WHEY PRODUCTS IN BAKED GOODS - US Dairy Export Council

WHEY PRODUCTS IN BAKED GOODS - US Dairy Export Council

WHEY PRODUCTS IN BAKED GOODS - US Dairy Export Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

APPLICATIONS MONOGRAPH ■BAKERY<strong>WHEY</strong> <strong>PRODUCTS</strong> <strong>IN</strong> <strong>BAKED</strong> <strong>GOODS</strong>By Kimberlee Burrington, Food Scientist,Whey Applications Program Director,Center for <strong>Dairy</strong> Research, University of Wisconsin-Madison, <strong>US</strong>AWhey-basedingredients in bread:• Enhance crust browning• Improve toastingqualities• Enhance crumbstructure (providea fine, even crumbwithout additionaldough conditioners)• Have the potential toslow staling of bread,thus increasing shelf-life• Enhance bread flavorWhey proteins are an importantfunctional component in breadformulations. They enhance crustbrowning, crumb structure and flavor,improve toasting qualities and retardstaling. Whey-based ingredients canbe customized to meet specific protein,mineral and lactose compositions. Thisis important because composition anddegree of denaturation affect wheyingredient functionality.The following parameters provide aguideline for selecting a whey-basedingredient for application in a breadformulation:• In order to optimize loaf volume,the whey-based ingredient shouldbe low in lactose, high in protein andthe protein should be significantlydenatured.• Optimum usage levels vary, but 2-3%is a good starting point to obtainmaximum benefits.• Water absorption is lower for wheyingredients than for flour, with waterabsorption increasing as proteindenaturation levels increase;therefore water requirements mayneed to be adjusted depending onthe whey ingredient used.• Time required to mix dough tomaximum consistency (resistance)may increase (mixogram timeto peak).• If the whey-based ingredient ishigh in lactose, adjustments in theprocess or other ingredients may beneeded to maintain yeast growth andcarbon dioxide production.• Baking time and temperatures mayrequire adjustment because crustcolor might develop more rapidlywith whey-based ingredients.eA2.11

APPLICATIONS MONOGRAPH ■BAKERYFUNCTIONAL BENEFITSThere are specific functional properties thatare associated with whey proteins. Theyinclude:(1) solubility, (2) water binding/absorption, (3) viscosity, (4) gelation,(5) cohesion, adhesion and elasticity,(6) emulsification and (7) foaming. Mostof these characteristics are importantin the processing of baked goods. Thereformulation of bakery products withadded whey protein (supplementation) isdone for functional reasons. Whey proteinconcentrates (WPCs) have found uses inbiscuits, cookies, cakes, sponges, icings andglazes to improve texture and appearance.Dough volume can be increased in breadand cake, and moistness can be improvedin a variety of products. Whey proteinisolate (WPI), whey protein concentrate 34%(WPC34) and whey protein concentrate 80%(WPC80) have been found to improve thecolor, thickness and chewiness of full fat andlow fat cookie formulations. WPIs and WPCswith more than 75% protein can be addedto cake formulations to improve volumeand appearance.Whey products are used by the bakingindustry because of their functionalbenefits. Some of the benefits recognizedby consumers include good crust colordeveloped through the Maillard browningreaction, good dairy flavor, softer crumband extended shelf-life. Additional benefitsthat the baker may recognize are the abilityto reduce ingredient costs by partially orcompletely replacing egg products, milkpowder or other ingredients such asshortening. Less commonly recognizedare the nutritional benefits of adding wheyproteins to bakery products. Whey proteinshave a high concentration of lysine, thedeficient amino-acid in wheat protein.Increasing the ratio of whey proteins towheat protein results in an improvedamino-acid profile. Bread, soft rolls andbuns are the major applications for wheyproducts. A typical usage level of whey orlactose in bread, soft rolls and buns is 2-4%of the flour weight.FUNCTIONALITYWhey protein concentrates (WPCs) havemany functional properties most of whichare associated with the whey proteins.Some of the basic functionalities that aWPC can provide are whipping/foaming,emulsification, high solubility, gelation,water binding, and viscosity development.Generally, WPCs with higher protein contenthave improved functionality over those withlower protein content. Other factors thatinfluence their functionality are the wheysource, amount of heat treatment receivedduring manufacture, and lipid and mineralcontent. Whey protein conformation andfunctionality are interrelated and dictated bychanges in their globular folded structure.Their functional properties are affected byseveral factors within a food application,including concentration, state of the wheyproteins, pH, ionic environment, (pre-) heattreatment, and the presence of lipids.In the native state, whey proteins arehighly soluble and adeptly performemulsification and whipping functionsin a food application. Heating whey proteinscan result in a loss of solubility due to thedenaturation of the proteins, especially inthe pH range of 4.0-6.5. While solubility isadversely affected by heat, emulsificationcan be improved through controlled heatdenaturation. As the whey protein unfolds,hydrophobic amino acid residues areexposed, which enhance the ability ofthe protein to orient at the oil/waterinterface. The presence of salts during theemulsification process influences wheyprotein conformation and solubility. In theirundenatured form, whey proteins can formrigid gels that hold water and fat andprovide structural support.The formation of disulfidebonds and ionic bondingcontrolled by calciumions appears to determinegel structure.The water-binding abilities of whey proteinscan help reduce formula costs as theproteins hold additional water. Viscositydevelopment is closely related to gelationand other protein-protein interactions.Foaming properties are best when the wheyproteins are undenatured, not competingwith other surfactants at the air/waterinterface, and stabilized by an increase inviscosity when foam formation occurs.Whey proteins also contribute to browningby reacting with lactose and other reducingsugars present in a formulation, providingcolor to heated products. WPCs are alsobland tasting and contribute no foreign oroff-flavors when used as an ingredient.Modified whey can also improve the flavorand texture of reduced fat, low fat and fatfree baked goods.NUTRITIONWhey protein concentrates contributenutrition to a food application through theirmineral content as well as their proteincontent (see Nutrition section of theReference Manual). Whey proteins containa high level of essential amino acids andare considered to be a high quality proteinsource. WPCs also contain significantamounts of calcium and other minerals thatcan be added advantages when fortifyingfood products.2eA2.2

APPLICATIONS MONOGRAPH ■BAKERY<strong>WHEY</strong> PROTE<strong>IN</strong> CONCENTRATES <strong>IN</strong> <strong>BAKED</strong> <strong>PRODUCTS</strong>:FUNCTIONALITY <strong>IN</strong> SPECIFIC <strong>PRODUCTS</strong>eA2.3BREADS<strong>Dairy</strong> ingredients have been usedextensively in the development of breads.A softer, more tender crumb is oftenproduced as a result of whey productaddition. Breads made with WPC have alsoexhibited these benefits but with somenecessary modifications made to the WPC,to optimize its performance in bread. Intests performed using WPC34, WPC50 andWPC80 in breads, WPC34 produced thesoftest bread because it contained the leastamount of calcium. The amount of calciumplays a role in the rate of firming of bread.The mechanism behind this points to thefact that lower calcium WPCs aggregate athigher temperatures in the baking process,when there is more gelatinized starch,allowing the whey protein chains to extendbetween the starch chains and decreaseretrogradation. Increasing the lactosecontent in the dough can also producebread that retains its softness for a longerperiod of time. This softness has beenattributed to better emulsification of thefat in the formula. Lactose crystals in bakedgoods also have unique water holdingcapacity. Optimal mixing times wereincreased with the use of all WPCs. When 2,4 and 6% addition of WPC was tested, the4% level of WPC34 yielded the highest loafvolumes. Controlled heat treatment ofWPC34 to achieve partial denaturationof the whey proteins has also been shownto improve bread moistness and texture.Decreasing fermentation time is detrimentalto bread quality when using WPCs. Typically,the shorter the fermentation time, the moresensitive the bread is to whey proteins.WPCs (up to 2% protein addition) havebeen used in bread made by the spongedough process. The bread quality wasimproved by using high protein WPC,denaturing the protein to the same degreeas for high heat nonfat dry milk and addingsodium stearoyl-2-lactylate. Generally, thehigher the protein content of the WPC, thegreater the loss in loaf volume. Besidesimproving the softness of bread, WPCs areoften used to perform many of the functionsof eggs in baked products.3CAKESIn cakes, more protein is needed for crumbstrength. The finished structure of a cake isdependent upon the gelatinization of starchand denaturation of protein. The additionof sugar in cakes increases the gelationtemperature of gluten so the finishedstructure of the cake can not be obtainedwithout the addition of a protein with alower gelation temperature. Whole eggsand egg whites are added to achieve thisdesired structure. Successful application ofWPC as egg replacers in cakes is inverselyrelated to the sugar and fat level in the cakesystem. Egg whites in cakes can be partiallyor totally replaced by WPCs with a highprotein content (WPC80). The higher thesugar and the lower the fat, the harder it isto make an acceptable cake with a completereplacement of whole egg with WPC. Thehigher protein WPCs generally are requiredfor cake applications because of therequirement for gelation.The WPC34, WPC50, and WPC80 productsare well suited to partially replace thefunctions of whole egg in a cake application.WPC80 is better suited for egg whitereplacement. WPCs can provide body andviscosity to cake batters to help entrap airand retain carbon dioxide produced bythe leavening system. They can also helpin retaining moisture in cakes. Anotheringredient that can be replaced in a bakedproduct is fat. The addition of WPC80(at a 2% level) to a low fat pound cakeformula can result in a higher volume, softerproduct that is preferred over both a full fatcontrol and a low-fat control (no WPC80) inmoistness, flavor and overall characteristics.

APPLICATIONS MONOGRAPH ■BAKERYCOOKIESReplacement of whole egg in a soft cookiewith a WPC is also possible. In less aeratedproducts such as cookies, replacementof skim milk powder or egg is easilyaccomplished. Whey added to cookiesis an economical source of dairy solids.Both WPC34 and WPC80 have beenfound to improve the color, thickness,and chewiness of cookies. In reduced fatcookies, combinations of WPC80, modifiedstarch, emulsifiers and water are able toreplace whole eggs and shortening. Thisaddition results in batters with similarspread and baked cookies with similartexture, flavor and overall preference whencompared to the control. Egg whites informulas for scones and crepes can bereplaced with WPC80. The substitutionis made on an equal protein basis.The resulting products are similarto control products in overallacceptance, but they aregenerally more tenderin texture.CRACKERSIn contrast to cookies, crackers contain littleor no sugar. They are formulated with higherprotein flours, often a mixture of soft andhard wheat. The functional requirements forWPC in crackers are similar to that in breads.WPC has been used to replace flour in yeastleavened crackers. WPC34 gives superiorresults over WPC75 (when using WPC75,less than 5% of the flour can be replaced).The longer the fermentation time, the moresatisfactory is the cracker.PIE CR<strong>US</strong>TSWhey or lactose can be added to pie crusts.Whey at approximately 2-3% or lactoseat 6-8% of flour weight aid in emulsifyingthe shortening. This allows for a reductionin shortening without sacrificing thetender, flaky texture. Bakers also reportimprovements in color and flavor of thebaked crust.4eA2.4

APPLICATIONS MONOGRAPH ■BAKERYBAKERY MIXESBakery mixes are generally one of threedifferent types: complete mix, dough baseand dough concentrate. Dough bases orpartial mixes require that the end user addwater as well as oil or shortening and eggs.Dough concentrates are specificallydesigned for continuous, high throughput,automated production. Used for fatreduction, high solubility, water binding,and moisture retention, they blend well withother ingredients in a bakery dry mix. Mildflavor is another attribute of WPCs thattypically blends well with baked products.The bland, dairy flavor of WPC enhancesmany of the browning type flavors thatdevelop during baking. The added browningthat results due to the lactose content alsocontributes to an appealing surface color.BAKERY GLAZESBakery glazes based upon whey proteinconcentrates and caseinates have numerousadvantages over traditional glazes madefrom whole eggs and water. The whey-basedglaze is microbiologically stable andsalmonella-free. It tends to be less proneto microbial growth in the holding tank,although good sanitation practices arealways necessary. As a top spray on proofedbread or rolls, this type of glaze gives goodadhesion of toppings such as seeds andcrushed grains.NUTRITIONAL <strong>PRODUCTS</strong>Another area where WPCs deliver a tangiblebenefit is that of baked products designedfor the nutritionally conscious. Productssuch as energy bars or sports bars oftenare fortified with protein ingredients andminerals. WPC80 products are ideal forthese applications because WPC80 bringsnot only high protein concentrations butalso a high level of calcium, which couldreduce the need to add additional calciumin a vitamin fortified product. Proteinfortification is an excellent application forWPCs. More emphasis will likely be placedon the contributions of both protein andminerals in main stream food products.With protein levels ranging from 34-80% inWPCs and calcium levels from 500-600 mgper 100g of product, WPCs have a lot tocontribute nutritionally to an application.Specialty breads may be an area of interestas well as the cereal bar or energy bartype products.The typical levels used in baked productscan add small benefits to the overallnutrition of the product. The best returnsnutritionally are found in fat replacement.Replacing fat with protein has nutritionallabel appeal to most consumers.PROCESS<strong>IN</strong>GCONSIDERATIONSThere is a need to maintain consistentprocessing conditions for all WPCs soconsistent functionality can be deliveredto the customer at all times. It is alsonecessary for the applications technologistto understand the processes for preparationof each baked product and what changeswould have to be made to easily incorporatea WPC. Whether it is proof time, mixingtimes, order of addition of ingredients orlevels of ingredients, optimization is neededwhenever ingredient changes are made toa formula.Consistent quality is of great importance toa customer. Many U.S. manufacturers ofWPCs have the capabilities of producingconsistent, high quality products. It isimportant for their customers to workclosely with them so they can understandtheir quality and functional goals.eA2.55

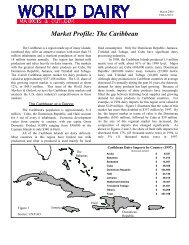

APPLICATIONS MONOGRAPH ■BAKERYLACTOSE FUNCTIONALITY <strong>IN</strong> <strong>BAKED</strong> <strong>PRODUCTS</strong>In baking, lactose is oftenused to replace sucrosefor a variety of functionalbenefits. Compared to othersugars, lactose results inlow relative sweetness,increased browning,enhanced emulsificationaction, moisture retention,non-hygroscopicityand enhanced flavors.When replacing sucrose(up to 50%), lactose cancontribute to improvedcrumb texture andfreshness, increased volume,reduced fat levels, improvedgas retention, andenhanced flavor.Use of lactose in bakery productsBakery product Lactose level (%) Benefits of lactose usageBreads and rolls 3-4% Produces golden brown color(does not turn dull in storage)Improves softnessReduces shortening requirements by upto 50% by replacing up to 50% sucrosePastries and sweet rolls 4-5% Produces golden brown colorEnhances flavorImproves softness and tendernessReduces shortening andsucrose requirementsPie crusts and shells 8% Shorter, flakier, more tender crustsImparts uniform, pleasing color to topand bottom crustsIncreases mixing toleranceProvides greater latitude as to typesof flour usedExtends shortening content(shortening can generally bereduced by about 5%)Distributes fat ideally withminimum mixingRetards sogginessCakes and muffins 10-15% Maximum tenderness withoutexcessive sweetnessGolden brown, flavorful crustProduces and improves cake volumeAccentuates flavorsCookie 3-5% Increases mixing toleranceEases release from rotary diesAssures ideal fat distributionSharpens and enhances flavorControls sweetness levelProduces optimum tendernessand ideal crust colorProduces richer tasting cookiesLevel is based on flour weight (100%), except for cakes and muffins where use level is based on replacementof other sugars.Lactose also shortens proofing times,especially where the overall sugar level ishigh. Doughs containing lactose show atendency to rise faster during the initialstages of proofing and show improvedstability and gas retention. Lactose readilyreacts with proteins (Maillard reaction)giving baked goods a highly flavored,desirable golden-brown color. Caramelizationby heat during baking also contributesflavor and color. Lactose influences andenhances the controlled browning of bakerygoods, leading to shorter baking times andlower temperatures to achieve even, stable,golden brown colors. This is a particularbenefit in products targeted for microwavefinishing. Lactose has unique, volatile flavorbinding and enhancing properties, which areparticularly useful in products with delicateflavors. Lactose has a strong affinity forflavorings and flavors. It is able to absorband accentuate flavors. This enables areduction in added flavors.Lactose also extends shortening in bakeryproducts, enabling a fat reduction in certainrecipes. Since lactose is not fermented bybaker’s yeast, it retains its functionalitycharacteristics through baking and storage.6eA2.6

QUESTIONS AND ANSWERSQ: Is proof time affected by the addition of whey tobreads or sweet rolls?A: Proof times should remain the same butcould increase with the addition of wheyto these products depending on theamount added. Generally, the moreprotein added, the more sensitive thedough is during fermentation.Q: I observed that the dough is becoming more stickywhen whey is added. Is it normal? How do Iremedy this problem?A: Yes, doughs can become more sticky whenwhey is added. Usually stickiness increaseswith the level of whey added to the dough.You could decrease your level of addition orchange the order of addition of the whey.Q: Is it preferable to use “denatured” whey?A: Generally, some denaturation is desirablefor baked products. Heating the whey,which partially unfolds the proteins in thewhey so they have enhanced water-bindingcapabilities and improved emulsification,causes denaturation. Most whole driedwhey will have some level of denaturationdue to typical processing conditions.Q: Will adding sweet whey result in a lower volumefor cakes?A: No. Research has shown that the additionof 15% whey solids (based on flour) toyellow cake formulations, containing20-40% shortening and 100% sugar,yielded improved volume.Q: Can sweet whey or WPC34 be used in frozendoughs? What level will work?A: Yes. Sweet whey and WPC34 can be addedto frozen doughs at typical levels of 1-6%.Q: In which products can WPC80 replace egg whites?What percent replacement is possible?A: It has been very difficult for WPCs tocompletely replace egg whites in cakeswithout loss of cake volume. Levels ofreplacement less than 50% should beachievable without significant lossesin cake quality.Q: Will whey powder result in excessive browning?A: Not necessarily. The addition of wheypowder will increase browning in a bakedproduct proportional to the amount ofwhey powder added.Q: Will the addition of whey powder or WPC34impact yeast-raised products?A: Addition of either of these products shouldnot significantly affect the quality ofyeast-raised products. The higher proteinproducts have been shown to increaseproof times, decrease finished volumes,and affect crumb structure. Both wheyproducts should provide improvements incrumb structure, texture, and crust color.Q: WPC80 is very expensive. Why should I use it andfor which products?A: WPC80 should be used for products thatrequire a strong gel structure. It can be usedfor a partial replacement of egg white,whole egg, or other functional ingredientsthat contribute to structure. Cakes and softcookies are good applications. WPC80 canalso provide protein to an energy bar typeproduct without contributing the off flavorsthat other protein sources provide.Q: Is it true that WPCs can replace emulsifiers?A: WPCs do have emulsifying capabilities.It may be possible to reduce the level ofemulsifiers used in a baked product for theircontribution to increasing shelf life. WPCshave been shown to improve crumb texturein breads over their shelf-life.Q: When using WPC in a pound cake (WPC80 asreplacement for egg white, 50% substitution),the volume of the product is lower than thecontrol formulation. What should be done toimprove the volume?A: First of all, make sure you are replacingthe egg white on a protein-protein basis.Often it is not as simple as replacing oneingredient with another to achieve acomparable product. Some slight increasesin leavening, changing the order of additionof the ingredient, or increasing the mixingtime may help to improve the volume.Q: When using WPC 34 in cookie dough, it makesthe dough too sticky. Furthermore, the cookiespreads out too much. Any tips on preventing thisfrom happening?A: Try adding the WPC34 in the creaming stageso the shortening can coat the lactose andprotein. Decrease the amount of water youare adding, to also help with stickiness andincreased spread. Typically, the additionof WPC34 to cookies will yield less spreadin a cookie.Q: Adding WPC 80 in cookie and cake dough makesthe dough too sticky. How can this be prevented?A: Stickiness is related to the amount of fator emulsifiers you still have in the dough,along with the amount of WPC80 you areadding. Try adding the WPC80 in thecreaming stage, decreasing the amountof water you are using or perhaps adjustingthe level of emulsifier/shortening.Q: I plan on using sweet whey as a calcium source.In what form is calcium in whey and is it wellabsorbed by the body?A: Calcium is in the form of calciumphosphate in whey. It has been shownto have greater bioavailability (in animalstudies), than calcium carbonate, calciumlactate, and calcium citrate.eA2.77

REFERENCESAbboud, A. 1995. “Technical Bulletin: Systemsapproach to reducing fat in baked goods,”American Institute of Baking, Manhattan, KS,17(12).Anonymous. 1996. <strong>Dairy</strong> Ingredient ApplicationGuide. Whey Ingredients. <strong>Dairy</strong> Management, Inc.,Rosemont, IL.Asp.E.H., 1996. The effects of milk derived ingredientson doughs and bread. M.S. thesis, Universityof Minnesota.Burrington, K.J. January, 1998. “More than justmilk.” Food Product Design.Chandan, R. 1997. Baked Products, In <strong>Dairy</strong>-BasedIngredients. Eagan Press, St. Paul, MN.Corliss, G.A. 1992. “Technical Bulletin: Proteinbasedfat substitutes in bakery foods,” AmericanInstitute of Baking, Manhattan, KS, 14(10).Haines, B. 1998. “<strong>Dairy</strong> ingredients and theiruse in bakery foods.” American Institute of BakingTechnical Bulletin, XX(3).Harper, W.J., 1991. “Whey protein functionalityin model foods systems.” Proceedings ofCDR/ADPI Whey Protein Workshop, October21-23, Madison, WI.Harper, W.J. and Zadow, J.G. 1984.“Heat induced changes in whey proteinconcentrates as related to bread manufacture.”New Zealand Journal of <strong>Dairy</strong> Science and Technology,19, p. 229-237.Hegenbart, S September, 1998.Maximizing convenience with bakery mixes:Food Product Design.Kulp, K. 1994. “Cookie Chemistry andTechnology.” American Institute of Baking.McWard, C. “Balancing act.” Baking and Snack,January, 1998.O’Donnell, K. 1996. “Technical Bulletin:Methods of bread dough making,” AmericanInstitute of Baking, Manhattan, KS, 18(12).Pyler, E.J. 1988. Baking Science and Technology,Third edition, Sosland Publishing Company,Merriam, Kansas.Appendix IRecommended Level of Addition as % of Total FormulaSweet Whey WPC34 to WPC80 Demineralized Whey,WPC50Modified WheyWhite Bread 1–5% 1–4% 1–3% 2–6%Sweet Rolls 2–5% 1–4% 1–3% 2–6%Cookies and Biscuits 1–5% 1–5% 1–4% 2–5%Crackers 1–5% 1–4% 1–3% 2–6%Pizza Dough 1–5% 1–4% 1–3% 2–6%Cakes 1–6% 1–4% 1–3%** 1–6%Icings & Fillings 1–3% 1–2% 1–2% 1–3%Low Fat, Low Sugar 2–10%~ 3–9%* 3–5%* 2–10%~Baked Goods** Replacement of up to 50% egg white.* Replacement of up to 50% fat.~ Replacement of up to 25% sugar.Lactose Low Protein Expected Benefit forWhey all categories of wheyingredients to varyingdegrees dependingon protein levelWhite Bread 1–5% 1–5% Extend shelf-life, improvecrumb structure and softness,provide crust browning.Sweet Rolls 1–5% 1–5% Extend shelf-life, improvecrumb softness, providesurface browning.Cookies and Biscuits 1–5% 1–5% Provide surface browning,improve tender texture, providepartial egg replacement.Crackers 1–5% 1–5% Contribute to cracking stabilityand surface color.Pizza Dough 1–5% 1–5% Provide structure, freeze-thawstability, crust browning.Cakes 1–6% 1–6% Provide soft crumb, partialegg replacement, add surfacebrowning.Icings & Fillings 1–3% 1–3% Partial replacement for sugar,add water-binding capabilitiesfor overall stability, reducessweetness.Low Fat, Low Sugar 2–10%~ 2–10%~ Partial replacement forBaked Goodsfat and/or sugar, addswater-binding and someemulsifying capabilities,reduces sweetness.Sherwin, C. 1995. “Technical Bulletin:Use of whey and whey products in bakedgoods,” American Institute of Baking, Manhattan,KS, 17(11).MANAGED BYDAIRY MANAGEMENT <strong>IN</strong>C ṬMPublished by U.S. DAIRY EXPORT COUNCIL ®Fax: U.S.A. (703) 528-3705U.S. Customers please contact DMI at:Tel: 1-800-248-8829Fax: (847) 995-1738RR E C Y C L E DE C Y CPA PE R SL EL A B<strong>US</strong>00E Copyright © 1999, <strong>US</strong>DEC. All rights reserved. Printed in U.S.A.8eA2.8