Cemsix - Barbour Product Search

Cemsix - Barbour Product Search

Cemsix - Barbour Product Search

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

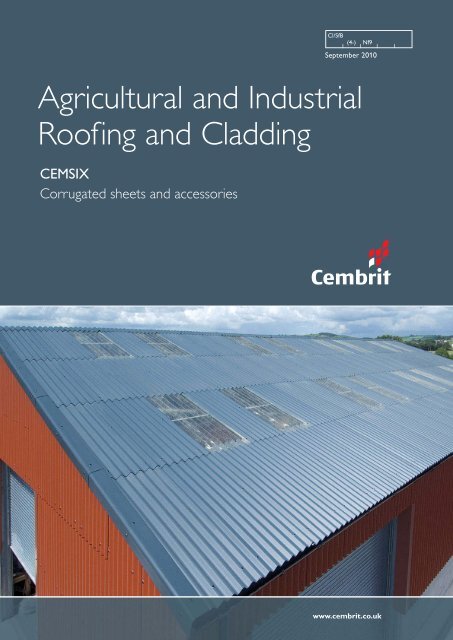

<strong>Cemsix</strong> CorrugatedSheetsProduced in the traditional 6" UK profile with 6 corrugations and overlaps/underlaps on both sides of the sheet, <strong>Cemsix</strong> is available in three colourationtypes, all with matching accessories; traditional grey fibre-cement corrugatedsheet, Cemscape ‘pre-weathered’ matt black fibre-cement corrugated sheet andcoloured corrugated sheet incorporating our unique 3 stage coating process.Natural GreyCemscapeColouredTile Red Spanish Red Laurel Green Olive Green MoccaVan Dyke Brown Cloud Grey Blue Blue/Black Black

www.cembrit.co.uk

<strong>Cemsix</strong> CorrugatedSheetsColouredtop coatPrimer coatCoated edgesAnti-blockon undersideBlue/BlackPolypropylene reinforcing stripsColourededges and endsTechnical InformationAvailable sheet lengths<strong>Cemsix</strong>WidthTranslucentSheet<strong>Cemsix</strong> width trimmedfor spaced roofingOverall widthNet covering widthThickness (nominal)1086mm1016mm6.0mm1375mm (4’6”) 1086mm 1000mm1525mm (5’) 1086mm 3 1000mm1675mm (5’6”) 1086mm 3 1000mmDensity (nominal) 1700kg/m 31825mm (6’) 1086mm 1000mmPitch of corrugationsOverall depthSide lapMinimum end lapMaximum purlin centresMaximum rail centresMaximum unsupported overhang146.5mm54mm70mm150mm1375mm1825mm350mm1975mm (6’6”) 1086mm 3 1000mm2125mm (7’) 1086mm 1000mm2275mm (7’6”) 1086mm 1000mm2440mm (8’) 1086mm 3 1000mm2600mm (8’6”) 1086mm 3 1000mm2750mm (9’) 1086mm 3 1000mm2900mm (9’6”) 1086mm 3 1000mmApproximate weight of roof as laid, with150mm end laps, single skin including fixings 17 kg/m 2Minimum pitch 5º3050mm (10’) 1086mm 3 1000mm3660mm (12’) 1086mm 3 1000mmTranslucent GRP rooflights are available in most common sheet lengths. They are used to provide naturalillumination to the interior. These fragile sheets must be fixed correctly complying to British Standards andHealth and Safety recommendations to reduce the risks of falls from height. Sheets must be fixed througheach corrugation at every purlin. Side laps must be stitched to adjacent sheets at max 450mm centres.

www.cembrit.co.uk

<strong>Cemsix</strong> CorrugatedAccessories<strong>Cemsix</strong> Barge Board<strong>Cemsix</strong> Roll Top BargeboardOne-piece FinialUsed to close verge at gable ends.Nominal 200mm wing for single skinconstructions and 300mm x 300mmfor double skin.Lengths: 2400 and 3000mmUsed to close verge at gable ends.Nominal 200mm wing for single skinconstructions and 300mm x 300mmfor double skin.Lengths: 1800mm (300mm x 300mm only),2500 mm and 3000mmUsed as an alternative to cranked plainwing bargeboard.200mm x 200mm<strong>Cemsix</strong> CrankedBarge Board<strong>Cemsix</strong> CrankedRoll Top BargboardTwo-piece RollTop FinialCloses verge apex when crown cranked ridgesheets are used.Available in 200mm x 200mm wing at1300mm girth (10º, 12.5º, 15º, 17.5º, 22.5º)and 2200mm girth (12.5º, 15º)Closes verge apex when crown cranked ridgesheets are used.Available in 1300mm girth300mm x 300mm wing (10º, 12.5º, 15º)200mm x 200mm wing (10º, 12.5º, 15º, 17.5º)Used as an alternative to cranked Roll TopBargeboard.200mm wing x 360mm deep300mm wing x 500mm deep* Please note the 1800m cranked crown sheets are fragile and further reinforcement will be required to conform with HSG 33

<strong>Cemsix</strong> CrankedCrown Ridge<strong>Cemsix</strong> Two-pieceClose Fitting Ridge<strong>Cemsix</strong> Two-piecePlain Wing RidgeTo suit a variety of roof pitches. 3 Girthsto provide smooth closure of roof apex.Available in 900mm (10º, 12.5º, 15º,17.5º, 22.5º)Available in 1200mm (12.5º, 15º)Available in 1800mm* (12.5º, 15º)Two piece ridge fitting adjustable to roofpitches not covered by standard crankedcrown ridges.370mm wingNet cover: 1016mm350 x 350 wingLength: 1160mmNet cover: 1060mm<strong>Cemsix</strong> Cranked CrownVentilation Ridge<strong>Cemsix</strong> Two-pieceVentilation Ridge<strong>Cemsix</strong> OpenProtected RidgeNormally used in single-skin construction,particularly in agricultural buildings.This fitment may not be fully weatherproofin swirling snow or rain.Available in 900mm (12.5º, 15º, 17.5º, 22.5º)Available in 1800mm (12.5º, 15º)Two piece ridge fitting adjustable to roofpitches not covered by standard crankedcrown ridges, to provide ventilation.Net cover: 1016mmPrevents rain ingress through ridge wheresheets finish short to allow ventilationthrough apex of roof.1500mm long with spigotNet cover: 1350mmwww.cembrit.co.uk

<strong>Cemsix</strong> CorrugatedAccessories (continued)Plain Wing Angle Ridge<strong>Cemsix</strong> Movement Joint<strong>Cemsix</strong> ApronFlashing Piece300 x 300 wing5º to 60º in 5º incrementsLength: 1200mmNet cover: 1080mmLength: 3000mmNet cover: 311mmUsed in long stretches of roofing andcladding to allow for expansion orstructural building movement.Used where cladding changes from pitchedto vertical or where sloping roof abuts abrick wall.Lengths: 1060mm left and right handNet cover: 1016mm<strong>Cemsix</strong> GRP Eaves Closer<strong>Cemsix</strong> GRP Eaves FillerUsed to prevent birds, vermin or winddriven particles entering at the eaves witha drip into the gutter.Net cover: 1016mmUsed to prevent birds, vermin or wind drivenparticles entering at the eaves and provides asoffit to the underside of the sheets.Net cover: 1016mm

PerformanceHealth and SafetyThe sheets incorporate polypropylene reinforcing strips forenhanced safety. They have been tested for fragility in accordancewith ACR(M) 001:2000 test for fragile roof assemblies (to classC) Impact Resistance Test Method and BS EN 15057:2006 FibreCement Profiled Sheets.Any roof or wall clad in sheets should be treated as fragile.Care must be taken when working on roofs and the precautionsdetailed in BS 5502-20:90 regarding permanent walkways mustbe followed.StrengthThe sheets are denoted Class C1X, having a minimumbreaking load of 4250Na and conform with the requirementsof BS EN 494:2004.FireWhen tested in accordance with BS 476-3:1958 sheets achievean EXT.S.AA designation. When tested in accordance withBS 476-6:1989 and BS 476-7:1997 sheets had a fire propagationindex of ≤3.5 sheets, a sub-index of ≤0.6 and a Class 1 surface.The sheets have a Class 0 surface and are deemed low risk andunrestricted by the requirements of National Building Regulations.DurabilityEvidence indicates that sheets should have a life far in excessof 30 years, with paint colour stability of 5 years. As with allcementitious material, the sheets will cure and weather over time.A 30 year guarantee is available on application.Installation<strong>Cemsix</strong> corrugated sheets are installed in accordance withBS 5502-21:1990, BS 5427-1:1976 and BS 8219:2001.www.cembrit.co.uk

Design SpecificationsDesign<strong>Cemsix</strong> corrugated sheet can be fixed to steel or timber purlins.Fixing holes should be predrilled, or self drilling self tapping top fix fixingscan be used. Fixing should be undertaken according to BS 8219:2001.PURLIN: the horizontalbars on the roof to whichthe sheets are fixedRAILS: the horizontalbars on the wall to whichthe sheets are fixedDirection of lay left to rightPrevailingWind DirectionPurlin spacings should be a maximum of 1375mmwith two fixings per purlin per sheet.

Design SpecificationsMitring schemeTo avoid having 4 layers of overlapping roof sheets,the corners of two sheets must be mitred.Each mitre must be cut straight and cleanly eitherby hand or by power saw. The angle and size of mitreis governed by the end and side lap dimensions. It isrecommended that a good quality butyl mastic stripis used to seal the overlapping sheets to provide aweatherproof join. Two corners of opposing sheetsshould be mitred the equivalent of the head and sidelap (i.e. maximum 70mm x 150mm) with a gap betweensheets of 3-6mm.150mm3 to 6mmSheets on the perimeter of the roof will have one mitre(except the first and last sheets which remain complete),all other sheets will therefore have two mitres.70mmSheets are laid from eaves to ridge one column at atime, with the side lap corresponding to the prevailingwind direction. On duo pitched roofs opposingcolumns of sheets should be installed sequentiallyto assist in locating the cranked crown (see below).150mmLaying sequence411Ridge512RidgecourseMitre613714CrankedCrown RidgeIntermediatecoursesMitre150 mm to300mm end lap310Eavescourse29Wind Direction18www.cembrit.co.uk

Design SpecificationsOverlap sealing – see tables on opposite pageThe overlaps on low pitched roofs should be sealed with butylstrips, creating a windproof joint and protecting the fixing holesfrom wind driven precipitation.Butyl StripPrevailingWind DirectionExampleIn this example lay right to left so side lap is protected from prevailing wind.

Sheltered to moderate sitesLess than 56.5 l/m 2 of wind-driven rain per spellMinimumRoof pitchMinimumEnd lapEnd lapstreatmentSide lapstreatment≥22 1 /2° 150mm Unsealed Unsealed≥15° 300mm Unsealed Unsealed≥15° 150mm Sealed Unsealed≥10° 150mm Sealed Sealed≥5° * 300mm Double sealed Sealed* The minimum pitch for <strong>Cemsix</strong> corrugated sheet is 5º. On roofpitches between 5º and 10º the maximum slope length is 15m.For longer spans please contact Cembrit for advice.Moderate to severe sitesLess than 56.5 l/m 2 of wind-driven rain per spellMinimumRoof pitchMinimumEnd lapEnd lapstreatmentSide lapstreatment≥25° 150mm Unsealed Unsealed≥17 1 /2° 150mm Sealed Unsealed≥15° 150mm Sealed Sealed≥10° 300mm Sealed Sealed≥5° * 300mm Double sealed Sealed* The minimum pitch for <strong>Cemsix</strong> corrugated sheet is 5º. On roofpitches between 5º and 10º the maximum slope length is 15m.For longer spans please contact Cembrit for advice.www.cembrit.co.uk

Design SpecificationsSite DustIf cutting or drillingsheets is likelyto result in dustgeneration, adequateventilation and/orprotection mustbe provided. Healthand Safety ExecutiveGuidance NoteEH 44 Dust inthe Workplace:general principlesof protection shouldbe followed.Standard RoofingNominaldepth54mmSpaced RoofingNominaldepth54mmlap70mmFixingFixingNominal pitch146.5mmnominal width 1086mmnet cover 1000mmNominal pitch146.5mmnet cover 1016mmFixingFixing

Design SpecificationsSheet fixingPre-drillingEvery sheet should be twice fixed at each purlin.It is extremely important that thecorrect roof purlins/rail system,type of fixing and washers areselected, to eliminate leakage/corrosion and the generaldeterioration of the construction.It is recommended that a self-drillingTop-Fix screw is adopted. Thissimple method offers a fast, lowcostfixing solution. Using a highspeedscrew gun, drive in the fixing.The fixing system is only suitable forroofs up to and including 30º pitch.Using a tungsten carbide tipped drillat 90º angle to the sheet, drill a hole2mm larger than the selected fixing.The drill point should be no less than60º to the sheet. Always drill at the‘apex’ of the profile. Do not fix asheet in the ‘valley’ or on a ‘slope’of the profile.NEVER hammer fixing throughthe sheet. This will invalidate theguarantee. Fibre-cement sheetswill shatter under impact andsubsequently allow water topenetrate the apparent fixing.ALWAYS pre-drill.To achieve a watertight andweathertight seal, it is important toconfirm that the sealing washer iscorrectly tightened. Not over tight,not too loose. After a period of time,when the material has settled, thefixings may require re-tighteningwith hand tools. Be sure to useroof ladders to avoid walking onthe roof sheets.Note: Where <strong>Cemsix</strong> is used as a vertical cladding, sheets should be fixed in the valley of the 1st corrugation in from the overlap.The following screws and washers are available ex-stock:120mm drive screws for timber purlins.105mm screws for Zed purlins between 1.6mmand 2.5mm thick steel.110mm self drilling steel screws for hot rolled steelbetween 3mm and 6mm thick steel.130mm screws for timber purlins.www.cembrit.co.uk

Storageand handling1. Coloured sheets and accessories should ideally be stored inside abuilding. Until the sheets are in position on the building they couldbe subject to damage from site debris and accidental collision.Rainwater, condensation and extreme weather conditions canalso adversely affect the sheets (particularly coloured sheets)during storage.2. Stacks without additional timber cross bearers should notexceed 1200mm. Cross bearers should be no more than onemetre apart. Different length sheets should ideally be stackedseparately, but if stacked with longer sheets they must be laidon the top and their cross bearers must line up vertically.3. The sheets are supplied covered in shrink-wrapping.It is strongly recommended that the wrapping is NOTremoved until the sheets are required for fixing. Shouldany sheets remain at the end of the working period theedges MUST BE COVERED.4. If several stacks are to be laid one on top of the other,timber cross bearers should be placed at 50mm intervalsup to a maximum height of 300mmIt is important that the ground is level and firm.If it is not possible to store theproduct inside a building, a suitablesite should be selected. The groundshould be firm and level and asclose to the construction work aspossible. The sheets must be stackedon cross bearers, thus raising themoff the ground. A simple protectiveframe should be constructed andcovered with a waterproof material.Air must be allowed to circulate allround the stack. The whole frame andstack should be tilted to encouragerainwater to drain freely.Crane handling should be carefulto avoid damage to the edges ofthe sheets. Use rope slings (notchains) and over-width spreaders toeliminate the possibility of damagingthe edges of the sheets.The corners of the sheets areparticularly vulnerable duringtransportation.Whether the product is storedinside or outside, the stacks shouldbe regularly inspected to ensurethat moisture has not penetratedthe coverings. Coloured sheets areparticularly vulnerable at this stage.Never push, drag or slide a sheetfrom a stack. Always consciouslyremove the sheet by lifting fromthe stack. Similarly, lift the sheet intoposition on a roof, do not push ordrag over the purlins or otherroof sheets.Recycling centre

www.cembrit.co.ukSports Pavilion

The information contained in this publication and otherwise suppliedto users of the company’s products is based on the company’s generalexperience, best knowledge and belief. However, because of factorsbeyond the company’s knowledge and control, which can affect theuse of the products, no warranty is given or implied with respect tosuch information.The company’s policy is one of continuous improvement.Cembrit Limited therefore reserves the right to alter specificationsat any time and without notice.Cembrit Ltd57 Kellner RoadLondonSE28 0AXTel: +44 (0)20 8301 8900Fax: +44 (0)20 8301 8901sales@cembrit.co.ukAs with all manufactured materials, colours and textures of corrugatedsheets and accessories may vary according to light and weather conditions.It is advisable to ask for samples of sheets prior to specification andpurchase. Owing to this and limitations of the printing process, coloursof sheets in this brochure may only be taken as indicative.Please ensure that you have the latest version of this datasheet bychecking that the publication date on the top right of the front covercorresponds with the downloadable version on our website.Branch listings51 London * T +44 (0)20 8301 89002 Southampton T +44 (0)23 8061 56313 Bovey Tracey T +44 (0)1626 8357224 Llandow * T +44 (0)1446 7737775 Normanton * T +44 (0)1924 8908903421* Main corrugated sheet branchwww.cembrit.co.uk