Mixing and Granulation - GEA Pharma Systems

Mixing and Granulation - GEA Pharma Systems

Mixing and Granulation - GEA Pharma Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

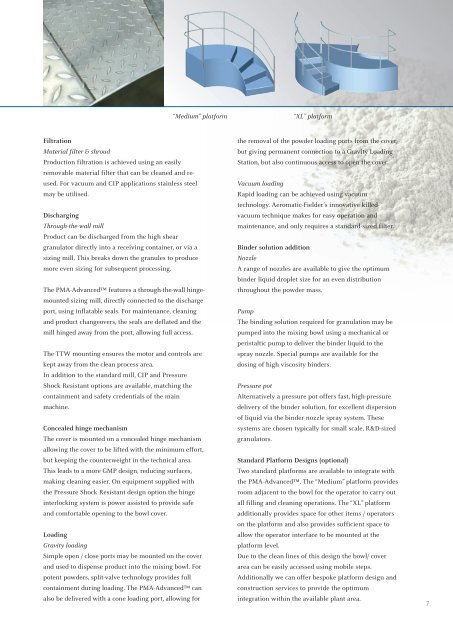

“Medium” platform“XL” platformFiltrationMaterial filter & shroudProduction filtration is achieved using an easilyremovable material filter that can be cleaned <strong>and</strong> reused.For vacuum <strong>and</strong> CIP applications stainless steelmay be utilised.DischargingThrough-the-wall millProduct can be discharged from the high sheargranulator directly into a receiving container, or via asizing mill. This breaks down the granules to producemore even sizing for subsequent processing.The PMA-Advanced features a through-the-wall hingemountedsizing mill, directly connected to the dischargeport, using inflatable seals. For maintenance, cleaning<strong>and</strong> product changeovers, the seals are deflated <strong>and</strong> themill hinged away from the port, allowing full access.The TTW mounting ensures the motor <strong>and</strong> controls arekept away from the clean process area.In addition to the st<strong>and</strong>ard mill, CIP <strong>and</strong> PressureShock Resistant options are available, matching thecontainment <strong>and</strong> safety credentials of the mainmachine.Concealed hinge mechanismThe cover is mounted on a concealed hinge mechanismallowing the cover to be lifted with the minimum effort,but keeping the counterweight in the technical area.This leads to a more GMP design, reducing surfaces,making cleaning easier. On equipment supplied withthe Pressure Shock Resistant design option the hingeinterlocking system is power assisted to provide safe<strong>and</strong> comfortable opening to the bowl cover.LoadingGravity loadingSimple open / close ports may be mounted on the cover<strong>and</strong> used to dispense product into the mixing bowl. Forpotent powders, split-valve technology provides fullcontainment during loading. The PMA-Advanced canalso be delivered with a cone loading port, allowing forthe removal of the powder loading ports from the cover,but giving permanent connection to a Gravity LoadingStation, but also continuous access to open the cover.Vacuum loadingRapid loading can be achieved using vacuumtechnology. Aeromatic-Fielder’s innovative killedvacuumtechnique makes for easy operation <strong>and</strong>maintenance, <strong>and</strong> only requires a st<strong>and</strong>ard-sized filter.Binder solution additionNozzleA range of nozzles are available to give the optimumbinder liquid droplet size for an even distributionthroughout the powder mass.PumpThe binding solution required for granulation may bepumped into the mixing bowl using a mechanical orperistaltic pump to deliver the binder liquid to thespray nozzle. Special pumps are available for thedosing of high viscosity binders.Pressure potAlternatively a pressure pot offers fast, high-pressuredelivery of the binder solution, for excellent dispersionof liquid via the binder nozzle spray system. Thesesystems are chosen typically for small scale, R&D-sizedgranulators.St<strong>and</strong>ard Platform Designs (optional)Two st<strong>and</strong>ard platforms are available to integrate withthe PMA-Advanced. The “Medium” platform providesroom adjacent to the bowl for the operator to carry outall filling <strong>and</strong> cleaning operations. The “XL” platformadditionally provides space for other items / operatorson the platform <strong>and</strong> also provides sufficient space toallow the operator interface to be mounted at theplatform level.Due to the clean lines of this design the bowl/ coverarea can be easily accessed using mobile steps.Additionally we can offer bespoke platform design <strong>and</strong>construction services to provide the optimumintegration within the available plant area.7