Volume 16, No. 1 Winter 2011 - Marine Corps Systems Command

Volume 16, No. 1 Winter 2011 - Marine Corps Systems Command

Volume 16, No. 1 Winter 2011 - Marine Corps Systems Command

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Vo1. <strong>16</strong> <strong>No</strong>. 1 <strong>Winter</strong> <strong>2011</strong>Program ManagerFor AmmunitionMr. Jerry L. MazzaEditorMr. David DenomyIn this Issue:Message from the PMElectronic Daily UnitReport Page 3Improving QualityAssurancePage 4MARINE CORPSBy Jerry L. Mazza, PM Ammunition, <strong>Marine</strong> <strong>Corps</strong> <strong>Systems</strong> <strong>Command</strong>I welcome you to this winter edition of our Ammunition Quarterly,a periodical intended to provide information across the AmmunitionCommunity. Among that articles in this edition, I draw your focus tothe “Ammunition Career Roadmap” for our 2311’s and 2340’s.While not unique across all MOS’s, this roadmap provides acomprehensive career mapping of the community. Driven by LtColOliver and our Master Gunnery Sergeants, it represents a snapshot ofthe entire 2300 Occupational field, from potential billets by grade, tothe requisite and recommend training at all levels. This is anotherproduct of your Ammunition Logistics Focus Team (ALFT) and Ihope it provides each of you with a tool to assess your career growthin the community.Complimenting this effort, the ALFT has been busy in leading thedevelopment of our first every <strong>Marine</strong> <strong>Corps</strong> Order (MCO) onAmmunition Total Life Cycle Management (TCLM). We have asignificant number of policies at all levels – from DoD to DoN, to thenumerous <strong>Marine</strong> <strong>Corps</strong> Orders and bulletins that provide guidanceon a specific segment of our mission.What we do not have is a singular publication that connects themany policies together in a single document. Our MCO on TCLMattempts to link ALL the core functions, roles and responsibilitiesacross the MOS into broad document. The intent is to ensure thatthroughout the <strong>Corps</strong>, everyone from our Senior Leadership to themost junior have a source that prescribes the “who does what” in<strong>Marine</strong> <strong>Corps</strong> ammunition. Soon, this Order will be out for formalstaffing and I look forward to your comments. Along with therecently published <strong>Marine</strong> <strong>Corps</strong> Warfighing Publication 4.11.9 –Ammunition Logistics, this MCO will be complimentary to thatpublication and help us all in educating our own as well as thoseoutside our unique MOS.

<strong>Winter</strong> <strong>2011</strong>Face of DefensePage 9Ammunition TechnicianAward of the YearPage 10PromotionsPages 11-122311 RoadMapPage 132340 RoadMapPage 14-15As we continue our march into Fiscal Year 2012, a few words onthe “State Of Ammunition.” There were significant efforts betweenthe Deputy <strong>Command</strong>ant, Combat Development and Integration (DCCD&I) Ammo staff (LtCol Leighty and GySgt Cullen)and PM Ammo,in the development of the Program Objective Memorandum (POM) 13budgetary profile for conventional ammunition.With the drive for efficiencies and reductions, I feel thatcollectively, we advanced a plan that would provide for the futureammunition procurements while accepting risk in some of our TotalMunitions Requirements (TMR) demands. Much like othercommodities, ammunition is not fully funded thus, we will continue tomanage the best we can. I do foresee some support challenges in thefuture.I would hope that as our large procurement years that includedadditional Overseas Contingency Operations (OCO) funding continueto deliver over the next 2-3 years, good inventory managementpolicies and ammo discipline will help mitigate <strong>Marine</strong> Forcesimpacts.More than ever, now is the time to ensure we are judicious in our livefire training. It is imperative that we convey at all levels, theimportance of efficient and effective usage of this high costcommodity. Together, with your help, we can ensure sufficient assetsto train with while maintaining adequate war reserve munitions.I hope you find this edition of your Ammunition Quarterlyinformative and welcome you, each reader, each AmmunitionTechnician, and each Ammunition Officer to contribute future articlesof interest to all.Semper fi,2

<strong>Winter</strong> <strong>2011</strong>Electronic Daily Unit ReportElectronic Daily Unit ReportBy: CWO2 John J. (JJ) Scholten, Las Pulgas ASP OICCamp Pendleton, CAThe Electronic Daily Unit Report (eDUR) has beenreleased by the Las Pulgas Ammunition Supply Point.The eDUR is live on SharePoint and tracks the totalissues for the day. All users, both internal to theAmmunition Supply Point and external MajorSubordinate <strong>Command</strong>s (MSC’s) have visibility oftheir unit’s arrival, time issue commenced, and timethey departed. Additional features include the ASP’sability to enter remarks to explain a certain status. Inexample, the vehicle inspectors can provide real-timeinformation to the customer as to why their unit hasnot yet commenced their issue.This effort has assisted the customer and ASP alikeby providing better visibility of issue status. For thecustomer, they receive real-time information on theprogress of their issue. For the ASP, it has improveddocument flow and reduced customer wait-time byproviding the Sections with real-time information ondocument/issue status.The eDUR may be accessed at:https://1mlgsharepoint.nmci.usmc.mil/mse/clr15/1stSupplyBn/ammo/Shared%20Documents/DUR%20WP.aspx3

<strong>Winter</strong> <strong>2011</strong>Improving Quality Assurance<strong>Systems</strong> While BoostingProductivity.By CW02 Jeremy Parham OIC MCAGCC ASPIn December of 2009 the MCAGCC FieldAmmunition Supply Point had flooded and themajority of the ammunition was retrograded to theCenter Magazine Area for inspection, sentencing, andrepackaging. For the most part the ammunition wasdelivered in fairly poor condition and processed morelike a using unit turn in than a storage activity tostorage activity shipment.Over two months the ammunition was processedand hundreds of hand written DD Form 1348s andmaterial condition code tags were created and applied.Countless ammo cans and boxes were re-stenciled asthe ammunition was repackaged and consolidated. Asthe consolidation of the ammo progressed we startedto notice disparities in the uniformity of the taggingand marking of containers. Furthermore, most of themarkings did not contain all the required informationand needed to be reworked. Once the ammunitionfinally started moving back into storage dozens ofadditional errors were identified. Extensive causativeresearch would later show clerical errors, itemmisidentification, and overall lack of experience as theprimary causes.For the most part every company, business ororganization has at least one quality assurance systemthat systematically ensures the product meets thespecified requirements. For example <strong>Marine</strong> <strong>Corps</strong>ammunition supply points use the Monthly InventoryReview Report (MIRR) and Physical InventoryControl Program (PICP) to ensure inventory accuracyrequirements are being met. Both are excellent qualityassurance systems that provided useful andmeasureable results for the final product.The down side to such systems is they don’tprevent or catch errors before they happen. Toaddress this issue the Center Magazine Area hasdeveloped a supplemental quality assurance systemthat emphasizes catching errors before they get intothe final product.This system consists of an integrated QualityAssurance Team, a collection of automated toolsand an implementation plan that makes that makesthe system practical for everyday use. Due to thepreventive nature of this system it benefits thereceipt/sentencing inspection process, issues process,as well as maintenance processes when properlydeployed.From the start we wanted to create an integratedquality assurance team. By integrated I mean notonly do they perform receipt, sentencing, andinspections operations; but they directly participate inall aspects of daily operations. Currently the CMA’squality assurance team consists of three civilianemployees with ten or more years of ammunitionexperience. At the CMA the Storage Supervisor hasthe greatest visibility of friction points and thereforethe quality assurance team report directly to theStorage Supervisor. This ensures the qualityassurance team is employed at the greatest points offriction at the start of the operation and this alleviatessome of the problems cause by inexperiencedpersonnel.It is important to understand the quality assuranceteam augments the section or area supervisors and arenot a replacement for the Staff <strong>No</strong>n CommissionedOfficers or <strong>No</strong>n Commissioned Officers that shouldbe assigned to those key billets. An integrated teamwill also develop a strong working relationship withthe supported sections. This working relationship isvital because the quality assurance team fills the rolesof trainers, mentors, and coaches for all personnelinvolved in operations. After all, the purpose ofhiring civilian employees is to ensure continuity soestablished operating procedures are preserved overthe long term.At some point every facility should develop datamanagement tools that allow the user to completeprocesses correctly while minimizing data entry andduplication redundancy. Such tools are key to oursystem in preventing errors from being introducedinto the inventory. At the CMA we developed ourtools using a Microsoft Access database supported bydata downloaded from the Ordnance InformationSystem and the MAKE. Microsoft Access hasprovided plenty of functionality and we continue tofind new ways to incorporate it into our processes.Our database, AMMO TOOLS, is collection of about10 tools and at least five of those are used daily.4

<strong>Winter</strong> <strong>2011</strong>AMMO TOOLS SCREENCommon errors such as incorrect lots, invalid lot /NIIN combinations, invalid defect codes, and missedNARs practically never occur. <strong>No</strong>t having to paintand stencil most containers and the reduction of manhours is a significant side benefit as well. Thoughall are useful, the tools that support completing unitturns in, the creation of material condition code tags,and the production of labels are the most effective atpreventing errors and enforcing uniformity. To betterexplain; I will cover some of the more importantaspects of AMMO TOOLS in detail.When conducting unit turn- ins all sorts of thingscan be done incorrectly. Most often items aremisidentified, DD Form 1348s are not legible, missingrequired information, or the lot number is writtendown incorrectly. When designing the turn in portionof AMMO TOOLS we kept these things inmind and ensured the functionality managed theseproblems. (1348Front)(1348Back) Currently AMMOTOOLS Turn-Ins section provides the followingfunctionality:5

<strong>Winter</strong> <strong>2011</strong>At some point every section in the CMA will berequire to either re-label a can or apply MCC tags.These operations are supported by the AMMOTOOLS packaging section which provides thefollowing functionality:• Single document number entry displaysall documents associated to the turn-in.• Auto populates the DD Form 1348 basedoff the original issue document. Thisincludes document numbers, lot numbers,NSN, DODIC, UIC, and nomenclature.• Clearly displays original issue quantitiespreventing the turn-in quantity fromexceeding the issue quantity.• Requires application of defect codes toitems with NARS or not in CC A.• Limits defect codes to command approvedlist.• Checks for NARs.• Identifies the storage location of on handassets.• Generates inventory sheets for jointinventory.• Generates turn-in verification sheets insupport of PICP requirements.• Validates all required fields.• Supports serialized turn-ins.• Supports found on stations turn-ins.• Creates MCC tags.• Adds turn-in document number and dateto MCC Tag to assist with causativeresearch• Creates label.• Limits Lot/NSN combination to knowvalid combinations. This preventsuser from making up lots or applyinglots to improper NSN.• Displays appropriate MCC tag colorfor user reference.• Validates required fields.• Requires application of defect codes toitems with NARS or not in CC A.• Limits defect codes to commandapproved list.AMMO TOOLS also has some nice to have items.These items mostly provide visibility formanagement and consist of the following:• Transaction History Retrieval• NEW Report which includes NEW,hazard class, chemical symbols, andHERO.• Gain and Loss report• Reversal ReportUnfortunately all good things have a price. Thedevelopment of such tools can easily take severalweeks or more and the skills required to develop atool cannot be learned over night. A poorlydeveloped tool can be disastrous; potentiallyintroducing hundreds of errors into the inventorymaking thorough testing a must prior to deployment.Both parts of this system, Quality Assurance Teamand automated tools, require significanthardware/equipment investments to be deployedefficiently and effectively.6

<strong>Winter</strong> <strong>2011</strong>QA TeamWorkstationDespite the cost of hardware and equipmentcompromises cannot be made if you want the systemto be practical in application. If the quality assuranceteam takes 20-30 minutes to move from one locationto the next because they are walking or waiting fortransportation they do not have the flexibility toeffectively respond to calls of the sections they aresuppose to support. If a runner is required to use thetools developed to prevent errors from beingintroduced into the inventory efficiency will beextremely poor.To deploy our automated tools we createdworkstations. Each workstation consists or a laptopcomputer, Xerox Duplex capable printer, and a Zebralabel printer. Ten work stations are currentlydeployed in our busiest storage areas and twoworkstations are deployed on our operationalhardstand to support issues and receipts ofammunition.MCC Tag Generated7

<strong>Winter</strong> <strong>2011</strong>Mobile WorkstationWe also created four mobile workstations to supportsurge efforts and to provide support to locationswithout dedicated workstations.To maximize effectiveness and ensure at least onework station is always where it is needed most wechose to assign each member of the QualityAssurance Team and the Storage Supervisor themobile workstations.In the future we will continue working with theQuality Assurance Team in an attempt to find someadditional innovative ways to insert them into thedaily work load. Our current automated tools areconstantly under review and we will add more usefulfeatures over time. We do plan on developing someother tools before the end of <strong>2011</strong> if time andresources permit.Can Label GeneratedIf everything goes as planned we may see sometype of smarter forecasting tool for ASPs as well as atool that improves communication between the ASPand using unit. Neither is a typical ASP qualityassurance tool but better forecasting will hopefullylead to smaller more manageable inventories. Anyimprovement in the way using units do business willbe a step in the right direction.8

<strong>Winter</strong> <strong>2011</strong>Face of Defense: <strong>Marine</strong>sSupply Ammunition toTroopsBy Navy Petty Officer 2nd Class MatthewSnodgrassII <strong>Marine</strong> Expeditionary Force (Forward)CAMP LEATHERNECK, Afghanistan, Oct. 31,<strong>2011</strong> – A sophisticated supply system keepsammunition readily available for troops posted insouthwestern Afghanistan, according to a senior<strong>Marine</strong> <strong>Corps</strong> noncommissioned officer who’sinvolved in the effort.<strong>Marine</strong> <strong>Corps</strong> Lance Cpl. Timothy Oehlert guides an ammunition-ladenforklift at the supply point on Camp Leatherneck, Afghanistan, Oct. 21,<strong>2011</strong>. U.S. Navy photo by Petty Officer 2nd Class Matthew SnodgrassWe supply all [Regional <strong>Command</strong>] Southwestcoalition units with ammunition,” said <strong>Marine</strong> <strong>Corps</strong>Master Sgt. Adam Newsum, the ammunition supplypoint operations chief for 2nd <strong>Marine</strong> LogisticsGroup (Forward) here.Ammunition deliveries in Afghanistan areconducted by ground supply convoys or helicopter,said Newsum, a New York City native.“We make sure the ammunition is properly stored,transported, handled and inventoried,” he said, “andthen we get it to the warfighters so they can conducttheir missions.”Several units work together, Newsum said, tocoordinate the movement of a vast amount ofammunition to ensure <strong>Marine</strong>s and other troops inAfghanistan can accomplish their missions.Ammunition supplies, he said, must besystematically requested, tallied, and transported withefficiency and accuracy. Every shipment, he added,must be accounted for down to the last round -- quitea chore considering the numbers.“We supply anywhere between $7 and $12 milliondollars of ammunition a month to all the coalitionforces within Helmand province,” said <strong>Marine</strong> <strong>Corps</strong>Staff Sgt. Brian Taylor, who hails from Dayton,Ohio.Currently, Taylor said, about $250 million ofammunition has been distributed to Regional<strong>Command</strong> Southwest units.“We’ve moved almost $60 million worth of ammoover the past six months,” he added.Ammunition deliveries to Afghanistan are airliftedfrom Kuwait to Camp Leatherneck, Taylor explained.“Then we look at who in our inventory list needsammunition,” he continued, “and decide what will bethe most efficient way for it to get to their finallocations.”Ammunition is something most <strong>Marine</strong>s take forgranted “without realizing how much effort goes intoensuring they always have a constant supply,” Taylorsaid.“The <strong>Marine</strong>s I have out here get all the credit forgetting the job done,” Newsum said. “They’remotivated, disciplined and want to be here. For many,this is their second tour of duty out here or Iraq.We’re all glad to be helping our guys get themissions done.”9

<strong>Winter</strong> <strong>2011</strong>Ammunition Technicianof the Year AwardsOn the evening of 24 May <strong>2011</strong> Active DutyAmmunition Technicians along with one hundredfifty Retired Ammunition personnel, <strong>Marine</strong> <strong>Corps</strong>Association Representatives and AmmunitionIndustry Corporate sponsors gathered at theSpringfield Hilton in Springfield, Virginia to honorthe second Ammunition Technician of the YearAward recipients.Four awards were presented; The AmmunitionTechnician of the Year, Ammunition TechnicianNCO of the Year, Ammunition Technician SNCOof the Year, and Ammunition Officer of the Year.The recipients are: Lance Corporal Scott Todd, 3DSupply Battalion , CLR-35, Ammunition Company,3D MLG; Sgt Brynsela Alercia 1 st MARDIV(FWD), I MEF Afghanistan ; Staff SergeantMichael Ruegger, H&S Company, Task Force 2/3,RCT-1, 1 st MARDIV (FWD) ; CW04 Kurt Garrett,PM Ammo, MARCORSYSCOM.All were honored for their superior personalachievements in the course of their duties during2010 in support of Ammunition related duties.<strong>Command</strong>er, <strong>Marine</strong> <strong>Corps</strong> <strong>Systems</strong> <strong>Command</strong>,Brigadier General Frank Kelley was the guest ofhonor to present the recipients with their awards.Gunnery Sergeant Tasha Johnson who has allowedus to honor the memory of her husband by namingthe Ammunition Awards program was there tocongratulate the awardees.The Gunnery Sergeant Edwin Johnson Jr.Ammunition Technician of the Year Award isdedicated in the remembrance of one of our ownAmmunition Technicians, Gunnery Sergeant EdwinJohnson who was lost to us when his MobileTransition Team was ambushed during a patrol inKunar Province, Afghanistan, in support ofOperation Enduring Freedom on Sept 8, 2009. TheAward dinner allowed us the opportunity to honor afallen comrade as well as pay tribute to of our finestAmmunition Technicians in the <strong>Marine</strong> <strong>Corps</strong>today.These awards, approved by Headquarters <strong>Marine</strong><strong>Corps</strong>, will now be an annual event in continuing torecognize our Ammunition Community. We lookforward to seeing more of our community at the <strong>2011</strong>Ammo Tech of the year award. Keep Charging andThanks for all that each of you do every day to makeour Ammunition Community better.Semper FiLtCol John OliverBGen Frank Kelley presents Ammunition Technician of the YearAward to: LCPL Scott Todd with GySgt Tasha Johnson andSgtMaj James Dalgarn.BGen Frank Kelley presents Ammunition Technician <strong>Marine</strong>NCO of the Year Award to: Sgt Brynsela Alercia with GySgtTasha Johnson and SgtMaj James Dalgarn10

<strong>Winter</strong> <strong>2011</strong>BGen Frank Kelley presents Ammunition Technician SNCO ofthe Year Award to: SSgt Michael Ruegger with GySgt TashaJohnson and SgtMaj James Dalgarn.BGen Frank Kelley presents Ammunition Officer of the YearAward to: CW04 Kurt Garrett with GySgt Tasha Johnson andSgtMaj James DalgarnPromotionsWe would like to recognize the people who werepromoted since the last edition of AQ.Here are the LtCOL’sLtCol EMMINGER, R. F.LtCol MARCHAND, M. G.Here are the CAPT’sCapt MORRELL, G. L.Capt SMITH, M. G.Capt HECKENBERG, C. A.Here are the MAJ’sMaj STEVENS, DMaj HAMMERS, DHere is the CWO5CW05 GARRETT, K. C.11

<strong>Winter</strong> <strong>2011</strong>Here are the CWO4’sCWO4 HAREWOOD A. ACWO4 FOUCHI, S. T.Here are the WO’sWO COURTS, J. A.WO WHITE, T. J.WO RULLI JR, W. J.WO HILTON, E. P.WO DAVIS, J. C.HOLLINGSWORTH, J. H.Here are the CWO3’sCWO3 RODRIGUEZ, I.CWO3 ARNOLD, J. L.CWO3 ECKROTH, R. RCWO3 PARHAM, J. D.CWO3 HOSTUTTLER JR, D.CWO3 PETERS, T. E.CW03 XIMENEZ, R.CW03 FOGG, T. J.CW03 AMAYA, F. DCW03 SCHOLTEN, J. JCW03 MEDLEY, M. C.CW03 LAMSON, C. M.CW03 DEERING, C. L.MGySgt's for the 2311 community:MGySgt FIELDS, SMSgt's for the 2311 community:Here are the CWO2’sCWO2 QUEEN, E. G.CWO2 PULTORAK, M. SGySgt's for the 2311 community:GySgt GONZALES, IGySgt JONES, L.T.GySgt MERCADO, DGySgt PULIDO, AGySgt RODRIQUEZ, N.A.GySgt TAYLOR, B.L.12

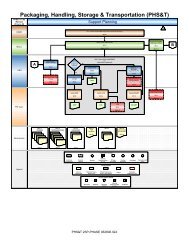

<strong>Winter</strong> <strong>2011</strong>2311RoadMapAmmunition Career Overview - MOS 2311 (Enlisted)Pvt / PFC / LCpl / Cpl / Sgt / SSgt / GySgt / MSgt / MGySgt13

<strong>Winter</strong> <strong>2011</strong>2340 CWO RoadMapAmmunition Career Overview – MOS 2340 (WO/CWO)WO / CWO2 / CWO3 / CWO4 / CWO514

<strong>Winter</strong> <strong>2011</strong>2340 LDO RoadMapAmmunition Career Overview – MOS 2340 (LDO)Capt / Major / LtCol15

<strong>16</strong><strong>Winter</strong> <strong>2011</strong>