Praj Industries Ltd, Ethanol Presentation - Water Recycle And Reuse

Praj Industries Ltd, Ethanol Presentation - Water Recycle And Reuse

Praj Industries Ltd, Ethanol Presentation - Water Recycle And Reuse

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

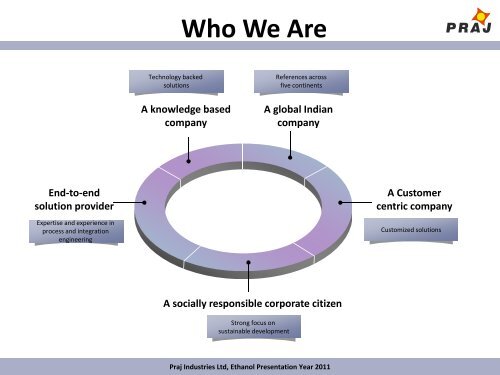

Who We AreTechnology backedsolutionsA knowledge basedcompanyReferences acrossfive continentsA global IndiancompanyEnd‐to‐endsolution providerExpertise and experience inprocess and integrationengineeringA Customercentric companyCustomized solutionsA socially responsible corporate citizenStrong focus onsustainable development<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

What Do We DoAlcohol /Fuel <strong>Ethanol</strong>PlantsBreweryPlants<strong>Water</strong> andWastewaterTreatmentBionutrientsCustomizedProcessEquipmentsAgri Services<strong>Praj</strong> with its 25 years of experience in process engineering, has the capability to provide technology,basic and detailed engineering, key equipments and whole turnkey plants in the ethanol,brewery and water and waste water treatment areas.<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Our VisionWe aspire to bethe most preferred organization for all stakeholdersthroughenvironment friendly, sustainable solutionsthat can make the world a better place<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Our MissionWe willDevelop and deliver cost‐effective, safe, clean and reliable solutionsthat will maximize prosperity of our customerWe willInvest and partner in development and realization of new ideasrecognizing the risks and working to mitigate themWe willBe a socially responsible corporate citizenWe willCreate wealth for our stakeholders<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

<strong>Water</strong> and Waste <strong>Water</strong> BusinessQuality of water intake<strong>Water</strong> balanceMulti‐effluent solutions<strong>Praj</strong> now offers solutionsto various industries viz.SugarFood processingDairyChemicalPharmaceuticalCosmeticsTextilesPowerFertilizerMetalto treat, reuse and recyclewastewater effectively.With a wide experience on treatment of most challenging wastewater and waterrelated applications in the distillery and brewery industry,entry into water and wastewater arena came easily to <strong>Praj</strong>.<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

<strong>Praj</strong>: End to End SolutionsPre and post treatmentMicrobial reductionCooling tower managementOil water separationZero liquid discharge<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

<strong>Water</strong> Treatment SolutionsUnder One RoofDemineralization, softening,disinfection, clarification,flocculation, filtration, desalinationEnd to end solutionsAerobic and anaerobic treatmentsFocus on superiortechnicalperformanceDisinfection, clarification,flocculationEvaporation, distillation,dehydration<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

<strong>Water</strong> Treatment SolutionsUnder One RoofHigh qualitywatersystems andrelatedequipmentsExperience withcomplex andchallengingeffluents invarious industriesThis partnership will enable us serve clients in various industries viz.pharmaceutical, biopharmaceutical, food & beverage as well as the cosmetics industry& become a “one stop shop” for water management.<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

<strong>Water</strong> Systemsin association with Neela Systems LimitedHighly purified waterPurified water<strong>Water</strong> for injectionsTo serve thepharmaceuticals, lifesciences, food andbeverages andcosmetics industries<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Process VesselsEngineering and DesignFabricationTesting and InspectionValidation and Start‐Up AssistanceReplacement PartsNeela specializes in producing stainless steel storage tanks, pressure vessels and mixing tanksaccording to the principles of heat and mass transfer to fulfill the needs ofliquid pharmaceutical product manufacturing.<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Modular Process SystemsVessels for various in‐process applicationsincluding Mixing & AgitationClean utilitiesProcess piping, CIP, SIPHighly sterile equipments andaccessories for thebiopharmaceuticalsmanufacturing processStructural, Instrumentation , Automation<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

MegamodulesSingularModularMegamodule'RTU' (Ready To Use) conceptSimple straight line process demarcationsDefined interfacesBetter Sharing of utilitiesDefined modules for automationFaster design, construction & qualificationFacilitates high level of interchangeability, upgradation & expansionsReduced on site construction activities<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Offerings : <strong>Water</strong> TreatmentDM PlantsEasy to install & operateComplete assembly with backwash & regeneration equipmentProduces DM water of high puritySoftening PlantsEasy to install and operateProduces soft , non‐scale forming waterHigh capacity Cation exchange resinConsistent treated water qualityLow operating costs<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Offerings : <strong>Water</strong> TreatmentFiltration PlantsWe offer Pressure Sand Filters, Multi grade Filters, Dual MediaFilters, Activated carbon Filters, Iron filtersEasy to operate & practically no maintenanceBetter filter quality at higher flow rate than conventional filtersNegligible pressure dropMembrane Filtration PlantsHigh RecoveryHigh RejectionLower foot printsOptimum Chemical ConsumptionEnergy efficient and Skid Mounted Plants<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Wastewater TreatmentAerobic &anaerobictreatmentsPhysico‐chemicaltreatmentso Disinfectiono Clarificationo Flocculationo SettlingWaste to energyConcentration &separationo Evaporationo Distillationo Dehydrationo Drying<strong>Recycle</strong> & reuseZero liquiddischargeIn association with <strong>Praj</strong>, Neela has thecapability to serve the entire gamut ofwater chain ; pretreatment, water neededfor special purposes and also wastewatertreatment.<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Offerings : Wastewater TreatmentECOSAP‐CEConventional and extended activatedsludge processHigher organic removal efficiencyHigh efficiency slow speed surface aeratorsand diffusers for various applicationsEfficient clarifier mechanism for sludgerecycleThe technology is based fluidized bed attachedgrowth bioreactorSpecially designed plastic media ensues higherbiofilm surface areaVery high organic removal efficiencyOdorless operationsSimple to operate compact plantECOSAP‐FB<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Offerings : Wastewater TreatmentSewage TreatmentThe technology is based cyclicactivated sludge treatmentProven performance withvery high organic removalefficiencyFully automated processSimple to operate compactplantHigh flexibility of operationECOCAT‐SBROptimum energyconsumption<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Offerings : Wastewater TreatmentECOFIL‐RO/UF/MF/NFECOFIL is advanced microfiltration, ultrafiltration, nano filtration, reverse osmosissystemsHigh recoveryHigh rejectionFlexible designLower footprintsTailor made pre treatments and posttreatments depending on applicationsCan be coupled with biological treatmentECOFIL‐RO/UF/MF/NFSolutions to recycle and reuse water<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Offerings : Wastewater TreatmentECOBRANE‐SB/XTECOBRANE is membrane bioreactor with submerged and external configurationsHigher MLSS upto 25 g/L is maintainedHigher organic removal efficiencies66‐75% reduction in footprint as compared to conventional systemsSafe, easy and economical cleaningHigh quality effluent, excellent process stability, low membrane fouling, less wastesludge productionModular In design and constructionMinimum civil work<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Energy from Wastewater• Feed : wastewaterBiogas cleaning• Advancedbiochemical scrubber• Elemental sulfur• PowerBiomethanationBiogas engineECOMET‐XT/SB give high biogas yield from wastewaterBiogas is cleaned for reduction in content with advanced biochemical scrubberand elemental sulfur is recovered as byproductHigh energy efficient biogas engine generates 1.8‐2.2 KWH electricity per m 3 ofbiogas fed<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Physico Chemical TreatmentDisinfection technologiesChlorination: relatively inexpensive and highly effective overa wide range of biological agentsOzonation Technology : Disinfection along withcolor, phenolics, cyanide, odors, COD, turbidity and surfactantremovalClarification and Flocculation technologiesHigher removal efficiency with energy efficient systemsWe Offers Clarifiers, Clariflocculators and LamellaSettlers for a wide range of applications<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Concentration & SeparationTechnologiesEnvironment friendly , energy efficientrange of evaporatorsIntegrated evaporation technologyCombination of pressure and vacuum systemCombination of concentration and lowpressure steam generationFalling film reboilersHigh steam economy using TVR and MVRApplications: Starch, dairy, food, pulp andpaper, textile, pharma, dye & pigments, soapECOVAPand biofuels, chlor‐alkali, petrochemical &polymer industries<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Concentration & SeparationTechnologiesAdvanced designs to have minimummoisture content in the productHighly efficient column internals ensuremore effective separation of impuritiesHighly efficient integrated solventrecovery plantsComplete automationConsistent product qualityHigh energy efficiency<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Concentration & SeparationTechnologiesState of the art pressure swing adsorptiontechnologyLonger desiccant lifeHigh product drynessLow energy consumptionSkid mounted modular units for smallercapacityMore than 100 installations world wide<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

ServicesResearch and DevelopmentAudit and ConsultancyFeasibility StudyTechnology SelectionProcess DesignMechanical DesignE&I DesignBasic EngineeringDetailed EngineeringServicesStart up and CommissioningTrainingAfter Sale ServiceProcurementEquipment SupplySite SupervisionGeneral ContractingConstruction & ErectionInstrumentation and Control<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Our Resources<strong>Praj</strong> Matrix : The Innovation CentreCertified as In‐House R&D laboratory unit by Department of Scientific and Industrial Research, GOIEmploys highly qualified PhDs, scientists, microbiologists and molecular biologists<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Our ResourcesManufacturing FacilitiesPuneKandlaNeela Systems LimitedCaters to domesticmarketFabrication capacity6000 MT/yearSpecial EconomicZone : Units 1 & 2SEZ Unit 2 dedicatedto customizedequipments mfgFabrication capacity2500 MT/year (eachunit)State‐of‐the‐artmanufacturing facilityat Wada, Thane tobuild US FDA, UKMCAand WHO compliantwater systems<strong>Praj</strong> manufacturing facilities can produce process equipments suited to the needs ofvarious industries viz. oil and gas, petrochemicals, pharmaceuticals, dairy etc.Codes and standards: ASME, TEMA, B5500, PED, DIN, IS2825, Ad MerkblatterCapability to handles numerous metals : Austenitic Steels, Carbon Steel, Titanium,Hastelloy, Nickel, Monel 400, Incoloy<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

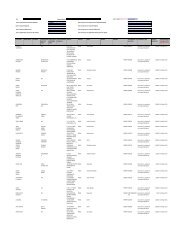

Our Presence<strong>Praj</strong>’s ReferencesUnited KingdomRussiaUnited StatesMexicoGuatemalaPeruTrinidad & TobagoDominican RepublicJamaicaEI Salvador NicaraguaVenezuelaCosta RicaBarbadosPanamaGuyanaColombiaArgentinaBrazilBoliviaGermanySwitzerlandRomaniaSpainBelgiumBulgariaAlgeriaSierraLeoneNigeriaZimbabweEgyptPolandHungaryCzech RepublicSaudiArabiaUnited ArabEmiratesEthiopiaKenyaTanzaniaMalawiMozambiqueSwazilandSouth AfricaTurkeyPakistanIndiaSri LankaNepalBhutanCambodiaThailandVietnamIndonesiaPhilippinesAustraliaJapanPapuaNew Guinea<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, Analyst <strong>Presentation</strong> Year 2011

Manufacturing Capabilities<strong>Praj</strong>’s Pune/Kandla facilities<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011

Manufacturing CapabilitiesNeela’s Wada, Thane Facility<strong>Praj</strong> <strong>Industries</strong> <strong>Ltd</strong>, <strong>Ethanol</strong> <strong>Presentation</strong> Year 2011