Chapter 47: Theory and Analysis of Structures - Free

Chapter 47: Theory and Analysis of Structures - Free

Chapter 47: Theory and Analysis of Structures - Free

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

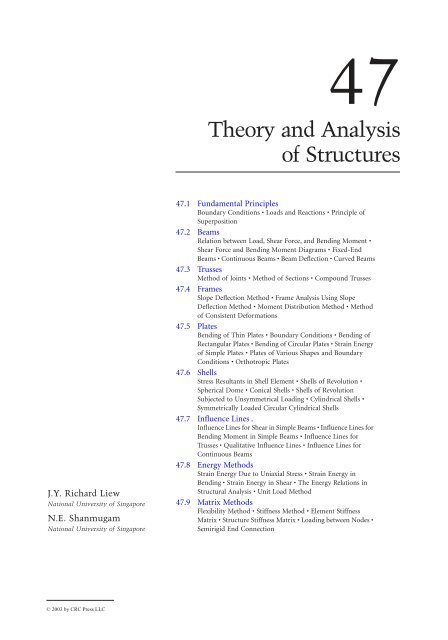

<strong>47</strong><strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong><strong>of</strong> <strong>Structures</strong>J.Y. Richard LiewNational University <strong>of</strong> SingaporeN.E. ShanmugamNational University <strong>of</strong> Singapore<strong>47</strong>.1 Fundamental PrinciplesBoundary Conditions • Loads <strong>and</strong> Reactions • Principle <strong>of</strong>Superposition<strong>47</strong>.2 BeamsRelation between Load, Shear Force, <strong>and</strong> Bending Moment •Shear Force <strong>and</strong> Bending Moment Diagrams • Fixed-EndBeams • Continuous Beams • Beam Deflection • Curved Beams<strong>47</strong>.3 TrussesMethod <strong>of</strong> Joints • Method <strong>of</strong> Sections • Compound Trusses<strong>47</strong>.4 FramesSlope Deflection Method • Frame <strong>Analysis</strong> Using SlopeDeflection Method • Moment Distribution Method • Method<strong>of</strong> Consistent Deformations<strong>47</strong>.5 PlatesBending <strong>of</strong> Thin Plates • Boundary Conditions • Bending <strong>of</strong>Rectangular Plates • Bending <strong>of</strong> Circular Plates • Strain Energy<strong>of</strong> Simple Plates • Plates <strong>of</strong> Various Shapes <strong>and</strong> BoundaryConditions • Orthotropic Plates<strong>47</strong>.6 ShellsStress Resultants in Shell Element • Shells <strong>of</strong> Revolution •Spherical Dome • Conical Shells • Shells <strong>of</strong> RevolutionSubjected to Unsymmetrical Loading • Cylindrical Shells •Symmetrically Loaded Circular Cylindrical Shells<strong>47</strong>.7 Influence Lines .Influence Lines for Shear in Simple Beams • Influence Lines forBending Moment in Simple Beams • Influence Lines forTrusses • Qualitative Influence Lines • Influence Lines forContinuous Beams<strong>47</strong>.8 Energy MethodsStrain Energy Due to Uniaxial Stress • Strain Energy inBending • Strain Energy in Shear • The Energy Relations inStructural <strong>Analysis</strong> • Unit Load Method<strong>47</strong>.9 Matrix MethodsFlexibility Method • Stiffness Method • Element StiffnessMatrix • Structure Stiffness Matrix • Loading between Nodes •Semirigid End Connection© 2003 by CRC Press LLC

<strong>47</strong>-2 The Civil Engineering H<strong>and</strong>book, Second Edition<strong>47</strong>.1 Fundamental Principles<strong>47</strong>.10 Finite Element MethodBasic Principle • Elastic Formulation • Plane Stress • PlaneStrain • Choice <strong>of</strong> Element Shapes <strong>and</strong> Sizes • Choice <strong>of</strong>Displacement Function • Nodal Degrees <strong>of</strong> <strong>Free</strong>dom •Isoparametric Elements • Isoparametric Families <strong>of</strong> Elements •Element Shape Functions • Formulation <strong>of</strong> Stiffness Matrix •Plates Subjected to In-Plane Forces • Beam Element • PlateElement<strong>47</strong>.11 Inelastic <strong>Analysis</strong>An Overall View • Ductility • Redistribution <strong>of</strong> Forces •Concept <strong>of</strong> Plastic Hinge • Plastic Moment Capacity • <strong>Theory</strong><strong>of</strong> Plastic <strong>Analysis</strong> • Equilibrium Method • MechanismMethod • <strong>Analysis</strong> Aids for Gable Frames • Grillages •Vierendeel Girders • Hinge-by-Hinge <strong>Analysis</strong><strong>47</strong>.12 Stability <strong>of</strong> <strong>Structures</strong>Stability <strong>Analysis</strong> Methods • Column Stability • Stability <strong>of</strong>Beam-Columns • Slope Deflection Equations • Second-OrderElastic <strong>Analysis</strong> • Modifications to Account for Plastic HingeEffects • Modification for End Connections • Second-OrderRefined Plastic Hinge <strong>Analysis</strong> • Second-Order Spread <strong>of</strong>Plasticity <strong>Analysis</strong> • Three-Dimensional Frame Element •Buckling <strong>of</strong> Thin Plates • Buckling <strong>of</strong> Shells<strong>47</strong>.13 Dynamic <strong>Analysis</strong>Equation <strong>of</strong> Motion • <strong>Free</strong> Vibration • Forced Vibration •Response to Suddenly Applied Load • Response to Time-Varying Loads • Multiple Degree Systems • Distributed MassSystems • Portal Frames • Damping • Numerical <strong>Analysis</strong>The main purpose <strong>of</strong> structural analysis is to determine forces <strong>and</strong> deformations <strong>of</strong> the structure due toapplied loads. Structural design involves form finding, determination <strong>of</strong> loadings, <strong>and</strong> proportioning <strong>of</strong>structural members <strong>and</strong> components in such a way that the assembled structure is capable <strong>of</strong> supportingthe loads within the design limit states. An analytical model is an idealization <strong>of</strong> the actual structure.The structural model should relate the actual behavior to material properties, structural details, loading,<strong>and</strong> boundary conditions as accurately as is practicable.<strong>Structures</strong> <strong>of</strong>ten appear in three-dimensional forms. For structures that have a regular layout <strong>and</strong> arerectangular in shape, subject to symmetric loads, it is possible to idealize them into two-dimensionalframes arranged in orthogonal directions. A structure is said to be two-dimensional or planar if all themembers lie in the same plane. Joints in a structure are those points where two or more members areconnected. Beams are members subjected to loading acting transversely to their longitudinal axis <strong>and</strong>creating flexural bending only. Ties are members that are subjected to axial tension only, while struts(columns or posts) are members subjected to axial compression only. A truss is a structural systemconsisting <strong>of</strong> members that are designed to resist only axial forces. A structural system in which jointsare capable <strong>of</strong> transferring end moments is called a frame. Members in this system are assumed to becapable <strong>of</strong> resisting bending moments, axial force, <strong>and</strong> shear force.Boundary ConditionsA hinge or pinned joint does not allow translational movements (Fig. <strong>47</strong>.1a). It is assumed to be frictionless<strong>and</strong> to allow rotation <strong>of</strong> a member with respect to the others. A roller permits the attached structuralpart to rotate freely with respect to the rigid surface <strong>and</strong> to translate freely in the direction parallel tothe surface (Fig. <strong>47</strong>.1b). Translational movement in any other direction is not allowed. A fixed support(Fig. <strong>47</strong>.1c) does not allow rotation or translation in any direction. A rotational spring provides some© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-3(a) Hinge support(b) Roller support(c) Fixed support(d) Rotational spring(e) Translational springFIGURE <strong>47</strong>.1 Various boundary conditions.rotational restraint but does not provide any translational restraint (Fig. <strong>47</strong>.1d). A translational springcan provide partial restraints along the direction <strong>of</strong> deformation (Fig. <strong>47</strong>.1e).Loads <strong>and</strong> ReactionsLoads that are <strong>of</strong> constant magnitude <strong>and</strong> remain in the original position are called permanent loads.They are also referred to as dead loads, which may include the self weight <strong>of</strong> the structure <strong>and</strong> otherloads, such as walls, floors, ro<strong>of</strong>, plumbing, <strong>and</strong> fixtures that are permanently attached to the structure.Loads that may change in position <strong>and</strong> magnitude are called variable loads. They are commonly referredto as live or imposed loads, which may include those caused by construction operations, wind, rain,earthquakes, snow, blasts, <strong>and</strong> temperature changes, in addition to those that are movable, such asfurniture <strong>and</strong> warehouse materials.Ponding loads are due to water or snow on a flat ro<strong>of</strong> that accumulates faster than it runs <strong>of</strong>f. Windloads act as pressures on windward surfaces <strong>and</strong> pressures or suctions on leeward surfaces. Impact loadsare caused by suddenly applied loads or by the vibration <strong>of</strong> moving or movable loads. They are usuallytaken as a fraction <strong>of</strong> the live loads. Earthquake loads are those forces caused by the acceleration <strong>of</strong> theground surface during an earthquake.A structure that is initially at rest <strong>and</strong> remains at rest when acted upon by applied loads is said to bein a state <strong>of</strong> equilibrium. The resultant <strong>of</strong> the external loads on the body <strong>and</strong> the supporting forces orreactions is zero. If a structure is to be in equilibrium under the action <strong>of</strong> a system <strong>of</strong> loads, it mustsatisfy the six static equilibrium equations:Â Fx = 0, Â Fy = 0, Â Fz= 0Â Mx = 0, Â My = 0, Â Mz= 0(<strong>47</strong>.1)The summation in these equations is for all the components <strong>of</strong> the forces (F) <strong>and</strong> <strong>of</strong> the moments(M) about each <strong>of</strong> the three axes x, y, <strong>and</strong> z. If a structure is subjected to forces that lie in one plane, sayx-y, the above equations are reduced to:Â Fx = 0, Â Fy = 0, Â Mz= 0(<strong>47</strong>.2)Consider a beam under the action <strong>of</strong> the applied loads, as shown in Fig. <strong>47</strong>.2a. The reaction at supportB must act perpendicular to the surface on which the rollers are constrained to roll upon. The support© 2003 by CRC Press LLC

<strong>47</strong>-4 The Civil Engineering H<strong>and</strong>book, Second Edition400 kNA5 mC60°5 mB30°(a) Applied load400 Sin 60° = 346.4 kNA x400 Cos 60° = 200 kN B xA yB yFIGURE <strong>47</strong>.2 Beam in equilibrium.reactions <strong>and</strong> the applied loads, which are resolved in vertical <strong>and</strong> horizontal directions, are shown inFig. <strong>47</strong>.2b.From geometry, it can be calculated that B y = 3B x 1. Equation (<strong>47</strong>.2) can be used to determine themagnitude <strong>of</strong> the support reactions. Taking moment about B givesfrom which10A y – 346.4 ¥ 5 = 0A y = 173.2 kNEquating the sum <strong>of</strong> vertical forces, SF y , to zero gives<strong>and</strong> hence we getTherefore173.2 + B y – 346.4 = 0B y = 173.2 kNEquilibrium in the horizontal direction, SF x = 0, gives<strong>and</strong> hence(b) Support reactionsB = B 3 = 100 kN.xyA x – 200 – 100 = 0A x = 300 kNThere are three unknown reaction components at a fixed end, two at a hinge, <strong>and</strong> one at a roller. If,for a particular structure, the total number <strong>of</strong> unknown reaction components equal the number <strong>of</strong>equations available, the unknowns may be calculated from the equilibrium equations, <strong>and</strong> the structureis then said to be statically determinate externally. Should the number <strong>of</strong> unknowns be greater than thenumber <strong>of</strong> equations available, the structure is statically indeterminate externally; if less, it is unstableexternally. The ability <strong>of</strong> a structure to support adequately the loads applied to it is dependent not onlyon the number <strong>of</strong> reaction components but also on the arrangement <strong>of</strong> those components. It is possiblefor a structure to have as many or more reaction components than there are equations available <strong>and</strong> yetbe unstable. This condition is referred to as geometric instability.© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-5Principle <strong>of</strong> SuperpositionThe principle states that if the structural behavior is linearly elastic, the forces acting on a structure maybe separated or divided into any convenient fashion <strong>and</strong> the structure analyzed for the separate cases.The final results can be obtained by adding up the individual results. This is applicable to the computation<strong>of</strong> structural responses such as moment, shear, deflection, etc.However, there are two situations where the principle <strong>of</strong> superposition cannot be applied. The firstcase is associated with instances where the geometry <strong>of</strong> the structure is appreciably altered under load.The second case is in situations where the structure is composed <strong>of</strong> a material in which the stress is notlinearly related to the strain.<strong>47</strong>.2 BeamsOne <strong>of</strong> the most common structural elements is a beam; it bends when subjected to loads actingtransversely to its centroidal axis or sometimes by loads acting both transversely <strong>and</strong> parallel to this axis.The discussions given in the following subsections are limited to straight beams in which the centroidalaxis is a straight line with a shear center coinciding with the centroid <strong>of</strong> the cross-section. It is alsoassumed that all the loads <strong>and</strong> reactions lie in a simple plane that also contains the centroidal axis <strong>of</strong> theflexural member <strong>and</strong> the principal axis <strong>of</strong> every cross-section. If these conditions are satisfied, the beamwill simply bend in the plane <strong>of</strong> loading without twisting.Relation between Load, Shear Force, <strong>and</strong> Bending MomentShear force at any transverse cross-section <strong>of</strong> a straight beam is the algebraic sum <strong>of</strong> the componentsacting transverse to the axis <strong>of</strong> the beam <strong>of</strong> all the loads <strong>and</strong> reactions applied to the portion <strong>of</strong> the beamon either side <strong>of</strong> the cross-section. Bending moment at any transverse cross-section <strong>of</strong> a straight beam isthe algebraic sum <strong>of</strong> the moments, taken about an axis passing through the centroid <strong>of</strong> the cross-section.The axis about which the moments are taken is, <strong>of</strong> course, normal to the plane <strong>of</strong> loading.When a beam is subjected to transverse loads, there exist certain relationships between load, shearforce, <strong>and</strong> bending moment. Let us consider the beam shown in Fig. <strong>47</strong>.3 subjected to some arbitraryloading, p. Let S <strong>and</strong> M be the shear <strong>and</strong> bending moment, respectively, for any point m at a distance x,which is measured from A, being positive when measured to the right. Corresponding values <strong>of</strong> the shear<strong>and</strong> bending moment at point n at a differential distance dx to the right <strong>of</strong> m are S + dS <strong>and</strong> M + dM,respectively. It can be shown, neglecting the second order quantities, thatdSp =dx(<strong>47</strong>.3)<strong>and</strong>S =dMdx(<strong>47</strong>.4)p/unit lengthAxx C× × × ×C m n Ddxx DLBFIGURE <strong>47</strong>.3 Beam under arbitrary loading.© 2003 by CRC Press LLC

<strong>47</strong>-6 The Civil Engineering H<strong>and</strong>book, Second EditionEquation (<strong>47</strong>.3) shows that the rate <strong>of</strong> change <strong>of</strong> shear at any point is equal to the intensity <strong>of</strong> loadapplied to the beam at that point. Therefore, the difference in shear at two cross-sections C <strong>and</strong> D isX DS - S = pÚ dxDC(<strong>47</strong>.5)X cWe can write this in the same way for moment asMDxD- MC= S dxÚxC(<strong>47</strong>.6)Shear Force <strong>and</strong> Bending Moment DiagramsIn order to plot the shear force <strong>and</strong> bending moment diagrams, it is necessary to adopt a sign conventionfor these responses. A shear force is considered to be positive if it produces a clockwise moment abouta point in the free body on which it acts. A negative shear force produces a counterclockwise momentabout the point. The bending moment is taken as positive if it causes compression in the upper fibers<strong>of</strong> the beam <strong>and</strong> tension in the lower fiber. In other words, a sagging moment is positive <strong>and</strong> a hoggingmoment is negative. The construction <strong>of</strong> these diagrams is explained with an example given in Fig. <strong>47</strong>.4.Section E <strong>of</strong> the beam is in equilibrium under the action <strong>of</strong> applied loads <strong>and</strong> internal forces actingat E, as shown in Fig. <strong>47</strong>.5. There must be an internal vertical force <strong>and</strong> internal bending moment tomaintain equilibrium at section E. The vertical force or the moment can be obtained as the algebraicsum <strong>of</strong> all forces or the algebraic sum <strong>of</strong> the moment <strong>of</strong> all forces that lie on either side <strong>of</strong> section E.The shear on a cross-section an infinitesimal distance to the right <strong>of</strong> point A is +55, <strong>and</strong> therefore theshear diagram rises abruptly from zero to +55 at this point. In portion AC, since there is no additionalload, the shear remains +55 on any cross-section throughout this interval, <strong>and</strong> the diagram is a horizontal,as shown in Fig. <strong>47</strong>.4. An infinitesimal distance to the left <strong>of</strong> C the shear is +55, but an infinitesimalx30 kN 4 kN/m 40 kNAC D E F3 4 6 8 955 kN30 m55+ 2511−343351265165B39 kN39FIGURE <strong>47</strong>.4 Bending moment <strong>and</strong> shear force diagrams.A55 kN4 kN/mEC D3 m 4 m 6 mVCTFIGURE <strong>47</strong>.5 Internal forces.© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-7distance to the right <strong>of</strong> this point the concentrated load <strong>of</strong> magnitude 30 has caused the shear to bereduced to +25. Therefore, at point C, there is an abrupt change in the shear force from +55 to +25. Inthe same manner, the shear force diagram for portion CD <strong>of</strong> the beam remains a rectangle. In portionDE, the shear on any cross-section a distance x from point D isS = 55 – 30 – 4x = 25 – 4xwhich indicates that the shear diagram in this portion is a straight line decreasing from an ordinate <strong>of</strong>+25 at D to +1 at E. The remainder <strong>of</strong> the shear force diagram can easily be verified in the same way. Itshould be noted that, in effect, a concentrated load is assumed to be applied at a point, <strong>and</strong> hence, atsuch a point the ordinate to the shear diagram changes abruptly by an amount equal to the load.In portion AC, the bending moment at a cross-section a distance x from point A is M = 55x. Therefore,the bending moment diagram starts at zero at A <strong>and</strong> increases along a straight line to an ordinate <strong>of</strong>+165 at point C. In portion CD, the bending moment at any point a distance x from C is M = 55(x +3) – 30x. Hence, the bending moment diagram in this portion is a straight line increasing from 165 atC to 265 at D. In portion DE, the bending moment at any point a distance x from D is M = 55(x + 7) –30(X + 4) – 4x 2 /22. Hence, the bending moment diagram in this portion is a curve with an ordinate <strong>of</strong>265 at D <strong>and</strong> 343 at E. In an analogous manner, the remainder <strong>of</strong> the bending moment diagram caneasily be constructed.Bending moment <strong>and</strong> shear force diagrams for beams with simple boundary conditions <strong>and</strong> subjectto some selected load cases are given in Fig. <strong>47</strong>.6.Fixed-End BeamsWhen the ends <strong>of</strong> a beam are held so firmly that they are not free to rotate under the action <strong>of</strong> appliedloads, the beam is known as a built-in or fixed-end beam <strong>and</strong> it is statically indeterminate. The bendingmoment diagram for such a beam can be considered to consist <strong>of</strong> two parts viz. the free bending momentdiagram obtained by treating the beam as if the ends are simply supported <strong>and</strong> the fixing moment diagramresulting from the restraints imposed at the ends <strong>of</strong> the beam. The solution <strong>of</strong> a fixed beam is greatlysimplified by considering Mohr’s principles, which state that:1. The area <strong>of</strong> the fixing bending moment diagram is equal to that <strong>of</strong> the free bending momentdiagram.2. The centers <strong>of</strong> gravity <strong>of</strong> the two diagrams lie in the same vertical line, i.e., are equidistant froma given end <strong>of</strong> the beam.The construction <strong>of</strong> the bending moment diagram for a fixed beam is explained with an exampleshown in Fig. <strong>47</strong>.7. P Q U T is the free bending moment diagram, M s , <strong>and</strong> P Q R S is the fixing momentdiagram, M i . The net bending moment diagram, M, is shaded. If A s is the area <strong>of</strong> the free bending momentdiagram <strong>and</strong> A i the area <strong>of</strong> the fixing moment diagram, then from the first Mohr’s principle we haveA s = A i <strong>and</strong>12Wab 1¥ ¥ L = (L 2 M A + M B) ¥ LM M WabA + B =L(<strong>47</strong>.7)From the second principle, equating the moment about A <strong>of</strong> A s <strong>and</strong> A i , we have2 2( )WabMA+ 2MB= 2a + 3ab+b3L(<strong>47</strong>.8)© 2003 by CRC Press LLC

<strong>47</strong>-8 The Civil Engineering H<strong>and</strong>book, Second EditionLOADING SHEAR FORCE BENDING MOMENTq o / unit lengthxA C Ba bLR AR A = q o aM x = q ox 22M max = q oa 22q o / unit lengthA C Ba bLR AR A = q o bM max = q o b a + b − 2q o / unit lengthA C D Ba b cLq oA C Ba bLR AR AR A = q o bR A = q oa2M max = q o b a + b − 2xM x = q ox36aM max = q oa 26PAaCLb BR AR A = PM maxxM x = P.xM max = P.aMAAaR AC Ba bLq oBbLR Bs = a − LR AZero shearR A = q oa s 1−−32R B = q oas6R BxM max = M x = MxM max = q oa 2 1− s + 2 s6 3when x = a 1−s−3s −3FIGURE <strong>47</strong>.6 Shear force <strong>and</strong> bending moment diagrams for beams with simple boundary conditions subjected toselected loading cases.Solving Eqs. (<strong>47</strong>.7) <strong>and</strong> (<strong>47</strong>.8) for M A <strong>and</strong> M B we getMMAB=Wab2L2Wa 2=b2L© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-9LOADING SHEAR FORCE BENDING MOMENTR AAaR Aq oLbBR BR A = q oa 2b1 −2 3R B = q oa b3R BxM max = q oa 2 1− 2 b 3/23 3When x = a 1 − 2 b3PR AAR AL/2LBR BR A = R B = P − 2R BM max = P L4PPAaR ALBaR BR A = R B = PM max = PaPAaR ALbBR BR AR A = Pb/LR BR B = Pa/LM max = Pa bLPPR AA C D Ba b cLR A a > cR BRA = P(b + 2c)LR B = P(b +2a)LR BM C = Pa(b + 2c)LM D = Pc(b + 2a)LPPABL/3 L/3 L/3LR AR BR AR A = R B = PR BM max = P L3P P PA C D E BL/6 L/3 L/3 L/6LR AR BR AR A = R B = 3 P2R BM C = M E = P L4M D = 5 PL12FIGURE <strong>47</strong>.6 (continued).Shear force can be determined once the bending moment is known. The shear force at the ends <strong>of</strong> thebeam, i.e., at A <strong>and</strong> B, areSSABM=M=AB- ML- MLBending moment <strong>and</strong> shear force diagrams for fixed-end beams subjected to some typical loadingcases are shown in Fig. <strong>47</strong>.8.BA++WbLWaL© 2003 by CRC Press LLC

<strong>47</strong>-10 The Civil Engineering H<strong>and</strong>book, Second EditionLOADING SHEAR FORCE BENDING MOMENTPPPR AA C D E BL/4 L/4 L/4 L/4LR AR BR A = R B = 3 P2R BM C = M E = 3P L8M D = P L2PPPPR AA C D E F BL/8 L/4 L/4 L/4 L/8LR AR BR A = R B = 2PR BM C = M F = P L4M D = M E = P L2q o = unit loadSC A D B ES LR AR BR AR A = R B = q o S + L − 2RBM A = M B = − q oS 22M D = q o8L 2 + M Aq o = unit loadR BC A D B ES L SR AR BR AR A = R B = q o SM A = M B = − q oS 22q o = unit loadC AB DS LR AQR BR AR BR A = q o (S + L) 2 R2 L B = q o (L + S) ( L − S)2Lq o L 2 /8M A = q oS 22FIGURE <strong>47</strong>.6 (continued).AaLWTbBSM APWabLURQM BFIGURE <strong>47</strong>.7 Fixed-end beam.Continuous BeamsContinuous beams like fixed-end beams are statically indeterminate. Bending moments in these beamsare functions <strong>of</strong> the geometry, moments <strong>of</strong> inertia, <strong>and</strong> modulus <strong>of</strong> elasticity <strong>of</strong> individual members,besides the load <strong>and</strong> span. They may be determined by Clapeyron’s theorem <strong>of</strong> three moments, themoment distribution method, or the slope deflection method.An example <strong>of</strong> a two-span continuous beam is solved by Clapeyron’s theorem <strong>of</strong> three moments. Thetheorem is applied to two adjacent spans at a time, <strong>and</strong> the resulting equations in terms <strong>of</strong> unknownsupport moments are solved. The theorem states that© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-11LOADING SHEAR FORCE BENDING MOMENTWAAA CadWq oA C BLA CaLPPCLq o /unit lengthDbLLq o /unit lengthPeA C BL/2 L/2bPBBA C D BL/3 L/3 L/3cBBq oM A M BR AR BM A = M B = − q o L212R A = R B = q o L/2M C = q o L224R AR B M AM BWhen r is the simple support reaction −qM A = o [e 3 (4L − 3e) − c 3 (4L − 3c)]R A = r A + M A − M BRL B = r B + M B − M 12LbA −qL M B = o [d 3 (4L − 3d) − a 3 (4L − 3a)]12Lbx M xMR AM BAR Bq o L 2MR A = 0.15q o L R B = 0.35q o Lx = − 10x 3J60 L 3 − 9x + 2NL+ M max = q o L2 /46.6 when x = 0.55LM A = − q o L 2 /30 M B = − q o L2 /20q o L 2 /32R AR M BAM BR A = R B = q o L/45q o L 2M A = M B = −96R M AC = PL8R B M AM BR A = R B = P/2M A = M B = − PL/8R A2Pa 2 b 2RM C =BL 3R A = P Jb − 2 N J1 + 2 a M−NAMBL LR B = P Ja − 2 N J1 + 2 b Pab 2Pba 2−M MNA = −B = −L L L 2L 2R AR BR A = R B = PM APL/9M A = M B = − 2PL/9MBFIGURE <strong>47</strong>.8 Shear force <strong>and</strong> bending moment diagrams for built-up beams subjected to typical loading cases.Ê AxMAL1 + 2MB L1 + L2 MCL26ÁË L1 1( ) + = +1Ax ˆ2 2L˜¯2(<strong>47</strong>.9)in which M A , M B , <strong>and</strong> M C are the hogging moment at supports A, B, <strong>and</strong> C, respectively, <strong>of</strong> two adjacentspans <strong>of</strong> length L 1 <strong>and</strong> L 2 (Fig. <strong>47</strong>.9); A 1 <strong>and</strong> A 2 are the area <strong>of</strong> bending moment diagrams produced bythe vertical loads on the simple spans AB <strong>and</strong> BC, respectively; x 1 is the centroid <strong>of</strong> A 1 from A; <strong>and</strong> x 2 isthe distance <strong>of</strong> the centroid <strong>of</strong> A 2 from C. If the beam section is constant within a span but remainsdifferent for each <strong>of</strong> the spans Eq. (<strong>47</strong>.9) can be written as© 2003 by CRC Press LLC

<strong>47</strong>-12 The Civil Engineering H<strong>and</strong>book, Second EditionLOADING SHEAR FORCE BENDING MOMENTP P PA C D E BL/6 L/3 L/3 L/6R A = R B = 3P/2R AM D =11PL/72R BM A PL/4M BM A = M B = −19PL/72P P PA C D E BL/4 L/4 L/4 L/4R AR A = R B = 3P/2 R BM AM D = 3PL/163PL/8 M BM A = M B = −5PL/16P P P PM D = M E = 5PL/32A C D E FBL/8 L/4 L/4 L/4 L/8R AR A = R B = 2P R BM APL/4M BM A = M B = −11PL/32FIGURE <strong>47</strong>.8 (continued).ABCLoadL 2L 1M BM CM AA 1 A 2x 1 x 2BendingmomentFIGURE <strong>47</strong>.9 Continuous beams.ML IÊML L ˆM L 1 22Ax1 1Ax2 2+ 2 Á +6Ë I I ¯˜ + I= ÊLI+ ˆÁË LI˜¯1A B C11 22112 2(<strong>47</strong>.10)in which I 1 <strong>and</strong> I 2 are the moments <strong>of</strong> inertia <strong>of</strong> the beam sections in spans L 1 <strong>and</strong> L 2 , respectively.Example <strong>47</strong>.1The example in Fig. <strong>47</strong>.10 shows the application <strong>of</strong> this theorem.For spans AC <strong>and</strong> BCÈMA ¥ 10 + 2MC( 10 + 10) + MB¥ 10 = 6 ÍÎ¥ 500 ¥ 10 ¥ 5 ¥ 250 ¥ 10 ¥ 5˘+1010˙˚1212Since the support at A is simply supported, M A = 0. Therefore,4M C + M B = 1250 (<strong>47</strong>.11)Considering an imaginary span BD on the right side <strong>of</strong> B <strong>and</strong> applying the theorem for spans CB <strong>and</strong> BD© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-13A200 kN 20 kN/mCIIBD5 m 10 m 10 m500285.7 250107.271.4117.9Spans AC <strong>and</strong> BCFIGURE <strong>47</strong>.10 Example <strong>of</strong> a continuous beam.128.682.1M 10 2M 10 M 10 6¥ + ( ) + ¥ = ¥C B DM + 2M = 500 QM -M23C B C D¥ 10 ¥ 5 ¥ 210( )(<strong>47</strong>.12)Solving Eqs. (<strong>47</strong>.11) <strong>and</strong> (<strong>47</strong>.12) we getM B = 107.2 kNmM C = 285.7 kNmShear force at A isSAM=A- MLC+ 100 = - 28. 6 + 100 = 71.4 kNShear force at C isSCÊ M= ÁË- MLˆ Ê M - Mˆ+ 100˜ + Á+ 100˜¯ Ë L¯C A C B( ) + ( + ) == 28. 6 + 100 17. 9 100 246.5kNShear force at B isThe bending moment <strong>and</strong> shear force diagrams are shown in Fig. <strong>47</strong>.10.Beam DeflectionSBÊ M= ÁËB- ML=- 17. 9 + 100 = 82.1kNThere are several methods for determining beam deflections: (1) moment area method, (2) conjugatebeam method, (3) virtual work, <strong>and</strong> (4) Castigliano’s second theorem, among others.The elastic curve <strong>of</strong> a member is the shape the neutral axis takes when the member deflects underload. The inverse <strong>of</strong> the radius <strong>of</strong> curvature at any point <strong>of</strong> this curve is obtained asCˆ+ 100˜¯© 2003 by CRC Press LLC

<strong>47</strong>-14 The Civil Engineering H<strong>and</strong>book, Second Edition1 M=R EI(<strong>47</strong>.13)in which M is the bending moment at the point <strong>and</strong> EI the flexural rigidity <strong>of</strong> the beam section. Sincethe deflection is small, 1/R is approximately taken as d 2 y/dx 2 , <strong>and</strong> Eq. (<strong>47</strong>.13) may be rewritten as:M = EI2dy2dx(<strong>47</strong>.14)In Eq. (<strong>47</strong>.14), y is the deflection <strong>of</strong> the beam at distance x measured from the origin <strong>of</strong> coordinate.The change in slope in a distance dx can be expressed as M dx/EI, <strong>and</strong> hence the slope in a beam isobtained asqBBM- qA=Ú EI dxA(<strong>47</strong>.15)Equation (<strong>47</strong>.15) may be stated: the change in slope between the tangents to the elastic curve at twopoints is equal to the area <strong>of</strong> the M/EI diagram between the two points.Once the change in slope between tangents to the elastic curve is determined, the deflection can beobtained by integrating further the slope equation. In a distance dx the neutral axis changes in directionby an amount dq. The deflection <strong>of</strong> one point on the beam with respect to the tangent at another pointdue to this angle change is equal to dd = x dq, where x is the distance from the point at which deflectionis desired to the particular differential distance.To determine the total deflection from the tangent at one point, A, to the tangent at another point,B, on the beam, it is necessary to obtain a summation <strong>of</strong> the products <strong>of</strong> each dq angle (from A to B)times the distance to the point where deflection is desired, ordBBMx dx- dA=Ú EIA(<strong>47</strong>.16)The deflection <strong>of</strong> a tangent to the elastic curve <strong>of</strong> a beam with respect to a tangent at another pointis equal to the moment <strong>of</strong> M/EI diagram between the two points, taken about the point at which deflectionis desired.Moment Area MethodThe moment area method is most conveniently used for determining slopes <strong>and</strong> deflections for beamsin which the direction <strong>of</strong> the tangent to the elastic curve at one or more points is known, such as cantileverbeams, where the tangent at the fixed end does not change in slope. The method is applied easily tobeams loaded with concentrated loads, because the moment diagrams consist <strong>of</strong> straight lines. Thesediagrams can be broken down into single triangles <strong>and</strong> rectangles. Beams supporting uniform loads oruniformly varying loads may be h<strong>and</strong>led by integration. Properties <strong>of</strong> some <strong>of</strong> the shapes <strong>of</strong> M/EIdiagrams that designers usually come across are given in Fig. <strong>47</strong>.11.It should be understood that the slopes <strong>and</strong> deflections obtained using the moment area theorems arewith respect to tangents to the elastic curve at the points being considered. The theorems do not directlygive the slope or deflection at a point in the beam compared to the horizontal axis (except in one or twospecial cases); they give the change in slope <strong>of</strong> the elastic curve from one point to another or the deflection<strong>of</strong> the tangent at one point with respect to the tangent at another point. There are some special cases inwhich beams are subjected to several concentrated loads or the combined action <strong>of</strong> concentrated <strong>and</strong>uniformly distributed loads. In such cases it is advisable to separate the concentrated loads <strong>and</strong> uniformly© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-15Center <strong>of</strong> gravityCenter <strong>of</strong> gravityfor half parabolaab + a + b33(a)5 −8 −23 −8 −2Center <strong>of</strong> gravityA = w a312aCenter <strong>of</strong> gravityyFIGURE <strong>47</strong>.11 Typical M/EI diagram. −2a−2 −2(b)w = uniform loadw K− O(a)( − a)2 + a(c)y = kx nyA = n + 1xx = n + 1n + 2 q/unit lengthAL/2EILq28EIL/2BMEI diagramδ cδ 3 = 1qq4δ 1 = 2 4EIq4δ 2 = 4 8EI428EIFIGURE <strong>47</strong>.12 Deflection — simply supported beam under UDL.distributed loads, <strong>and</strong> the moment area method can be applied separately to each <strong>of</strong> these loads. Thefinal responses are obtained by the principle <strong>of</strong> superposition.For example, consider a simply supported beam subjected to uniformly distributed load q, as shownin Fig. <strong>47</strong>.12. The tangent to the elastic curve at each end <strong>of</strong> the beam is inclined. The deflection, d 1 , <strong>of</strong>the tangent at the left end from the tangent at the right end is found as ql 4 /24EI. The distance from theoriginal chord between the supports <strong>and</strong> the tangent at the right end, d 2 , can be computed as ql 4 /48EI.© 2003 by CRC Press LLC

<strong>47</strong>-16 The Civil Engineering H<strong>and</strong>book, Second EditionCQQC′A 1 A′ ANO′ 1 N1 O 1 OP′ 1 P 1 PB′ B 1 BQQDyEANOB(a)(b)FIGURE <strong>47</strong>.13 Bending <strong>of</strong> curved beams.The deflection <strong>of</strong> a tangent at the center from a tangent at the right end, d 3 , is determined as ql 4 /128EI.The difference between d 2 <strong>and</strong> d 3 gives the centerline deflection as (5/384) x (ql 4 /EI).Curved BeamsThe beam formulas derived in the previous section are based on the assumption that the member to whichbending moment is applied is initially straight. Many members, however, are curved before a bendingmoment is applied to them. Such members are called curved beams. In the following discussion all theconditions applicable to straight-beam formulas are assumed valid, except that the beam is initially curved.Let the curved beam DOE shown in Fig. <strong>47</strong>.13 be subjected to the load Q. The surface in which thefibers do not change in length is called the neutral surface. The total deformations <strong>of</strong> the fibers betweentwo normal sections, such as AB <strong>and</strong> A 1 B 1 , are assumed to vary proportionally with the distances <strong>of</strong> thefibers from the neutral surface. The top fibers are compressed, while those at the bottom are stretched,i.e., the plane section before bending remains plane after bending.In Fig. <strong>47</strong>.13 the two lines AB <strong>and</strong> A 1 B 1 are two normal sections <strong>of</strong> the beam before the loads areapplied. The change in the length <strong>of</strong> any fiber between these two normal sections after bending isrepresented by the distance along the fiber between the lines A 1 B 1 <strong>and</strong> A¢B¢; the neutral surface isrepresented by NN 1 , <strong>and</strong> the stretch <strong>of</strong> fiber PP 1 is P 1 P ¢ 1 , etc. For convenience, it will be assumed thatline AB is a line <strong>of</strong> symmetry <strong>and</strong> does not change direction.The total deformations <strong>of</strong> the fibers in the curved beam are proportional to the distances <strong>of</strong> the fibersfrom the neutral surface. However, the strains <strong>of</strong> the fibers are not proportional to these distances becausethe fibers are not <strong>of</strong> equal length. Within the elastic limit the stress on any fiber in the beam is proportionalto the strain <strong>of</strong> the fiber, <strong>and</strong> hence the elastic stresses in the fibers <strong>of</strong> a curved beam are not proportionalto the distances <strong>of</strong> the fibers from the neutral surface. The resisting moment in a curved beam, therefore,is not given by the expression sI/c. Hence the neutral axis in a curved beam does not pass through thecentroid <strong>of</strong> the section. The distribution <strong>of</strong> stress over the section <strong>and</strong> the relative position <strong>of</strong> the neutralaxis are shown in Fig. <strong>47</strong>.13b; if the beam were straight, the stress would be zero at the centroidal axis<strong>and</strong> would vary proportionally with the distance from the centroidal axis, as indicated by the dot–dashline in the figure. The stress on a normal section such as AB is called the circumferential stress.Sign ConventionsThe bending moment M is positive when it decreases the radius <strong>of</strong> curvature <strong>and</strong> negative when itincreases the radius <strong>of</strong> curvature; y is positive when measured toward the convex side <strong>of</strong> the beam <strong>and</strong>negative when measured toward the concave side, that is, toward the center <strong>of</strong> curvature. With these signconventions, s is positive when it is a tensile stress.Circumferential StressesFigure <strong>47</strong>.14 shows a free-body diagram <strong>of</strong> the portion <strong>of</strong> the body on one side <strong>of</strong> the section; theequations <strong>of</strong> equilibrium are applied to the forces acting on this portion. The equations obtained are© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-17+Mσ dayZσ daOydaXYYFIGURE <strong>47</strong>.14 <strong>Free</strong>-body diagram <strong>of</strong> curved beam segment.CdθRdθ + ∆dθC′RdayρA 1O′ 1∆dθP′ 1H P 1B′B 1ANeutralsurfaceO 1OO 1 = dsBAOPρyFIGURE <strong>47</strong>.15 Curvature in a curved beam.ÚSF = z0 or sda= 0SM = z0 or M = ysdaÚ(<strong>47</strong>.17)(<strong>47</strong>.18)Figure <strong>47</strong>.15 represents the part ABB 1 A 1 <strong>of</strong> Fig. <strong>47</strong>.13a enlarged; the angle between the two sectionsAB <strong>and</strong> A 1 B 1 is dq. The bending moment causes the plane A 1 B 1 to rotate through an angle Ddq, therebychanging the angle this plane makes with the plane BAC from dq to (dq + Ddq); the center <strong>of</strong> curvatureis changed from C to C¢, <strong>and</strong> the distance <strong>of</strong> the centroidal axis from the center <strong>of</strong> curvature is changedfrom R to r. It should be noted that y, R, <strong>and</strong> r at any section are measured from the centroidal axis <strong>and</strong>not from the neutral axis.It can be shown that the bending stress s is given by the relationM Ê 1s= Á1+aR Ë Zy ˆ˜R + y ¯(<strong>47</strong>.19)© 2003 by CRC Press LLC

<strong>47</strong>-18 The Civil Engineering H<strong>and</strong>book, Second Editionin whichs is the tensile or compressive (circumferential) stress at a point at distance y from the centroidal axis<strong>of</strong> a transverse section at which the bending moment is M; R is the distance from the centroidal axis <strong>of</strong>the section to the center <strong>of</strong> curvature <strong>of</strong> the central axis <strong>of</strong> the unstressed beam; a is the area <strong>of</strong> the crosssection;<strong>and</strong> Z is a property <strong>of</strong> the cross-section, the values <strong>of</strong> which can be obtained from the expressionsfor various areas given in Fig. <strong>47</strong>.17. Detailed information can be obtained from Seely <strong>and</strong> Smith (1952).Example <strong>47</strong>.2The bent bar shown in Fig. <strong>47</strong>.16 is subjected to a load P = 1780 N. Calculate the circumferential stressat A <strong>and</strong> B, assuming that the elastic strength <strong>of</strong> the material is not exceeded.We know from Eq. (<strong>47</strong>.19)in which a = the area <strong>of</strong> rectangular section (40 ¥ 12 = 480 mm 2 )R = 40 mmy A = –20y B = +20P = 1780 NM = –1780 ¥ 120 = –213,600 N mm.From Table <strong>47</strong>.2.1, for rectangular section1Z =- ya Ú da R+ yP M ʈs= + Á +a aR˜Ë1 1 yZ R+y ¯Z 1 R È R+c˘=- + logeh ÍÎ R-c˙˚h = 40 mmHence,c = 20 mm40 È 40 + 20˘Z =- 1+loge0.098640 ÍÎ 40 - 20˙ ˚=PPA40 mmB40 mm120 mm12 mmSection A − BFIGURE <strong>47</strong>.16 Bent bar.© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-19hZ = 1 − c 1 c 4 5 c 6 7 c 8K − O2+ −8 K−4 R R O + 6 4 K −R O + 12 8 K −R O + ...cRR 2 RZ = −1 + 2 R 2K −c O − 2K−c O K − O − 1 chZ = 1 c 2 1 c 4 1 c 6−K−3 R O + −5 K−R O + −7 K−R O + ...cRZ = −1 + 2 hRZ = −1 + R R + c− Blog e Kh R − c OFhb 1c 1 c 2bRZ = −1 + a h ;[b 1 h + (R + c 1 )(b − b 1 )] log R +e K R −c1O − (b − bc1 )h?2R2RZ = −1 + (b + b 1 )h ;Bb 1 + b − b 1 +(R + ch1 )F log e KRR −c1O − (b − bc1 )?2hc 1c 2R2 B (R + c 1 ) log R +e K R −c1c2O − hFhZ = 1 − c 1K − O2 c 4 5 c 6+ −8 K − O + 4 R R 6 4 K −R O +7 c 8128 K −R O + ...c RZ = −1 + 2 KR −c O2− 2 K R − cO K R − cO2− 1FIGURE <strong>47</strong>.17 Analytical expressions for Z.Therefore<strong>47</strong>.3 Trusses1780s A= + - 213600 ÊÁ +480 480 ¥ 40 Ë1 10.09861780s B= + - 213600 ÊÁ +480 480 ¥ 40 Ë1 10.0986-20ˆ˜40 - 20 ¯20 ˆ˜40 + 20 ¯= 105.4 N/mm 2 (tensile)= –45 N/mm 2 (compressive)A structure that is composed <strong>of</strong> a number <strong>of</strong> members pin-connected at their ends to form a stableframework is called a truss. If all the members lie in a plane, it is a planar truss. It is generally assumedthat loads <strong>and</strong> reactions are applied to the truss only at the joints. The centroidal axis <strong>of</strong> each memberis straight, coincides with the line connecting the joint centers at each end <strong>of</strong> the member, <strong>and</strong> lies in aplane that also contains the lines <strong>of</strong> action <strong>of</strong> all the loads <strong>and</strong> reactions. Many truss structures are threedimensionalin nature. However, in many cases, such as bridge structures <strong>and</strong> simple ro<strong>of</strong> systems, thethree-dimensional framework can be subdivided into planar components for analysis as planar trusses© 2003 by CRC Press LLC

<strong>47</strong>-20 The Civil Engineering H<strong>and</strong>book, Second Editionhc 12RZ = −1 +c 22− c 2 1R 2 − c 12 − R 2 − c 22c 2Rbhb 11RZ = − 1 + ;bc bc2 − b 1 c 212Kc22 R − 2Kc2OORO2− 1c2Kc 2c 2RR R− b 1 c 1 2K O2− 2Kc 1 c1ORO2− 1 ?c1Kc 1c 1c 4c 3b t 1RbZ = − 1 + R − a[b 1 log e (R + c 1 ) + (t − b 1 )log e (R + c 4 )+ (b − t)log e (R − c 3 ) − b log e (R − c 2 )]tbc 1c 2 c 2Rt/2t/2 bc 1 c 1c 2 c 2Rt/2The value <strong>of</strong> Z for each <strong>of</strong> these three sections may befound from the expression above by makingb 1 = b, c 2 = c 1 , <strong>and</strong> c 3 = c 4Z = − 1 + R − aRb log e KR+ c 2+ (t − b)log R + c1e K O− cR − c2O1t/2bArea = a = 2[(t − b) c 1 + bc 2 ]c 1c 1 c 1c 2 c 2Rtbc 1c 3c 2RIn the expression for the unequal I given above makec 4 = c 1 <strong>and</strong> b 1 = t, thent/2t/2c 3 c 1c 2bZ = − 1 + R − a[t log e (R + c 1 ) + (b − t) log e (R − c 3 ) − b log e (R − c 2 )]Area = a = tc 1 − (b − t)c 3 + bc 2RFIGURE <strong>47</strong>.17 (continued).without seriously compromising the accuracy <strong>of</strong> the results. Figure <strong>47</strong>.18 shows some typical idealizedplanar truss structures.There exists a relation between the number <strong>of</strong> members, m, the number <strong>of</strong> joints, j, <strong>and</strong> the reactioncomponents, r. The expression is© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-21Warren trussPratt trussHowe trussFink trussWarren trussPratt trussBowstring trussFIGURE <strong>47</strong>.18 Typical planar trusses.m = 2j – r (<strong>47</strong>.20)which must be satisfied if it is to be statically determinate internally. r is the least number <strong>of</strong> reactioncomponents required for external stability. If m exceeds (2j – r), then the excess members are calledredundant members, <strong>and</strong> the truss is said to be statically indeterminate.For a statically determinate truss, member forces can be found by using the method <strong>of</strong> equilibrium.The process requires repeated use <strong>of</strong> free-body diagrams from which individual member forces aredetermined. The method <strong>of</strong> joints is a technique <strong>of</strong> truss analysis in which the member forces aredetermined by the sequential isolation <strong>of</strong> joints — the unknown member forces at one joint are solved<strong>and</strong> become known for the subsequent joints. The other method is known as method <strong>of</strong> sections, in whichequilibrium <strong>of</strong> a part <strong>of</strong> the truss is considered.Method <strong>of</strong> JointsAn imaginary section may be completely passed around a joint in a truss. The joint has become a freebody in equilibrium under the forces applied to it. The equations SH = 0 <strong>and</strong> SV = 0 may be appliedto the joint to determine the unknown forces in members meeting there. It is evident that no more thantwo unknowns can be determined at a joint with these two equations.Example <strong>47</strong>.3A truss shown in Fig. <strong>47</strong>.19 is symmetrically loaded <strong>and</strong> is sufficient to solve half the truss by consideringjoints 1–5. At joint 1, there are two unknown forces. Summation <strong>of</strong> the vertical components <strong>of</strong> all forcesat joint 1 gives135 – F 12 sin45° = 0which in turn gives the force in members 1 <strong>and</strong> 2, F 12 = 190 kN (compressive). Similarly, summation <strong>of</strong>the horizontal components givesF 13 – F 12 cos45° = 0© 2003 by CRC Press LLC

<strong>47</strong>-22 The Civil Engineering H<strong>and</strong>book, Second Edition2A5 61135 kN3 <strong>47</strong>90 kN 90 kN90 kNA6 m 6 m 6 m 6 m135 kN6 m1F 1245°135 kN F 13245°F 12F 23F 25FIGURE <strong>47</strong>.19 Example <strong>of</strong> the method <strong>of</strong> joints, planar truss.Substituting for F 12 gives the force in member 1–3 asF 13 = 135 kN (tensile)Now, joint 2 is cut completely, <strong>and</strong> it is found that there are two unknown forces F 25 <strong>and</strong> F 23 . Summation<strong>of</strong> the vertical components givesThereforeSummation <strong>of</strong> the horizontal components gives<strong>and</strong> henceF 23 FF 453545°F 13 3 F 34F 34 4 F 6790 kN90 kNF 12 cos45° – F 23 = 0F 23 = 135 kN (tensile)F 12 sin45° – F 25 = 0F 25 = 135 kN (compressive)After solving for joints 1 <strong>and</strong> 2, one proceeds to take a section around joint 3 at which there are nowtwo unknown forces viz. F 34 <strong>and</strong> F 35 . Summation <strong>of</strong> the vertical components at joint 3 givesF 23 – F 35 sin45° – 90 = 0Substituting for F 23 , one obtains F 35 = 63.6 kN (compressive). Summing the horizontal components <strong>and</strong>substituting for F 13 one gets© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-23Therefore,–135 – 45 + F 34 = 0F 34 = 180 kN (tensile)The next joint involving two unknowns is joint 4. When we consider a section around it, the summation<strong>of</strong> the vertical components at joint 4 givesF 45 = 90 kN (tensile)Now, the forces in all the members on the left half <strong>of</strong> the truss are known, <strong>and</strong> by symmetry the forcesin the remaining members can be determined. The forces in all the members <strong>of</strong> a truss can also bedetermined by using the method <strong>of</strong> sections.Method <strong>of</strong> SectionsIn this method, an imaginary cutting line called section is drawnthrough a stable <strong>and</strong> determinate truss. Thus, a section divides thetruss into two separate parts. Since the entire truss is in equilibrium,any part <strong>of</strong> it must also be in equilibrium. Either <strong>of</strong> the two parts <strong>of</strong>the truss can be considered, <strong>and</strong> the three equations <strong>of</strong> equilibriumSF x = 0, SF y = 0, <strong>and</strong> SM = 0 can be applied to solve for memberforces.Example <strong>47</strong>.3 above (Fig. <strong>47</strong>.20) is once again considered. To calculatethe force in members 3–5, F 35 , section AA should be run tocut members 3–5 as shown in the figure. It is required only to considerthe equilibrium <strong>of</strong> one <strong>of</strong> the two parts <strong>of</strong> the truss. In this case,the portion <strong>of</strong> the truss on the left <strong>of</strong> the section is considered. Theleft portion <strong>of</strong> the truss as shown in Fig. <strong>47</strong>.20 is in equilibrium underthe action <strong>of</strong> the forces viz. the external <strong>and</strong> internal forces. Consideringthe equilibrium <strong>of</strong> forces in the vertical direction, one canobtain135 kNF 3545°90 kNFIGURE <strong>47</strong>.20 Example <strong>of</strong> themethod <strong>of</strong> sections, planar truss.AA135 – 90 + F 35 sin45˚ = 0Therefore, F 35 is obtained asThe negative sign indicates that the member force is compressive. The other member forces cut by thesection can be obtained by considering the other equilibrium equations viz. SM = 0. More sections canbe taken in the same way to solve for other member forces in the truss. The most important advantage<strong>of</strong> this method is that one can obtain the required member force without solving for the other memberforces.Compound TrussesF =-45 235kNA compound truss is formed by interconnecting two or more simple trusses. Examples <strong>of</strong> compoundtrusses are shown in Fig. <strong>47</strong>.21. A typical compound ro<strong>of</strong> truss is shown in Fig. <strong>47</strong>.21a in which twosimple trusses are interconnected by means <strong>of</strong> a single member <strong>and</strong> a common joint. The compoundtruss shown in Fig. <strong>47</strong>.21b is commonly used in bridge construction, <strong>and</strong> in this case, three membersare used to interconnect two simple trusses at a common joint. There are three simple trusses interconnectedat their common joints, as shown in Fig. <strong>47</strong>.21c.© 2003 by CRC Press LLC

<strong>47</strong>-24 The Civil Engineering H<strong>and</strong>book, Second Edition(a) Compound ro<strong>of</strong> truss(b) Compound bridge trussFIGURE <strong>47</strong>.21 Compound truss.The method <strong>of</strong> sections may be used to determine the member forces in the interconnecting members<strong>of</strong> compound trusses, similar to those shown in Fig. <strong>47</strong>.21a <strong>and</strong> b. However, in the case <strong>of</strong> a cantileveredtruss the middle simple truss is isolated as a free-body diagram to find its reactions. These reactions arereversed <strong>and</strong> applied to the interconnecting joints <strong>of</strong> the other two simple trusses. After the interconnectingforces between the simple trusses are found, the simple trusses are analyzed by the method <strong>of</strong>joints or the method <strong>of</strong> sections.<strong>47</strong>.4 FramesFrames are statically indeterminate in general; special methods are required for their analysis. Slopedeflection <strong>and</strong> moment distribution methods are two such methods commonly employed. Slope deflectionis a method that takes into account the flexural displacements such as rotations <strong>and</strong> deflections <strong>and</strong>involves solutions <strong>of</strong> simultaneous equations. Moment distribution, on the other h<strong>and</strong>, involves successivecycles <strong>of</strong> computation, each cycle drawing closer to the “exact” answers. The method is more laborintensive but yields accuracy equivalent to that obtained from the “exact” methods.Slope Deflection Method(c) Cantilevered constructionThis method is a special case <strong>of</strong> the stiffness method <strong>of</strong> analysis. It is a convenient method for performingh<strong>and</strong> analysis <strong>of</strong> small structures.Let us consider a prismatic frame member AB with undeformed position along the x axis deformed intoconfiguration p, as shown in Fig. <strong>47</strong>.22. Moments at the ends <strong>of</strong> frame members are expressed in terms <strong>of</strong>the rotations <strong>and</strong> deflections <strong>of</strong> the joints. It is assumed that the joints in a structure may rotate or deflect,but the angles between the members meeting at a joint remain unchanged. The positive axes, along withthe positive member-end force components <strong>and</strong> displacement components, are shown in the figure.yV ABM AB Ay APθ Aψ ABV BA M BAψ ABθ BBy B∆ ABxabFIGURE <strong>47</strong>.22 Deformed configuration <strong>of</strong> a beam.© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-25The equations for end moments may be written asMM2EI= 2q + q -3yl( ) +2EI= 2q + q -3ylMAB A B AB FAB( ) +MBA B A AB FBA(<strong>47</strong>.21)in which M FAB <strong>and</strong> M FBA are fixed-end moments at supports A <strong>and</strong> B, respectively, due to the appliedload. y AB is the rotation as a result <strong>of</strong> the relative displacement between member ends A <strong>and</strong> B given asD y + y= =1 1y ABAB A B(<strong>47</strong>.22)where D AB is the relative deflection <strong>of</strong> the beam ends. y A <strong>and</strong> y B are the vertical displacements at ends A<strong>and</strong> B. Fixed-end moments for some loading cases may be obtained from Fig. <strong>47</strong>.8. The slope deflectionequations in Eq. (<strong>47</strong>.21) show that the moment at the end <strong>of</strong> a member is dependent on memberproperties EI, length l, <strong>and</strong> displacement quantities. The fixed-end moments reflect the transverse loadingon the member.Frame <strong>Analysis</strong> Using Slope Deflection MethodThe slope deflection equations may be applied to statically indeterminate frames with or without sidesway. A frame may be subjected to side sway if the loads, member properties, <strong>and</strong> dimensions <strong>of</strong> theframe are not symmetrical about the centerline. Application <strong>of</strong> the slope deflection method can beillustrated with the following example.Example <strong>47</strong>.4Consider the frame shown in Fig. <strong>47</strong>.23 subjected to side sway D to the right <strong>of</strong> the frame. Equation (<strong>47</strong>.21)can be applied to each <strong>of</strong> the members <strong>of</strong> the frame as follows:Member AB:M2EI Ê 3Dˆ= Á2q+ q - ˜ + M6 Ë 20 ¯AB A B FABq A = 0,MM2EIÊ= + - MËÁˆ˜ +20 2 3Dq q20 ¯BA B A FBAFAB= M = 0FBAB180 kN3 m 6 mC6 mAEI − Same forall members9 mDFIGURE <strong>47</strong>.23 Example <strong>of</strong> the slope deflection method.© 2003 by CRC Press LLC

<strong>47</strong>-26 The Civil Engineering H<strong>and</strong>book, Second EditionHenceMM BAAB2EI= qB-3y6( )2EI= -( y )20 2q3 B(<strong>47</strong>.23)(<strong>47</strong>.24)in whichy = D 6Member BC:MM2EI= ( 2q+ q - 3 ¥ 0)+M9BC B C FBCCB= 2EI 2 q + q - 3 ¥ 0C B9( ) +MFCB2180 ¥ 3 ¥ 6M FBC =-=-240ft-kips29M2180¥ 3 ¥ 6=-= 120 ft-kips9FCB 2HenceM2EI= ( 2q+ q )- 2409BC B C(<strong>47</strong>.25)2EI ( 2 ) + 899M CB= q C+ q B(<strong>47</strong>.26)Member CD:M2EIÊ 3Dˆ= Á2q+ q - ˜ + M9 Ë 30 ¯CD C D FCDq D = 0,MM2EIÊ 3Dˆ= Á2q+ q - ˜ + M9 Ë 30 ¯DC D C FDCFCD= M = 0FDCHenceMCDM2EI Ê 1 ˆ 2EI= Á2qC- ¥ 6y˜ = 2qC-2y9 Ë 3 ¯ 9DC( )2EI Ê 1 ˆ 2EI= Á qC- ¥ 6y˜ = qC-2y9 Ë 3 ¯ 9( )(<strong>47</strong>.27)(<strong>47</strong>.28)© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-27Considering moment equilibrium at joint BSubstituting for M BA <strong>and</strong> M BC , one obtainsSM B = M BA + M BC = 0EI 10 qB+ 2 qC- 9 y9or( ) =2402160110 qB+ 2qC- 9y= EI(<strong>47</strong>.29)Considering moment equilibrium at joint CSubstituting for M CB <strong>and</strong> M CD we getSM C = M CB + M CD = 02EI 4 qC+ qB- 2 y9or( ) =-120qB4qC2y+ - = - 540EI(<strong>47</strong>.30)For summation <strong>of</strong> base shears equal to zero, we haveorSH = H A + H D = 0M + M M + M+6 9AB BA CD DCSubstituting for M AB , M BA , M CD , <strong>and</strong> M DC <strong>and</strong> simplifying= 02qB+ 12qC- 70y= 0(<strong>47</strong>.31)Solution <strong>of</strong> Eqs. (<strong>47</strong>.29) to (<strong>47</strong>.31) results in342.7qB=EI.q = - 169 1CEI© 2003 by CRC Press LLC

<strong>47</strong>-28 The Civil Engineering H<strong>and</strong>book, Second Edition<strong>and</strong>y = 103.2EI(<strong>47</strong>.32)Substituting for q B , q C , <strong>and</strong> y from Eq. (<strong>47</strong>.32) into Eqs. (<strong>47</strong>.23) to (<strong>47</strong>.28) we getMoment Distribution MethodM AB = 11.03 kNmM BA = 125.3 kNmM BC = –125.3 kNmM CB = 121 kNmM CD = –121 kNmM DC = –83 kNmThe moment distribution method involves successive cycles <strong>of</strong> computation, each cycle drawing closerto the “exact” answers. The calculations may be stopped after two or three cycles, giving a very goodapproximate analysis, or they may be carried out to whatever degree <strong>of</strong> accuracy is desired. Momentdistribution remains the most important h<strong>and</strong>-calculation method for the analysis <strong>of</strong> continuous beams<strong>and</strong> frames, <strong>and</strong> it may be solely used for the analysis <strong>of</strong> small structures. Unlike the slope deflectionmethod, this method does require the solution to simultaneous equations.The terms constantly used in moment distribution are fixed-end moments, the unbalanced moment,distributed moments, <strong>and</strong> carryover moments. When all <strong>of</strong> the joints <strong>of</strong> a structure are clamped to preventany joint rotation, the external loads produce certain moments at the ends <strong>of</strong> the members to which theyare applied. These moments are referred to as fixed-end moments. Initially the joints in a structure areconsidered to be clamped. When the joint is released, it rotates if the sum <strong>of</strong> the fixed-end moments atthe joint is not zero. The difference between zero <strong>and</strong> the actual sum <strong>of</strong> the end moments is the unbalancedmoment. The unbalanced moment causes the joint to rotate. The rotation twists the ends <strong>of</strong> the membersat the joint <strong>and</strong> changes their moments. In other words, rotation <strong>of</strong> the joint is resisted by the members,<strong>and</strong> resisting moments are built up in the members as they are twisted. Rotation continues until equilibriumis reached — when the resisting moments equal the unbalanced moment — at which time thesum <strong>of</strong> the moments at the joint is equal to zero. The moments developed in the members resistingrotation are the distributed moments. The distributed moments in the ends <strong>of</strong> the member cause momentsin the other ends, which are assumed fixed; these are the carryover moments.Sign ConventionThe moments at the end <strong>of</strong> a member are assumed to be positive when they tend to rotate the memberclockwise about the joint. This implies that the resisting moment <strong>of</strong> the joint would be counterclockwise.Accordingly, under a gravity loading condition the fixed-end moment at the left end is assumed ascounterclockwise (–ve) <strong>and</strong> at the right end as clockwise (+ve).Fixed-End MomentsFixed-end moments for several cases <strong>of</strong> loading may be found in Fig. <strong>47</strong>.8. Application <strong>of</strong> momentdistribution may be explained with reference to a continuous beam example, as shown in Fig. <strong>47</strong>.24.Fixed-end moments are computed for each <strong>of</strong> the three spans. At joint B the unbalanced moment isobtained <strong>and</strong> the clamp is removed. The joint rotates, thus distributing the unbalanced moment to theB ends <strong>of</strong> spans BA <strong>and</strong> BC in proportion to their distribution factors. The values <strong>of</strong> these distributedmoments are carried over at one half rate to the other ends <strong>of</strong> the members. When equilibrium is reached,© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-29902 (Uniformly distributed)A3EI B EI C EI39 7.5D−500.6 0.4 0.45 0.5550 −150 150 −1041043060 40 −20.7 −25.3−10.4 20 −12.7+6.2 +4.2 −9.0 −11.03.1 −4.5 2.1 −5.5+2.7 +1.8−0.9 −1.21.4−0.50.9−0.6+0.3 +0.2−0.4 −0.5−15.5 119.2 −119.2 +142 −142 85.2FIGURE <strong>47</strong>.24 Example <strong>of</strong> a continuous beam by moment distribution.joint B is clamped in its new rotated position <strong>and</strong> joint C is released afterwards. Joint C rotates underits unbalanced moment until it reaches equilibrium, the rotation causing distributed moments in theC ends <strong>of</strong> members CB <strong>and</strong> CD <strong>and</strong> their resulting carryover moments. Joint C is now clamped <strong>and</strong> joint Bis released. This procedure is repeated again <strong>and</strong> again for joints B <strong>and</strong> C, the amount <strong>of</strong> unbalancedmoment quickly diminishing, until the release <strong>of</strong> a joint causes negligible rotation. This process is calledmoment distribution.The stiffness factors <strong>and</strong> distribution factors are computed as follows:The fixed-end moments areDFDFDFDFBABCCBCDI=KBA20= = 0.6Â K I 20 + I 30I=KBC30= = 0.4Â K I 20 + I 30I=KCB30= = 0.45Â K I 30 + I 25I=KCD25= = 0.55Â K I I 30 + I 25MFAB =- 50; MFBC =- 150;MFCD=-104M = 50; M = 150;M = 104FBA FCB FDCWhen a clockwise couple is applied near the end <strong>of</strong> a beam, a clockwise couple <strong>of</strong> half the magnitudeis set up at the far end <strong>of</strong> the beam. The ratio <strong>of</strong> the moments at the far <strong>and</strong> near ends is defined as thecarryover factor, 0.5 in the case <strong>of</strong> a straight prismatic member. The carryover factor was developed forcarrying over to fixed ends, but it is applicable to simply supported ends, which must have final moments<strong>of</strong> zero. It can be shown that the beam simply supported at the far end is only three fourths as stiff asthe one that is fixed. If the stiffness factors for end spans that are simply supported are modified by threefourths, the simple end is initially balanced to zero <strong>and</strong> no carryovers are made to the end afterward.This simplifies the moment distribution process significantly.© 2003 by CRC Press LLC

<strong>47</strong>-30 The Civil Engineering H<strong>and</strong>book, Second Edition3A EI BC EIEI10D1020202EI 2EI20E20F20+15.82+0.20+3.12+12.5 0.2581.64+ 0.39+ 6.25+25.0+50.0 0.50+80.86−0.39+1.57−1.57+6.25−25.00.25 +100.0 0.25 0.25−100.0+ 12.5− 25.0− 1.56− 12.5− 0.39+ 3.13− 26.95− 0.79+ 0.20− 97.46−50.0+12.5+ 3.13+ 0.20−34.17−53.92− 0.79− 3.130.50−50.0− 25.0− 1.57− 0.40− 26.97FIGURE <strong>47</strong>.25 Example <strong>of</strong> a nonsway frame by moment distribution.Moment Distribution for FramesMoment distribution for frames without side sway is similar to that for continuous beams. The exampleshown in Fig. <strong>47</strong>.25 illustrates the applications <strong>of</strong> moment distribution for a frame without side sway.Similarly,EIDF = 20BAEI EI+ +20 20DFMMBEFBCFBE2EI20= 0.25= 05 .; DFBC= 025 .= 0100;MFCB= 100= 50;M = -50FEBStructural frames are usually subjected to side sway in one direction or the other, due to asymmetry<strong>of</strong> the structure <strong>and</strong> eccentricity <strong>of</strong> loading. The sway deflections affect the moments, resulting in anunbalanced moment. These moments could be obtained for the deflections computed <strong>and</strong> added to theoriginally distributed fixed-end moments. The sway moments are distributed to columns. Should a framehave columns all <strong>of</strong> the same length <strong>and</strong> the same stiffness, the side sway moments will be the same foreach column. However, should the columns have differing lengths or stiffnesses, this will not be the case.The side sway moments should vary from column to column in proportion to their I/l 2 values.The frame in Fig. <strong>47</strong>.26 shows a frame subjected to sway. The process <strong>of</strong> obtaining the final momentsis illustrated for this frame.The frame sways to the right, <strong>and</strong> the side sway moment can be assumed in the ratio40020 : 3002 220(or) 1 : 0.75© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-31B1.5 (Uniformly distributed)C1060020 4003002010AD30+109.7+ 0.3+ 2.90.43+31.5+25+500.57− 112.5− 36+ 42− 6.7+ 3.8− 0.6+ 0.3− 109.748.8− 1.2+ 1.9− 13.4+21− 72+ 112.5−48.8− 0.70.64 13.06− 7.6−40.50.36−50+50010.005.504.502.44FIGURE <strong>47</strong>.26 Example <strong>of</strong> a sway frame by moment distribution.Final moments are obtained by adding distributed fixed-end moments <strong>and</strong> 13.06/2.99 times thedistributed assumed side sway moments.Method <strong>of</strong> Consistent DeformationsThis method makes use <strong>of</strong> the principle <strong>of</strong> deformation compatibility to analyze indeterminate structures.It employs equations that relate the forces acting on the structure to the deformations <strong>of</strong> the structure.These relations are formed so that the deformations are expressed in terms <strong>of</strong> the forces, <strong>and</strong> the forcesbecome the unknowns in the analysis.Let us consider the beam shown in Fig. <strong>47</strong>.27a. The first step, in this method, is to determine thedegree <strong>of</strong> indeterminacy or the number <strong>of</strong> redundants that the structure possesses. As shown in the figure,the beam has three unknown reactions, R A , R C , <strong>and</strong> M A . Since there are only two equations <strong>of</strong> equilibriumavailable for calculating the reactions, the beam is said to be indeterminate to the first degree. Restraintsthat can be removed without impairing the load-supporting capacity <strong>of</strong> the structure are referred to asredundants.Once the number <strong>of</strong> redundants are known, the next step is to decide which reaction is to be removedin order to form a determinate structure. Any one <strong>of</strong> the reactions may be chosen to be the redundant,provided that a stable structure remains after the removal <strong>of</strong> that reaction. For example, let us take thereaction R C as the redundant. The determinate structure obtained by removing this restraint is thecantilever beam shown in Fig. <strong>47</strong>.27b. We denote the deflection at end C <strong>of</strong> this beam, due to P, by D CP .The first subscript indicates that the deflection is measured at C, <strong>and</strong> the second subscript indicates that© 2003 by CRC Press LLC

<strong>47</strong>-32 The Civil Engineering H<strong>and</strong>book, Second Edition− 31.700.57+28.5+ 7.4− 4.2+31.70.4328.30+ 1.3− 2.1+14.80+14.300.64−100+1000−75.0+75.00− 3.2+ 21.5+ 50−100−28.3+ 0.8+ 8.4+37.5−75.00.361.59Total2.991.40172.4+123.6+ 48.820− 28.8−138.5+109.7−109.7+138.5+ 28.8−172.4−123.6− 48.810.001.44 8.6211.44FIGURE <strong>47</strong>.26 (continued).M AR AAPBL/2 L/2(a) Actual structureCR C∆ CRR C(c) Determinate structuresubject to redundantPb) Determinate structuresubject to actual loads∆ CPP316 PL 1116 P 516 P(d)FIGURE <strong>47</strong>.27 Beam with one redundant reaction.the deflection is due to the applied load P. Using the moment area method, it can be shown that D CP =5PL 3 /48EI. The redundant R C is then applied to the determinate cantilever beam, as shown in Fig. <strong>47</strong>.27c.This gives rise to a deflection D CR at point C, the magnitude <strong>of</strong> which can be shown to be R C L 3 /3EI.© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-33In the actual indeterminate structure, which is subjected to the combined effects <strong>of</strong> the load P <strong>and</strong>the redundant R C , the deflection at C is zero. Hence the algebraic sum <strong>of</strong> the deflection D CP in Fig. <strong>47</strong>.27b<strong>and</strong> the deflection D CR in Fig. <strong>47</strong>.27c must vanish. Assuming downward deflections to be positive, we writeorfrom whichDCP- D =0CR3 35PLRLC- = 048EI3EIR C= 516 P(<strong>47</strong>.33)Equation (<strong>47</strong>.33), which is used to solve for the redundant, is referred to as an equation <strong>of</strong> consistentdeformations.Once the redundant R C has been evaluated, the remaining reactions can be determined by applyingthe equations <strong>of</strong> equilibrium to the structure in Fig. <strong>47</strong>.27a. Thus SF y = 0 leads to<strong>and</strong> SM A = 0 givesR A= P- 5 =16 P 1116 PPL 5M A= - =2 16 PL 316 PLA free body <strong>of</strong> the beam, showing all the forces acting on it, is shown in Fig. <strong>47</strong>.27d.The steps involved in the method <strong>of</strong> consistent deformations follow:1. The number <strong>of</strong> redundants in the structure are determined.2. Enough redundants to form a determinate structure are removed.3. The displacements that the applied loads cause in the determinate structure at the points wherethe redundants have been removed are calculated.4. The displacements at these points in the determinate structure, due to the redundants, areobtained.5. At each point where a redundant has been removed, the sum <strong>of</strong> the displacements calculated insteps 3 <strong>and</strong> 4 must be equal to the displacement that exists at that point in the actual indeterminatestructure. The redundants are evaluated using these relationships.6. Once the redundants are known, the remaining reactions are determined using the equations <strong>of</strong>equilibrium.<strong>Structures</strong> with Several RedundantsThe method <strong>of</strong> consistent deformations can be applied to structures with two or more redundants. Forexample, the beam in Fig. <strong>47</strong>.28a is indeterminate to the second degree <strong>and</strong> has two redundant reactions.If the reactions at B <strong>and</strong> C are selected to be the redundants, then the determinate structure obtainedby removing these supports is the cantilever beam, shown in Fig. <strong>47</strong>.28b. To this determinate structurewe apply separately the given load (Fig. <strong>47</strong>.28c) <strong>and</strong> the redundants R B <strong>and</strong> R C , one at a time (Fig. <strong>47</strong>.28d<strong>and</strong> e).Since the deflections at B <strong>and</strong> C in the original beam are zero, the algebraic sum <strong>of</strong> the deflections inFig. <strong>47</strong>.28c, d, <strong>and</strong> e at these same points must also vanish. Thus© 2003 by CRC Press LLC

<strong>47</strong>-34 The Civil Engineering H<strong>and</strong>book, Second EditionW 1 W 2M ABA L/2 L/2CR AR B(a)R CAB(b)CW 1 W 2∆ BP(c)∆ CP∆ BB∆ CBR B(d)∆ CC∆ BC(e)R CFIGURE <strong>47</strong>.28 Beam with two redundant reactions.D - D - D = 0BP BB BCD - D - D = 0CP CB CC(<strong>47</strong>.34)It is useful in the case <strong>of</strong> complex structures to write the equations <strong>of</strong> consistent deformations in theformDD- d R - d R = 0BP BB B BC C- d R - d R = 0CP CB B CC C(<strong>47</strong>.35)in which d BC , for example, denotes the deflection at B due to a unit load at C in the direction <strong>of</strong> R C .Solution <strong>of</strong> Eq. (<strong>47</strong>.35) gives the redundant reactions R B <strong>and</strong> R C .Example <strong>47</strong>.5Determine the reactions for the beam shown in Fig. <strong>47</strong>.29, <strong>and</strong> draw its shear force <strong>and</strong> bending momentdiagrams.It can be seen from the figure that there are three reactions viz. M A , R A , <strong>and</strong> R C , one more than thatrequired for a stable structure. The reaction R C can be removed to make the structure determinate. Weknow that the deflection at support C <strong>of</strong> the beam is zero. One can determine the deflection d CP at Cdue to the applied load on the cantilever in Fig. <strong>47</strong>.29b. In the same way the deflection d CR at C due tothe redundant reaction on the cantilever (Fig. <strong>47</strong>.29c) can be determined. The compatibility equationgives© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-35M A20 kN 10 kNADCEIEIR A 2 m 2 m 2 mB(a)R C20 kN 10 kNδ CP40EI100EI(b)20EIδ CRR C4R CEI(c)6.25 kN+ +−13.75 kN10 kN−5 kNm(d)7.5 kNm+−20 kNmFIGURE <strong>47</strong>.29 Example <strong>47</strong>.5.dCP- d =0CRBy moment area method,ddCP20ʈ= ¥ 2 ¥ 1+ 1 20 2 40¥ ¥ 2 ¥ ¥ 2 + ¥ 2 ¥ 3 + 1 60 2 1520¥ ¥ 2 ¥ Á ¥ 2 + 2˜ =EI 2 EI 3 EI 2 EI Ë 3¯ 3EI124REICCR= ¥ ¥ ¥ ¥ =423464R3EISubstituting for d CP <strong>and</strong> d CR in the compatibility equation, one obtains,C15203EI64R- C=03EI© 2003 by CRC Press LLC

<strong>47</strong>-36 The Civil Engineering H<strong>and</strong>book, Second Editionfrom whichBy using statical equilibrium equations we getR C = 23.75 kN≠R A = 6.25 kN≠<strong>and</strong> M A = 5 kNm.The shear force <strong>and</strong> bending moment diagrams are shown in Fig. <strong>47</strong>.29d.1. Solutions to fix-based portal frames subjected to various loading: Fig. <strong>47</strong>.30 shows the bendingmoment diagram <strong>and</strong> reaction forces <strong>of</strong> fix-based portal frames subjected to loading typicallyencountered in practice. Closed-form solutions are provided for moments <strong>and</strong> end forces t<strong>of</strong>acilitate a quick solution to the simple frame problem.2. Solutions to pin-based portal frames subjected to various loading: Fig. <strong>47</strong>.31 shows the bendingmoment diagram <strong>and</strong> reaction forces <strong>of</strong> pin-based portal frames subjected to loading typicallyencountered in practice. Closed-form solutions are provided for moments <strong>and</strong> end forces t<strong>of</strong>acilitate a quick solution to the simple frame problem.Frame II bB C Coefficients:I c I c a = (ILb /L)/(I c /h)A Db 1 = a + 2 b 2 = 6a + 1FRAME DATAhw per unit length−− B +B C−2LA DA +H AM AV A−C −wL 28+ DV DH DM DM A = M D = 1w2Lb21M B = M C = −6 w bL 2= - 2M A1M max =wL 28+ M BV A = V D = wL2H A = H D = 3M AhFIGURE <strong>47</strong>.30 Rigid frames with fixed supports.© 2003 by CRC Press LLC

<strong>Theory</strong> <strong>and</strong> <strong>Analysis</strong> <strong>of</strong> <strong>Structures</strong> <strong>47</strong>-37aABhCw per unitheightDM A =wh 2 a + 3 4a + 14 6b 1 b 2wh 28−B+AV DV AH AM AM B = wh24h/2−C −a- +2a6b 1 b 2+ D H LM DV DM D = wh2 a + 3 4a + 1+M - -4 6b 1 b C = wh2 a 2a24 6b 1 b 2wh(2a + 3)H D = H A = -(wh - H D8b ) V A = - V D = - wh2 a1 Lb 2Constants:3Paa 1 aa 1 =a X 1 =hb 2−B CPPB +C −ALD− A H A + DM AV DM DH DM A = − Pa + X 1M B = X 1M D = +Pa − X 1 M C = − X 1V A = −V D = − 2X 1LH A = −H D = − PFIGURE <strong>47</strong>.30 (continued).<strong>47</strong>.5 PlatesBending <strong>of</strong> Thin PlatesA plate in which its thickness is small compared to the other dimensions is called a thin plate. The planeparallel to the faces <strong>of</strong> the plate <strong>and</strong> bisecting the thickness <strong>of</strong> the plate, in the undeformed state, is calledthe middle plane <strong>of</strong> the plate. When the deflection <strong>of</strong> the middle plane is small compared with thethickness, h, it can be assumed that1. There is no deformation in the middle plane.2. The normals <strong>of</strong> the middle plane before bending are deformed into the normals <strong>of</strong> the middleplane after bending.3. The normal stresses in the direction transverse to the plate can be neglected.© 2003 by CRC Press LLC