong>the</strong> position referencecame from <strong>the</strong> VTB model)Figure 5: Commanded position and actualposition of one of <strong>the</strong> motors as visualized byVTB. The actual position is delayed <strong>with</strong> respectto <strong>the</strong> commanded position by two time steps.VIII. ApplicationsThe HIL experience here described is a start<strong>in</strong>g po<strong>in</strong>tfor a wider experience <strong>in</strong> VTB project. New features willbe added to automate <strong>the</strong> <strong>in</strong>terface between any plant partand <strong>the</strong> simulator.The pr<strong>in</strong>ciple of <strong>the</strong> VTB design approach, <strong>with</strong>reference to HIL, could be summarized as follows:• at <strong>the</strong> beg<strong>in</strong>n<strong>in</strong>g of <strong>the</strong> project noth<strong>in</strong>g is availableso that a complete virtual model is compulsory• dur<strong>in</strong>g <strong>the</strong> project, as soon as a part is available,def<strong>in</strong>e <strong>the</strong> <strong>in</strong>terface, and substitute <strong>the</strong> virtualmodel <strong>with</strong> <strong>the</strong> real plantThis should guarantee that any subsystem of a complexpart is developed <strong>with</strong> an appropriate <strong>in</strong>terface <strong>with</strong> <strong>the</strong>rest of <strong>the</strong> system.Fur<strong>the</strong>rmore, <strong>the</strong> realized system is also extremely<strong>in</strong>terest<strong>in</strong>g from <strong>the</strong> didactic po<strong>in</strong>t of view. In effect, itallows a group of students to share among <strong>the</strong>mselves as<strong>in</strong>gle remote real platform. Students can design anddevelop a system us<strong>in</strong>g only virtual prototypes, <strong>the</strong>n, when<strong>the</strong> simulation is completely work<strong>in</strong>g, <strong>the</strong>y can substitute<strong>the</strong> virtual prototypes <strong>with</strong> real hardware accessed througha network connection.An <strong>in</strong>terest<strong>in</strong>g example has been already developed<strong>with</strong> reference to <strong>the</strong> current application.

As discussed above, <strong>the</strong> system implemented <strong>in</strong>cludestwo DC motors <strong>with</strong> position control. The complete systemhas been modeled <strong>with</strong> Simul<strong>in</strong>k before <strong>the</strong>implementation. Only <strong>the</strong> speed and position control hasbeen at <strong>the</strong> end downloaded on <strong>the</strong> dSPACE board.This procedure suggests a set of exercises for studentthat will be applied <strong>in</strong> <strong>the</strong> Electrical Drive course atPolitecnico di Milano:• development of a suitable model start<strong>in</strong>g from plantspecification• tun<strong>in</strong>g of <strong>the</strong> speed control• design of <strong>the</strong> position control us<strong>in</strong>g pole placementapproach• design of coord<strong>in</strong>ated trajectories on a two axis controlLet us focus, e.g., on <strong>the</strong> third example that has beenalready def<strong>in</strong>ed <strong>in</strong> details.Start<strong>in</strong>g from <strong>the</strong> project specification a detailed modelof <strong>the</strong> control can be def<strong>in</strong>ed <strong>in</strong> terms of transfer function.Apply<strong>in</strong>g <strong>the</strong> control <strong>the</strong>ory <strong>the</strong> controller transfer functioncan be calculated.The <strong>the</strong>ory can <strong>the</strong>n experimentally verified:• program VTB to def<strong>in</strong>e a reference trajectory• download <strong>the</strong> new control us<strong>in</strong>g <strong>the</strong> obta<strong>in</strong>ed transferfunction• start VTB and dSPACE system analyz<strong>in</strong>g <strong>the</strong> positionevolution both graphically and visuallyThis could be considered a first test: <strong>the</strong>n <strong>the</strong> studentcould check <strong>the</strong> control parameter sensitivity syn<strong>the</strong>siz<strong>in</strong>gdifferent controllers start<strong>in</strong>g form wrong plant parameterspecification. The procedure is really simple andcompletely automated and allows <strong>the</strong> student to set-up asequence of experiments <strong>in</strong> a very short time.Thanks to <strong>the</strong> network distributed characteristics of <strong>the</strong>application, <strong>in</strong> a short time <strong>the</strong> experiment will be <strong>in</strong>cluded<strong>in</strong> a <strong>Virtual</strong> Laboratory structure so that students wouldaccess <strong>the</strong> laboratory at any time from <strong>the</strong> universitynetwork for <strong>the</strong> practical tests.IX.Fur<strong>the</strong>r DevelopmentsTwo fur<strong>the</strong>r developments are under consideration at<strong>the</strong> moment:• <strong>the</strong> DSPACE board can be used not only as an<strong>in</strong>terface to control systems but also as a generalpurpose data acquisition board. For this reason <strong>the</strong>authors are work<strong>in</strong>g to def<strong>in</strong>e advanced Matlabcommands to make communication easier and moreflexible• at <strong>the</strong> moment Matlab acts as a bottleneck on <strong>the</strong>communication protocol. The authors are work<strong>in</strong>g on<strong>the</strong> possibility to directly communicate <strong>with</strong> <strong>the</strong>dSPACE board at low level. This should improve <strong>the</strong>total throughput and <strong>the</strong> simulation performance.X. ACKNOWLEDGMENTThis work was supported <strong>in</strong> part by <strong>the</strong> Office of NavalResearch under Grant N00014-96-1-0926. The activity of<strong>the</strong> first author has been partially supported by C.N.R. (<strong>the</strong>Italian Council for Research) <strong>in</strong>side <strong>the</strong> <strong>in</strong>itiative ShortTerm Mobility for Researchers. The help of Teems Lovettand Bill Mckay from <strong>the</strong> University of South Carol<strong>in</strong>a <strong>in</strong><strong>the</strong> implementation of <strong>the</strong> network communicationsoftware is gratefully acknowledged. The help ofFerd<strong>in</strong>anda Ponci <strong>in</strong> <strong>the</strong> hardware realization is alsogratefully acknowledged.REFERENCE[1] Carmeli, S., Castelli Dezza, F., Monti, A., “A new platformfor real time test<strong>in</strong>g of electrical drive digital control”, IEEECOMPEL 98, 19-22 July 1998, Como (Italy)[2] De Paola, E., Mar<strong>in</strong>a, G., Monti, A., Tramalloni, L., "Afrequency analysis method for real-time simulation", EPE99,Lausanne (CH), September 1999[3] Beker, B.; Hudg<strong>in</strong>s, J.L.; Coronati, J.; Gillett, B.; Shekhawat,S., Extraction of parasitic circuit elements <strong>in</strong> a PEBB forapplication <strong>in</strong> <strong>the</strong> virtual test bed, Industry ApplicationsConference, 1997. Thirty-Second IAS Annual Meet<strong>in</strong>g, IAS'97., Conference Record of <strong>the</strong> 1997 IEEE Volume: 2 ,Page(s): 1217 -1221 vol.2[4] Gokdere, L.U.; Brice, C.W.; Dougal, R.A., Graphical andvisual simulation of electric drive systems , Electric Mach<strong>in</strong>esand Drives, 1999. International Conference IEMD '99,Page(s): 685 -687[5] MGA Software, "ACSL Model, ACSL reference manual",1995 (for more details see http://www.acslsim.com/)[6] The Mathworks, "Matlab: Application Program InterfaceGuide", 1996 (for more details seehttp://www.mathworks.com/)[7] The Mathworks, "Simul<strong>in</strong>k: User Guide", 1998[8] Microsim, "PSPICE A/D Simulator User Guide", 1997 (formore details see http://pcb.cadence.com/)[9] dSpace, "Matlab Interface and Trace Library", 1999 (for moredetails see http://www.dspace<strong>in</strong>c.com/)[10] Shem-Tov Agrawala, Ashok K., Levi “Real-Time SystemDesign”, McGraw-Hill, 1990.