Imatra MoCN 206 M - Ovako

Imatra MoCN 206 M - Ovako

Imatra MoCN 206 M - Ovako

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

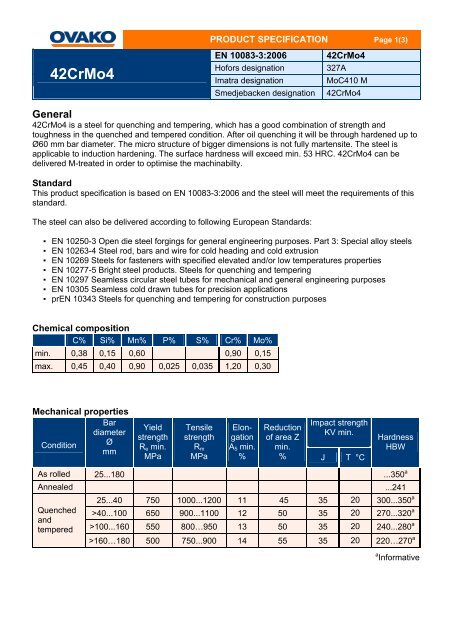

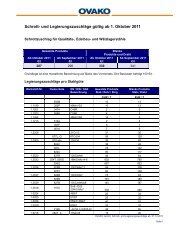

42CrMo4PRODUCT SPECIFICATION Page 1(3)EN 10083-3:2006 42CrMo4Hofors designation327A<strong>Imatra</strong> designationMoC410 MSmedjebacken designation 42CrMo4General42CrMo4 is a steel for quenching and tempering, which has a good combination of strength andtoughness in the quenched and tempered condition. After oil quenching it will be through hardened up toØ60 mm bar diameter. The micro structure of bigger dimensions is not fully martensite. The steel isapplicable to induction hardening. The surface hardness will exceed min. 53 HRC. 42CrMo4 can bedelivered M-treated in order to optimise the machinabilty.StandardThis product specification is based on EN 10083-3:2006 and the steel will meet the requirements of thisstandard.The steel can also be delivered according to following European Standards:▪ EN 10250-3 Open die steel forgings for general engineering purposes. Part 3: Special alloy steels▪ EN 10263-4 Steel rod, bars and wire for cold heading and cold extrusion▪ EN 10269 Steels for fasteners with specified elevated and/or low temperatures properties▪ EN 10277-5 Bright steel products. Steels for quenching and tempering▪ EN 10297 Seamless circular steel tubes for mechanical and general engineering purposes▪ EN 10305 Seamless cold drawn tubes for precision applications▪ prEN 10343 Steels for quenching and tempering for construction purposesChemical compositionC% Si% Mn% P% S% Cr% Mo%min. 0,38 0,15 0,60 0,90 0,15max. 0,45 0,40 0,90 0,025 0,035 1,20 0,30Mechanical propertiesBardiameterConditionØmmYieldstrengthR e min.MPaTensilestrengthR mMPaElongationA 5 min.%Reductionof area Zmin.Impact strengthKV min.% J T °CHardnessHBWAs rolled 25...180 ...350 aAnnealed ...24125...40 750 1000...1200 11 45 35 20 300...350 aQuenched >40...100 650 900...1100 12 50 35 20 270...320 aandtempered >100...160 550 800…950 13 50 35 20 240...280 a>160…180 500 750...900 14 55 35 20 220…270 aa Informative

42CrMo4PRODUCT SPECIFICATION Page 2(3)EN 10083-3:2006 42CrMo4Hofors designation327A<strong>Imatra</strong> designationMoC410 MSmedjebacken designation 42CrMo4Reference data for guidanceHeat treatmentTemperature °CCoolingHot forming 1 050...850 In airAnnealing 680…720 Slowly (15°C/h) until 600°CStress relieving b 450...650 In airHardening 840…880 Quenching in oil or in waterTempering 540...680 In airStress relieving after inductionhardening150…180 In airb The temperature of stress relieving must chosen approx. 50°C below the tempering temperature.WeldingThe steel has a restrictive weldability. For instructions regarding filler metals, working temperature andpost heat treatments please contact to our technical customers service.Tempering diagramMPa140012001000J, %, HRC100908070800600400200605040302010HBW50040030020000400 450 500 550 600 650 700Tempering temperature °CR m Tensile strength, MPaR p0,2 0,2% proof stress MPaA 5 Elongation, gauge 5×d, %HRC Rockwell hardnessKV Impact strengthwith ISO-V test bar at +20°C, JThe values are informative. They are based on oil quenching with a Ø60 mm probe.

42CrMo4PRODUCT SPECIFICATION Page 3(3)EN 10083-3:2006 42CrMo4Hofors designation327A<strong>Imatra</strong> designationMoC410 MSmedjebacken designation 42CrMo4HardenabilityThe hardenability will be calculated from the actual analysis according to <strong>Ovako</strong> formula JoD. If agreedat the time of enquiry and order, the hardenability can be verified with a end quench test.HRC65605550454035302520 40 60 75 90 100 Bar diameter, mm(oil quenching)HLHH200 10 20 30 40 50Distance from the quenched end, mmThe hardenability of 42CrMo4 varies within the limits of the scatter band. Quenched from850 °C. The hardness of an oil quenched piece (at 1/3 radius) can be estimated using the bar diameterscale of the diagram.Minimum proof stress R p0,2 (MPa) at elevated temperaturesBar diameterCondition Ø°Cmm50 100 150 200 250 300 350 400 450 500+QT 25...60 720 702 677 640 602 562 518 475 420 375The table is based on EN 10269 +A1.Minimum impact energy (J) at low temperature with ISO-V test piecesBar diameterConditionØ°Cmm-100 -50 -40 -20 0 +20+QT 25...60 27 40 50The table is based on EN 10269 +A1.DisclaimerThis specification is for information purposes only. <strong>Ovako</strong> takes no responsibility for thesuitability of the steels referred to in this specification to a given product or end use. We reservethe right to change or correct the data in this specification without prior notification. <strong>Ovako</strong> takesno responsibility for any errors in this information, or for any consequences resulting from itsuse