Xaloy

Xaloy

Xaloy

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

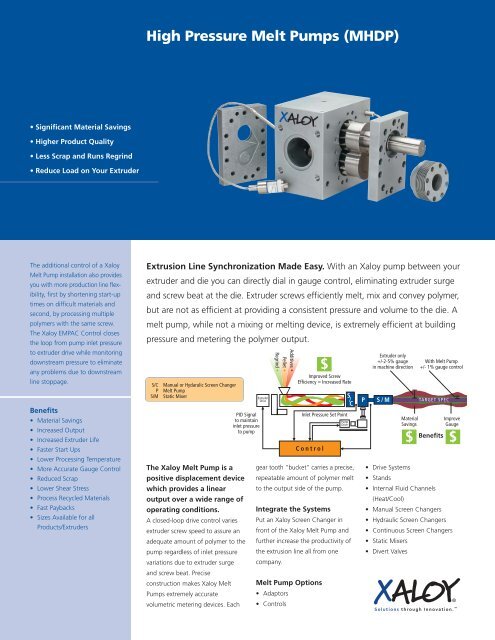

High Pressure Melt Pumps (MHDP)• Significant Material Savings• Higher Product Quality• Less Scrap and Runs Regrind• Reduce Load on Your ExtruderThe additional control of a <strong>Xaloy</strong>Melt Pump installation also providesyou with more production line flexibility,first by shortening start-uptimes on difficult materials andsecond, by processing multiplepolymers with the same screw.The <strong>Xaloy</strong> EMPAC Control closesthe loop from pump inlet pressureto extruder drive while monitoringdownstream pressure to eliminateany problems due to downstreamline stoppage.Benefits• Material Savings• Increased Output• Increased Extruder Life• Faster Start Ups• Lower Processing Temperature• More Accurate Gauge Control• Reduced Scrap• Lower Shear Stress• Process Recycled Materials• Fast Paybacks• Sizes Available for allProducts/ExtrudersExtrusion Line Synchronization Made Easy. With an <strong>Xaloy</strong> pump between yourextruder and die you can directly dial in gauge control, eliminating extruder surgeand screw beat at the die. Extruder screws efficiently melt, mix and convey polymer,but are not as efficient at providing a consistent pressure and volume to the die. Amelt pump, while not a mixing or melting device, is extremely efficient at buildingpressure and metering the polymer output.S/C Manual or Hydarulic Screen ChangerP Melt PumpS/M Static MixerPID Signalto maintaininlet pressureto pumpThe <strong>Xaloy</strong> Melt Pump is apositive displacement devicewhich provides a linearoutput over a wide range ofoperating conditions.A closed-loop drive control variesextruder screw speed to assure anadequate amount of polymer to thepump regardless of inlet pressurevariations due to extruder surgeand screw beat. Preciseconstruction makes <strong>Xaloy</strong> MeltPumps extremely accuratevolumetric metering devices. EachExtruderDriveAdditives •Pellet •Regrind •gear tooth “bucket” carries a precise,repeatable amount of polymer meltto the output side of the pump.Integrate the SystemsPut an <strong>Xaloy</strong> Screen Changer infront of the <strong>Xaloy</strong> Melt Pump andfurther increase the productivity ofthe extrusion line all from onecompany.Melt Pump Options• Adaptors• ControlsInlet Pressure Set PointControl$Improved ScrewEfficiency = Increased RatePumpDriveS /CPExtruder only+/-2-5% gaugein machine directionS/MWith Melt Pump+/- 1% gauge controlTARGET SPECMaterialImproveSavingsGaugeBenefits$ $• Drive Systems• Stands• Internal Fluid Channels(Heat/Cool)• Manual Screen Changers• Hydraulic Screen Changers• Continuous Screen Changers• Static Mixers• Divert Valves

High Pressure Melt Pumps (MHDP)SpecificationsMODELMHDP MHDP MHDP MHDP MHDP MHDP MHDP MHDP MHDP MHDP MHDP110/043 155/080 183/100 240/120 275/175 300/200 350/230 430/300 550/350 600/300 600/400CC/REV 3.9 16.7 31.1 56.5 112.3 186.1 246.5 494.9 731 1103 1471LBS/HR/RPM @ S.G. = 1.0 0.519 2.21 4.11 7.46 14.85 24.60 32.57 65.41 96.6 146 194KG/HR/RPM @ S.G. = 1.0 0.236 1.00 1.87 3.38 6.73 11.16 14.77 29.66 43.8 66 88Thruput/min. 1.0 S.G. @5 rpm (lbs/hr) 2.6 11 21 37 74 123 163 327 483 729 972Thruput/min. 1.0 S.G. @5 rpm (kg/hr) 1.2 5 9 17 34 56 74 148 219 331 441Thruput/min. 1.0 S.G. @50 rpm (lbs/hr) 26 110 206 373 742 1230 1629 3271 4830 7288 9720Thruput/min. 1.0 S.G. @50 rpm (kg/hr) 12 50 93 169 337 558 739 1483 2190 3305 4408Heater KW Required 0.6 1 1.6 3 4 4 4 9 12 16 N/APump Weight LBS 22 49 66 135 188 199 312 706 1260 1500 1625Pump Weight KG 10 22 30 61 85 90 141 320 572 680 737Process and Material DependentMaximum Operating Pressure: 10,000 psig (689 BAR)Maximum Differential Pressure: 7,500 psig (517 BAR)Maximum Temperature: 650 F (343 C)Transducer Ports: 4 locations in body for 155 size and larger pumpsNote: The MJHDP model is an option. The pump body has internalchannels to accept a heat/cool fluid media. The MJHDP option isutilized for heat sensitive polymers when very accurate temperatureregulation is required.Accurate Metering = Tighter Product Spec and Material SavingsMelt Pumps operate at a constant speed and precisely meter polymer to die.FilterScrewbeatSurgeInputOutputDischarge Pressuresup to 10,000 psi689 BAR400 –300 –200 –100 –0 – lllllllll0 1000 2000 3000 4000 5000–$lllllllllWith Pump–Extruder Only––ExtruderEfficiencyCurve––AmplifyImprove Screw Efficiency and Increase OutputMelt Pumps efficiently build pressure; thereby reducing extruderhead pressure. By reducing extruder pressure, a screw can operatemore efficiently and can convey more material.www.xaloy.comAMERICAS +1 724 656 5600+1 800 897 2830 (toll free)GERMANY +49 (0) 7132 99935 0THAILAND +66 (38) 717 084JAPAN +81 45 661 3508CHINA +86 21 6307 1217FRANCE +33 631 638 647ITALY +39 039 328217NETHERLANDS +31 413 271500POLAND +48 691 719888TURKEY+MIDDLE EAST +90 216 549 37 77INDIA +91 79 4032 7380