CPMill ball track milling cutters - MAPAL Dr. Kress KG

CPMill ball track milling cutters - MAPAL Dr. Kress KG

CPMill ball track milling cutters - MAPAL Dr. Kress KG

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

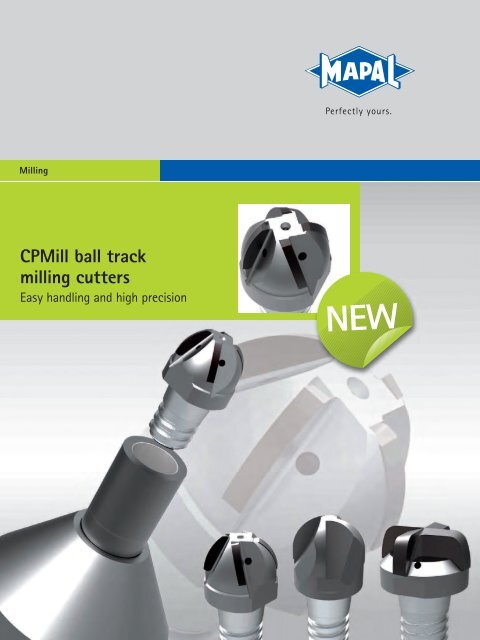

Milling<strong>CPMill</strong> <strong>ball</strong> <strong>track</strong><strong>milling</strong> <strong>cutters</strong>Easy handling and high precisionNEW

<strong>CPMill</strong> - Complete Performance MillingThe new generation of <strong>MAPAL</strong> replaceable <strong>milling</strong> <strong>cutters</strong> for the machining ofconstant-velocity joints sets new standards. In intensive dialogue with the users,important features were redesigned or decisively further developed. The results are:Easy handling, high precision and excellent cost-effectiveness.Outer raceInner race2

Milling | <strong>CPMill</strong> - Complete Performance MillingAdvantages of<strong>CPMill</strong> <strong>ball</strong> <strong>track</strong> <strong>milling</strong> <strong>cutters</strong>Easy handling for quick <strong>milling</strong> head changingPrecision connection for perfect radial run-outHigh rigidity and stability for optimum powertransmissionHelically arranged blades for more performanceSuitable PCBN grades for reduced cuttingmaterial costsHandlingThe new CFS (Complete Fitting System) connectionensures quick and easy changing of the <strong>milling</strong>heads and high repetition accuracy. Releasing andclamping is performed from the front so thatthe tool holder can remain on the machine. Theproverbial <strong>MAPAL</strong> precision thereby guaranteesthat the radial run-out at the blades always remains< 3 µm even after tool changing. All theblades of the tool head are thus uniformly incontact with the workpiece. Together with the highstability of the connection, this is a preconditionfor the best possible performance and service lifeof the tools, and for a perfect geometry of the <strong>ball</strong><strong>track</strong>s in the workpiece.Cost-effectivenessThe helically arranged blades allow an innovative<strong>milling</strong> concept to be employed additional to theincreased performance thanks to the new connection.Particularly when <strong>milling</strong>, this cutting edgegeometry ensures a smooth start of cutting andhence a quiet <strong>milling</strong> process. That results in significantlyless wear on the blades compared with thestraight blade arrangement. When using the <strong>CPMill</strong><strong>ball</strong> <strong>track</strong> <strong>milling</strong> <strong>cutters</strong>, this results in a furtherincrease in the tool life and an improved <strong>ball</strong> <strong>track</strong>geometry. A further positive effect of the helicalblade arrangement is that higher feed rates can beused. The resulting shorter cycle times increase theproductivity of the machine. Further savings areoffered by the tool logistics. Since the <strong>milling</strong> headsare disposable heads, regrinding and the associatedcosts are eliminated.Tool lifeThe right cutting material makes a major contributionto cost-effectiveness. <strong>MAPAL</strong> has vast experience inthe use of PCBN (polycrystalline cubic boron nitride)as cutting material for hard machining. The mostsuitable grade can be selected from a wide varietyof available materials. The cutting material can befully utilised, as the disposable heads do not have tobe reconditioned. Furthermore, a new, specially developedand very high-performance grade is availablefor the <strong>CPMill</strong> <strong>milling</strong> programme. Alongside connectionand blade arrangement, the right PCBN and thecareful processing of the cutting edge are thus thethird success factor for the new <strong>CPMill</strong> <strong>ball</strong> <strong>track</strong> <strong>milling</strong><strong>cutters</strong>.3

CFS – Complete Fitting SystemA perfect precision connectionThe exact interplay of taper and face contact ensures maximum stabilityand rigidity.Releasing und damping is performed from the front so that the tool holder can remainon the machine.Radial run-out less than 3 µm.4

Milling | <strong>CPMill</strong> - Complete Performance MillingThe objective in the development of the newconnection was to make the handling of thetipped tools as simple as possible. At the sametime, maximum stability and rigidity were tobe achieved, together with very high accuracyat tool changing.Precise designThe most important elements of the new connectionare the taper and face contact. The exact interplayof these elements ensures maximum stabilityand rigidity. Taper and face contact are complementedby a threaded journal directly adjoiningthe taper and connected to the taper in one piece.These three characteristics coordinated perfectlywith one another ensure the highest changeoveraccuracy, high clamping force and very simplehandling at the new connection. The positive interplayof face contact and taper has been knownsince the introduction of the HSK and HFS (HeadFitting System) by <strong>MAPAL</strong>, but only if these aremanufactured with the highest precision. Thatmeans the concentricity has to be 100%. The directconnection of the clamping thread has no impacton the radial run-out of the system as long as itruns with the same absolute precision as the otherelements.Absolute qualityModern production facilities allow face contact andtaper to be manufactured with the highest accuracy,and hence to reliably achieve a radial run-out ofbetter than 3 µm. The high stability of the systemresults from the pretension of the taper. Whenclamping completely, the taper expands slightly inthe holder and the face connection has a perfectcontact. Trials have also shown that the productionof the thread as a flat thread also contributes to ahigh radial run-out precision.Perfect fitThis new CFS connection perfectly meets the highdemands of hard <strong>milling</strong>. The exact balancing oftaper and face contact in the tool and in the holderguarantees maximum stability, and at the sametime has a damping effect that ensures long toollives of the tools. The use of carbide for the productionof the holder also helps to reduce vibrations.The holders thus consist of a steel tool body and ashrink-fitted sold carbide shank with the new CFSconnection.5

<strong>CPMill</strong> <strong>ball</strong> <strong>track</strong> <strong>milling</strong> <strong>cutters</strong>Ideal geometries and cutting materialsTOOL LIFE+30%Bladesaxially parallelNEWBladesin helical formProcess-reliable form and dimensional accuracy of the partComparison of tool life - The helical form surpasses axially parallel bladesSpecial PCBN grades for hard <strong>milling</strong>6

Milling | <strong>CPMill</strong> - Complete Performance MillingThe main challenge during <strong>ball</strong> <strong>track</strong> <strong>milling</strong> is toreliably achieve the demanded <strong>track</strong> clearance,fit and contact angle allowing for the adjustmentangle. The tolerances here lie in the µ-range.In order to be able to meet these high geometricdemands, <strong>ball</strong> <strong>track</strong> <strong>milling</strong> <strong>cutters</strong> have beenmade to date only with axially parallel solderedblades. <strong>MAPAL</strong> <strong>CPMill</strong> <strong>ball</strong> <strong>track</strong> <strong>milling</strong> <strong>cutters</strong>are now available in the new generation also withinclined (helically installed) blades. With speciallydeveloped 3D methods for the design, the latestproduction facilities and optimised measuring programmes,<strong>MAPAL</strong> can produce these replaceableheads also with the proven high accuracy. For themachining result that means higher <strong>milling</strong> quality,and at the same time improved cost-effectiveness.Soft cuttingDuring the <strong>milling</strong> of <strong>ball</strong> <strong>track</strong>s, the completegeometry of the tool is imaged in the workpiece.If vibrations occur during machining, these leadto deviations from the <strong>track</strong> form and to microstructurecracking at the blades. The helicallyarranged blades of the new <strong>CPMill</strong> <strong>ball</strong> <strong>track</strong><strong>milling</strong> <strong>cutters</strong> contact the workpiece with a softcut. Vibrations are practically eliminated comparedwith axially parallel blades. The result is smootherrunning of the tool, and hence a better <strong>track</strong> form andsurface quality. The smoother running also preventsmicrostructure cracking at the blades. The blade thusremains sharp for longer, and the tool life increases byup to 30% compared with tools with axially parallelblades.Optimum cutting materialOf crucial importance for the tool life is the cuttingmaterial. In this respect, the <strong>MAPAL</strong> <strong>CPMill</strong> <strong>ball</strong><strong>track</strong> <strong>milling</strong> <strong>cutters</strong> bring important furtherdevelopments to the market. New PCBN gradesoptimised and developed specially for hard <strong>milling</strong>allow the machining costs to be further reduced.Particularly important for the choice of the grade is adetailed analysis of the material to be machined.<strong>MAPAL</strong> offers know-how and engineering for completesupport – from the choice of the right PCBN gradethrough the optimisation of the existing productionprocess right up to Tool Management.Soft <strong>milling</strong><strong>MAPAL</strong> manufactures solid carbide <strong>milling</strong> headsfrom the <strong>CPMill</strong> Series also for soft <strong>milling</strong>, andthus offers a complete system for the machining ofconstant-velocity joints.7

<strong>MAPAL</strong> - the major specialistReaming and fine boringGun boring<strong>Dr</strong>illingActuatingMillingTurningClampingSetting and measuringCustomer servicesV1.0.0<strong>MAPAL</strong> Präzisionswerkzeuge <strong>Dr</strong>. <strong>Kress</strong> <strong>KG</strong>P.O. Box 1520 · D-73405 Aalen · Phone +49 (0) 7361 585-0 · Fax +49 (0) 7361 585-150info@de.mapal.com · www.mapal.com<strong>CPMill</strong>-E-01-010-0111-ZEL Printed in Germany. Right of technical modifications reserved.