Startup Challenges at PCU's SWTP

Startup Challenges at PCU's SWTP

Startup Challenges at PCU's SWTP

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

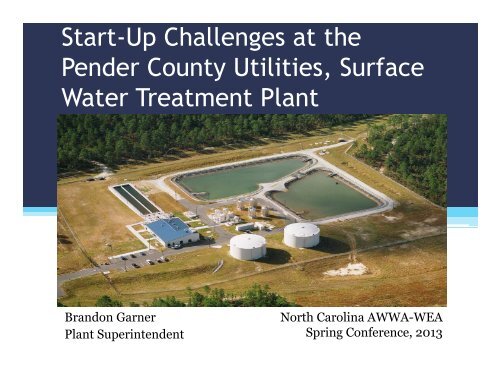

Start-Up <strong>Challenges</strong> <strong>at</strong> thePender County Utilities, SurfaceW<strong>at</strong>er Tre<strong>at</strong>ment PlantBrandon GarnerPlant SuperintendentNorth Carolina AWWA-WEASpring Conference, 2013

How It Happened• Background• The 3 Big <strong>Challenges</strong>▫ Filter Media Install<strong>at</strong>ion▫ Plant Disinfection▫ Plant Start-Up• Summary• Questions

HistoryPender County needed a sustainable w<strong>at</strong>erresource to provide w<strong>at</strong>er to the citizenry andindustry, and to allow for future expansion▫ Previously, Pender County Utilities was apurchase w<strong>at</strong>er system, buying w<strong>at</strong>er fromnearby Wallace

Wh<strong>at</strong>s the Answer for W<strong>at</strong>er?• Build a surface w<strong>at</strong>er tre<strong>at</strong>ment plant!• Dont forget to:▫ Meet current w<strong>at</strong>er demands▫ Meet future w<strong>at</strong>er needs in short-term▫ Allow for expansion to meet needs 10, 15, 20…yrs

Key Players▫ Pender County Utilities▫ Camp, Dresser, McKee and Smith▫ Crowder Construction Company▫ Industrial Control Systems

Honorable Mention▫ Public W<strong>at</strong>er Supply▫ Division of W<strong>at</strong>er Quality▫ Environmental Chemists, Inc.▫ Hach

Significant Facts• Total project cost was $30 Million▫ Included the plant and a pipeline project• Notable D<strong>at</strong>es▫ Notice to Proceed: Nov 1, 2010▫ Substantial Completion: Oct. 15, 2012▫ Final Approval: Nov 14, 2012

Plant Details

Interesting Plant Facts• Current production r<strong>at</strong>e isabout 1 MGD• Configured with 3 filtersallows maximum productionr<strong>at</strong>e of 4.5 MGD• Infrastructure is in place totre<strong>at</strong> 6 MGD• 7 members on plant staffincluding the dog!

Interesting Construction Facts• 6500 CYD concrete, 500 tons rebar, 26 tons ofcopper, and over 2000 electrical termin<strong>at</strong>ions• Clearwell 2 was selected as a bid altern<strong>at</strong>e• Ammonium Sulf<strong>at</strong>e and HFS feed systems inplace for the future

The 3 Big <strong>Challenges</strong>• Installing the Filter Media• Disinfection• Going Live

Big #1: Installing Filter Media• W<strong>at</strong>er Supply• Volume vs. Capacity

W<strong>at</strong>er Supply• No available w<strong>at</strong>er supply• Used an onsite well

Volume vs. Capacity• Approxim<strong>at</strong>ely 1 CW of w<strong>at</strong>er to adequ<strong>at</strong>elybackwash fines from media• Roughly 5 Days to fill CWs from the well

Timing is Everything!

Big #2: Disinfection• Where do you get w<strong>at</strong>er from• Procedure• Keep it Hot!

Where Does the W<strong>at</strong>er Come From?

Wh<strong>at</strong> is the ProcedureI know theres a chicken or an egg around heresomewhere!

Keep it Hot!• It was important to maintain chlorine residualsthroughout the process• After disinfection of a section was complete, thechlorine residuals had to stay up or it would voidthe entire process

Big #3: Going Live• SCADA-the alphabet test soup (UFT, WFT, ORT,FDT, PAT)• Mechanical Start-ups• Bringing the two together

Everybody In-the Road to FDT & PATPerformance Acceptance Test (30-Day Test)Functional Demonstr<strong>at</strong>ion TestICSCCCOper<strong>at</strong>ional Readiness TestMechanical Start-UpWitnessed Factory Test Electrical Start-UpUnwitnessed Factory Test Mechanical Install<strong>at</strong>ion

Summary• Birthday is Nov. 14, 2012• Big <strong>Challenges</strong>▫ Installing Filter Media▫ Disinfection▫ Going Live• Teamwork!

Questions?