Double-Wall Cylinders/ Repairable Stainless Steel ... - PW Romex

Double-Wall Cylinders/ Repairable Stainless Steel ... - PW Romex

Double-Wall Cylinders/ Repairable Stainless Steel ... - PW Romex

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

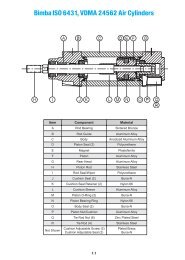

Bimba <strong>Double</strong>-<strong>Wall</strong> ® <strong>Cylinders</strong>Important <strong>Double</strong>-<strong>Wall</strong> ® InformationPiston Rod Diameter –5/8" and 1" diameter rods are standard.These rods are made of high strength steel and are suitable formost applications. On long stroke, high thrust applications cautionshould be exercised and the column strength and stop lengthchart on page 6.11 should be reviewed.Material –Hard chrome plated rods are supplied as standard onall models except 1-1/2" MRS, which are 303 stainless steel.Special materials such as 303 stainless steel are available onrequest.Rod End Options –Bimba offers six popular NFPA rod end styles(see page 6.5). Bimba considers the one-piece male style #2, asthe primary standard rod end. Asmall male rod stud, style #2S, isalso offered as astandard option. The stud is made from 125,000P.S.I. min. yield steel and is roll threaded for increased strength.Special rod ends with different thread lengths, pitch and class areavailable upon request.Cushions –The <strong>Double</strong>-<strong>Wall</strong> ® offers exclusive <strong>Stainless</strong>-Cushions ® ,type 304 stainless steel sleeves which enhancecushion performance and life. The cushion seal is contained onthe piston rod for easy inspection and replacement whennecessary. Air cushions may be specified on either or both endswithout changing the cylinder’s overall length.The cushion design allows for aflush mounted adjustment screweven in the fully open setting. Unless otherwise specified,cushioned models are shipped with the adjustment screwslocated in positions 4and 8asshown on the cylinder dimensionaldrawings.Adjustment screws may be ordered in other than standardpositions at no additional charge. Simply add these designationsas the last digits of the model number:A2 –Head Adjustment Screw –Position 2A3 –Head Adjustment Screw –Position 3A6 –Cap Adjustment Screw –Position 6A7 –Cap Adjustment Screw –Position 7A26 –Adjustment Screws –Positions 2and 6A37 –Adjustment Screws –Positions 3and 7Mountings –<strong>Double</strong>-<strong>Wall</strong> cylinders utilize easy to assemble “bolton” mounting kits. Basic cylinders (less mountings) and mountingkits are ordered and shipped as separate items. All necessaryhardware iscontained in the kit. The clevis mounting kit forexample contains the clevis cap, pivot pin, retaining rings, andmounting cap screws.The clevis and pivot caps are high strength aluminum die castingsand have oil-filled bronze bushings. Side and end lug kits containbrackets which are stamped from high strength steel. Flange kitsare offered in both steel and aluminum. All mountings are epoxycoated.“Bolt on” <strong>Double</strong>-<strong>Wall</strong> mounting kits give your local BIMBADistributor inventory versatility allowing him to stock Basiccylinders of various popular strokes and bores without comittingthem exclusively to one mounting style. This means greater “offthe shelf” availability for you.Delivery –Ordering standard cylinders with the primary standardstyle #2 rod end will allow you to take advantage of asubstantiallocal Distributor stock of <strong>Double</strong>-<strong>Wall</strong> cylinders. Avery large stockof cushioned (both ends) and non-cushioned finished cylinders isalways maintained at our Monee, Illinois plant. In addition wemaintain avast inventory of finished heads, caps, rods, etc. forquick assembly of your optional feature ornon-standard strokerequirement.Specials –Bimba Manufacturing welcomes the opportunity tocustom design acylinder to meet your exact specifications andrequirements. As aleading manufacturer of custom specialcylinders, we can provide the engineering expertise to help youwith whatever design problem you face. We also maintain aspecials department within our manufacturing facilities to assureyou of the most expedient delivery possible. Please contact yourlocal Bimba Distributor or Customer Service Department withdetails of your special requirement.<strong>Double</strong>-<strong>Wall</strong> <strong>Cylinders</strong><strong>Repairable</strong><strong>Stainless</strong> <strong>Steel</strong> <strong>Cylinders</strong>6.15 ForTechnical Assistance: 800-442-4622