Mixing and Granulation - GEA Pharma Systems

Mixing and Granulation - GEA Pharma Systems

Mixing and Granulation - GEA Pharma Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

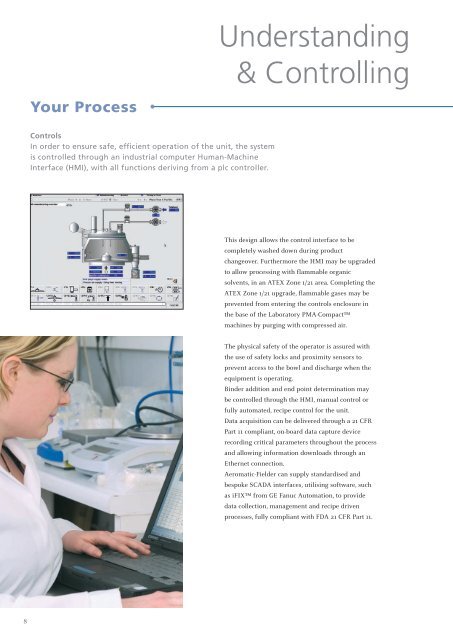

Underst<strong>and</strong>ing& ControllingYour Process•ControlsIn order to ensure safe, efficient operation of the unit, the systemis controlled through an industrial computer Human-MachineInterface (HMI), with all functions deriving from a plc controller.This design allows the control interface to becompletely washed down during productchangeover. Furthermore the HMI may be upgradedto allow processing with flammable organicsolvents, in an ATEX Zone 1/21 area. Completing theATEX Zone 1/21 upgrade, flammable gases may beprevented from entering the controls enclosure inthe base of the Laboratory PMA-Compactmachines by purging with compressed air.The physical safety of the operator is assured withthe use of safety locks <strong>and</strong> proximity sensors toprevent access to the bowl <strong>and</strong> discharge when theequipment is operating.Binder addition <strong>and</strong> end point determination maybe controlled through the HMI, manual control orfully automated, recipe control for the unit.Data acquisition can be delivered through a 21 CFRPart 11 compliant, on-board data capture devicerecording critical parameters throughout the process<strong>and</strong> allowing information downloads through anEthernet connection.Aeromatic-Fielder can supply st<strong>and</strong>ardised <strong>and</strong>bespoke SCADA interfaces, utilising software, suchas iFIX from GE Fanuc Automation, to providedata collection, management <strong>and</strong> recipe drivenprocesses, fully compliant with FDA 21 CFR Part 11.8