HV SERIES Vent Silencers HIGH-PERFORMANCE ... - Universal

HV SERIES Vent Silencers HIGH-PERFORMANCE ... - Universal

HV SERIES Vent Silencers HIGH-PERFORMANCE ... - Universal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

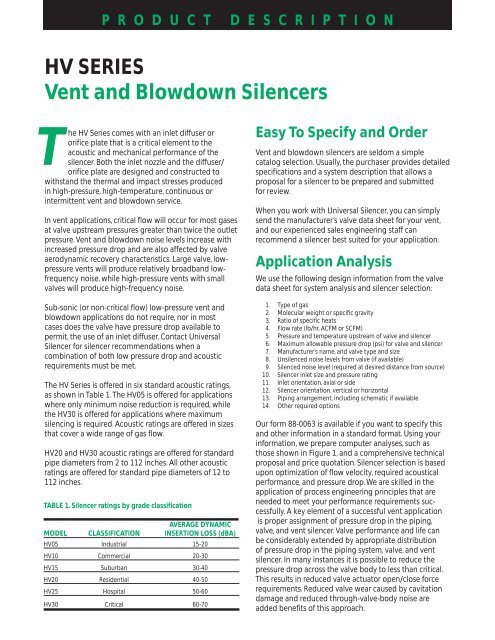

P R O D U C TD E S C R I P T I O N<strong>HV</strong> <strong>SERIES</strong><strong>Vent</strong> and Blowdown <strong>Silencers</strong>The <strong>HV</strong> Series comes with an inlet diffuser ororifice plate that is a critical element to theacoustic and mechanical performance of thesilencer. Both the inlet nozzle and the diffuser/orifice plate are designed and constructed towithstand the thermal and impact stresses producedin high-pressure, high-temperature, continuous orintermittent vent and blowdown service.In vent applications, critical flow will occur for most gasesat valve upstream pressures greater than twice the outletpressure. <strong>Vent</strong> and blowdown noise levels increase withincreased pressure drop and are also affected by valveaerodynamic recovery characteristics. Large valve, lowpressurevents will produce relatively broadband lowfrequencynoise, while high-pressure vents with smallvalves will produce high-frequency noise.Sub-sonic (or non-critical flow) low-pressure vent andblowdown applications do not require, nor in mostcases does the valve have pressure drop available topermit, the use of an inlet diffuser. Contact <strong>Universal</strong>Silencer for silencer recommendations when acombination of both low pressure drop and acousticrequirements must be met.The <strong>HV</strong> Series is offered in six standard acoustic ratings,as shown in Table 1. The <strong>HV</strong>05 is offered for applicationswhere only minimum noise reduction is required, whilethe <strong>HV</strong>30 is offered for applications where maximumsilencing is required. Acoustic ratings are offered in sizesthat cover a wide range of gas flow.<strong>HV</strong>20 and <strong>HV</strong>30 acoustic ratings are offered for standardpipe diameters from 2 to 112 inches. All other acousticratings are offered for standard pipe diameters of 12 to112 inches.TABLE 1. Silencer ratings by grade classificationAVERAGE DYNAMICMODEL CLASSIFICATION INSERTION LOSS (dBA)<strong>HV</strong>05 Industrial 15-20<strong>HV</strong>10 Commercial 20-30<strong>HV</strong>15 Suburban 30-40<strong>HV</strong>20 Residential 40-50<strong>HV</strong>25 Hospital 50-60<strong>HV</strong>30 Critical 60-70Easy To Specify and Order<strong>Vent</strong> and blowdown silencers are seldom a simplecatalog selection. Usually, the purchaser provides detailedspecifications and a system description that allows aproposal for a silencer to be prepared and submittedfor review.When you work with <strong>Universal</strong> Silencer, you can simplysend the manufacturer’s valve data sheet for your vent,and our experienced sales engineering staff canrecommend a silencer best suited for your application.Application AnalysisWe use the following design information from the valvedata sheet for system analysis and silencer selection:1. Type of gas2. Molecular weight or specific gravity3. Ratio of specific heats4. Flow rate (lb/hr, ACFM or SCFM)5. Pressure and temperature upstream of valve and silencer6. Maximum allowable pressure drop (psi) for valve and silencer7. Manufacturer’s name, and valve type and size8. Unsilenced noise levels from valve (if available)9. Silenced noise level (required at desired distance from source)10. Silencer inlet size and pressure rating11. Inlet orientation, axial or side12. Silencer orientation, vertical or horizontal13. Piping arrangement, including schematic if available14. Other required optionsOur form 88-0063 is available if you want to specify thisand other information in a standard format. Using yourinformation, we prepare computer analyses, such asthose shown in Figure 1, and a comprehensive technicalproposal and price quotation. Silencer selection is basedupon optimization of flow velocity, required acousticalperformance, and pressure drop. We are skilled in theapplication of process engineering principles that areneeded to meet your performance requirements successfully.A key element of a successful vent applicationis proper assignment of pressure drop in the piping,valve, and vent silencer. Valve performance and life canbe considerably extended by appropriate distributionof pressure drop in the piping system, valve, and ventsilencer. In many instances it is possible to reduce thepressure drop across the valve body to less than critical.This results in reduced valve actuator open/close forcerequirements. Reduced valve wear caused by cavitationdamage and reduced through-valve-body noise areadded benefits of this approach.