Sleeve vs Antifriction Bearings - Siemens Industry, Inc.

Sleeve vs Antifriction Bearings - Siemens Industry, Inc.

Sleeve vs Antifriction Bearings - Siemens Industry, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

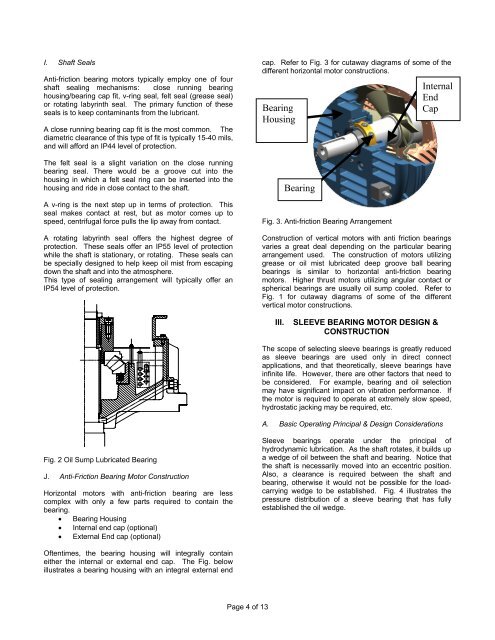

I. Shaft SealsAnti-friction bearing motors typically employ one of fourshaft sealing mechanisms: close running bearinghousing/bearing cap fit, v-ring seal, felt seal (grease seal)or rotating labyrinth seal. The primary function of theseseals is to keep contaminants from the lubricant.A close running bearing cap fit is the most common. Thediametric clearance of this type of fit is typically 15-40 mils,and will afford an IP44 level of protection.The felt seal is a slight variation on the close runningbearing seal. There would be a groove cut into thehousing in which a felt seal ring can be inserted into thehousing and ride in close contact to the shaft.A v-ring is the next step up in terms of protection. Thisseal makes contact at rest, but as motor comes up tospeed, centrifugal force pulls the lip away from contact.A rotating labyrinth seal offers the highest degree ofprotection. These seals offer an IP55 level of protectionwhile the shaft is stationary, or rotating. These seals canbe specially designed to help keep oil mist from escapingdown the shaft and into the atmosphere.This type of sealing arrangement will typically offer anIP54 level of protection.cap. Refer to Fig. 3 for cutaway diagrams of some of thedifferent horizontal motor constructions.BearingHousingBearingFig. 3. Anti-friction Bearing ArrangementInternalEndCapConstruction of vertical motors with anti friction bearingsvaries a great deal depending on the particular bearingarrangement used. The construction of motors utilizinggrease or oil mist lubricated deep groove ball bearingbearings is similar to horizontal anti-friction bearingmotors. Higher thrust motors utilizing angular contact orspherical bearings are usually oil sump cooled. Refer toFig. 1 for cutaway diagrams of some of the differentvertical motor constructions.III.SLEEVE BEARING MOTOR DESIGN &CONSTRUCTIONThe scope of selecting sleeve bearings is greatly reducedas sleeve bearings are used only in direct connectapplications, and that theoretically, sleeve bearings haveinfinite life. However, there are other factors that need tobe considered. For example, bearing and oil selectionmay have significant impact on vibration performance. Ifthe motor is required to operate at extremely slow speed,hydrostatic jacking may be required, etc.A. Basic Operating Principal & Design ConsiderationsFig. 2 Oil Sump Lubricated BearingJ. Anti-Friction Bearing Motor ConstructionHorizontal motors with anti-friction bearing are lesscomplex with only a few parts required to contain thebearing.• Bearing Housing• Internal end cap (optional)• External End cap (optional)<strong>Sleeve</strong> bearings operate under the principal ofhydrodynamic lubrication. As the shaft rotates, it builds upa wedge of oil between the shaft and bearing. Notice thatthe shaft is necessarily moved into an eccentric position.Also, a clearance is required between the shaft andbearing, otherwise it would not be possible for the loadcarryingwedge to be established. Fig. 4 illustrates thepressure distribution of a sleeve bearing that has fullyestablished the oil wedge.Oftentimes, the bearing housing will integrally containeither the internal or external end cap. The Fig. belowillustrates a bearing housing with an integral external endPage 4 of 13