Forcible Entry Techniques for Roll-Down Security Gates - American ...

Forcible Entry Techniques for Roll-Down Security Gates - American ...

Forcible Entry Techniques for Roll-Down Security Gates - American ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

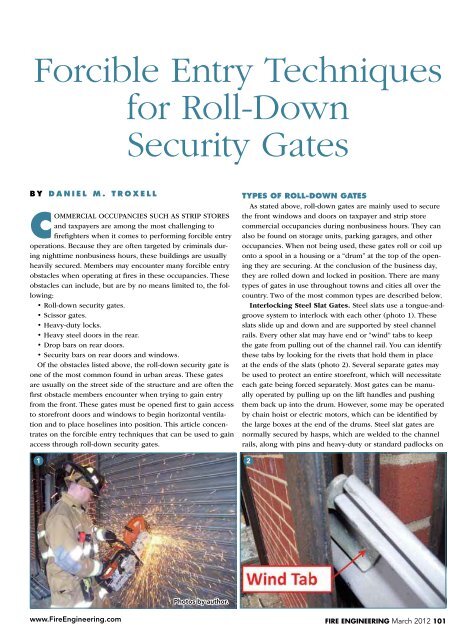

● <strong>Forcible</strong> entry3 4both of the rails. Round padlocks may also be found. If roundpadlocks are used, they are often in protective steel guardsthat are welded to the channel rail. <strong>Gates</strong> can also be securedby slide bolts and other devices (photos 3-4). Slide bolts canoften be found on the gates operated with a chain hoist. Onthese gates, padlocks are used along with the slide bolts tosecure the gates, and additional padlocks are often used toseparately secure the chain-hoist mechanism.Open-Grille <strong>Gates</strong>. These gates consist of a network ofhorizontal hollow steel or aluminum tubes and vertical flatplates, which <strong>for</strong>m an open-grille gate. As with the steel slattype, this gate also slides up and down in steel or aluminumchannel rails (photo 5). When positioned on the outside of astructure, the gate is usually secured in the same manner asthe steel slat gates. However, open-grille gates can also be onthe inside of the structure behind the storefront windows anddoors. This is often the case when you are operating at fires innewer or renovated taxpayers and strip stores. In this situation,the gates are often locked on the inside with a slidingbarlocking mechanism, which secures the bottom of the gateto the channel. These gates can be operated manually, by achain hoist, or electrically.SIZE-UPBe<strong>for</strong>e initiating a roll-down gate <strong>for</strong>cible entry operation, youmust per<strong>for</strong>m a size-up. First, determine the location of the fire.Enter 168 at fireeng.hotims.comEnter 169 at fireeng.hotims.com

Enter 170 at fireeng.hotims.com

● <strong>Forcible</strong> entry5Enter 171 at fireeng.hotims.comThis is especially necessary at strip stores and row taxpayer fires.Several roll-down gates may be present; they can span acrossseveral storefronts. Because of mushrooming and migration intothe exposure occupancies, smoke may be issuing from behind allof the gates, and the exact location of the fire may not be evidentfrom the street. In this case, reports from the roof team and companiesin the rear can assist in pinning down the exact location ofthe fire. In addition, a thermal imaging camera (TIC) can be usedto discern which gate has the highest amount of heat behind it.Once you determine the exact location of the fire and whichgates need to be opened, size up the gates themselves. Whattype of gate is it? What types of locks does it have? Are theremultiple locks? Are the locks engaged? Is the gate manually orelectrically operated? What is the quickest way to gain entry?Once you have the answers to these questions, you can begin<strong>for</strong>cible entry operations.Enter 172 at fireeng.hotims.comREMOVING THE PADLOCKSMost often, the fastest way to gain entry through these gatesis to remove the padlocks. This is also the preferred methodbecause it allows the gate to be raised intact to completelyclear the opening. Size up the locks as well. Check to see ifthe locks are attached to the pins. Sometimes the locks arein place but the pins are not. Also, the pins may be in place,but they may not be inserted into the channel rail and gate. Inaddition, if locks with long staples are used along with shortpins, you may be able to pull the pin out of the pinhole in thegate without removing the lock.You basically will find a standard or a circular type of padlockduring the size-up. Standard padlocks are portable or detachablelocking devices that consist of a lock body and movableU-shaped staple. The lock can be regular or heavy duty. Regularpadlocks have a staple that is one-quarter inch or less in diameterand lock on only one side of the staple. Heavy-duty padlocks(case-hardened steel) have staples with a diameter larger thanone-quarter inch and may lock on both sides of the staple—known as “heel and toe” locking (photo 6). These padlocks canbe operated by keys or numerical combinations, and they areavailable in a wide variety of shapes and sizes.As the name implies, circular padlocks have a circularshapedlock body and are often protected by circular steelguards that are welded to the channel rails. These locks areextremely difficult to access and usually cannot be <strong>for</strong>ced by104 March 2012 FIRE ENGINEERING www.FireEngineering.com

6or a rope attached) to the body of thelock. The chain can then be tensionedso that the lock is in a parallel positionand held steady. You can also use thepike end of the halligan to steady lockswith long staples by placing the pikeend through the staple. Once the lock issteadied, position the saw blade so thatboth sides of the staple will be cut. Aswith any metal-cutting operation, beginwith a low revolution per minute (rpm)on the saw until a groove is started in<strong>for</strong>cible entry ●the staple; then increase to full rpm tocomplete the cut through both sides(photo 8). Once the cuts are completeon all of the locks, pull out the pins, androll up the door. If no other means areavailable to steady the lock, pin the lockitself up against the channel rail with thesaw blade, and cut.Some truck companies carry a toolknown as the “duck bill” lock breaker.This tool is quite effective in removingpadlocks if a saw is not available. Place7the same methods used <strong>for</strong> standardpadlocks. Some common circular padlockbrands are the following:• Abus Disc.• <strong>American</strong> 2000 or “hockey puck”(photo 7).• Master 6271 series.• Master 736 series.• Brinks R70.• Locks by other manufacturers thatare similar to the Brinks and Abuslocks.Usually, the quickest method <strong>for</strong>removing padlocks is to cut the lockswith a saw equipped with an aluminumoxide or diamond-segmented blade. Ifpossible, these locks should be held ina stable position be<strong>for</strong>e cutting begins.You can accomplish this by clampinga pair of locking pliers (with a chainwww.FireEngineering.comEnter 173 at fireeng.hotims.com

● <strong>Forcible</strong> entry8910111312the “bill” of the lock breaker in thestaple of the lock, with the bottom ofthe bill resting on the lock body. Strikethe back of the bill with a sledgehammeror flathead ax, using as much <strong>for</strong>ceas necessary to separate the staple fromthe lock body (photo 9). Note that if thelock is attached to a chain, the duck billlock breaker may not develop enough<strong>for</strong>ce to break the lock because of theslack between the chain links and thestretching of the chain. Regular padlockscan be <strong>for</strong>ced in a similar mannerby driving the pike of a halligan barinto the space between the staple and the lock body. Thismethod is effective only if the diameter of the pike is largerthan the space between the staple and the lock body.As mentioned previously, you may encounter gates securedwith circular padlocks that are set in steel guards. It is quitedifficult to cut the staples on these locks because they arerecessed in the guards and protected by the pin and bracket.However, these locks can be defeated by using a saw to cutthe channel rails above and below the locks. Make the cuts atabout a 45-degree angle to <strong>for</strong>m a triangular-shaped section inthe channel rail; the narrow side of the cut should be towardthe outside of the channel rail (photo 10). After completing thecuts, drive the <strong>for</strong>k end of the halligan bar around the cut section.On thicker channel rails, you may have to use the flatheadax or sledgehammer to drive the <strong>for</strong>k around the cut section.After the <strong>for</strong>k is driven into the cut section, use the bar to bendthe cut section of the channel rail out and away from the gateto pull out the pin (photo 11). The pike end of the halligan canalso sometimes be placed between the lock and the guard andused to bend the cut section away from the gate.14You can defeat the <strong>American</strong> 2000, Master 6271, or Master736 hockey puck locks by using a saw to cut through the lockbody and guard, if present. For the <strong>American</strong> 2000, make a cutthrough the lock at a point just below and parallel with the“2000” lettering on the lock body. For the Master locks, makea cut three-quarters of the way up on the lock body from thekeyway. These cuts must be completely through the lock bodyto cut the staple (on the back side of the lock) and defeat thelock (photos 12-13). If no saw is available and the hockeypuck locks are not in guards, you can remove them with apipe wrench with an extended handle and twist the lock offthe bracket (photo 14). Hockey puck-type locks, especially theMaster Lock 736 version, can often be found along with guardplates securing the rear doors of commercial vans and worktrucks. For a fire in these types of vehicles, remove these locksby cutting them with a saw as described above.CUTTING STEEL SLAT GATESSteel slate gates may be recessed into a wall pocket or corner,which can restrict access to the locking devices, and there106 March 2012 FIRE ENGINEERING www.FireEngineering.com

1516• Place the pike of the halliganinto one of the holes in oneof the side sections and pullthe slat out of the channelrail toward the center of thegate, guiding it past the centersection (photo 18).• Repeat the process on theother side of the gate toremove the other side section. When this is complete,use one of the holes in the center section<strong>for</strong>cible entry ●to pull that section toward one of thechannel rails. If necessary, you can drivethis section out with a flathead ax whileusing the halligan bar to guide the sectionaround the channel rail (photos 19).Once this section is removed, the sectionbelow it will fall to the ground, andthe remaining portion of the gate abovecan be raised up and out of the way. Thecut section on the ground can then beremoved and cleared out of the way togain access (photo 20). This is extremelymay be multiple locking devices on asingle gate. In these cases, it may befaster to cut the steel slats instead of thelocks. You can do this in several ways.Three methods are described below.1Slash Cut Method (photo 15). Thisis the fastest and easiest method ofthe three.• Locate the slat just above the lockson both sides of the gate that doesnot have wind tabs attached to it.With the pike of the halligan bar,make a purchase point approximatelyone to two feet in from thechannel rail. Make another hole sixto 12 inches in from the first hole,toward the channel (photo 16).• Repeat this process on the otherside of the gate.• With the saw, starting at a pointtwo slats above the slat with thepurchase points, make a “slash” cutdown between the purchase pointholes and through (if possible) thebottom edge of the gate (photo 17).• Repeat this process on the otherside of the gate. When these cutshave been completed, the slat abovethe locks with the purchase pointswill have been cut into three sections(two side sections and a centersection).www.FireEngineering.comEnter 174 at fireeng.hotims.com

● <strong>Forcible</strong> entry1718Enter 175 at fireeng.hotims.comFDIC * Booth # 3815Enter 176 at fireeng.hotims.comimportant because the storefront doors that are usually behindthese gates typically swing outward, and any remaining portionof the gate that remains after cutting may prevent thedoors from opening fully.Use caution when per<strong>for</strong>ming this operation, as the springloadedupper section of the gate may pull upward violentlyas the doors coil back up into the drum when released. Thisaction can exert a lot of <strong>for</strong>ce on the entire gate system, whichis usually attached by lag bolts to the wood or masonry walls ofthe structure. If these points of attachment are weak or compromised,the <strong>for</strong>ce of the door coiling up into the drum may causethe entire door system (channel rails, gate, and drum) to separatefrom the building and fall on the members working in thearea. The heat of the fire can also cause the springs to lose theirtension and allow the gate to close unexpectedly. To preventthis, secure the gate in the open position by placing a pike poleunder the bottom edge or by clamping locking pliers on thechannel rail directly below the bottom of the gate. If the gateis in a recessed pocket that would prevent the center slat frombeing pulled out to one side, you may have to make an additionalcut in the slat to divide it in two, which will allow the twosections to be pulled toward the center of the gate and removed.2Tee-Pee Cut Method (photo 21). This method, also knownas the ”Inverted Vee” method, involves making longer andmore difficult cuts than those in the Slash Cut method.• Drive the pike end of the halligan bar into the slatsabove the locks on both sides to make holes <strong>for</strong> purchase108 March 2012 FIRE ENGINEERING www.FireEngineering.com

<strong>for</strong>cible entry ●19 20points, similar to the procedures outlined in the Slash Cutmethod.• Make a 45-degree cut from the center of the door, startingas high up above the level of the locks as the saw operatorcan safely reach, and continue the cut down to andthrough the bottom outside edge of the gate.• Make a second 45-degree cut starting about six inchesbelow the top of the first cut. This will allow the gateto maintain some stability while the second cut is beingcompleted. Extend this cut down to the opposite bottomoutside edge of the gate (photo 22).• After completing the second cut, go back and cut theremaining six-inch section at the top. After this is completed,the entire Tee-Pee-shaped cut section will drop outof the gate.Don’t make the mistake and think that the operation is completeat this point and use this opening to enter and operate.Although it can be used to gain an initial knockdown of thefire with a hoseline in some instances, this opening usually isnot large enough to be safely used as a means of ingress andegress from the building. Taking a few more steps, you canmake this opening much larger.Enter 177 at fireeng.hotims.com

<strong>for</strong>cible entry ●21222324• Place the pike end of the halliganinto one of the purchase points in thesection of the slat remaining abovethe lock and used to slide the sectiontoward the center of the tee-pee cut toremove it (photo 23).25• Repeat this procedure on the slatsection on the other side of thegate. Once the sections are pulledout, the upper portion of the doorwill be free of the locks and can berolled up. Again, use caution whenper<strong>for</strong>ming this operation on springloadeddoors. They may pull upwardviolently when released from thelocks and cause the door system toseparate from the building.3Box Cut Method (photo 24). Theprocedures used <strong>for</strong> cutting steelslat gates cannot be used on open-grilleEnter 178 at fireeng.hotims.comEnter 179 at fireeng.hotims.com

● <strong>Forcible</strong> entrygates because they differ considerably in construction. Asmentioned above, these gates consist of a network of horizontalhollow steel tubes and vertical flat steel plates. The onlyway to effectively cut these gates is to per<strong>for</strong>m a box cut.• Starting on either the left or right side of the gate near thechannel rail, make a vertical cut from the top to the bottomof the gate (photo 25).• When this is complete, make a horizontal cut across thetop of the gate, intersecting with the vertical cut.• Make another vertical cut on the opposite side of the gate,also intersecting with the horizontal cut. When completed,the entire box-shaped section will drop out of the gate.Note that since these gates are often inside of occupancies, thestorefront glass may have to be broken to gain access to them.This can sometimes create an uncontrollable ventilation opening.If this is the case, ensure that hoselines are in position and thatvertical ventilation has been completed be<strong>for</strong>e breaking any glasson occupancies actively involved in fire. The box cut method canalso be used on steel slat gates that are electrically operated orare of the type that do not allow the slats to be separated, suchas the sheet-curtain roll-down gates commonly found on selfstorageunits. The box cut method can also be used on steel slatgates that have been severely warped by the heat of the fire, inwhich case it will be extremely difficult and often impossible toslide out the slats or raise any portion of the gate.•••<strong>Forcible</strong> entry through roll-down gates on commercial occupanciesis a challenging and labor-intensive operation <strong>for</strong>firefighters, especially if they are not familiar with the typesof gates they encounter or the procedures that can be used togain entry through them. Go out into your response area afterbusiness hours and check out the types of roll-down gates andother security devices out there. Size up the gates you find,and conduct regular drills on the tools and procedures youcan use to get through them quickly and efficiently. ●● DANIEL M. TROXELL, a 35-year veteran of the fireservice, is a captain with the Washington, D.C., Fire Department(DCFD). A Pro Board-certified level III instructor,he serves as an adjunct instructor with the DCFD TrainingAcademy and has developed and taught courses <strong>for</strong>in-service company training and probationary firefightertraining. He is an instructor <strong>for</strong> Traditions Training, LLC,a company specializing in “combat ready” street-smartfirefighter training. In addition, he manages Troxfire TrainingSolutions, LLC, which specializes in the developmentof realistic training props and classes <strong>for</strong> truck companyoperations. He has a bachelor of science degree in fireprotection engineering and a master of science degree inapplied management, both from the University of Marylandat College Park.Daniel Troxell will present “Commercial Building <strong>Forcible</strong><strong>Entry</strong> Challenges” on Thursday, April 19, 2012, 10:30a.m.-12:15 p.m., at FDIC in Indianapolis.Enter 180 at fireeng.hotims.com