Gas Turbine inleT and exhausT sysTems - Universal

Gas Turbine inleT and exhausT sysTems - Universal

Gas Turbine inleT and exhausT sysTems - Universal

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

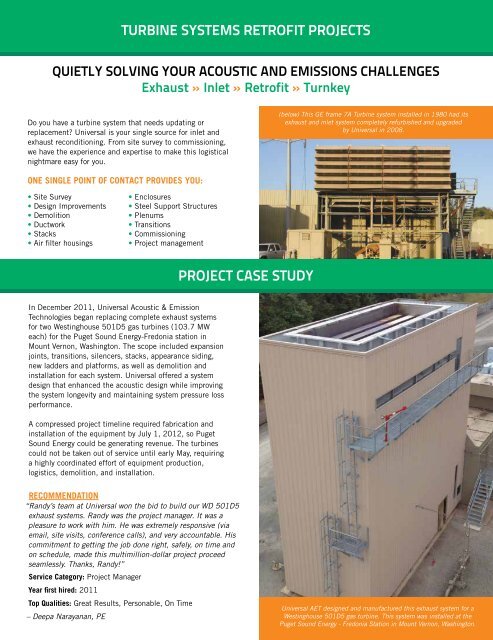

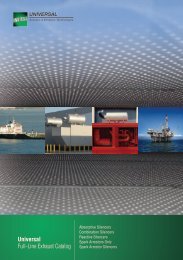

<strong>Turbine</strong> Systems Retrofit ProjectsQUIETLY SOLVING YOUR ACOUSTIC AND EMISSIONS CHALLENGESExhaust » Inlet » Retrofit » TurnkeyDo you have a turbine system that needs updating orreplacement? <strong>Universal</strong> is your single source for inlet <strong>and</strong>exhaust reconditioning. From site survey to commissioning,we have the experience <strong>and</strong> expertise to make this logisticalnightmare easy for you.(below) This GE frame 7A <strong>Turbine</strong> system installed in 1980 had itsexhaust <strong>and</strong> inlet system completely refurbished <strong>and</strong> upgradedby <strong>Universal</strong> in 2008.One single point of contact provides you:• Site Survey• Design Improvements• Demolition• Ductwork• Stacks• Air filter housings• Enclosures• Steel Support Structures• Plenums• Transitions• Commissioning• Project managementPROJECT CASE STUDYIn December 2011, <strong>Universal</strong> Acoustic & EmissionTechnologies began replacing complete exhaust systemsfor two Westinghouse 501D5 gas turbines (103.7 MWeach) for the Puget Sound Energy-Fredonia station inMount Vernon, Washington. The scope included expansionjoints, transitions, silencers, stacks, appearance siding,new ladders <strong>and</strong> platforms, as well as demolition <strong>and</strong>installation for each system. <strong>Universal</strong> offered a systemdesign that enhanced the acoustic design while improvingthe system longevity <strong>and</strong> maintaining system pressure lossperformance.A compressed project timeline required fabrication <strong>and</strong>installation of the equipment by July 1, 2012, so PugetSound Energy could be generating revenue. The turbinescould not be taken out of service until early May, requiringa highly coordinated effort of equipment production,logistics, demolition, <strong>and</strong> installation.Recommendation“R<strong>and</strong>y’s team at <strong>Universal</strong> won the bid to build our WD 501D5exhaust systems. R<strong>and</strong>y was the project manager. It was apleasure to work with him. He was extremely responsive (viaemail, site visits, conference calls), <strong>and</strong> very accountable. Hiscommitment to getting the job done right, safely, on time <strong>and</strong>on schedule, made this multimillion-dollar project proceedseamlessly. Thanks, R<strong>and</strong>y!”Service Category: Project ManagerYear first hired: 2011Top Qualities: Great Results, Personable, On Time– Deepa Narayanan, PE<strong>Universal</strong> AET designed <strong>and</strong> manufactured this exhaust system for aWestinghouse 501D5 gas turbine. This system was installed at thePuget Sound Energy - Fredonia Station in Mount Vernon, Washington.