HV SERIES Vent Silencers HIGH-PERFORMANCE ... - Universal

HV SERIES Vent Silencers HIGH-PERFORMANCE ... - Universal

HV SERIES Vent Silencers HIGH-PERFORMANCE ... - Universal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

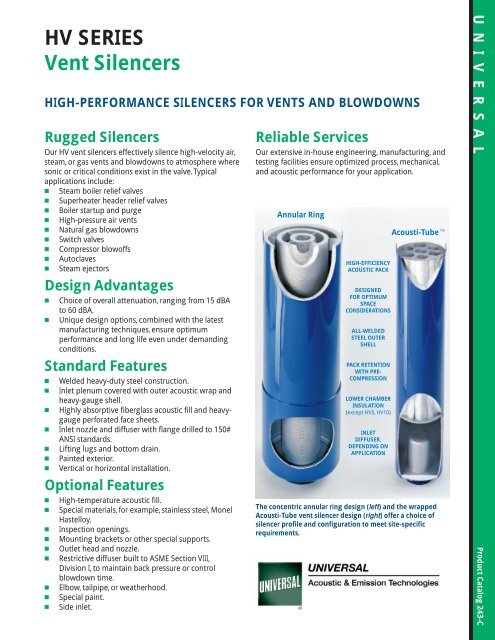

<strong>HV</strong> <strong>SERIES</strong><strong>Vent</strong> <strong>Silencers</strong><strong>HIGH</strong>-<strong>PERFORMANCE</strong> SILENCERS FOR VENTS AND BLOWDOWNSRugged <strong>Silencers</strong>Our <strong>HV</strong> vent silencers effectively silence high-velocity air,steam, or gas vents and blowdowns to atmosphere wheresonic or critical conditions exist in the valve. Typicalapplications include: Steam boiler relief valves Superheater header relief valves Boiler startup and purge High-pressure air vents Natural gas blowdowns Switch valves Compressor blowoffs Autoclaves Steam ejectorsDesign AdvantagesChoice of overall attenuation, ranging from 15 dBAto 60 dBA.Unique design options, combined with the latestmanufacturing techniques, ensure optimumperformance and long life even under demandingconditions.Standard Features Welded heavy-duty steel construction. Inlet plenum covered with outer acoustic wrap andheavy-gauge shell. Highly absorptive fiberglass acoustic fill and heavygaugeperforated face sheets. Inlet nozzle and diffuser with flange drilled to 150#ANSI standards. Lifting lugs and bottom drain. Painted exterior. Vertical or horizontal installation.Optional FeaturesHigh-temperature acoustic fill.Special materials, for example, stainless steel, MonelHastelloy.Inspection openings.Mounting brackets or other special supports.Outlet head and nozzle.Restrictive diffuser built to ASME Section VIII,Division I, to maintain back pressure or controlblowdown time.Elbow, tailpipe, or weatherhood.Special paint.Side inlet.Reliable ServicesOur extensive in-house engineering, manufacturing, andtesting facilities ensure optimized process, mechanical,and acoustic performance for your application.Annular Ring<strong>HIGH</strong>-EFFICIENCYACOUSTIC PACKDESIGNEDFOR OPTIMUMSPACECONSIDERATIONSALL-WELDEDSTEEL OUTERSHELLPACK RETENTIONWITH PRE-COMPRESSIONLOWER CHAMBERINSULATION(except <strong>HV</strong>5, <strong>HV</strong>10)INLETDIFFUSER,DEPENDING ONAPPLICATIONAcousti-TubeThe concentric annular ring design (left) and the wrappedAcousti-Tube vent silencer design (right) offer a choice ofsilencer profile and configuration to meet site-specificrequirements.U N I V E R S A LProduct Catalog 243-C

P R O D U C TD E S C R I P T I O N<strong>HV</strong> <strong>SERIES</strong><strong>Vent</strong> and Blowdown <strong>Silencers</strong>The <strong>HV</strong> Series comes with an inlet diffuser ororifice plate that is a critical element to theacoustic and mechanical performance of thesilencer. Both the inlet nozzle and the diffuser/orifice plate are designed and constructed towithstand the thermal and impact stresses producedin high-pressure, high-temperature, continuous orintermittent vent and blowdown service.In vent applications, critical flow will occur for most gasesat valve upstream pressures greater than twice the outletpressure. <strong>Vent</strong> and blowdown noise levels increase withincreased pressure drop and are also affected by valveaerodynamic recovery characteristics. Large valve, lowpressurevents will produce relatively broadband lowfrequencynoise, while high-pressure vents with smallvalves will produce high-frequency noise.Sub-sonic (or non-critical flow) low-pressure vent andblowdown applications do not require, nor in mostcases does the valve have pressure drop available topermit, the use of an inlet diffuser. Contact <strong>Universal</strong>Silencer for silencer recommendations when acombination of both low pressure drop and acousticrequirements must be met.The <strong>HV</strong> Series is offered in six standard acoustic ratings,as shown in Table 1. The <strong>HV</strong>05 is offered for applicationswhere only minimum noise reduction is required, whilethe <strong>HV</strong>30 is offered for applications where maximumsilencing is required. Acoustic ratings are offered in sizesthat cover a wide range of gas flow.<strong>HV</strong>20 and <strong>HV</strong>30 acoustic ratings are offered for standardpipe diameters from 2 to 112 inches. All other acousticratings are offered for standard pipe diameters of 12 to112 inches.TABLE 1. Silencer ratings by grade classificationAVERAGE DYNAMICMODEL CLASSIFICATION INSERTION LOSS (dBA)<strong>HV</strong>05 Industrial 15-20<strong>HV</strong>10 Commercial 20-30<strong>HV</strong>15 Suburban 30-40<strong>HV</strong>20 Residential 40-50<strong>HV</strong>25 Hospital 50-60<strong>HV</strong>30 Critical 60-70Easy To Specify and Order<strong>Vent</strong> and blowdown silencers are seldom a simplecatalog selection. Usually, the purchaser provides detailedspecifications and a system description that allows aproposal for a silencer to be prepared and submittedfor review.When you work with <strong>Universal</strong> Silencer, you can simplysend the manufacturer’s valve data sheet for your vent,and our experienced sales engineering staff canrecommend a silencer best suited for your application.Application AnalysisWe use the following design information from the valvedata sheet for system analysis and silencer selection:1. Type of gas2. Molecular weight or specific gravity3. Ratio of specific heats4. Flow rate (lb/hr, ACFM or SCFM)5. Pressure and temperature upstream of valve and silencer6. Maximum allowable pressure drop (psi) for valve and silencer7. Manufacturer’s name, and valve type and size8. Unsilenced noise levels from valve (if available)9. Silenced noise level (required at desired distance from source)10. Silencer inlet size and pressure rating11. Inlet orientation, axial or side12. Silencer orientation, vertical or horizontal13. Piping arrangement, including schematic if available14. Other required optionsOur form 88-0063 is available if you want to specify thisand other information in a standard format. Using yourinformation, we prepare computer analyses, such asthose shown in Figure 1, and a comprehensive technicalproposal and price quotation. Silencer selection is basedupon optimization of flow velocity, required acousticalperformance, and pressure drop. We are skilled in theapplication of process engineering principles that areneeded to meet your performance requirements successfully.A key element of a successful vent applicationis proper assignment of pressure drop in the piping,valve, and vent silencer. Valve performance and life canbe considerably extended by appropriate distributionof pressure drop in the piping system, valve, and ventsilencer. In many instances it is possible to reduce thepressure drop across the valve body to less than critical.This results in reduced valve actuator open/close forcerequirements. Reduced valve wear caused by cavitationdamage and reduced through-valve-body noise areadded benefits of this approach.

P R O D U C TD E S C R I P T I O NUNIVERSAL SILENCERA FLEETGUARD/NELSON COMPANYP. O. Box 411, Stoughton, Wisconsin 53589608-873-4272 Fax 608-873-4298Example Valve DataSilencer Acoustic ApplicationPeak FrequencyOctave Band Data from Noise SourcesComparison of Two Methodsfor Calculating Noise LevelsTotal Volume Upstream and Downstreamfrom the ValveFIGURE 1. Sample printouts of <strong>Universal</strong>’s vent application analyses.We can verify the valve flow and pressure dropcharacteristics from your valve manufacturer’s data sheet.We offer complete application engineering service,including determination of blowdown time; bottledvolume calculations; and complete valve, pipe treatment,and vent discharge acoustic performance predictions.Application NotesNote that pipe size immediately downstream froma valve affects the octave band distribution of the noisespectrum. <strong>Universal</strong> Silencer has developed proprietarymethods to predict this distribution so that we can selectthe appropriate balance of reactive and absorptiveelements in the vent silencer design.The annular vent silencers are assembled with structuralmembers that provide for thermal expansion in hightemperatureapplications. The acoustic fill is long fiber,non-combustible, inert, vermin- and moisture-resistantfiberglass of at least four-pound-per-cubic-foot density,and is protected by both fiberglass cloth and a perforatedmetal face sheet. The silencer is packed with a minimumof 10% compression fill, and pack retaining rings areprovided to minimize voids and settling of the fill.The silencer will be designed so that the inlet flange anddiffuser are matched to the discharge rating of the valve.We can work with you to obtain a more cost-effectivevalve and piping system by using a restrictive diffuser ororifice plate to stage the system pressure drop. Forconservatism, vent silencers with restrictive diffusers aredesigned with pressure ratings that match the PSV inletpressure rating. Also, you should assure yourself byreviewing the valve manufacturer’s data sheet that thecontrol valve will not malfunction from the rated backpressure of the restrictive diffuser you specified.The following cautionary statement pertains to applicationsin pure oxygen service: Customers are encouraged to contactthe Compressed Gas Association (CGA) for more standardsrelated to preparation and cleaning for this type of service.Construction FeaturesThese silencers are welded heavy-duty fabrications. Allmaterials are free from rust, weld splatter, mill scale, andother contaminants. The inlet nozzle and diffuser areconstructed of steel and are welded. The diffuser providescontrolled pressure expansion to atmosphere and providesuniform flow distribution through the acoustic section ofthe silencer.The lined inlet plenum (expansion chamber) of the silenceris provided with a double shell separated by a layer ofacoustic insulation and sound-deadening material. Theinner shell is solid to prevent shell-radiated noise andmigration of the acoustic fill. The transmission loss acrossthe plenum and bottom head is comparable to the silencerattenuation.

UNIVERSAL<strong>HV</strong> <strong>SERIES</strong><strong>Vent</strong> andBlowdown <strong>Silencers</strong>Contact us for moreinformation aboutour complete line ofindustrial silencersand air filter/filtersilencers:Our corporate headquarters are located in Stoughton,Wisconsin, just southeast of Madison, the state capital. Thisnew building houses administration, sales, and engineeringdepartments. Manufacturing facilities are in Muscoda, 75miles west of Stoughton, and Montello, 70 miles north.Our products have been used to protect,quiet, and optimize the performance ofindustrial equipment for 50 years.We maintain a fully equipped facility fortesting filters and silencers under actualoperating conditions. We are an ISO 9001registered firm and ASME Code certified. <strong>Vent</strong> silencer specification sheet, form 88-0063 Air filters and filter silencers, catalog 241-A Cartridge air filters and filter silencers, catalog 242-B CB compact blower silencers, catalog 255-A CBF/CBFI compact blower filter-silencers, catalog 261-A Reciprocating engines, catalog 246-A Rotary positive blowers, catalog 244-D Axial fans, catalog 249-D Compressors, information provided by application Vacuum pumps, catalog 222-B Industrial fans, catalog 249-A Steam ejectors, pressure reduction valves, andother special applications Gas turbines, catalog B-249-A Acousti-Tube <strong>Silencers</strong>, catalog 260 Acousti-Tube Silencer Series,technical bulletin 94-1315 Uni-Pulse inlet filtersystems, catalog 250Preservinga quietenvironment.P. O. Box 411, Stoughton, Wisconsin 53589608-873-4272 Fax 608-873-4298info@universalAET.comwww.universalAET.comCopyright 2010 <strong>Universal</strong> LLC. All rights reserved. Acousti-Tube and Uni-Pulse are trademarks of <strong>Universal</strong>Specifications subject to change. 243-C-6/98