You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

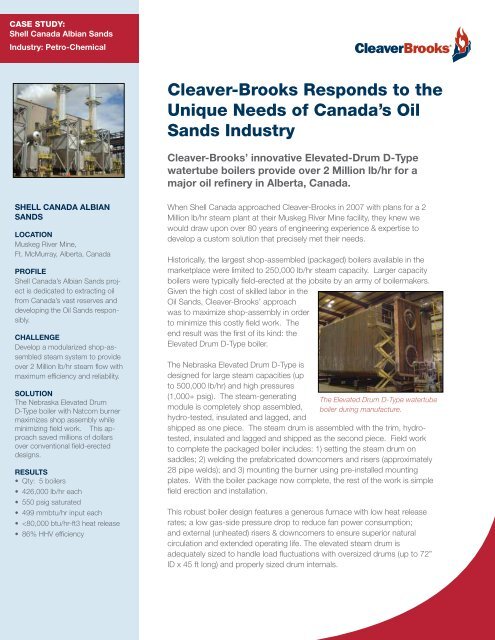

CASE STUDY:<strong>Shell</strong> <strong>Canada</strong> <strong>Albian</strong> <strong>Sands</strong>Industry: Petro-ChemicalCleaver-Brooks Responds to theUnique Needs of <strong>Canada</strong>’s Oil<strong>Sands</strong> IndustryCleaver-Brooks’ innovative Elevated-Drum D-Typewatertube boilers provide over 2 Million lb/hr for amajor oil refinery in Alberta, <strong>Canada</strong>.<strong>Shell</strong> <strong>Canada</strong> <strong>Albian</strong><strong>Sands</strong>LocationMuskeg River Mine,Ft. McMurray, Alberta, <strong>Canada</strong>Profile<strong>Shell</strong> <strong>Canada</strong>’s <strong>Albian</strong> <strong>Sands</strong> projectis dedicated to extracting oilfrom <strong>Canada</strong>’s vast reserves anddeveloping the Oil <strong>Sands</strong> responsibly.ChallengeDevelop a modularized shop-assembledsteam system to provideover 2 Million lb/hr steam flow withmaximum efficiency and reliability.SolutionThe Nebraska Elevated DrumD-Type boiler with Natcom burnermaximizes shop assembly whileminimizing field work. This approachsaved millions of dollarsover conventional field-erecteddesigns.Results• Qty: 5 boilers• 426,000 lb/hr each• 550 psig saturated• 499 mmbtu/hr input each•

Installation in progress.Each boiler also includes a dual burner,state-of-the-art, low NOx combustionsystem with rack-mounted fuel trainsincluding flame safety and combustioncontrols that maximize systemreliability and efficiency. Fuel skidswere pre-piped, pre-wired & testedat the factory. The original contractcalled for 76 ppm NOx emissions.Final source testing revealed that ourdesign achieved