ETA 08-0818 - bei Powers Europe

ETA 08-0818 - bei Powers Europe

ETA 08-0818 - bei Powers Europe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

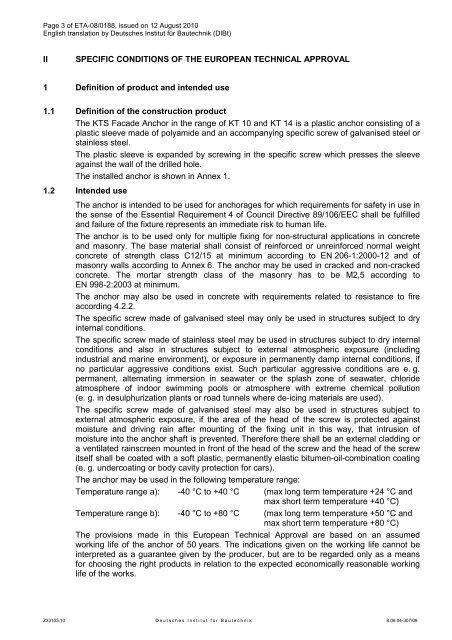

Page 3 of <strong>ETA</strong>-<strong>08</strong>/0188, issued on 12 August 2010English translation by Deutsches Institut für Bautechnik (DIBt)IISPECIFIC CONDITIONS OF THE EUROPEAN TECHNICAL APPROVAL1 Definition of product and intended use1.1 Definition of the construction productThe KTS Facade Anchor in the range of KT 10 and KT 14 is a plastic anchor consisting of aplastic sleeve made of polyamide and an accompanying specific screw of galvanised steel orstainless steel.The plastic sleeve is expanded by screwing in the specific screw which presses the sleeveagainst the wall of the drilled hole.The installed anchor is shown in Annex 1.1.2 Intended useThe anchor is intended to be used for anchorages for which requirements for safety in use inthe sense of the Essential Requirement 4 of Council Directive 89/106/EEC shall be fulfilledand failure of the fixture represents an immediate risk to human life.The anchor is to be used only for multiple fixing for non-structural applications in concreteand masonry. The base material shall consist of reinforced or unreinforced normal weightconcrete of strength class C12/15 at minimum according to EN 206-1:2000-12 and ofmasonry walls according to Annex 6. The anchor may be used in cracked and non-crackedconcrete. The mortar strength class of the masonry has to be M2,5 according toEN 998-2:2003 at minimum.The anchor may also be used in concrete with requirements related to resistance to fireaccording 4.2.2.The specific screw made of galvanised steel may only be used in structures subject to dryinternal conditions.The specific screw made of stainless steel may be used in structures subject to dry internalconditions and also in structures subject to external atmospheric exposure (includingindustrial and marine environment), or exposure in permanently damp internal conditions, ifno particular aggressive conditions exist. Such particular aggressive conditions are e. g.permanent, alternating immersion in seawater or the splash zone of seawater, chlorideatmosphere of indoor swimming pools or atmosphere with extreme chemical pollution(e. g. in desulphurization plants or road tunnels where de-icing materials are used).The specific screw made of galvanised steel may also be used in structures subject toexternal atmospheric exposure, if the area of the head of the screw is protected againstmoisture and driving rain after mounting of the fixing unit in this way, that intrusion ofmoisture into the anchor shaft is prevented. Therefore there shall be an external cladding ora ventilated rainscreen mounted in front of the head of the screw and the head of the screwitself shall be coated with a soft plastic, permanently elastic bitumen-oil-combination coating(e. g. undercoating or body cavity protection for cars).The anchor may be used in the following temperature range:Temperature range a): -40 °C to +40 °C (max long term temperature +24 °C andmax short term temperature +40 °C)Temperature range b): -40 °C to +80 °C (max long term temperature +50 °C andmax short term temperature +80 °C)The provisions made in this <strong>Europe</strong>an Technical Approval are based on an assumedworking life of the anchor of 50 years. The indications given on the working life cannot <strong>bei</strong>nterpreted as a guarantee given by the producer, but are to be regarded only as a meansfor choosing the right products in relation to the expected economically reasonable workinglife of the works.Z33103.10 D e u t s c h e s I n s t i t u t f ü r B a u t e c h n i k 8.06.04-307/09