Worm-Drive Hose Clamps - Electronic Fasteners Inc

Worm-Drive Hose Clamps - Electronic Fasteners Inc

Worm-Drive Hose Clamps - Electronic Fasteners Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

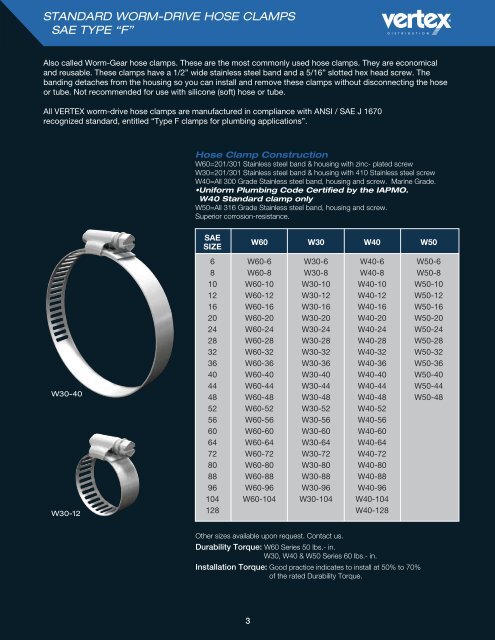

STANDARD WORM-DRIVE HOSE CLAMPSSAE TYPE “F”®Also called <strong>Worm</strong>-Gear hose clamps. These are the most commonly used hose clamps. They are economicaland reusable. These clamps have a 1/2” wide stainless steel band and a 5/16” slotted hex head screw. Thebanding detaches from the housing so you can install and remove these clamps without disconnecting the hoseor tube. Not recommended for use with silicone (soft) hose or tube.All VERTEX worm-drive hose clamps are manufactured in compliance with ANSI / SAE J 1670recognized standard, entitled “Type F clamps for plumbing applications”.<strong>Hose</strong> Clamp ConstructionW60=201/301 Stainless steel band & housing with zinc- plated screwW30=201/301 Stainless steel band & housing with 410 Stainless steel screwW40=All 300 Grade Stainless steel band, housing and screw. Marine Grade.•Uniform Plumbing Code Certified by the IAPMO.W40 Standard clamp onlyW50=All 316 Grade Stainless steel band, housing and screw.Superior corrosion-resistance.W30-40W30-12SAESIZE6810121620242832364044485256606472808896104128W60 W30 W40 W50W60-6W60-8W60-10W60-12W60-16W60-20W60-24W60-28W60-32W60-36W60-40W60-44W60-48W60-52W60-56W60-60W60-64W60-72W60-80W60-88W60-96W60-104W30-6W30-8W30-10W30-12W30-16W30-20W30-24W30-28W30-32W30-36W30-40W30-44W30-48W30-52W30-56W30-60W30-64W30-72W30-80W30-88W30-96W30-104W40-6W40-8W40-10W40-12W40-16W40-20W40-24W40-28W40-32W40-36W40-40W40-44W40-48W40-52W40-56W40-60W40-64W40-72W40-80W40-88W40-96W40-104W40-128W50-6W50-8W50-10W50-12W50-16W50-20W50-24W50-28W50-32W50-36W50-40W50-44W50-48Other sizes available upon request. Contact us.Durability Torque: W60 Series 50 lbs.- in.W30, W40 & W50 Series 60 lbs.- in.Installation Torque: Good practice indicates to install at 50% to 70%of the rated Durability Torque.3