User Instructions for the Bench Rest® Seater Die - Forster Products

User Instructions for the Bench Rest® Seater Die - Forster Products

User Instructions for the Bench Rest® Seater Die - Forster Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

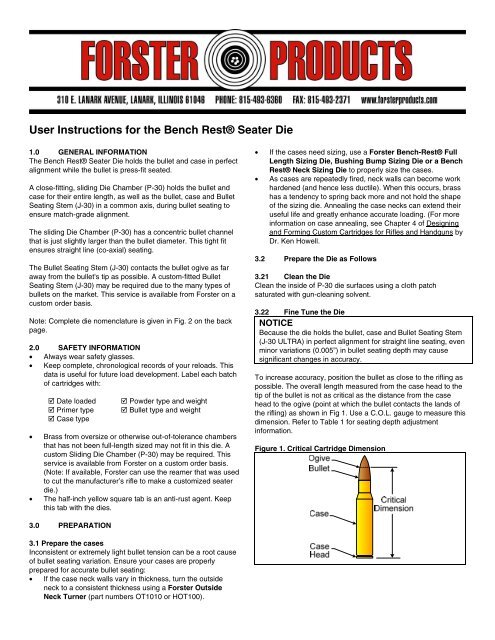

<strong>User</strong> <strong>Instructions</strong> <strong>for</strong> <strong>the</strong> <strong>Bench</strong> Rest® <strong>Seater</strong> <strong>Die</strong>1.0 GENERAL INFORMATIONThe <strong>Bench</strong> Rest® <strong>Seater</strong> <strong>Die</strong> holds <strong>the</strong> bullet and case in perfectalignment while <strong>the</strong> bullet is press-fit seated.A close-fitting, sliding <strong>Die</strong> Chamber (P-30) holds <strong>the</strong> bullet andcase <strong>for</strong> <strong>the</strong>ir entire length, as well as <strong>the</strong> bullet, case and BulletSeating Stem (J-30) in a common axis, during bullet seating toensure match-grade alignment.The sliding <strong>Die</strong> Chamber (P-30) has a concentric bullet channelthat is just slightly larger than <strong>the</strong> bullet diameter. This tight fitensures straight line (co-axial) seating.The Bullet Seating Stem (J-30) contacts <strong>the</strong> bullet ogive as faraway from <strong>the</strong> bullet's tip as possible. A custom-fitted BulletSeating Stem (J-30) may be required due to <strong>the</strong> many types ofbullets on <strong>the</strong> market. This service is available from <strong>Forster</strong> on acustom order basis.Note: Complete die nomenclature is given in Fig. 2 on <strong>the</strong> backpage.2.0 SAFETY INFORMATION• Always wear safety glasses.• Keep complete, chronological records of your reloads. Thisdata is useful <strong>for</strong> future load development. Label each batchof cartridges with: Date loaded Primer type Case type Powder type and weight Bullet type and weight• Brass from oversize or o<strong>the</strong>rwise out-of-tolerance chambersthat has not been full-length sized may not fit in this die. Acustom Sliding <strong>Die</strong> Chamber (P-30) may be required. Thisservice is available from <strong>Forster</strong> on a custom order basis.(Note: If available, <strong>Forster</strong> can use <strong>the</strong> reamer that was usedto cut <strong>the</strong> manufacturer’s rifle to make a customized seaterdie.)• The half-inch yellow square tab is an anti-rust agent. Keepthis tab with <strong>the</strong> dies.• If <strong>the</strong> cases need sizing, use a <strong>Forster</strong> <strong>Bench</strong>-Rest® FullLength Sizing <strong>Die</strong>, Bushing Bump Sizing <strong>Die</strong> or a <strong>Bench</strong>Rest® Neck Sizing <strong>Die</strong> to properly size <strong>the</strong> cases.• As cases are repeatedly fired, neck walls can become workhardened (and hence less ductile). When this occurs, brasshas a tendency to spring back more and not hold <strong>the</strong> shapeof <strong>the</strong> sizing die. Annealing <strong>the</strong> case necks can extend <strong>the</strong>iruseful life and greatly enhance accurate loading. (For morein<strong>for</strong>mation on case annealing, see Chapter 4 of Designingand Forming Custom Cartridges <strong>for</strong> Rifles and Handguns byDr. Ken Howell.3.2 Prepare <strong>the</strong> <strong>Die</strong> as Follows3.21 Clean <strong>the</strong> <strong>Die</strong>Clean <strong>the</strong> inside of P-30 die surfaces using a cloth patchsaturated with gun-cleaning solvent.3.22 Fine Tune <strong>the</strong> <strong>Die</strong>NOTICEBecause <strong>the</strong> die holds <strong>the</strong> bullet, case and Bullet Seating Stem(J-30 ULTRA) in perfect alignment <strong>for</strong> straight line seating, evenminor variations (0.005”) in bullet seating depth may causesignificant changes in accuracy.To increase accuracy, position <strong>the</strong> bullet as close to <strong>the</strong> rifling aspossible. The overall length measured from <strong>the</strong> case head to <strong>the</strong>tip of <strong>the</strong> bullet is not as critical as <strong>the</strong> distance from <strong>the</strong> casehead to <strong>the</strong> ogive (point at which <strong>the</strong> bullet contacts <strong>the</strong> lands of<strong>the</strong> rifling) as shown in Fig 1. Use a C.O.L. gauge to measure thisdimension. Refer to Table 1 <strong>for</strong> seating depth adjustmentin<strong>for</strong>mation.Figure 1. Critical Cartridge Dimension3.0 PREPARATION3.1 Prepare <strong>the</strong> casesInconsistent or extremely light bullet tension can be a root causeof bullet seating variation. Ensure your cases are properlyprepared <strong>for</strong> accurate bullet seating:• If <strong>the</strong> case neck walls vary in thickness, turn <strong>the</strong> outsideneck to a consistent thickness using a <strong>Forster</strong> OutsideNeck Turner (part numbers OT1010 or HOT100).

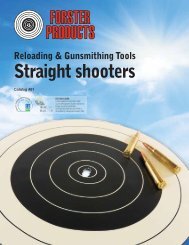

Table 1. Seating Depth Adjustment In<strong>for</strong>mationBullet SeatingBullet MovementStem (J-30)Adjustment17-243 Caliber<strong>Seater</strong> <strong>Die</strong>s257-375 Caliber<strong>Seater</strong> <strong>Die</strong>s1/8 turn 0.004” 0.0045”1/4 turn 0.008” 0.009”1/2 turn 0.016” 0.018”4.0 BULLET SEATING PROCEDURE1. Ensure <strong>the</strong> <strong>Die</strong> Body (L-30) is securely threaded to <strong>the</strong>Sleeve (O-30).2. With <strong>the</strong> press ram and shell holder at <strong>the</strong>ir highest points,screw <strong>the</strong> die in <strong>the</strong> press until <strong>the</strong> bottom of <strong>the</strong> sliding <strong>Die</strong>Chamber (P-30) touches <strong>the</strong> shell holder.3. Continue screwing <strong>the</strong> die clockwise until you have fullycompressed <strong>the</strong> sliding <strong>Die</strong> Chamber (P-30). Next, back itoff at least one full turn since <strong>the</strong> <strong>Die</strong> Chamber should neverbe fully compressed when seating bullets.4. Tighten <strong>the</strong> Cross Bolt <strong>Die</strong> Lock Ring (G-10) with a #2Phillips screwdriver.5. Screw <strong>the</strong> Bullet Seating Stem (J-30) almost all <strong>the</strong> way outof <strong>the</strong> <strong>Die</strong> Body (L-30).6. Lower <strong>the</strong> shell holder.7. Place a sample cartridge (setup round) of <strong>the</strong> correct lengthin <strong>the</strong> shell holder of your press.8. Raise <strong>the</strong> shell holder to its highest position by pulling <strong>the</strong>press handle completely.9. Screw <strong>the</strong> Bullet Seating Stem (J-30) down until it contacts<strong>the</strong> bullet of your “setup round”.10. Tighten <strong>the</strong> Lock Nut (A-10, K-30).11. Remove <strong>the</strong> setup round from shell holder. The die is nowproperly set in your press <strong>for</strong> accurate bullet seating.12. Check <strong>the</strong> cartridge length after seating <strong>the</strong> first bullet.Adjust <strong>the</strong> Bullet Seating Stem (J-30) to leng<strong>the</strong>n or shorten<strong>the</strong> cartridge, if needed.5.0 AFTER USEOil <strong>the</strong> die with a good quality gun oil be<strong>for</strong>e storing die until <strong>the</strong>next use.6.0 REPLACEMENT PARTSThe following replacement parts are available <strong>for</strong> a wide varietyof calibers. See our Web site at www.<strong>for</strong>sterproducts.com <strong>for</strong>specific sizes.• Bullet Seating Stem (J-30) (specify size)• Lock Nut (A-10 or K-30)• <strong>Die</strong> Body (L-30) (specify small or large thread)• Sleeve (O-30-SH, O-30-M1, O-30-M2, O-30-L)• <strong>Die</strong> Chamber (P-30) (specify caliber)For best prices, contact your <strong>Forster</strong> dealer. Experienced dealersand wholesale jobbers are an integral part of <strong>the</strong> shooting sports.Please make frequent use of <strong>the</strong>ir knowledge and support <strong>the</strong>m.If your dealer or wholesale jobber cannot supply you, pleasecontact us by email, fax or phone.Figure 2. <strong>Die</strong> Nomenclature<strong>Die</strong> with Empty<strong>Die</strong> Chamber (P-30)Bullet Seating Stem (J-30)Lock Nut (A-10, K-30)<strong>Die</strong> Body (L-30)Return Spring (M-30)Retainer Ring (N-30)<strong>Die</strong> Ready to SeatBulletName Number Size Used WithLockNutA-10K-3010-40 thread¼-40 thread243 andsmaller257 andlargerSleeve 0-30-SH 2.375” length caliberspecific0-30-M1 2.625” length0-30-M2 2.875” length0-30-L 3.125“ lengthSleeve (O-30-SH, O-30M1,O-30-M2, O-30-L)BulletCaseCross Bolt <strong>Die</strong> Lock Ring (G-10)<strong>Die</strong> Chamber (P-30)(caliber specific)WARRANTYAll <strong>Forster</strong> <strong>Products</strong> are warranted against defects in materials and workmanship <strong>for</strong> <strong>the</strong> life of <strong>the</strong> product. Parts which, by nature of <strong>the</strong>ir function,are subject to normal wear (such as springs, pins, etc.) and parts which have been altered, abused or neglected, are excluded from <strong>the</strong> warranty. If<strong>the</strong> product is deemed defective by workmanship or materials, it will be repaired, reconditioned or replaced (at <strong>Forster</strong>’s option). This warrantysupersedes all o<strong>the</strong>r warranties <strong>for</strong> <strong>Forster</strong> <strong>Products</strong> whe<strong>the</strong>r written or oral.www.<strong>for</strong>sterproducts.comDIE-0009 Issue 4, February 2009