Thread technology for high-strength fastenings Simple â fast â long ...

Thread technology for high-strength fastenings Simple â fast â long ...

Thread technology for high-strength fastenings Simple â fast â long ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

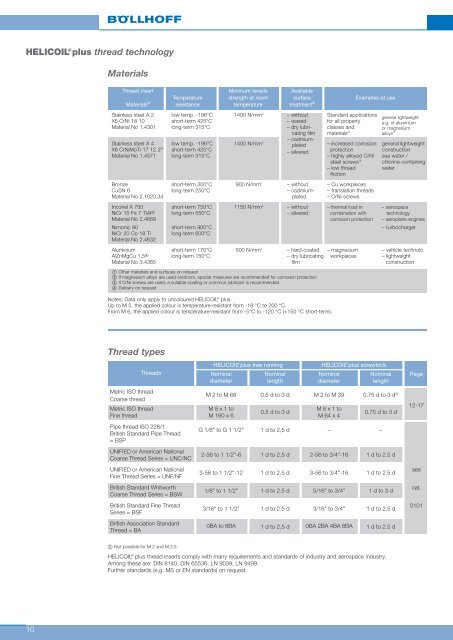

HELICOIL ® plus thread <strong>technology</strong>Materials<strong>Thread</strong> insert Minimum tensile AvailableTemperature <strong>strength</strong> at room surface Examples of useMaterials ➀ resistance temperature treatment ➀Stainless steel A 2 low temp. -196°C 1400 N/mm 2 – without Standard applications general lightweightX5 CrNi 18 10 short-term 425°C – waxed <strong>for</strong> all property e.g. of aluminiumMaterial No 1.4301 <strong>long</strong>-term 315°C – dry lubri- classes and or magnesiumcating film materials ➂ alloys ➁– cadmium-Stainless steel A 4 low temp. -196°C 1400 N/mm 2 plated – increased corrosion general lightweightX6 CrNiMoTi 17 12 2 ➃ short-term 425°C– silveredprotectionconstructionMaterial No 1.4571 <strong>long</strong>-term 315°C– <strong>high</strong>ly alloyed CrNi sea water /steel screws ➂ chlorine-containing– low thread waterfrictionBronze short-term 300°C 900 N/mm 2 – without – Cu workpiecesCuSN 6 <strong>long</strong>-term 250°C – cadmium- – translation threadsMaterial No 2.1020.34 plated – CrNi screwsInconel X 750 short-term 750°C 1150 N/mm 2 – without – thermal load in – aerospaceNiCr 15 Fe 7 TiAl <strong>long</strong>-term 550°C – silvered combination with <strong>technology</strong>Material No 2.4669 corrosion protection – aeroplane enginesNimonic 90 short-term 900°C – turbochargerNiCr 20 Co 18 Ti <strong>long</strong>-term 600°CMaterial No 2.4632Aluminium short-term 170°C 500 N/mm 2 – hard-coated – magnesium – vehicle technolo.AlZnMgCu 1,5 <strong>long</strong>-term 150°C – dry lubricating workpieces – lightweightMaterial No 3.4365 film construction Other materials and surfaces on request If magnesium alloys are used outdoors, special measures are recommended <strong>for</strong> corrosion protection If CrNi screws are used, a suitable coating or common lubricant is recommended Delivery on requestNotes: Data only apply to uncoloured HELICOIL ® plus.Up to M 5, the applied colour is temperature-resistant from -18 °C to 200 °C.From M 6, the applied colour is temperature-resistant from -5°C to -120 °C (+150 °C short-term).<strong>Thread</strong> typesMetric ISO threadCoarse threadHELICOIL ® plus free runningHELICOIL ® plus screwlock<strong>Thread</strong>s Nominal Nominal Nominal Nominal Pagediameter length diameter lengthM 2 to M 68 0.5 d to 3 d M 2 to M 39 0.75 d to 3 d ➄Metric ISO threadM 8 x 1 toM 8 x 1 to0.5 d to 3 dFine thread M 160 x 6 M 64 x 40.75 d to 3 dPipe thread ISO 228/1British Standard Pipe <strong>Thread</strong>G 1/8" to G 1 1/2" 1 d to 2,5 d – –= BSPUNIFIED or American NationalCoarse <strong>Thread</strong> Series = UNC/NC2-56 to 1 1/2"-6 1 d to 2.5 d 2-56 to 3/4"-16 1 d to 2.5 dUNIFIED or American NationalFine <strong>Thread</strong> Series = UNF/NF3-56 to 1 1/2"-12 1 d to 2.5 d 3-56 to 3/4"-16 1 d to 2.5 dBritish Standard WhitworthCoarse <strong>Thread</strong> Series = BSW1/8" to 1 1/2" 1 d to 2.5 d 5/16" to 3/4" 1 d to 3 dBritish Standard Fine <strong>Thread</strong>Series = BSF3/16" to 1 1/2" 1 d to 2.5 d 3/16" to 3/4" 1 d to 2.5 dBritish Association Standard<strong>Thread</strong> = BA0BA to 6BA 1 d to 2.5 d 0BA 2BA 4BA 6BA 1 d to 2.5 d12-17seecat.0101 Not possible <strong>for</strong> M 2 and M 2.5.HELICOIL ® plus thread inserts comply with many requirements and standards of industry and aerospace industry.Among these are: DIN 8140, DIN 65536, LN 9039, LN 9499.Further standards (e.g. MS or EN standards) on request.10